Oxford Plastics Product Guidelines

Oxford Plastics Product Guidelines

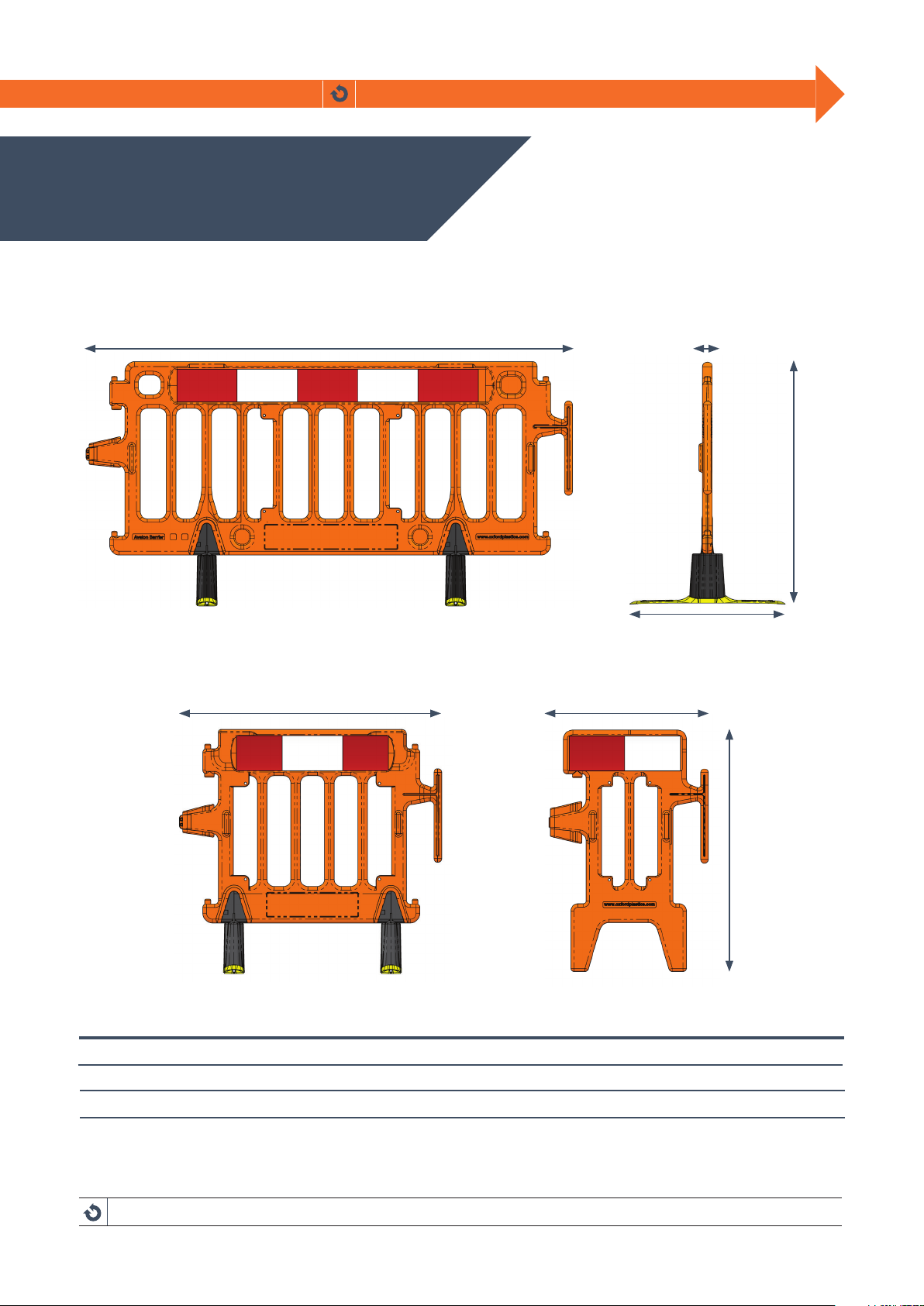

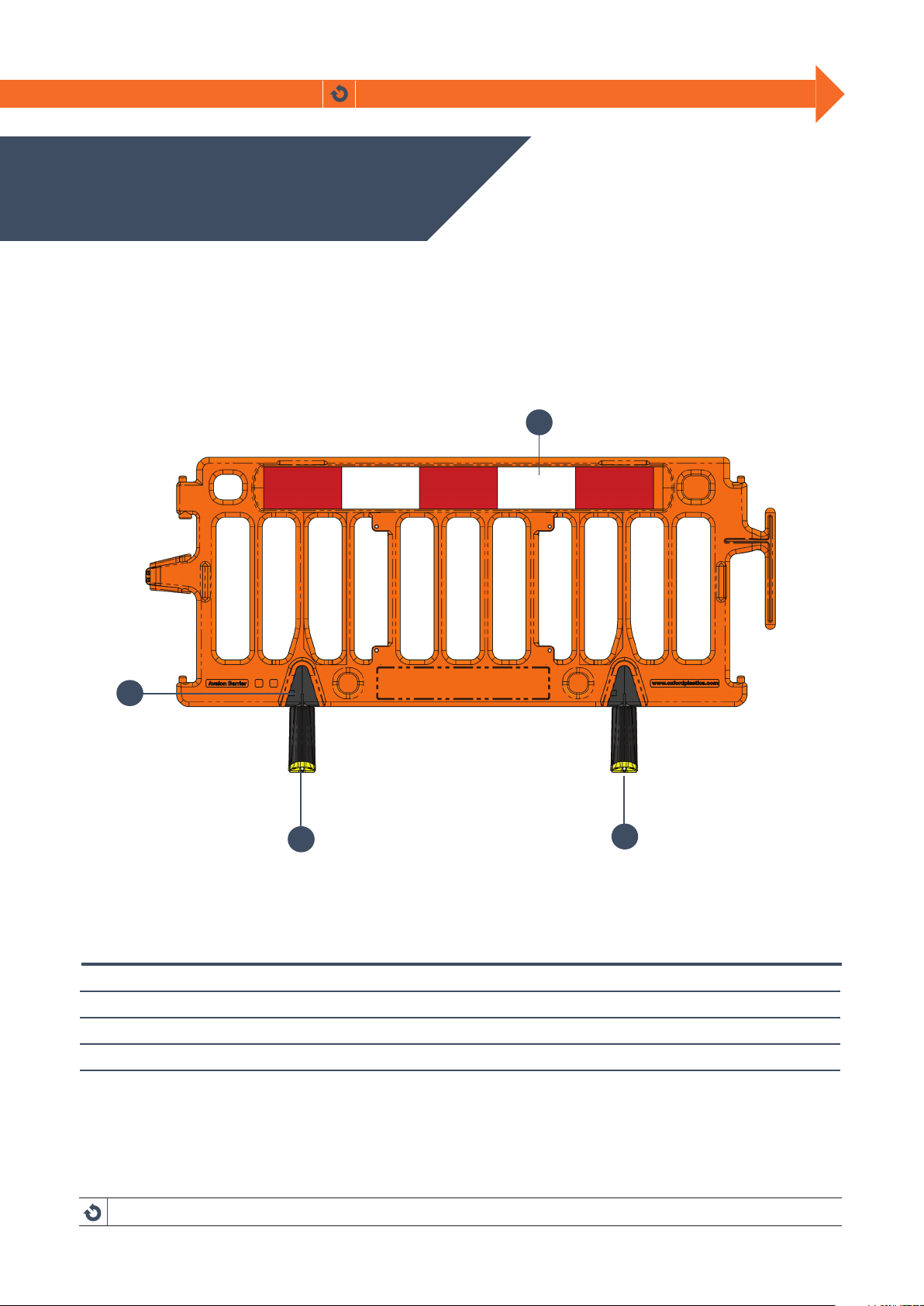

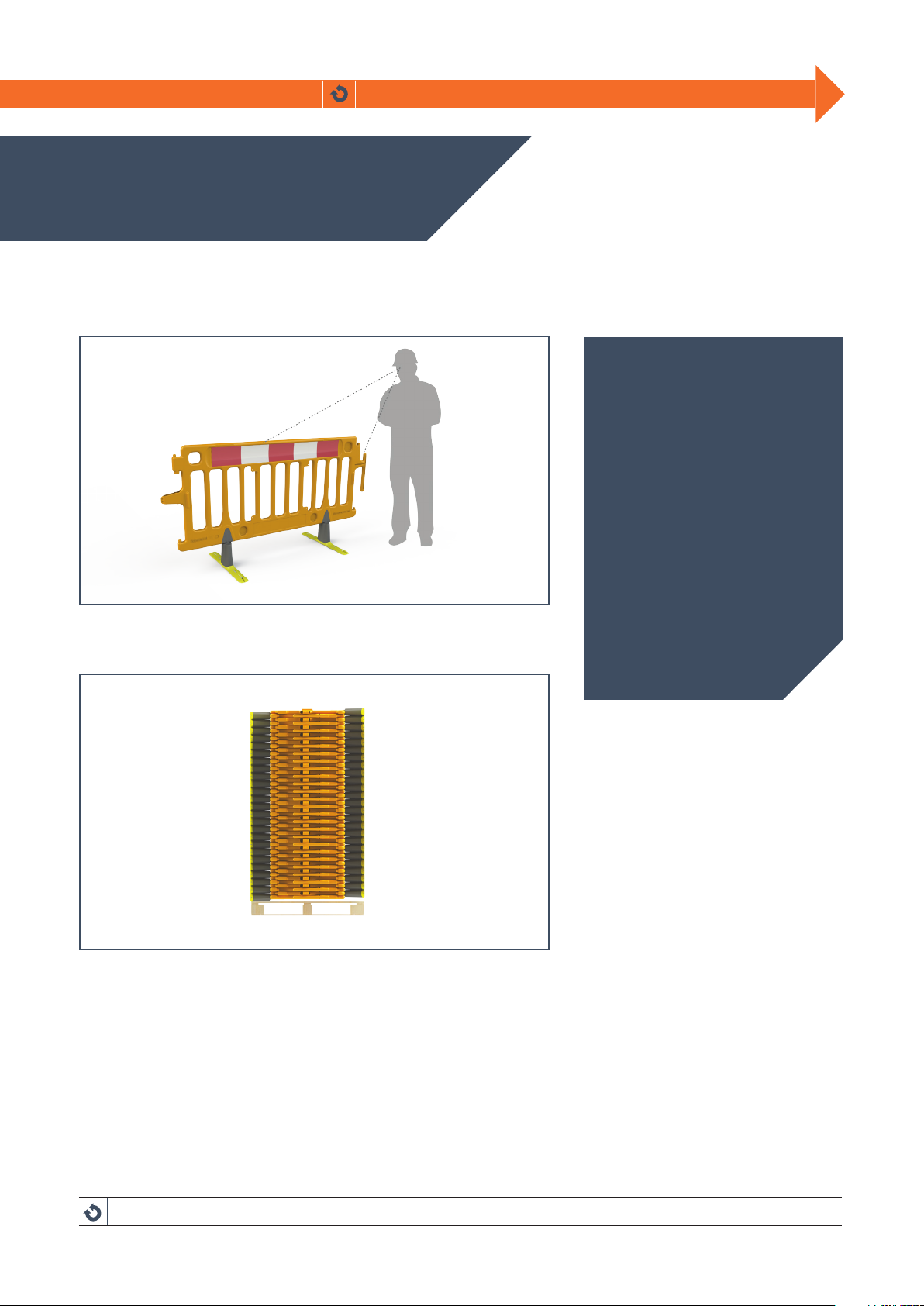

AVALON BARRIER |TECHNICAL SPECIFICATION

OXFORDPLASTICS.COM |VERSION 1 NO1 10

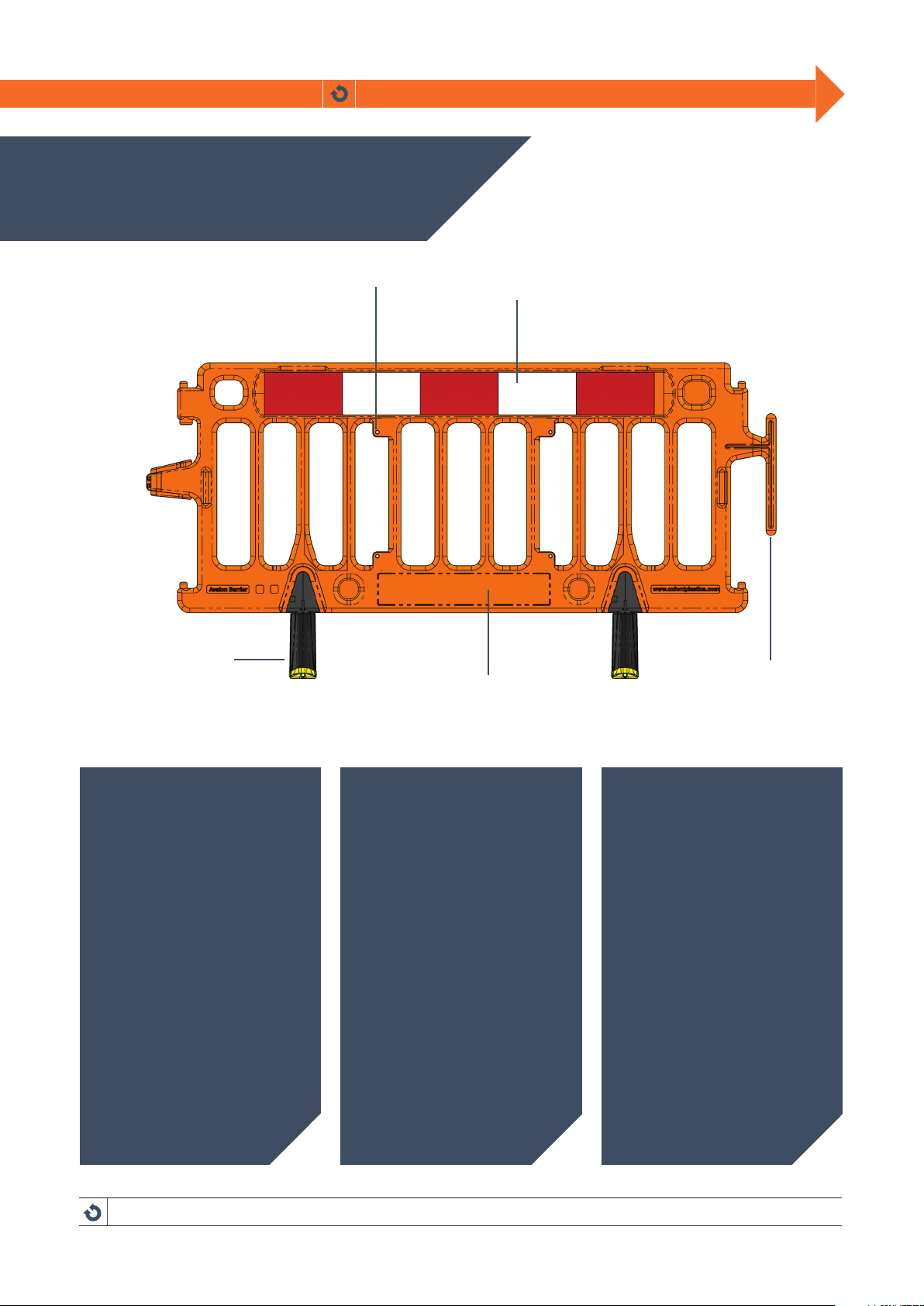

REPAIRING THE

REFLECTIVE

7 98

3

Place the barrier on a flat stable surface.

5

Clean the recessed reflective surface

area with a new cleaning sponge soaked

with the Alcohol and allow to air-dry for

15 seconds.

Use the applicator and, applying a firm

pressure, work one end to the other in a

zig-zag motion pushing down the sticker

and removing the air from underneath.

2

The applicator should be a handheld size,

approx. 12x8cm. Fabricate from a piece

of hard plastic or card, wrap this in felt,

wrap this in a tough fabric and secure

together with duct tape.

4

Use the scraper to lift the edges and peel

off the damaged reflective.

6

Use a new sponge coated in Standard

Primer and, starting at the bottom, ensure

that the primer has covered and wetted the

whole area. Leave to air dry for 5 minutes.

There should be no cuts or tears in the

reflective. Air bubbles should not exceed

5x15mm or 10x10mm. Air bubbles should

be no closer than 20mm to the edge.

Remove the backing paper from the

reflective strip and place it on the barrier,

ensuring that it is in the centre of the recess.

1

You will need a wallpaper

scraper, sponges, a self-made

applicator, a plunger can filled with PA

Isopropyl Alcohol, a plunger can filled with

standard CP906-P1 Primer and PPE.

A guide to reapplying reflective strips on

Chapter 8 barriers.