Shuangri Electric SR618C1 User manual

Installation and Operating Manual

SR618C1

System Regulator for Solar Thermal Systems

Shuangri Electron Co.,Ltd

http//www.shuangri.com

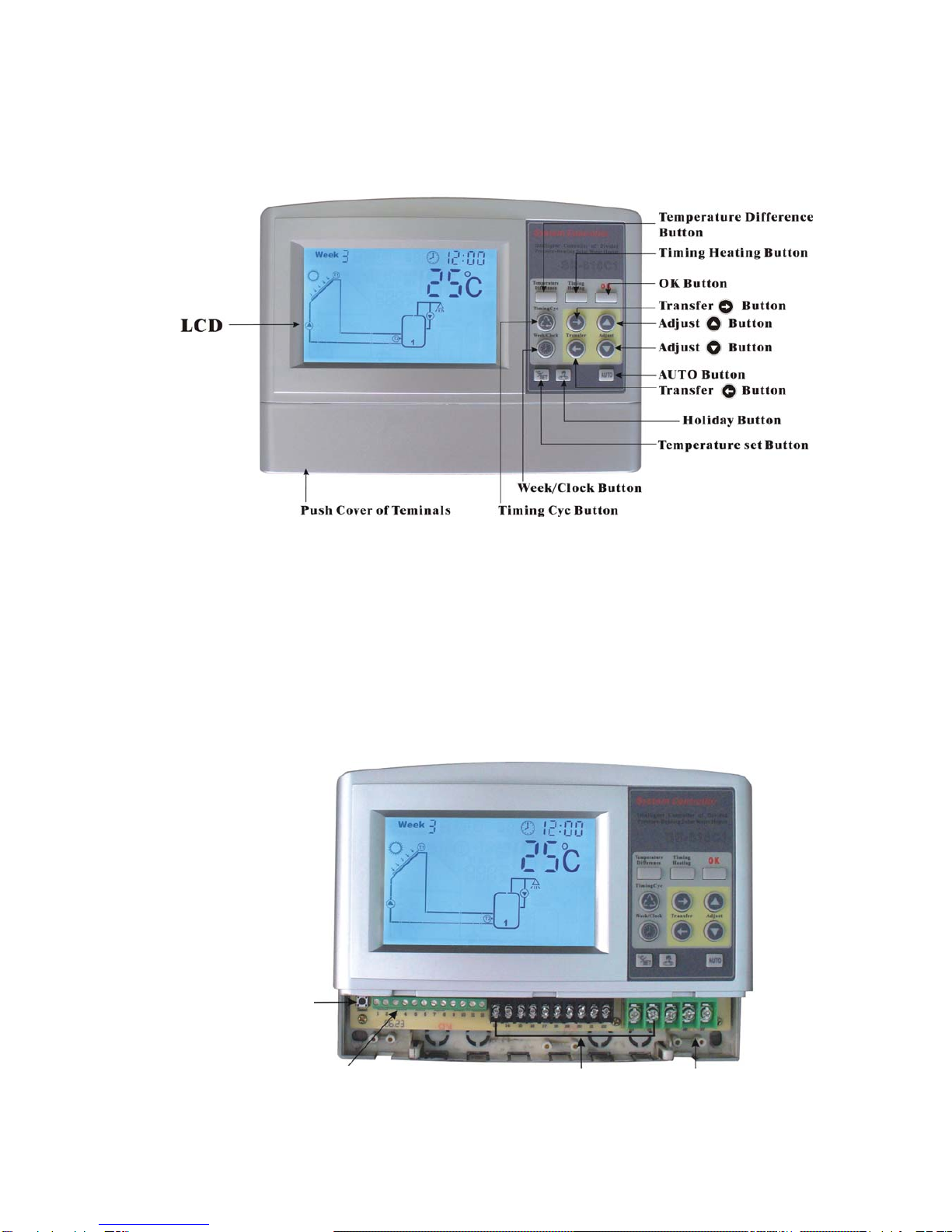

Display illustration

T0-T5 Input ports

6 In

p

uts Output ports

5ou

tputs

AC230V/115V

Reset Button

Shuangri Electron Co.,Ltd

http//www.shuangri.com

Shuangri Electron Co.,Ltd

http//www.shuangri.com

Contents

1. Safety information

1.1 Installation and commissioning

1.2 About this manual

1.3 Liability waiver

1.4 Description of symbols

2. Installation

2.1 Opening/closing controller case

2.2 Installing the controller

2.3 Power connection

2.3.1 Preparation before connection

2.3.2 Terminals connection

3. Commissioning

3.1 Setting the time

3.2 Choosing the solar system

3.3 Operating switch

3.4 Temperature query

4. Device setup

4.1Clock/week

4.2 Systems selection

4.3 System 1

4.4 System 2

4.5 System 3

4.6 System 4

4.7 System 5

4.8 System 6

4.9 System 7

4.10 System 8

4.11 Temperature difference controlling function

4.12 Maximal tank temperature

4.13 Maximal collector temperature

4.14 Collector emergency cut-off

4.15 Protection of collector at low temperature

4.16 Frost protection of collector

4.17 Temperature controlled hot water circulation pump

4.18 Time controlled hot water circulation pump

4.19 Temperature controlled auxiliary heating during three time sections

4.20 Holiday function

4.21 Auxiliary function

4.22 Auto function

4.23 Protection function

5.Troubleshooting

5.1 Trouble protection

5.2 Trouble checking

6.Technical data

Annex: Parameter settings

1. Safety information

1.1 Installation and commissioning

•When laying cables, please ensure that no damage occurs to any of the constructional fire safety measures

presented in the building.

•The controller must not be installed in rooms where easily inflammable gas mixtures are present or may

occur.

•The permissible environmental conditions must not be exceeded at the site of installation.

•Before connecting the device, make sure that the energy supply matches the specifications of controller on

the type plate.

•All devices connected to the controller must conform to the technical specifications of the controller.

•All operations on an open regulator are only to be conducted cleared from the power supply. All safety

regulations for working on the power supply are valid. Connecting and /or all operations that require opening

the regulator (e.g. changing the fuse) are only to be conducted by specialists.

1.2 About this manual

This manual describes the installation, function and operation of a solar thermal controller.

When installing the remaining components e.g. the solar collectors, pump assemblies and the storage unit, be

sure to observe the appropriate installation instructions provided by each manufacturer.

Installation, electrical connection, commissioning and maintenance of the device may only be performed by

trained professional personnel. The professional personnel must be familiar with this manual and follow the

instructions contained herein.

1.3 Liability waiver

The manufacturer cannot monitor the compliance with these instructions or the circumstances and methods

used for installation, operation, utilization and maintenance of this controller. Improper installation can cause

damages to material and persons. This is the reason why we do not take over responsibility and liability for

losses, damages or cost that might arise due to improper installation, operation or wrong utilization and

maintenance or that occur in some connection with the aforementioned. Moreover we do not take over liability

for patent infringements or infringements – occurring in connection with the use of this controller- on third

parties rights. The manufacturer preserves the right to put changes to product, technical date or installation

and operation instructions without prior notice. As soon as it becomes evident that safe operation is no longer

possible (e.g visible damage). Please immediate take the device out of operation. Note: ensure that the

device cannot be accidentally placed into operation.

1.4 Description of symbols

Safety instruction:

Safety instructions in the text are marked with a warning triangle. They indicate measures which can

lead to injury of persons or safety risks.

Operation steps: small triangle “►”is used to indicate operation step.

Shuangri Electron Co.,Ltd

http//www.shuangri.com

Notes: Contains important information on operation or function, is written in blue color

2.Installation

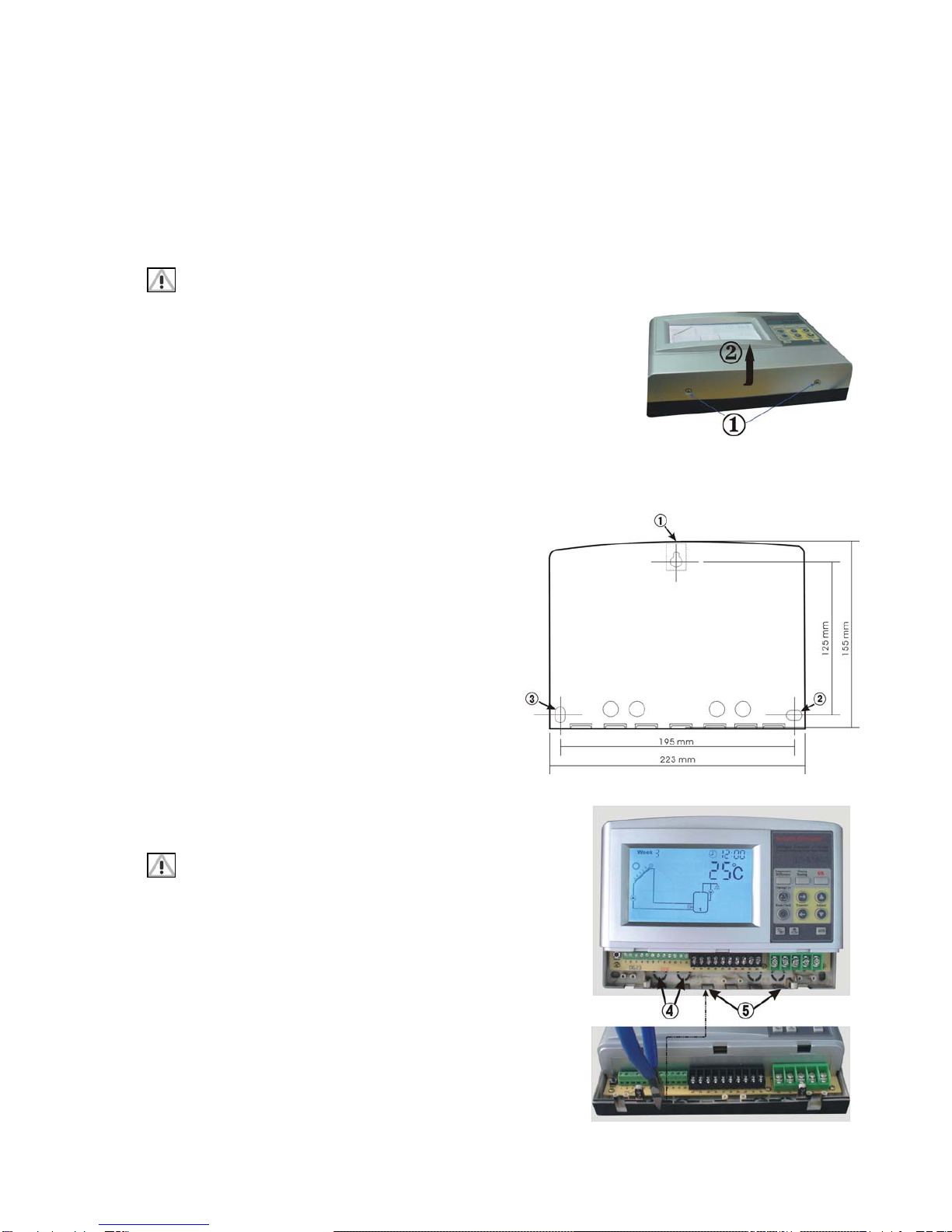

2.1 Opening/closing the case of controller

Danger of electrocution! Before opening the case please ensure power is switched off.

►Loosen the screw ①and remove the upper case ②in an upwards

direction.

►Close the case: insert the hinge grooves of upper case into the retaining

pegs of the lower case.

►pivot the upper case down.

►fasten the case tightly with the screw.

2.2 Installing the controller

Attention: the controller must only be installed in an area having an adequate level of protection.

►Choose a suitable location

Shuangri Electron Co.,Ltd

http//www.shuangri.com

►Drill the upper fastening hole

►Screw in the screw

►Remove the upper case

►Hang the bottom case in the recess ①in picture

►Mark the position of the lower fastening holes ②and

③

►Remove the bottom case again

►Drill the lower fastening holes

►Re-hang the case in the recess ①

►Screw the case firmly using the lower fastening holes

②and ③

►Mount the upper case.

2.3 Electrical connections

Remove the device from the mains supply before opening the

case! All guidelines and regulations of the local electricity

supplier must be observed!

2.3.1 Preparation before connections

Power can only be switched on when the housing of controller is

closed, an installer must make sure that the IP protection class of

the controller is not damaged during installation.

Depending on the type of installation, the cables may enter the

device through the rear of the case ④or the lower side of the case

⑤.

Cable come from the rear ④: remove the plastic flaps from the rear side of the case using an appropriate

tool.

Cable come from the below⑤: cut the left and right plastic flaps using an appropriate tool (e.g. knife) and

break them out of the case.

Notes: the flexible cabling must be fastened to the case using the strain-relief clamps provided

2.3.2 Terminal connection

Shuangri Electron Co.,Ltd

http//www.shuangri.com

Output ports Input ports

Power Connection

1. please note the

type of power

supply required

from the type

plate on the case

of the device

2. The protective

conductor must

be also be

connected

3. Cables type of

H05VV-…..

(NYM…) can be

used

Outputs Inputs

1. Outputs P1& P2: electromagnetic relays

max. switching current:3A

1. Inputs T0 and T1: for PT1000

temperature sensors.

2. Outputs P0/R1,R2: electromagnetic relays,

maximal switching current:5A

2. Inputs T2-T5: for NTC10K

sensors.

3. When using P0 circulation pump,

connection ports are 17 and 18; when

using R1 3-way electromagnetic valve,

connection ports 17, 18 &19. When power is

switched on. Port17 & 18 is shut off; port 17 &

19 is turned on.

4. When using R2 controls circulation pump,

connection ports are 20 and 21; when

using R2 controls 3- way electromagnetic

valve, connection ports 20, 21&22. When

power is switched on. Port 20 & 21 is shut off;

port 20 & 22 is turned on.

5. Output H1: electromagnetic relay, max

switching current 16A.

“Reset”:This button is on the terminal connection panel, when system program is out of working, press

“Reset” to recover the program of system to the factory settings.

Advice regarding the installation of temperature sensors:

Only original factory equipped Pt1000 temperature sensors are approved for use with the collector, it is

equipped with 1.5meter silicon cable and suitable for all weather conditions, the temperature sensor and

cable are temperature resistant up to 280oC, not necessary to distinguish the positive and negative polarity of

the sensor connection.

Only original factory equipped NTC10K,B=3950 temperature sensors are approved for use with tank and pipe,

it is equipped with 1.5meter PVC cable, and they are temperature resistant up to 105oC, not necessary to

distinguish the positive and negative polarity of the sensor connection.

All sensor cables carry low voltage, and to avoid inductive effects, must not be laid close to 230 volt or 400

volt cables (minimum separation of 100mm)

If external inductive effects are existed, e.g. from heavy current cables, overhead train cables, transformer

substations, radio and television devices, amateur radio stations, microwave devices etc, then the cables to

the sensors must be adequately shielded.

Sensor cables may be extended to a maximum length of ca. 100 meter, when cable’s length is up to 50m, and

then 0.75mm2cable should be used. When cable’s length is up to 100m, and then 1.5mm2cable should be

used.

Note: the connection of the pump and sensors depends on the chosen solar system, every port can only

connect one cable, fine core cables should use wire end sleeves.

3. Commissioning

Connect the sensors, pumps or switching valves to the controller before you connect the power

supply!

After switching on power to the controller, firstly it will ask for the “time” to be set and the correct

“solar system” to be chosen.

3.1 Setting the Clock/ Week

After power is switched on, “week 1” “00:00” displays on LCD screen.

►Press “Clock/week” button, hour selection area “00” blinks on display

screen.

►Press “▲”“▼” button to adjust hour of clock

►Press “Clock/week” button again, the minute selection area “00” blinks

►Press “▲”“▼” button to adjust minute of clock

►Press “Clock/week” button again, the week selection “week 1” blinks

►Press “▲”“▼” button to adjust week

After 6 seconds controller confirms the setting automatically, the current time and week are displayed on the

screen.

Shuangri Electron Co.,Ltd

http//www.shuangri.com

3.2 Choosing the solar system

The first solar system displays on the screen, the default setting is System

1.

►Press “OK” button for 3 minutes, “System 1” blinks on the screen.

►Press “▲” select system. 8 systems are available to be chosen (System

1-8).

After 6 seconds controller confirms the setting.

3.3 Operation switch

Manual mode: when operating the device first time, or when testing the function, the outputs of controller can

be operated manually. To do like the following steps:

►Press “Temperature set” button for 3 seconds; the temperature difference controlled circulation pump is

triggered.

►Press “Temperature set” button again, shut off this output.

►Press “ Timing Cyc” button for 3 seconds, the hot water circulation pump is triggered.

►Press “ Timing Cyc” button again, shut off this output.

►Press “ Timing Heating” button for 3 seconds, the auxiliary electricity heating or gas, oil boiler is triggered.

►Press “ Timing Heating ” button again, shut off this output

3.4 Temperature query function

►Press “→” button to check the temperature value of T0-T5 one by one. After 2 minutes, only temperature of

tank is displayed automatically on screen.

Shuangri Electron Co.,Ltd

http//www.shuangri.com

4. Device setup

4.1 Clock/Week display

►Press “Clock/week” button, the hour selection area “00”

blinks on display screen.

►Press “▲”“▼” button to adjust hour of clock

►Press “Clock/week” button again, the minute selection

area “00” blinks

►Press “▲”“▼” button to adjust minute of clock

►Press “Clock/week” button again, the week selection

“week 1” blinks

►Press “▲”“▼” button to adjust week

After 6 seconds controller confirms the setting

automatically, the current time and week are displayed on

the screen.

4.2 Chosen systems

►Press “OK” button for 3 seconds, “System 1” blinks on

the screen.

►Press “▲” select system. Total 8 systems are available to

be chosen. ( System 1-8)

After 6 seconds controller confirms the setting.

4.3 System 1

1 collector array – 1 storage tank – 1 pump

Description:

The solar circuit pump (P1) is switched on as soon as the

switch-on temperature difference between the collector

array (T1) and the storage tank (T2) is reached. If the

temperature difference between the collector array (T1)

and storage tank (T2) drops below the switch-off

temperature difference, or the storage tank (T2) reaches

the maximum storage temperature, then the solar circuit

pump is switched off.

T1: Temperature sensor for collector 1

T2: Temperature sensor in the bottom part of tank 1.

T3: Temperature sensor in the top part of tank ( for control

auxiliary heating)

T4: Temperature sensor on hot water pipe

P1: Solar circuit pump 1

P2: Hot water circuit pump

Note:

•H1 is connected with auxiliary heating, suitable for

system 1 – 8.

•T3, T4, P2 are suitable for system 1-8

•T3 is alternative, when no sensor (T3) is installed in the

top part of sensor, controller will use the signal of sensor

T2 automatically to control the auxiliary heating.

System 1 display

Shuangri Electron Co.,Ltd

http//www.shuangri.com

4.4 System 2

1 collector array – 2 storage tanks – 2 pump

Description:

If the switch – on temperature difference between the

collector array (T1) and one of the two storage tanks (T2,or

T5) is exceeded, then the appropriate solar circuit pump

(P1) or (P0) is switched on. According to the priority

switching, both storage tanks ( T2, T5) are loaded one after

the other, until either the relevant switch-off temperature

difference between the collector array ( T1) and storage

tank (T2, T5) falls below the threshold, or the maximum

storage temperature is reached.

T1: Temperature sensor for collector 1

T2: Temperature sensor in the bottom part of tank 1

T5: Temperature sensor in the tank 2

T4: Temperature sensor on hot water pipe

P1: Solar circuit pump 1

P0: Solar circuit pump 2

Note: the default priority tank is tank 1.

System 2 display

4.5 System 3

1 collector array – 2 storage tanks – 1 pump- 1

valve

Description:

If the switch – on temperature difference between the

collector array (T1) and one of the two storage tanks (T2,

T5) is exceeded, then the solar circuit pump (P1) is

switched on and the switching valve ( R1) is set to the

correct position depending on the storage tank to be

loaded. According to the priority switching, both storage

tanks ( T2, T5) are loaded one after the other, until either

the relevant switch-off temperature difference between the

collector array ( T1) and two storage tanks (T2, T5) falls

below the threshold, or the maximum storage temperature

of T2 or T5 is reached.

T1: Temperature sensor for collector 1

T2: Temperature sensor in the bottom part of tank 1

T5: Temperature sensor in the tank 2

P1: Solar circuit pump 1

R1: 3-way switching valve ( Ports 17,18 are shut off, Ports

17,19 are turned on )

Note: When no voltage is on the system, the switching

valve ( R1) must be set to storage tank 1( T2)

•The default priority tank is tank 1.

System 3 display

Shuangri Electron Co.,Ltd

http//www.shuangri.com

4.6 System 4

2 collector arrays( east/west roof) – 1 storage

tank – 2 pumps

Description:

If the switch – on temperature difference between the

storage tank ( T2) and one or the other of the collector

array ( T1,T0) is reached, then the solar circuit pump (P1)

for collector array 1 (T1) or solar circuit pump (P0) for

collector array 2 ( T0) is switched on, depending on where

the temperature difference occurs. If the switch-on

temperature difference is reached for both collector arrays

(T1, T0), then both pumps (P1, P0) are switched on. The

pumps switch off independently of each other. When either

the relevant switch off temperature difference between one

or both of collector arrays ( T1, T0) and the storage tank

( T2) falls below the threshold, or the maximum storage

temperature is reached, and then the corresponding circuit

pump is switched off.

T1: Temperature sensor for collector 1

T0: Temperature sensor for collector 2

T2: Temperature sensor in the bottom part of tank 1

P1: Solar circuit pump 1

P0: Solar circuit pump 2

System 4 display

4.7 System 5

2 collector arrays( east/west roof) – 1 storage tank

– 1 pump – 1 valve

Description:

The solar circuit pump ( P1) is switched on as soon as the

switch – on temperature difference between one of the two

collector arrays ( T1, T0) and storage tank 1( T2) is

exceeded, the switch valve R1 is always set so that flow

occurs through the warmer of the two collector arrays ( T1,

T2). The pump P1 switches off as soon as the switch-off

temperature difference between the two collector arrays

( T1, T0) and the storage tank ( T2) falls below the

threshold or the maximum storage temperature is reached.

T1: Temperature sensor for collector 1

T0: Temperature sensor for collector 2

T2: Temperature sensor in the bottom part of tank 1

P1: Solar circuit pump 1

R1: 3-way switching valve ( Ports 17,18 are shut off, Ports

17,19 are turned on )

Note:

When no voltage is on the system, the switching valve ( R1)

System 5 display

Shuangri Electron Co.,Ltd

http//www.shuangri.com

must be set to collector array 1 ( T1)

4.8 System 6

Valve-controlled 2 collector arrays ( east/west

roof) – 2 storage tanks – 1 pump – 2 valves

Description

If the switch-on temperature difference between one of the

two tanks ( T2, T5) and collector array1 ( T1) or collector

array 2 ( T0) is exceeded, then the solar circuit pump ( P1)

is switched on, switching valve (R1) switches the relevant

tank into the solar circuit, and switching valve (R2) switches

the affected collector array (T1 or T2) into the solar circuit

also. Switching valve 1 (R1) is always set so that flow

occurs through the warmer of the two collector arrays (T1,

T0). Switching valve 2 (R2) controls the loading of the

storage tanks (T2, T5) according to the priority switching.

Pump ( P1) switches off when the switch-off temperature

difference between either or both collector arrays and its

corresponding storage tank1 ( T2) and storage tank 2( T5)

falls below the threshold or the maximum storage

temperature ( T2 or T5) is reached.

T1: Temperature sensor for collector 1

T0: Temperature sensor for collector 2

T2: Temperature sensor in the bottom part of tank 1

T5: Temperature sensor in the bottom part of tank 2

P1: Solar circuit pump 1

R1: 3-way switching valve 1 ( Ports 17,18 are shut off, Ports

17,19 are turned on )

R2: 3-way switching valve 2 ( Ports 20,21 are shut off, Ports

20,22 are turned on )

Note:

•When no voltage is on the system, the switching valve 2

( R2) must be set to tank 1 ( T2), the switching valve 1

(R1) must be set to collector array 1( T1)

•Default priority tank is tank 1( T1)

System 6 display

Shuangri Electron Co.,Ltd

http//www.shuangri.com

4.9 System 7

Valve-controlled 2 collector arrays ( east/west

roof) – 2 storage tanks – 2 pumps – 1 valve

Description:

If the switch-on temperature difference between one of the

two tanks ( T2, T5) and collector array 1( T1) or collector

array 2 ( T0) is exceeded, then the switching valve R2

switched the corresponding collector array ( T1 or T0) into

the solar circuit. Depending on which storage tank has

reached the switch-on temperature, solar circuit pump (P1)

for storage tank 1 ( T2) or solar circuit pump ( P0) for

storage tank 2 ( T5) is switched on. The switching valve R2

is always set so that flow occurs through the warmer of the

two collector arrays. Both storage tanks ( T2, T5) are

loaded one after the other, according to the priority

switching, until either the relevant switch-off temperature

difference falls below the threshold, or the maximum

storage temperature( T2 or T5) is reached.

T1: Temperature sensor for collector 1

T0: Temperature sensor for collector 2

T2: Temperature sensor in the bottom part of tank 1

T5: Temperature sensor in the bottom part of tank 2

P1: Solar circuit pump 1

P0: Solar circuit pimp 2

R2: 3-way switching valve 1 ( Ports 20,21 are shut off, Ports

20,22 are turned on )

Note:

•When no voltage is on the system, the switching valve

( R2) must be set to collector array 1( T1)

•Default priority tank is tank 1( T1)

System 7 display

Shuangri Electron Co.,Ltd

http//www.shuangri.com

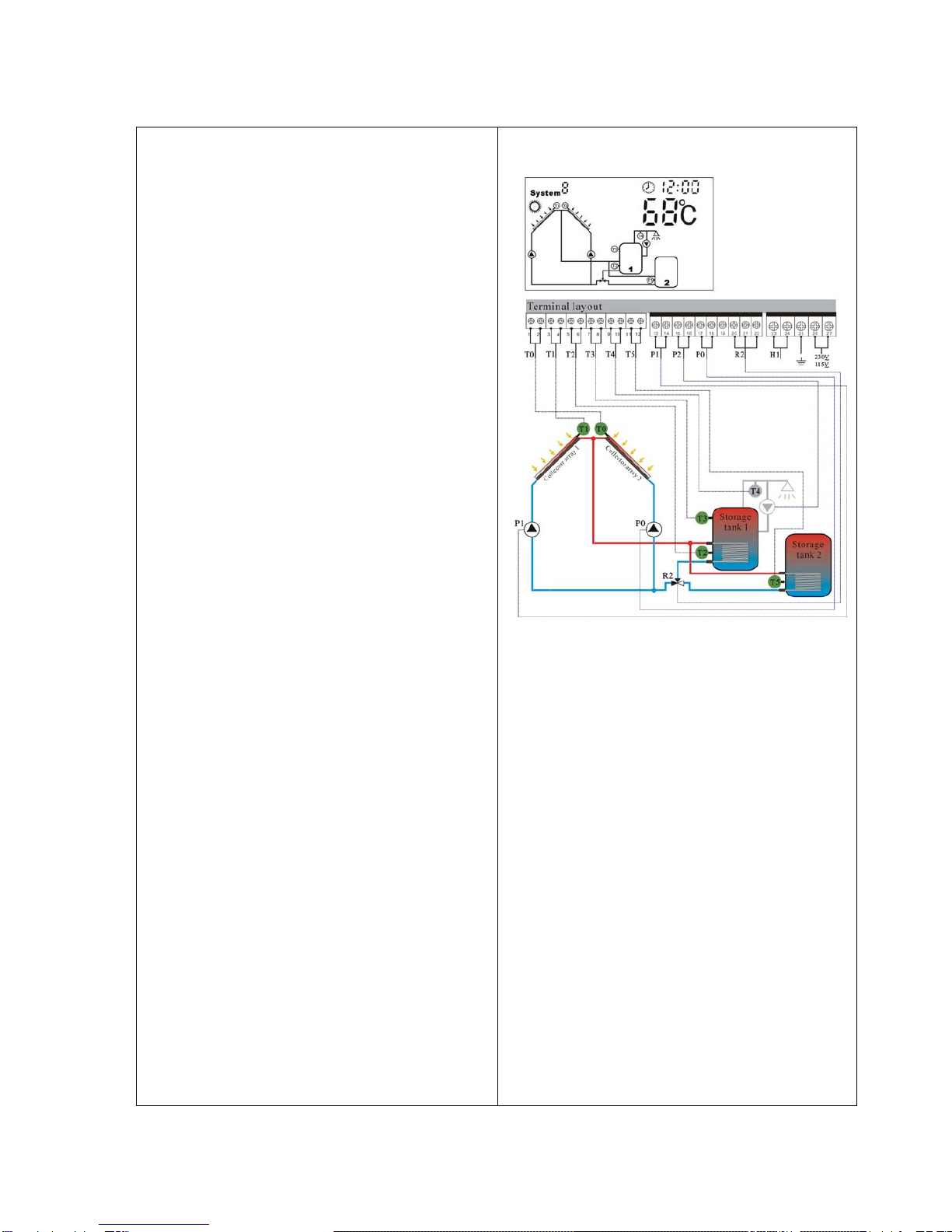

4.10 System 8

pump controlled 2 collector arrays( east/west

roof) – 2 storage tanks – 2 pumps – 1 valve

Description:

If the switch-on temperature difference between one

of the two tanks (T2, T5) and collector array1 (T1)

and collector array 2 (T0) is exceeded, then the

switching valve (R2) switches the relevant storage

tank (T2, or T5) into the solar circuit. If the switch-on

temperature difference between the storage tanks

(T2, T5) and one of the collector arrays (T1, T0) is

reached, then either solar circuit pump P1 for

collector array1 ( T1) , or solar circuit pump P0 for

collector array( T0) is switched on, depending on

where the temperature difference occurs. If the

switch-on temperature difference is reached for both

collector arrays (T1, T0), then both pumps (P1, P0)

are switched on. The switching valve (R2) controls

the loading of the storage tank (T2, t5) according to

the priority switching. The pumps ( P1, P0) switch

off independently of each other, when either the

relevant switch-off temperature for one or both of the

collector arrays ( T1, T0) with regard to the storage

tanks ( T3 or T4) falls below the threshold, or the

maximum storage temperature is reached.

T1: Temperature sensor for collector 1

T0: Temperature sensor for collector 2

T2: Temperature sensor in the bottom part of tank 1

T5: Temperature sensor in the bottom part of tank 2

P1: Solar circuit pump 1

P0: Solar circuit pimp 2

R2: 3-way switching valve 1 ( Ports 20,21 are shut off,

Ports 20,22 are turned on )

Note:

•When no voltage is on the system, the switching

valve ( R2) must be set to collector array 1( T1)

Default priority tank is tank 1( T1)

System 8 display

Shuangri Electron Co.,Ltd

http//www.shuangri.com

4.11 On/off of temperature difference controlling function

Functional description:

Solar circuit pump P1 is triggered by temperature difference function, so long as the preset temperature

difference between collector and tank is reached, solar pump is switched on.

When there are two tanks or two collector arrays, controller will compare the temperature between one tank

and one collector, one extra number indicates the correspondingly tank or collector.

For example: when we set the switch-on temperature difference is 8 oC, the switch-off temperature difference

is 4oC, and the temperature in bottom part of tank is 20oC, in this case, when the collector temperature

reaches 28oC, pump is triggered, when collector temperature falls below 24oC, pump stops.

Important information: the switch-on temperature difference 8oC and the switch-off temperature 4oC are

standard system setting according to many years’ experiences. Only in special application cases it is possible

to change (e.g. far distance heat transferring), switch-on and switch-off temperature difference are alternating

set. To avoid mistake the minimum difference between two temperature differences (∆Ton - ∆Toff ) is set as

2oC.

Setup steps:

►: Press “Temperature difference” button, switch-on delta T

setting area blinks.

Shuangri Electron Co.,Ltd

http//www.shuangri.com

►: Press “▲”“▼” button to adjust switch-on temperature

difference, adjustable range: (OFF + 2oC) ~ 20oC, default valve is

8oC.

►Press “ Temperature difference” button again, switch –off delta

T blinks

►: Press “▲”“▼” button to adjust switch-off temperature

difference, adjustable range: 0oC ~ ( On-2oC), default valve is 4oC.

After 6 seconds, controller confirms the setting.

4.12 Maximum tank temperature ( protection of tank at high temperature)

Functional description:

To avoid the temperature in tank is too high; controller will start its maximal tank temperature protection

function. Controller checks the temperature which getting from bottom part of tank and compares it with

turning-on and turning-off temperature of this function, when the temperature is higher than the turning-on

temperature, solar circuit pump is stopped, when the temperature is lower than tuning-off temperature, solar

circuit pump is triggered automatically. When the temperature of tank is higher than the maximum tank

temperature, even the condition of temperature difference circulation is reached, solar pump is still forbidden

to trigger.

Activate/deactivate this function:

►Press “Temperature set” button 2 times, the maximum tank

temperature setting area blinks, default setting is 90oC.

►Press“▲”“▼” button to adjust the maximum tank temperature

(adjustable range: 50oC – 95oC). After 6 seconds, controller

confirms the setting automatically.

►In the status of setting maximum tank temperature, press “OK”

button to deactivate this function, displays”----“

When signal of maximum tank temperature is displayed on screen, it indicates this function

activated.

4.13 Maximum collector temperature ( collector cooling function)

Functional description:

If the hot water in tank isn’t used, temperature in solar circulation will rise automatically after long time

sunshine, it is possible to avoid evaporating of heat transfer fluid by the restricted maximum collector

temperature. The heat loss through the collector will increase with the rising of temperature of heat transfer

liquid; this can be realized by the operation of solar circuit pump. . Through setting the maximal temperature

of collector can realize the cooling of collector.

Activate/deactivate this function:

►Press “Temperature set” button 3 times, the maximum collector

temperature setting area blinks, default setting is 115oC.

►Press“▲”“▼” button to adjust the maximum collector

temperature (adjustable range: 100oC –140oC), after 6 seconds,

controller confirms the setting automatically.

►In the status of setting collector maximum temperature, press

utton to deactivate this function, displays”-----“

Shuangri Electron Co.,Ltd

http//www.shuangri.com

“OK” b

When signal of maximum collector temperature is displayed on screen, it indicates this function

activated.

4.14 Collector emergency cut-off

Functional description:

When the temperature of collector exceeds 130oC, in order to protect the other components of solar circuit,

solar circuit pump is shut off compulsively. Restart conditions: the temperature of collector drops below 100oC

and tank temperature drops below the maximum tank temperature.

4.15 Protection of collector at low temperature

Functional description:

When the temperature of collector is below 15oC, even when the temperature difference exceeds switch-on

temperature difference, solar pump doesn’t work.

When the temperature of collector is above 20oC, solar pump starts to work.

4.16 Collector frost protection

Functional description:

In Winter when the temperature of collector is below the preset frost protection temperature (2-15oC),

electrical booster and solar pump starts work simultaneously. When the temperature of collector exceeds the

switch-off temperature of frost protection, controller stops solar pump and electrical booster and exits the

program.

Activate/deactivate this function:

►Press “temperature set” button 1 time, the frost protection

setting area blinks; default setting of 2oC is displayed.

►Press“▲”“▼” button to adjust the switch-on temperature of

frost protection, (adjustable range: 0oC –15oC), after 6 seconds,

controller confirms the setting automatically.

►In the status of setting frost protection temperature, press

“OK” button to deactivate this function, display”-----“.

When the signal displays on screen, it indicates frost protection function is activated.

4.17 Temperature-controlled hot water circuit pump

Functional description:

Solar system can provide temperature-controlled the hot water circulation function, this function needs a extra

hot water circulation pump ( P2) and a sensor (T4), which is positioned on the return pipe of hot water . When

the temperature signal of sensor T4 is less than the preset turning on temperature, the hot water circulation

pump (P2) triggers and works till the temperature exceeds the turning off temperature.

The default turning on temperature is 39oC; default turning off temperature is 45oC.

Activate/deactivate this function:

►Press “Temperature set” button 4 times, the hot water circulation

temperature setting area blinks, default setting is “OFF” mode,

“----”displays.

►Press “OK” button to activate this function.

►Press“▲”“▼” button to adjust the temperature of circulation

pump, (adjustable range: 20oC –50oC), after 6 seconds, controller

confirms the setting automatically.

►In the status of setting the temperature for circulation pump, press “OK” button to deactivate this function

Note: the position of the sensor T4 should be minimum 1.5m far from tank, so that avoid the measuring

error.

Shuangri Electron Co.,Ltd

http//www.shuangri.com

4.18 Time-controlled hot water circuit pump

Function description:

Solar system can provide time-controlled hot water circulation function, this function needs a extra circulation

pump (P2), this pump can be triggered by preset time. Within the preset time section pump operates for three

minutes, and then stops for 15 minutes, same process continues so. Three time sections can be set within

one day.

Setup steps:

►Press “ Timing Cyc” button, timing setting area blinks, to set

the start time of circulation.

►Press “▲”“▼” button to adjust hour

Shuangri Electron Co.,Ltd

http//www.shuangri.com

►Press “←”、“→” transfer button to minute area

►Press “▲”“▼” button to adjust minute

►Press “ Timing Cyc” button again to set the end time of

circulation

►Press “▲”“▼” button to adjust hour

►Press “←”、“→” transfer button to minute area

►Press “▲”“▼” button to adjust minute

•After 6 seconds, controller confirms setting automatically

•Doing like above steps. Within one day, three time sections can be set ( 1-3 displays on screen)

•If you want to shut off one timing circulation, then you set the turning on time and turning off time same

value ( for example, deactivate the function in the second time section, then you can set turning on/off time

is 10:00 ~ 10:00)

•Controller has memory function, the setting is remembered, don’t need to set everyday.

•The setting can be checked by pressing “Timing Cyc” button after setting.

Manual operation:

Press “ Timing Cyc” button for 3 seconds, the hot water circuit pump is triggered。If the time of this operation

is happened at the preset time section, it works as normal situation, namely works for 3 minutes, then stops

for 15 minutes, same process continues. If the time of this operation is not within the preset time section, it

works for 3 minutes, and then it stops automatically.

At the status that hot water circuit pump is working, press “ Timing Cyc” again to stop pump immediately.

4.19 Temperature controlled auxiliary heating at preset time sections

Functional description:

Solar system can be combined with electrical booster or gas, oil boiler, controller can achieve automatically

temperature and timing controlled heating, during the preset time sections electrical booster starts working

when the temperature (T3) of top part of tank is below the preset turning on temperature, when T3 exceeds

the preset turning off temperature, electrical booster stops heating.

When it is outside of the preset time section, electrical booster doesn’t work even when the tank temperature

reaches the turning –on temperature of electrical heating.

Setup steps:

►Press “Timing heating” button, timing area blinks on display, you can set turning on time and temperature of

electrical heating now,

►Press “▲”“▼” button to set hour,

►Press“←”、“→” button to shift to minute setting,

►Press “▲”“▼” to set minute.

►Press “←”、“→”again to shift to temperature area,

►Press “▲”“▼” to set turning on temperature of electrical

heating.

►Press “Timing heating” button again, you can set turning off

time and temperature of electrical heating

►press “▲”“▼” button to set hour,

►press“←”、“→” button to shift to minute setting,

►press “▲”“▼” to set minute.

►Press “←”、“→”again to shift to temperature setting,

►Press “▲”“▼” to set turning off temperature of electrical heating.

•6 seconds later controller confirms the settings

•Doing like above described steps, three timing sections can be set.( 1-3 displays)

•Default setting:

¾First heating time section: 4:00 turning on, 5:00 turning off

¾Second heating time section: not working, setting is 10:00 ~10:00

Shuangri Electron Co.,Ltd

http//www.shuangri.com

¾Third heating time section: 17:00 turning on, 22:00 turning off

¾Default turning on temperature of electrical booster is 50oC, turning off temperature is 55oC.

•If you want to shut off one timing heating, then you set the turning on time and turning off time same value

( for example, the second time section no this function, then you can set turning on/off time is 10:00 ~ 10:00)

•Controller has memory function, your setting is remembered, and you don’t need to set everyday.

•The setting can be checked by pressing “Timing heating” button.

Manual operation:

►Press “Timing heating” button for three seconds, electrical booster is triggered immediately, the

corresponding signal is lighted,

►Press “timing heating” button again, electrical booster switches off immediately.

Note: when no temperature sensor (T3) is installed in the top part of tank or T3 is damaged, controller

will take the signal from bottom temperature sensor ( T2) automatically and thereof control auxiliary

heating function.

When this signal displays on screen, it indicates the function activated.

4.20 Holiday function

Function description:

This function activates nightly storage tank back cooling and prevents high thermal loads of the solar system

due to completely heated storage tank. The function is activated when the collector temperature falls 8K

below the storage tank temperature at night between 10 pm and 6 am,.

Activate this function if:

•You intend to be absent for an extended period ( holiday)

•No hot water is required for an extended period.

The function is deactivated when the temperature in lower section

of storage tank falls down to 35oC.

Activating/deactivating the function

►Press “Holiday” button for 3 seconds, “Hd” blinks on display

screen, it indicates the function is active

►Press “Holiday” button for 3 seconds again, “Hd” hides, the function is deactivated.

Note:

•In the case of muti-storage tank systems, only storage tank 1 is used for storage tank back cooling.

•This function is only activated when you are not at home for long time, when you come back, please make

sure to deactivate it.

4.21 Auxiliary function

Note: the following described functions need an extra output port R2 to control pump or

electromagnetic valve, when all outputs are occupied, the desired function can’t be activated.

a. Temperature difference controlling (△T2)

setup steps:

►Press “ OK” button for 3 seconds, systems blinks

►Press “ →” one time and chosen the symbol which displays on

screen, chosen R2 temperature difference controlled output.

►Press “OK” to confirm setting, or 6 seconds later controller

confirms setting automatically

This function allows through temperature difference (sensor T0

and T5) to control a output port R2, it is used to control additional space heating or circulation.

►Press “Temperature difference” button three times, “△T2 ON” displays on screen.

►Press “▲”“▼” button to adjust switch-on temperature difference, adjustable range: ( OFF+2oC) ~

20oC,default is 8oC.

►Press “Temperature difference” button again, “△T2 OFF” displays on screen.

►Press “▲”“▼” button to adjust switch-off temperature difference, adjustable range: 0oC ~ (ON-2oC),default

is 4oC.

6 seconds later, controller confirms setting automatically.

Shuangri Electron Co.,Ltd

http//www.shuangri.com

Table of contents

Popular Control System manuals by other brands

eqss

eqss OverWatch JLG 94RT Series Install manual

Colorbeam

Colorbeam CORLORAY DMX 50W user guide

VPG

VPG TruckWeigh Installation, Setup and Calibration Manual

Recalart Electronic

Recalart Electronic MultiFun instruction manual

CENTURION SYSTEMS

CENTURION SYSTEMS SupaHelix installation manual

FUTABA

FUTABA 6EXA instruction manual