1

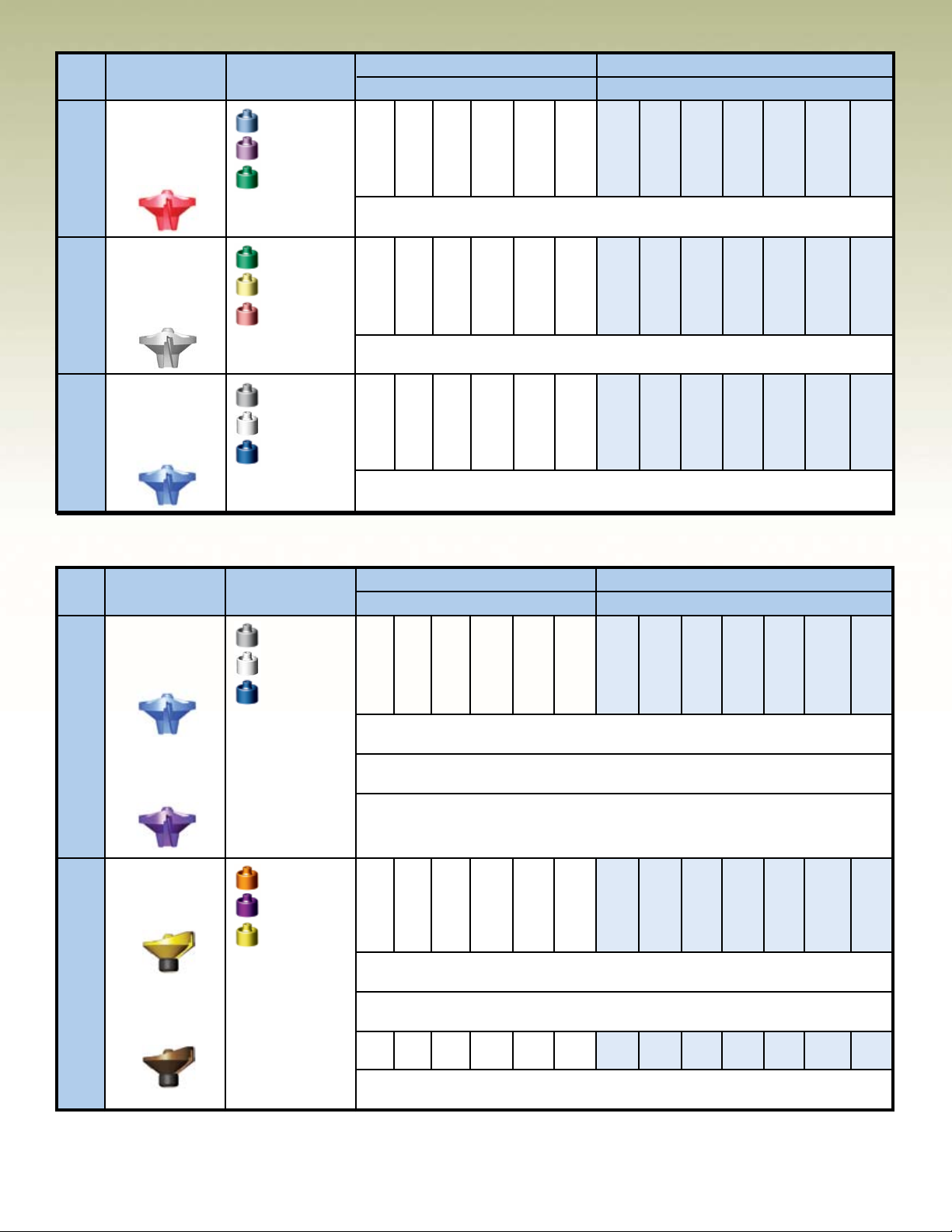

Uniformity is calculated for specific areas defined as Field, Strips, and Trees. Field includes everything,

Strips are bands (for this example 6' (1.8 m) wide) that encompass the trees, and trees are circles

(6' (1.8 m) in diameter for this example) that represent theoretical root zones.

Product: R10, P2 9° Red Plate, #50 2TN Nozzle

Spacing: 28 x 16' (8.5 x 4.9 m) triangular, Trees 7 x 16' (2.1 x 4.9 m)

% Overlap: 91% Precipitation Rate: .10 in./hour (2.5 mm/hour)

Pressure: 40 PSI (2.8 BAR) Test#: 3012-NA

CU DU SC

Field

1

88% 81% 1.3

Strips

1

88% 84% 1.2

Trees

1

88% 85% 1.2

Overlap Color Contour Output (details of this typical example)

Tree w/ Root ZonesSprinklerPrecipitation in/hour (mm/hour)

.04-.08

(1-2)

.08-.12

(2-3)

.12-.16

(3-4)

Crop Strips

WARRANTY AND DISCLAIMER

Nelson R10 & R10 Turbo Rotators,Feedtube Assemblies, and accessoriesare warranted for one year from the date of original sale to be free of defective material and workmanship when used within the working specifications

for which the products were designed and under normal use and service.The manufacturer assumes no responsibility for installation, removal or unauthorized repair of defective parts and the manufacturer will not be liable

for any crop or other consequential damages resulting from any defects or breach of warranty. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSES AND OF ALL OTHER OBLIGATIONS OR LIABILITIES OF MANUFACTURER. No agent, employee or representative of the manufacturer has authority to waive,

alter or add to the provisions of this warranty nor to make any representations or warranty not contained herein.

Rotator®is a registered trademark of Nelson Irrigation Corporation. Products in this brochure may be covered by one or more of the following U.S. Patent Numbers 4,796,811, 5,058,806, 5,297,737, 5,372,307, 5,823,580,

5,875,815, DES312,865, RE33,823 and other U.S. Patents pending or corresponding issued or pending foreign patents.

NELSON OVERLAP SOFTWARE

Nelson Overlap Computer Software Package

(#3001) determines the nozzle size, pressure, and

optimum sprinkler spacing for your irrigation system

to achieve the highest possible uniformity. Complete

performance information for the R10 and R10 Turbo

(including radius, stream height, and Overlap color

contours with CU, DU, SC and % overlap) is available from

your Nelson dealer or the Nelson factory.

NELSON IRRIGATION CORPORATION

848 Airport Road, Walla Walla, WA 99362-2271, U.S.A.

Tel: 509.525.7660 — Fax: 509.525.7907

NELSON IRRIGATION CORPORATION OF AUSTRALIA PTY LTD

35 Sudbury Street, Darra QLD 4074; P.O. Box 530, Sumner QLD 4074

Tel: +61 7 3715 8555 — Fax: +61 7 3715 8666

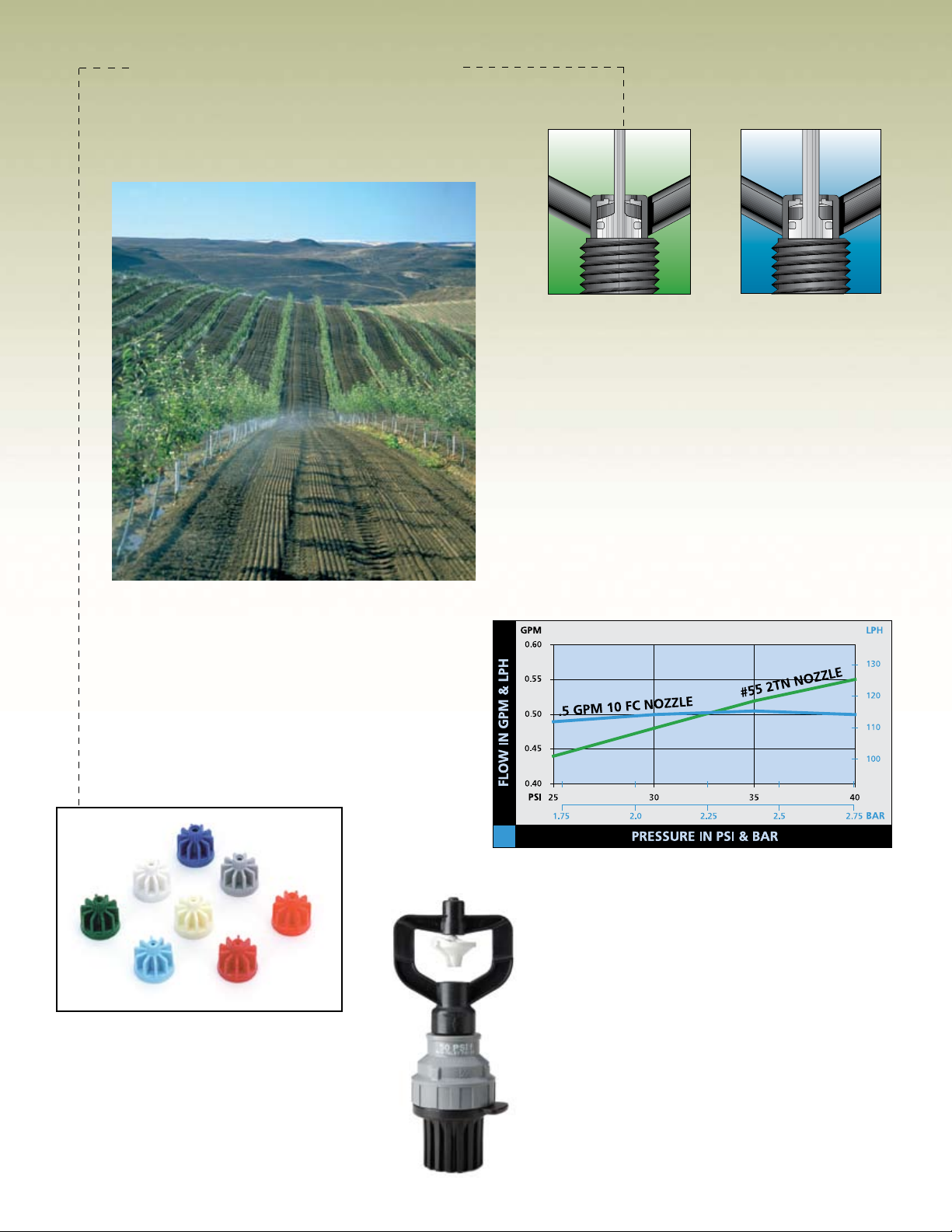

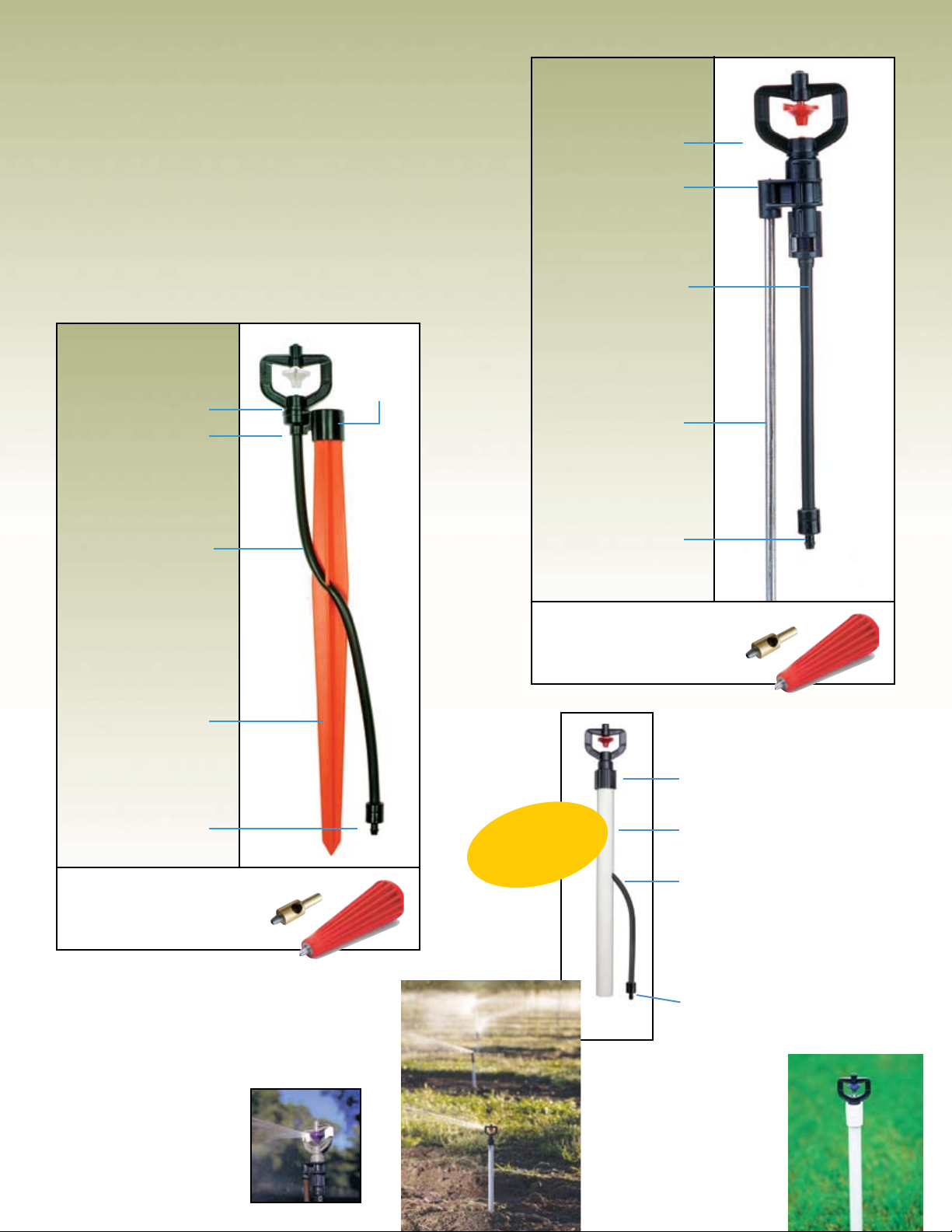

Mini Regulator (MR) — For systems in which pressure ranges are excessive, the Nelson Mini

Regulator provides uniform ow and distribution at each R10/R10T through pressure regulation.

Choose from 30, 35, 40, 45, or 50 PSI (2.0, 2.4, 2.8, 3.1 or 3.4 BAR) nominal pressures.

Mini Regulator Drain Check (MRDC) — To eliminate sprinkler drizzle during shut down and

start up and for pressure regulation use the Nelson Mini Regulator Drain Check. It is available

in the same nominal pressures as the Mini Regulator.

Mini Drain Check (MDC) — The MDC is a check valve only that opens 2-5 PSI (.14-.35

BAR) below the nominal pressure rating. Available in 20 and 35 PSI (1.4-2.4 BAR) options.

Ideal when a check feature only is needed or when it is necessary to operate the R10/R10T

at different pressures that best suit environmental conditions.

MRDCMR MDC

1/2” (1.25cm) FNPT or Female Acme Inlet for

direct connection to PVC or threaded adapters

Male Acme Outlet