TABLE OF CONTENTS

List of Figures

List of Tables

Section 1: Introduction........................................................................1-1

1.1 Manual Overview...............................................................1-1

1.2 Warnings, Cautions, and Notes.........................................1-1

1.2.1 Warning..............................................................1-1

1.2.2 Caution...............................................................1-1

1.2.3 Note....................................................................1-1

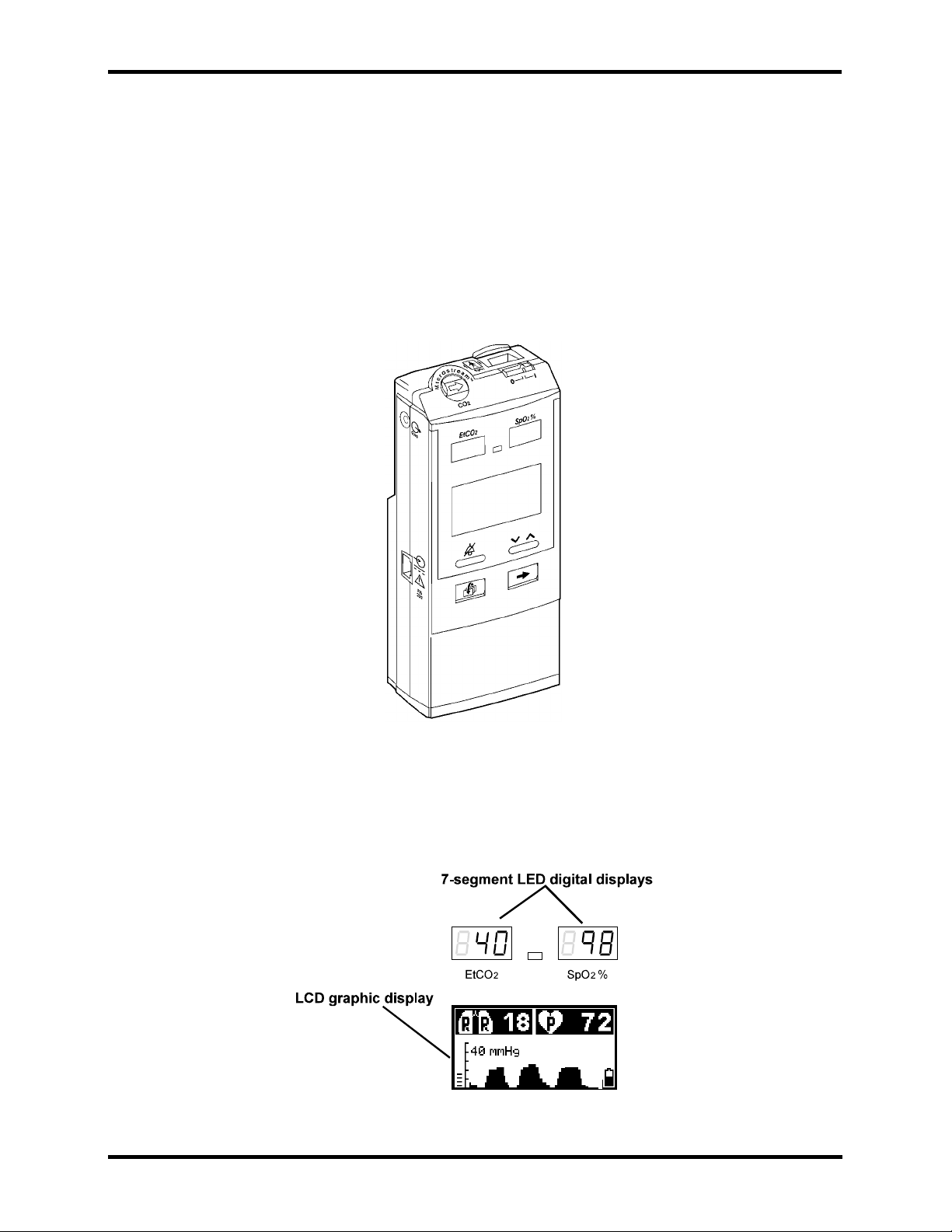

1.3 Product Description ...........................................................1-2

Section 2: Required Equipment

..........................................................2-1

2.1 Required Equipment..........................................................2-1

Section 3: Cleaning

...........................................................................3-1

3.1 Cleaning ...........................................................................3-1

3.1.1 Procedure...........................................................3-1

Section 4: Service Mode

......................................................................4-1

4.1 Introduction........................................................................4-1

4.2 Service Level 1..................................................................4-1

4.2.1 Information Screen.............................................4-1

4.2.2 Event Messages Screen....................................4-1

4.2.3 Interface Test Screen.........................................4-2

4.2.4 Accessing Service Mode and Service Level 1...4-3

4.3 Service Level 2..................................................................4-5

4.3.1 Default Alarm Limits...........................................4-7

4.3.2 Default Settings..................................................4-9

4.3.3 Flow Calibration ...............................................4-10

Section 5: Troubleshooting

.................................................................5-1

5.1 Introduction........................................................................5-1

5.2 Who Should Perform Repairs............................................5-1

5.3 Repair Level Supported.....................................................5-1

5.4 How to Use This Section ...................................................5-1

5.5 Obtaining Replacement Parts............................................5-1

5.6 Troubleshooting Guide ......................................................5-2

Section 6: Flow Calibration Check.....................................................6-1

6.1 Introduction........................................................................6-1

6.2 Flow Rate Check ...............................................................6-1

6.3 Flow Calibration Process...................................................6-2

Section 7: Disassembly Guide

............................................................7-1

7.1 Introduction........................................................................7-1

7.2. Opening the Monitor Case.................................................7-2

7.3 Replacing the CO2Board ..................................................7-4

7.4 Replacing the SpO2Board.................................................7-5

7.5 Replacing the Pump ..........................................................7-6

7.6 Replacing the Flow System...............................................7-7

7.6.1 Replacing the lines to the pump.........................7-8

7.6.2 Replacing the lines to the solenoid ....................7-9

7.7 Replacing the LCD and LED Display...............................7-11

7.7.1 Replacing the LCD...........................................7-11

7.7.2 Replacing the LED Display ..............................7-11

iii