Nelson

Irrigation

Corporation

848

Airport

Rd.

Walla

Walla,

WA

99362-2271

USA

Tel:

509.525.7660

Fax:

509.525.7907

[email protected] Web

site:

www.nelsonirrigation.com

2/18

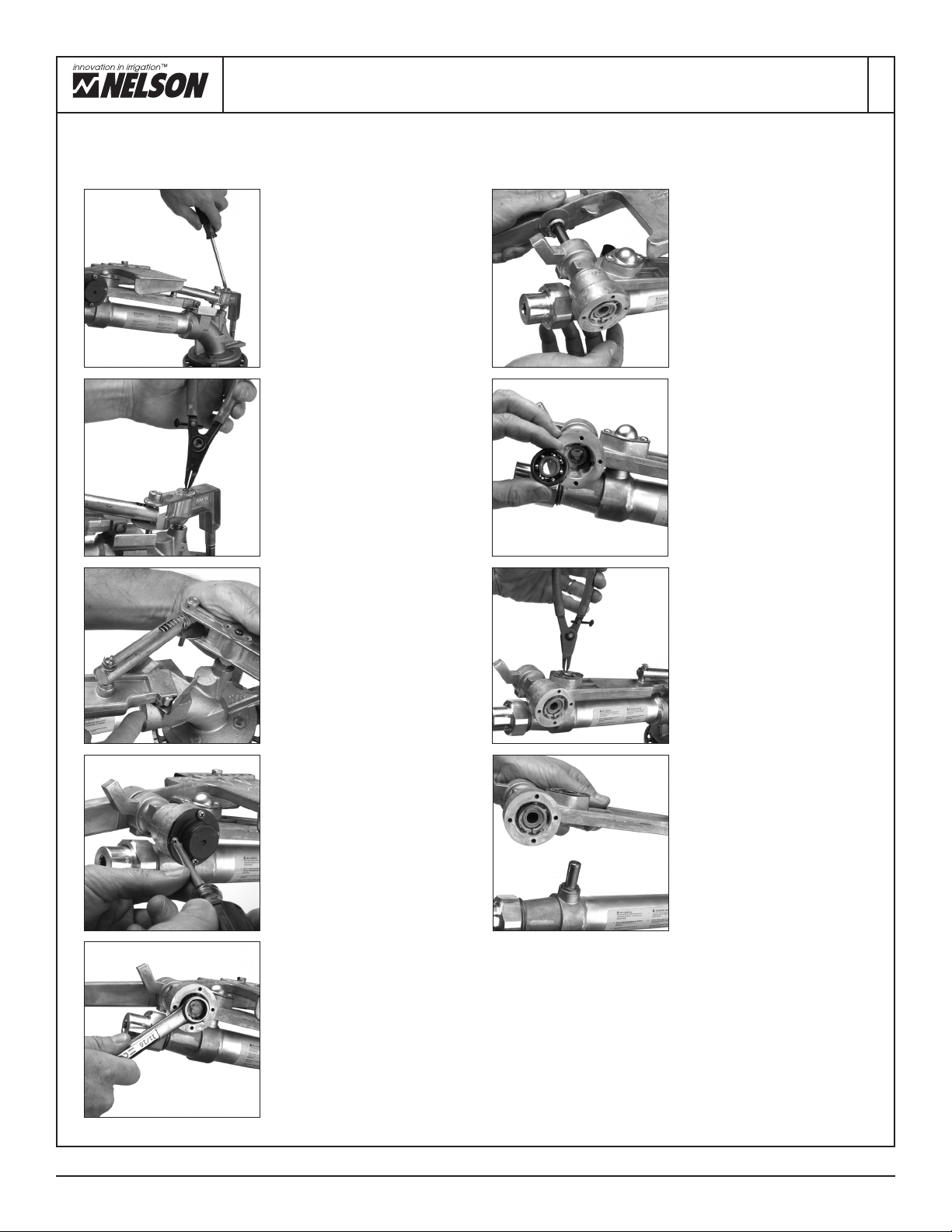

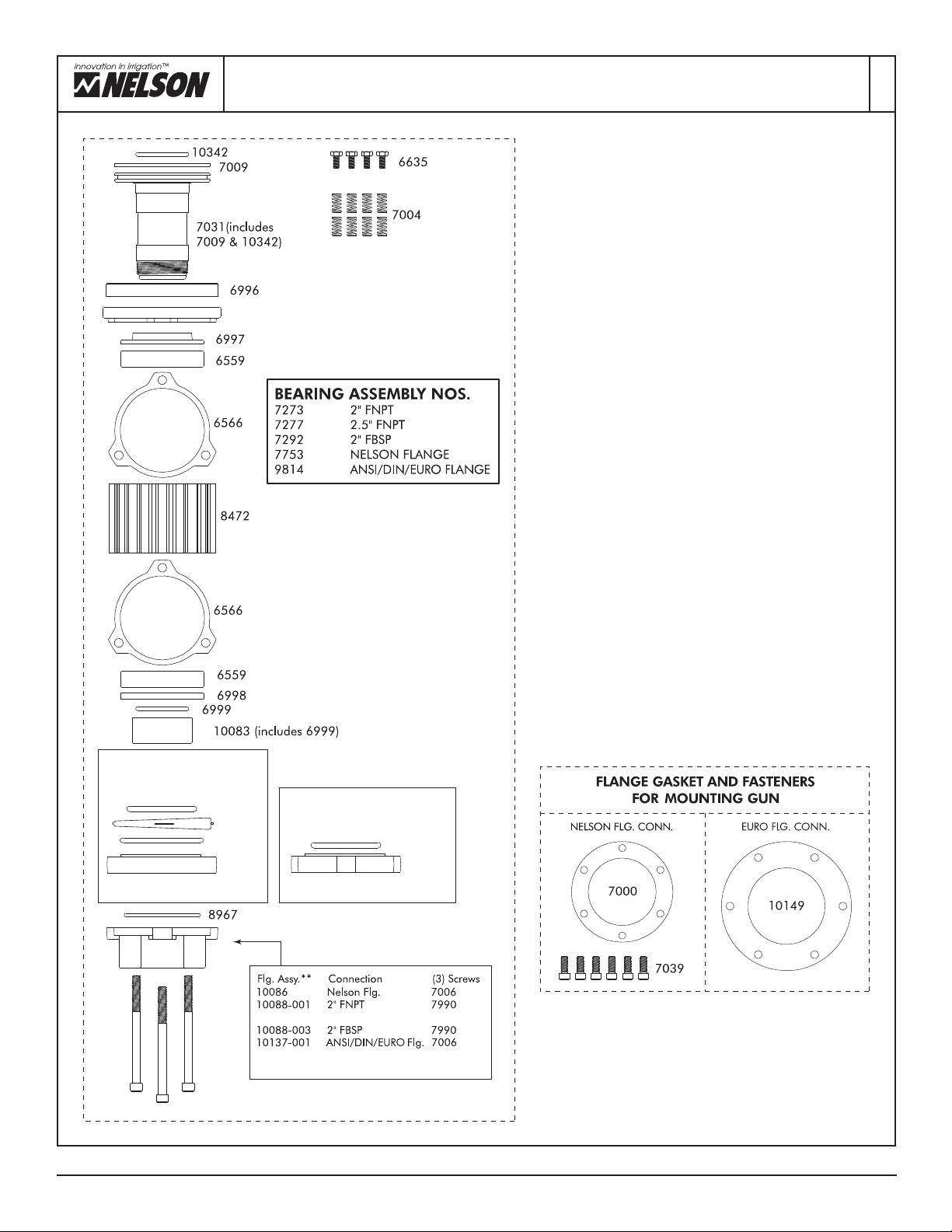

SR100 MAINTENANCE

SEE SR100 PARTS LISTS FOR COMPLETE PARTS LIST AND DESCRIPTION

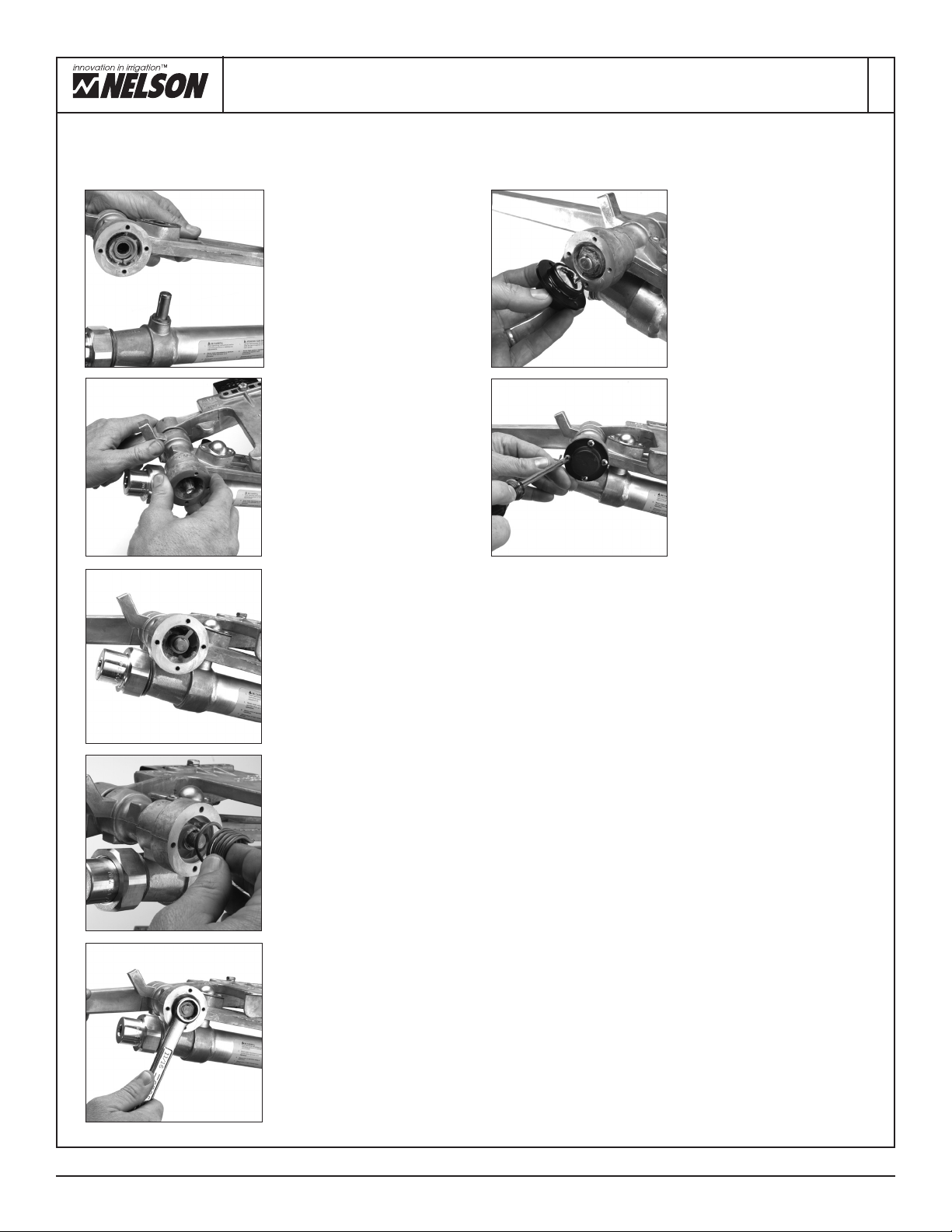

DISASSEMBLY REASSEMBLY

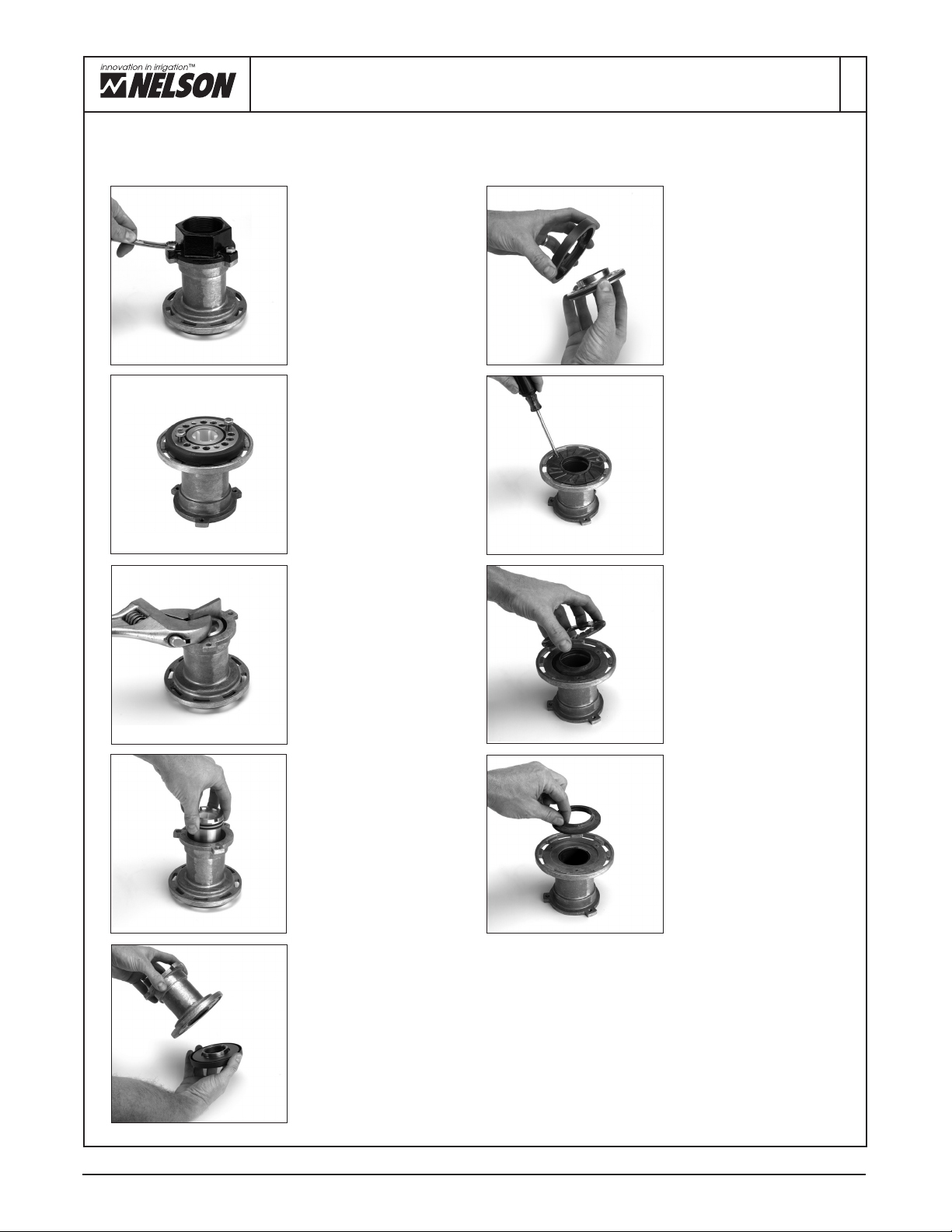

STEP 4 (Counterweight)

Inspect seal spacer and counter-weight

spacer for wear. If spacers show

excessive wear, replace both spacers

and #6600 Seals. To remove seals,

drive thin-bladed screwdriver under

lip of seal and pry seal out. To replace

seals, use block of wood over seal

making sure lip is to the outside, and

secure by lightly tapping on wooden

block until seal lip is flush with hub.

Apply a light coating of #9673 Silicone

Grease to #6600 Seal Lips.

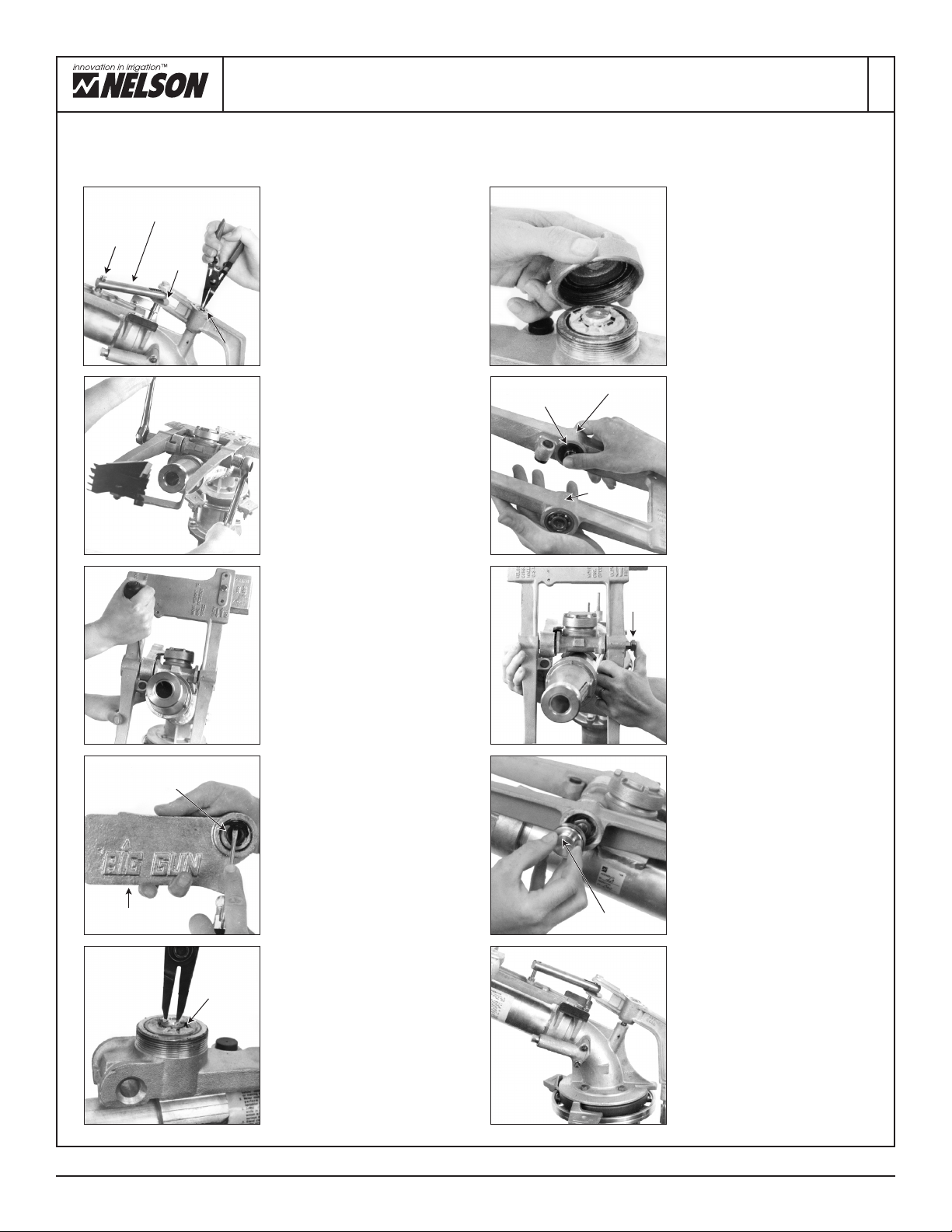

STEP 5 (Shift Lever)

Remove #10070-001 Cap Assem-

bly. Using external retaining ring

pliers, remove #8323-017 Retain-

ing Ring. Pull Shift lever from

mount. A gear puller will help in

removing the lever. Inspect all parts

for wear and replace as required.

STEP 9

Fill two #10067-001 Arm Cap

Assemblies with #6143 Grease

and snap into place. Install two

#6565 Retaining Rings. Arm

must have free movement at this

point. If arm feels sticky, assure

that lip seals at counterweight and

right arm hub are not rubbing on

each other.

STEP 10 (Trip Lever)

Mount trip lever assembly along

with spring guide onto their

respective pins. Install #8323-004

Retaining Ring. Install #8263 Cap

using two #8311 Screws. Install

#8409 Washer and #6714 Cotter

Pin onto spring guide.

STEP 3

Using a thin-bladed screwdriver,

push #8327-001 Spacer back

into arm hub. Holding onto counter-

weight, remove drive arm and

counterweight. Be careful not to

damage seals.

STEP 8

Holding counterweight in place on the

left side of shift lever, roll drive arm

into position shown by pushing on the

left arm bearing. Work #8327-001

Spacer into seal on counterweight.

Be sure spacer is correctly positioned

in counterweight to prevent cutting of

the seal lip. Push shaft through the

bearings and spacers and assemble

#6603 Nut. Torque to 25 ft. lbs. using

two 11/16” sockets. (Metric Torque =

34 NM or 3.5 MKG.)

STEP 2 (Drive Arm)

Using internal retaining ring pliers,

remove #6565 Retaining Ring

from both arm hubs. Remove two

#10067-001 Arm Caps. Using two

11/16” sockets, loosen and remove

one #6603 Nut from left side of

arm. Holding the opposite #6603

Nut, pull shaft free from hub.

STEP 7 (Drive Arm)

Lubricate #6600 Seal lips with

#9673 Silicone Grease. Install

#8327-001 Spacer flush with

#6600 Seal in left arm hub.

Insert two #6607-001 conical

Spacers into seals on inside of

counterweight and right drive arm

hub. Start #8297 Shaft into right

arm hub.

STEP 1 (Trip Lever)

Remove #6714 Cotter Pin from

#8197 Pin. Remove two #8311

Screws and #8263 Cap. Using

small retaining ring pliers, remove

#8323-004 Retaining Ring. Pull

entire trip lever assembly and

spring guide from gun. At this time

inspect wear on #8282 Follower.

Replace if worn.

STEP 6

At the upper portion of the gun,

inspect the mount shaft for wear.

Press the #8325 Shift Lever

assembly onto the mount. With

external retaining ring pliers, snap

the #8323-017 Retaining Ring

on. Screw on #10070-001 Cap

Assembly.

Spring

Guide

#8197

#8282

#8323-004

#6600

Counterweight

#8323-017

Mount Shaft

#10070-001

#8325

Left Hub

Right Hub

#8327-001

#8297

#10067-001