NELSEN WATER NRO ROC2HE-UL User manual

Nelsen NRO ROC2HE-UL

System Controller Documentation

Systems w/CPU-4 Control Board

Manufactured after March 2020

Since 1954

1

Table of Contents

Contents.........................................................................................................................................................................................................................................................................................................................Page #

Specifications, Table 1......................................................................................................................................................................................................................................................................................................2

Schematic, Figure 1..............................................................................................................................................................................................................................................................................................................3

Controller Overview, Figure 2...............................................................................................................................................................................................................................................................................4

Controller Detail: CPU-4..................................................................................................................................................................................................................................................................................................5

Controller Detail: TB-1.......................................................................................................................................................................................................................................................................................................6

Conductivity Probe Installation, Figure 5..........................................................................................................................................................................................................................................7

Installation Instructions...................................................................................................................................................................................................................................................................................................7

Controller Programming: Accessing Hidden Menus, Figure 6....................................................................................................................................................................8

System Start-up w/Permeate Flush..........................................................................................................................................................................................................................................................8

Controller Programming: Program Selections, Table 2.............................................................................................................................................................................................9

Controller Programming: Menu Navigation, Figure 7............................................................................................................................................................................................. 10

Controller Fault Displays................................................................................................................................................................................................................................................................................ 11-12

Warranty.............................................................................................................................................................................................................................................................................................................................................. 13

2

Table 1 - Specifications

Inputs

Tank level switches (2) Normally-Closed. Can be used with a single level switch.

Inlet pressure switch Normally-Open.

Pretreat lockout switch Normally-Open.

The Tank, Low Pressure and Pretreat inputs are 50% duty cycle square wave,

10VDC peak @ 10mA max.

The switch inputs are dry contacts only. Applying voltage to these terminals

will damage the controller.

Controller Power 110-120/208-240 VAC, 60/50Hz (Range: 110-240 VAC)

Permeate Conductivity 0-3000 PPM, 0-6000 μs (standard sensor, CP-1, K=.75)

Feed Conductivity (opt) 0-3000 PPM, 0-6000 μs (standard sensor, CP-1, K=.75)

Output Circuit Ratings

Feed Solenoid 1A. Voltage is the same as motor/supply voltage.

Flush Solenoid 1A. Voltage is the same as motor/supply voltage.

Motor 1.0 HP/110-120V, 2.0 HP/208-240V.

Circuit Protection

Relay Fuse F1 5x20mm - 2 Amp - BelFuse 5ST 2-R

Note: The fuses shown above are for supplemental protection only. Branch

circuit protection and disconnect means must be provided externally.

See Field Wiring Diagram for Branch Circuit protection requirements.

Other

Dimensions 7" tall, 7" wide, 4" deep. Nema 4X Polycarbonate Hinged Enclosure.

Weight 2.6 lb. (Basic Configuration, not including optional wire harness, etc.)

Environment 0-50°C, 10-90%RH (non-condensing)

Note: After our modifications the enclosure rating is Nema 1.

3

Figure 1 - Simplified Schematic

4

Figure 2 - Controller Overview

Terminal Board (TB-1 Re-E)CPU Board (CPU-4)

Conductivity Probe

Connections

Display

(4 line, 20 character)

Clear, concise feedback

on the RO’s status.

Alarm

Display backlight

flashes along with

audible beeper to

indicate alarm condition.

Keypad

System ON/OFF,

Up Arrow

Down Arrow

Manual Run,

Manual Flush

5

Typical Configuration

Permeate Conductivity Probe

Shield

White

Black

Cable to

Terminal Board

Figure 3 - Controller Detail: CPU-4

Typical Configuration

6

Figure 4 - Controller Detail: Terminal Board, TB-1 (See Fig. 1 for schematic)

7

Figure 5 - Conductivity Probe Installation

1 Drill the enclosure as needed and install liquid-

tight fittings for the wiring.

NOTE: The Controller can be ordered

pre-drilled or with fittings installed, or with

fittings and wiring installed. Contact Nelsen

Corporation for details.

2 Mount the enclosure in the desired location on

the RO system.

3 Bring the wires from the peripheral devices

into the enclosure and connect them to the

appropriate terminals. (See Figure 1, Figure 3 and

Figure 4.)

4 Install the conductivity cell in the permeate line.

(See Figure 5 for conductivity cell installation

instructions.)

7 Connect the conductivity cell to the terminals on

the CPU Board. (See Figure 3)

8 Provide power to the RO system.

9 Press the System On/Off switch to turn the

system ON.

10 Program Mode 2 is default (See Table 2) which is

a general purpose setting, without a flush valve.

NOTE: The Program Settings can be

customized to suit the specific needs

of an OEM and pre-programmed at the

factory with your settings. Contact Nelsen

Corporation for details.

11 Make any other changes you want to the

settings. Press System On/Off to save your

changes.

12 The controller is now ready for service.

NOTE: YOU MUST REMOVE THE JUMPER

WIRE FROM E23 TO E24 if using a single

point High Level RO water shut off float

switch control and connect the float switch

wires to terminals E23 and E24 (See Fig. 4).

If you are using a piggyback float plug leave

the jumper wire in place.

Installation

Install the Conductivity Probe in the “Run”

of a Tee or equivalent location. Orient the

probe so that air can not become trapped in

the area near the probe.

FLOW

FLOW

Conductivity

Probe

8

Figure 6 - Controller Programming: Accessing the Hidden Menus

System Start-up w/Permeate Flush

1 With the System ON, Press and

Hold the Up and Down Arrows.

2 With the Up and Down Arrows

depressed, Press the System On/Off

button. The menu will switch to the

RO Presets menu shown in Figure 7.

For systems equipped with a Permeate Flush, you must follow the procedure below for proper system start-

up. When there is no Permeate Water in the tank the RO will not start.

1. With the system on, Press and Hold the Up and Down Arrows

2. With the Up and Down Arrows depressed, Press the System On/Off button. This will switch to the

Hidden Menus as shown above.

3. If not already on the RO Presets Program, Press the Up or Down Arrows until you reach this screen.

4. Once on the RO Presets Program Screen, Press Manual to Edit this Screen.

5. Press the Up or Down Arrow to change to Program 2

6. Once on Program 2, Press Manual to Exit the screen.

7. Press System On/Off to save the changes and return to the Home Page.

Once your Permeate Tank has filled enough to do a proper permeate flush, follow the steps again

changing from Program 2 back to Program 3.

9

The controller has 4 separate, user-selectable sets of settings for configuring the RO. The factory default

settings are shown below. The settings are identical except for variations in the flush behavior.

• Program 1, High Pressure flush

• Program 2, No Flush

• Program 3, Permeate Flush, (low pressure, inlet valve closed)

• Program 4, Low Pressure, feed water flush

See the previous page for instructions on how to access the menu for selecting these programs.

See Appendix A for a detailed explanation of the Parameters and their affect on the RO’s operation.

Table 2 - Controller Programming: ROC2HE Program Selections

Parameter Value Program 1 Program 2 Program 3 Program 4

Tank Level Switch delay

(actuation and de-actuation) Seconds 2 2 2 2

Pressure Switch delay (actuation and de-actuation) Seconds 2 2 2 2

Pretreat Switch delay (actuation and de-actuation) Seconds 2 2 2 2

Pump start delay Seconds 10 10 10 10

Inlet Solenid stop delay Seconds 1 1 1 1

Pump start retry interval (restart delay after LP fault) Seconds 60 60 60 60

Low pressure fault shutdown, # of faults Faults 5 5 5 5

Low pressure fault shutdown, time period to count faults Minutes 10 10 10 10

Low pressure fault shutdown, reset after shutdown Minutes 60 60 60 60

Low pressure time out fault Seconds 60 60 60 60

Flush Behavior High Pressure No Flush Perm Flush Low Pres Flush

Startup Flush: Minutes from last ush Minutes 0 0 0 0

Startup Flush: Duration Seconds 0 0 0 30

Periodic Flush: Interval Minutes 60 0 0 0

Periodic Flush: Duration Seconds 30 0 0 0

Shutdown Flush: Time from last ush Minutes 10 0 0 0

Shutdown Flush: Minumum operation Minutes 30 0 0 0

Shutdown Flush: Duration Seconds 60 0 60 60

Idle Flush: Interval * Minutes 0 0 0 0

Idle Flush: Duration * Seconds 0 0 0 0

Timed Manual Run Minutes 5 5 5 5

Timed Manual Flush Seconds 5 0 5 5

* These features are disabled by default due to the potential for confusion on the part of end-users in the field.

They can be enabled when needed via the OEM PC programming interface which allows changes to all of

the values shown above.

10

Figure 7 - Controller Programming: Menu Navigation

11

Controller Fault Condition Displays

Below are examples and explanations of the displays which accompany the fault conditions possible on the

CPU-4. Fault conditions always indicate a problem of some sort which requires corrective action. the displays

provide sufficient information to recognize the source of the fault and the required corrective action.

Low Pressure Fault: (System is responding to low pressure condition per system settings)

Line 1 “Service Fault”

Line 2 “Low Feed Pressure”

Line 3

Line 4 “Restart in MM:SS”

Pre Treat Fault: (Pretreat Switch is closed indicating problem with pretreat system).

Line 1 “Service Fault”

Line 2 “Pretreat”

Line 3

Line 4 “Check Pretreat Sys.”

Permeate Conductivity Fault: (Permeate conductivity is higher than the alarm set-point.)

Line 1 “Service Fault”

Line 2 “Permeate TDS xxx ppm” or “Permeate Cond xxx uS”

Line 3 “Alarm SP xxx ppm” or “Alarm SP xxx uS”

Line 4 “To Reset Push OFF/ON”

Feed Conductivity Fault: (Feed conductivity is higher than the alarm set-point.)

Line 1 “Service Fault”

Line 2 “Feed TDS xxx ppm” or “Feed Cond xxx uS”

Line 3 “Alarm SP xxx ppm” or “Alarm SP xxx uS”

Line 4 “To Reset Push OFF/ON”

Conductivity Probe Error messages:

Line 2 “Inteference” - Noise detected by conductivity circuit, valid measurement not possible.

Line 2 “Over-range” - Measurement is out of range for the circuit, probe may also be shorted

Line 2 “Probe shorted” - Short circuit detected on temperature sensor in probe

Line 2 “Probe not detected” - Open circuit detected on temperature sensor in probe (white & unshielded wire)

Line 2 “Probe Startup 1” - Internal reference voltage too high to make valid measurement

Line 2 “Probe Startup 2” - Internal reference voltage too low to make valid measurement

Line 2 “Probe Startup 3” - Internal excitation voltage too high to make valid measurement

Line 2 “Probe Startup 4” - Internal excitation voltage too low to make valid measurement

12

Controller Fault Condition Displays

If RO Not Working and Display Shows “Tank Full” or “Tank Full Draw Down”

1. If using a single point high level float switch, the jumper in the wiring instructions must be installed. This

needs to be checked to make sure it is not loose and or disconnected, which would cause a failure and

one of the displays above. ie. Remove jumper and reinstall, making sure of a good connection. Re-check

display and operation.

2. Check the switch in the tank to make sure it is operating correctly. Check the switch with a multi-meter for

correct “on-off” operation. Replace switch or level control if faulty.

3. If someone connected 110v to the terminal strip connection for the high level shut off, they could have

fried the “opto-isolator”.

4. Also, if there were major lightning strikes and power outages with surges, it is possible that you may have

had a power surge that sent electric current to the dry contacts and possibly fried the “opto-isolator”.

This will prevent the system from turning on, and the display will show Tank Full messages.

5. If the jumper is verified to be in place with good connections, and if the high level cut off switch in the

storage tank is verified to be operational, then the board might need to be replaced due to number 3 or 4.

13

Nelsen Corporation (“Nelsen”) provides this limited warranty as described below (the “Limited Warranty”).

Limited Warranty

Subject to the terms of this Limited Warranty, Nelsen warrants to the original buyer (“Buyer”) of this Water Conditioner

product (the “Product”) solely from a Nelsen authorized dealer that the Product will be free from defects in material or

workmanship for a period of one (1) year after the date of original installation. This Limited Warranty shall apply only if

the Product is installed, operated and maintained in strict accordance with Nelsen’s or the manufacturer’s guidelines

and other legal requirements. The Product is sold with the understanding that Buyer has independently determined

the suitability and compatibility of such Product for Buyer’s purposes. Any statements, technical information or

recommendations concerning the Product or any parts therein by Nelsen are based upon data provided to Nelsen by its

suppliers and believed to be accurate, but do not constitute a guarantee or warranty. This Limited Warranty shall not

cover and shall be null and void if, in Nelsen’s discretion, the Product, or any parts therein, are: (a) manufactured by a

third party manufacturer; (b) modified after sale or use of replacement parts not specified by manufacturer requirements;

(c) improperly installed, stored, used, operated, handled or maintained; or (d) abused, misused or otherwise damaged

for any reason, including due to negligence, weather, fire, lightning, power surges or other acts of God or exposure to

freezing or hot water or the effects of normal wear and tear.

Third Party Warranties

In lieu of the above Limited Warranty, the Product, or any parts therein, may be covered by a third-party manufacturer’s

warranty. Nelsen’s authorized dealer will provide Buyer with a copy of any third-party manufacturer warranty prior to

purchase. Nelsen shall transfer and assign to Buyer any and all third-party manufacturer’s warranties on the Product,

or any parts therein, subject to the conditions and exclusions in the manufacturer’s warranty. Buyer’s exclusive remedy

under such third-party manufacturer’s warranty shall be against such third-party manufacturer and not Nelsen. Buyer

may need to register the Product with a third party manufacturer in order to obtain its warranty.

Additional Conditions

• This Limited Warranty does not cover any membranes or filters.

• This Limited Warranty shall not cover the Product if operated at water pressures or water temperatures or with

water contaminants that exceed manufacturer’s guidelines.

• The Product may include interconnecting piping that may have leaks, even if tested at the time of manufacture,

due to pipe vibrations and handling. The installer of the goods is responsible for checking the system for leaks upon

start-up and making any repairs if necessary.

• This Limited Warranty does not cover damage or failure of the Product, or any part therein, caused by friction, wear,

chemical attack or debris build-up on wear parts. For purposes hereof, “wear parts” shall include, without limitation,

end cap quad rings and parts requiring replacement under recommended maintenance procedures, including,

without limitation, o-rings and gaskets.

Warranty Claims

All claims under this Limited Warranty shall be submitted by Buyer to the authorized Nelsen dealer who sold the

Product in writing and shall include the Buyer’s name, address, telephone number, date of purchase of the Product,

receipt evidencing proof of purchase and a copy of this Limited Warranty. Nelsen or its authorized dealer will investigate

the claim. Buyer must fully cooperate in investigating and evaluating the claim, including, without limitation, providing

additional information upon request. TO BE ELIGIBLE FOR COVERAGE UNDER THIS LIMITED WARRANTY, BUYER

MUST SUBMIT A CLAIM WITHIN SIXTY (60) DAYS OF THE DATE THAT THE ALLEGEDLY DEFECTIVE PRODUCT OR

PART IS FIRST DISCOVERED BY BUYER AND, IN NO EVENT, LATER THAN SIXTY (60) DAYS AFTER THE WARRANTY

PERIOD HEREIN.

Continued on next page.

Appendix C - Controller Limited Warranty

14

© Nelsen Corporation Part # NRO-ROC2-MAN — RevE 0322

Repair or Replacement/Credit

Subject to the conditions and limitations herein, if Nelsen determines that the Product, or any part therein, does not

conform to this Limited Warranty, Nelsen will repair or replace the defective Product or part therein. Non-conforming

Products or parts therein must be returned to Nelsen’s authorized dealer at Buyer’s cost. Any replaced Products, or any

parts therein, shall be retained by and become the property of Nelsen. If Nelsen determines that the repair or replacement

of the Product or part therein is not commercially practicable, Nelsen will issue a credit in favor of Buyer in an amount

not to exceed the purchase price of the Product. Notwithstanding anything to the contrary herein, this Limited Warranty

does not cover any cost or labor associated with the removal or re-installation of the replacement Product or part

therein or any shipping costs associated with the returned Product or part therein, which remains the sole cost, risk and

responsibility of Buyer, unless otherwise agreed in writing by Nelsen.

Eligibility/Non-Transferable

This Limited Warranty applies only to Buyer if the Product is purchased from a Nelsen authorized dealer. This Limited

Warranty is personal to Buyer and may not be assigned or otherwise transferred by Buyer. Any attempt to transfer this

Limited Warranty shall be null and void and not recognized by Nelsen.

Disclaimer of Other Warranties/Limitation on Liability

EXCEPT AS PROVIDED ABOVE AND TO THE EXTENT PERMITTED BY LAW, THERE ARE NO OTHER REPRESENTATIONS

OR WARRANTIES WITH RESPECT TO THE PRODUCT, EITHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, OR ARISING

UNDER CUSTOM OF TRADE, INCLUDING, WITHOUT LIMITATION, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE. NO REPRESENTATIONS OR WARRANTIES AT ANY TIME MADE BY ANY

EMPLOYEE, AGENT OR REPRESENTATIVE OF NELSEN SHALL BE EFFECTIVE TO VARY OR EXPAND ANY WRITTEN

WARRANTY OR THE TERMS HEREOF. TO THE EXTENT A WAIVER OF IMPLIED WARRANTIES IS PROHIBITED BY

LAW, ANY IMPLIED WARRANTIES SHALL BE LIMITED TO THE DURATION OF ANY WRITTEN WARRANTY PROVIDED

BY NELSEN. IN NO EVENT SHALL NELSEN BE LIABLE TO BUYER OR TO ANY THIRD PARTY FOR CONSEQUENTIAL,

INCIDENTAL, SPECIAL OR PUNITIVE DAMAGES, OR FOR LOST PROFITS OR LOSS OF USE, RESULTING FROM OR IN ANY

MANNER RELATED TO THE PRODUCT, ITS DELIVERY, NON-DELIVERY, USE, OR INABILITY TO USE THE SAME, WHETHER

SUCH DAMAGES BE CLAIMED UNDER CONTRACT, TORT OR ANY OTHER LEGAL THEORY. NELSEN’S TOTAL LIABILITY

UNDER THIS OR ANY OTHER WARRANTY, EXPRESS OR IMPLIED, IS LIMITED TO REPAIR OR REPLACEMENT OF, OR

CREDIT FOR, THE PRODUCT OR ANY PART, AS STATED HEREIN.

Waiver of Class Action

ANY AND ALL CLAIMS ASSERTED BY BUYER OR ANY OTHER PERSON OR ENTITY SHALL BE RAISED IN AN INDIVIDUAL

CAPACITY AND NOT AS A PLAINTIFF OR CLASS MEMBER IN ANY PURPORTED CLASS OR REPRESENTATIVE

PROCEEDING, WHICH ARE HEREBY WAIVED.

Applicable Law

This Limited Warranty shall be interpreted and governed under the laws of the State of Ohio without giving effect to the

choice of law rules thereof. Nelsen and Buyer irrevocably consent and submit to the exclusive jurisdiction and venue

within the courts of Summit County, Ohio and/or the United States District Court for the Northern District of Ohio in

connection with any litigation arising out of, or in any way relating to, this Limited Warranty or the Product, including, but

not limited to, any and all claims for breach of warranty or products liability, and Nelsen and Buyer expressly waive any

objection to the jurisdiction and/or venue of such courts.

Appendix C - Controller Limited Warranty - continued

Table of contents

Popular Control System manuals by other brands

Gecko

Gecko in.yj-2 Quick start card

Rockford Fosgate

Rockford Fosgate SSC-500 installation manual

MacroAir Technologies

MacroAir Technologies Controller 4 Operation manual

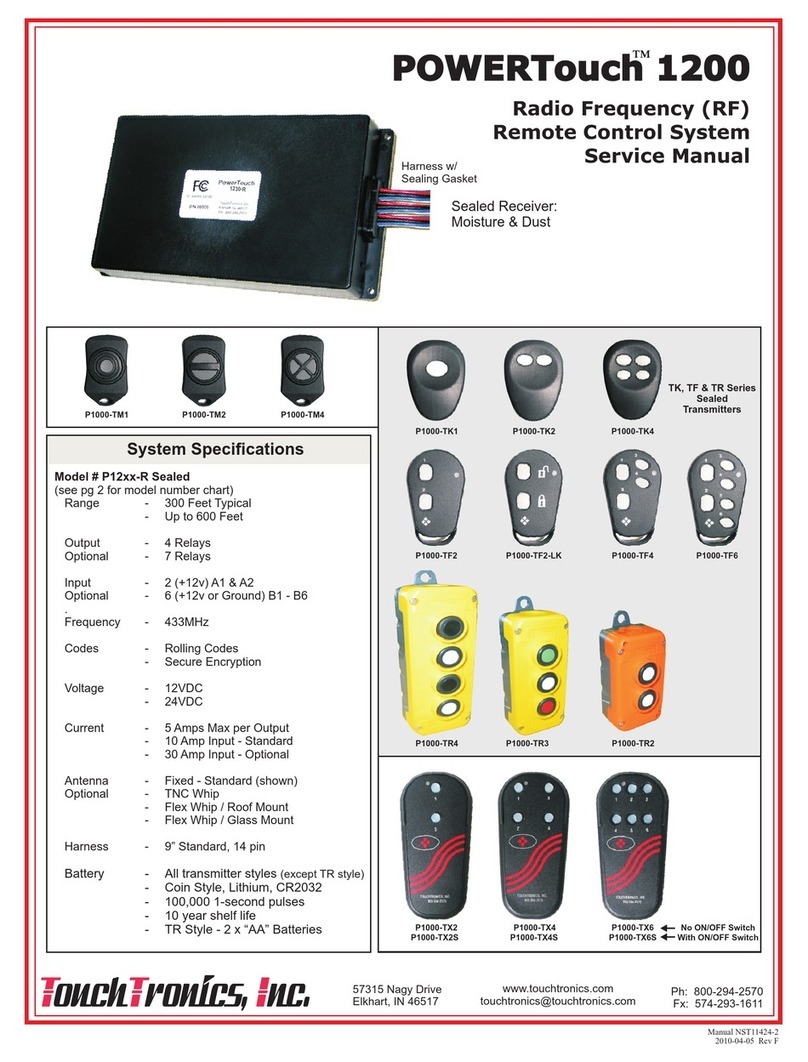

TouchTronics

TouchTronics 1210-R Service manual

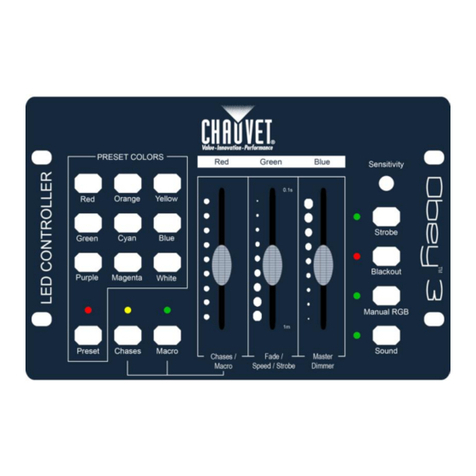

Chauvet

Chauvet Obey 3 user manual

Star

Star Unistar LCS800-008 Installation and instruction manual