Allanson AHVPS714-40-MV-PCB Installation instructions

1 Rev. 1 10/06/2020

AHVPS714-40-MV-PCB

14kV/40mA High Voltage Power Supply for Electrostatic Air Cleaner

Specifications and Operating Manual

1. Overview

The 14kVDC/40mA HV power supply is an OEM product and comes without AC

power ON/OFF controls and safety interlocks. It is system integrator

responsibility to assure that all national, state and local electrical safety codes

are followed.

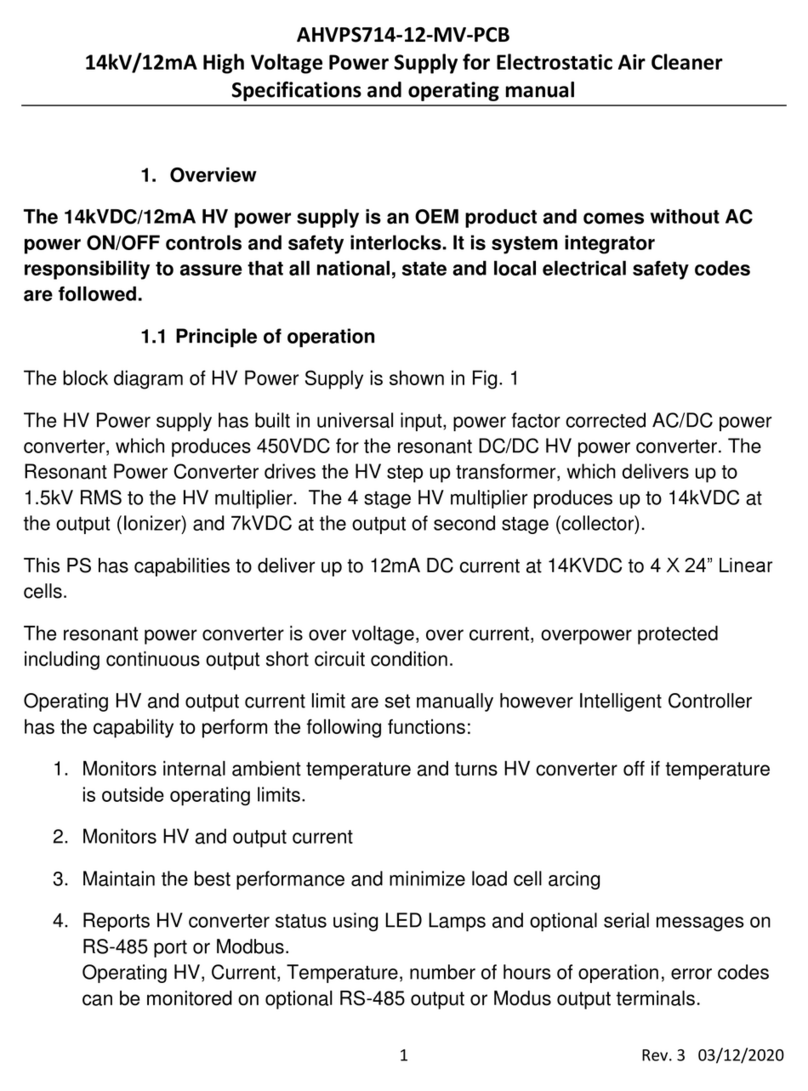

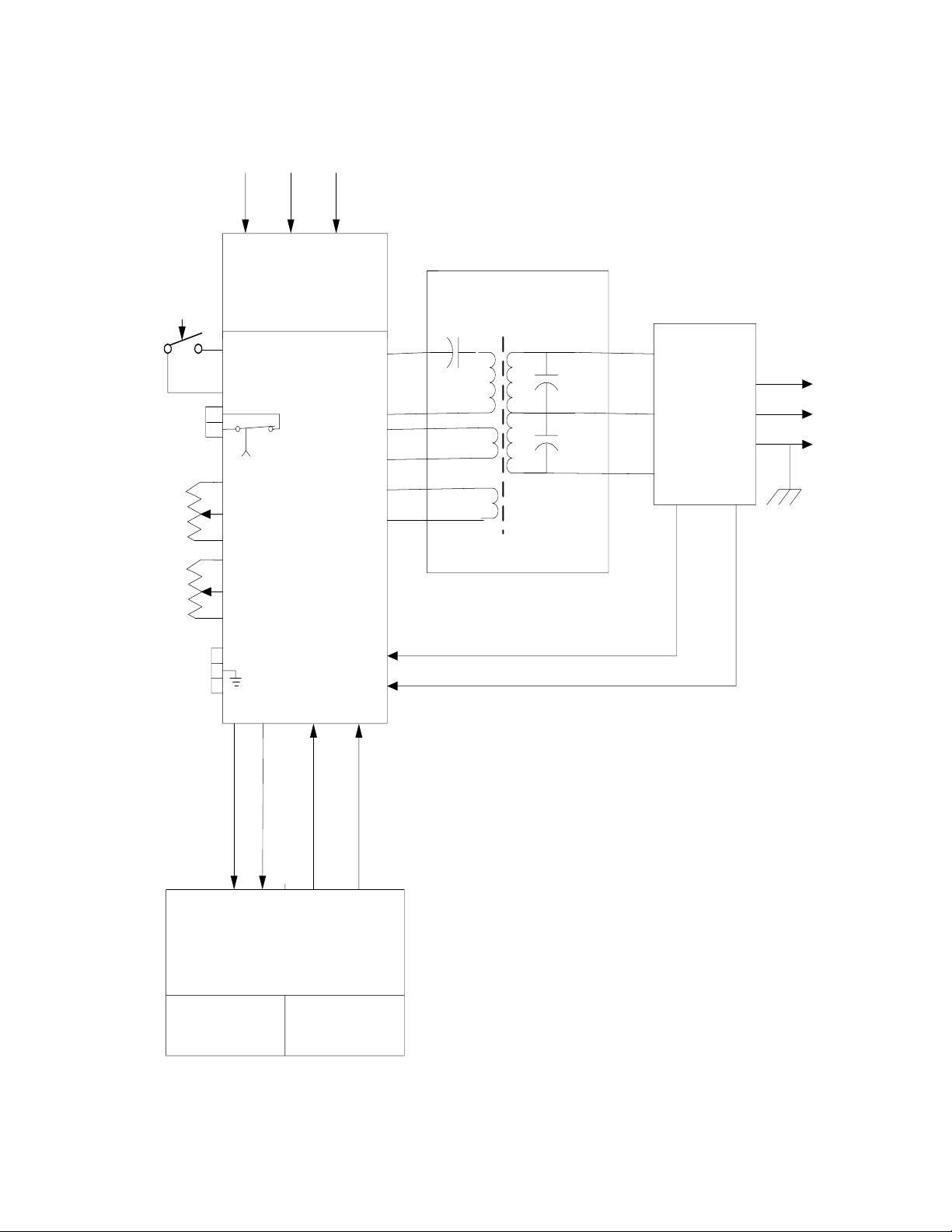

1.1 Principle of operation

The block diagram of HV Power Supply is shown in Fig. 1

The HV Power supply has built in universal input, power factor corrected AC/DC power

converter, which produces 450VDC for the resonant DC/DC HV power converter. The

Resonant Power Converter drives the HV step up transformer, which delivers up to

1.5kV RMS to the HV multiplier. The 4 stage HV multiplier produces up to 14kVDC at

the output (Ionizer) and 7kVDC at the output of second stage (collector).

This PS has capabilities to deliver up to 40mA DC current at 10KVDC or 33mA at

12KVDC (400W) to12 X 24” Linear cells.

The resonant power converter is over voltage, over current, overpower protected

including continuous output short circuit condition.

Operating HV and output current limit are set manually however Intelligent Controller

has the capability to perform the following functions:

1. Monitors internal ambient temperature and turns HV converter off if temperature

is outside operating limits.

2. Monitors HV and output current

3. Maintain the best performance and minimize load cell arcing

4. Reports HV converter status using LED Lamps and optional serial messages on

RS-485 port or Modbus.

Operating HV, Current, Temperature, number of hours of operation, error codes

can be monitored on optional RS-485 output or Modus output terminals.

2 Rev. 1 10/06/2020

Additional HV and current can be monitored on scaled down analog output.

I Monitor –100mV per 1mA

V monitor –100mV per 1KV

5. Keeps track of operating hours

6. Connect to Remote LED diagnostic PCB.

Status LED functionality and simplified flowchart are shown in Appendix A.

2.0 The HVPS has 3 distinct modes of operation:

Voltage Source Mode

Current Source Mode

Burn-in Mode

The HV and Current adjust potentiometers are located on the PCB.

The Burn-in mode is invoked by the pushbutton momentary switch located on PCB or 2 terminals for

remote.

2.1 Voltage source Mode

In Voltage Source Mode the HVPS maintains the preset voltage while current is determined by

the load. As long as current does not exceed the max limit of 40mA the HVPS will maintain the

preset HV.

Voltage mode example settings: The HV was set to 12kV and current limit was set to the

maximum value of 33mA. After connecting the clean load cell, the HVPS was operating at 12kV

with current floating around 33mA. With the same settings and dirty load cell connected, the

HVPS was still operating at 12kV, but the load current dropped to 30mA.

2.2 Current Source Mode

In Current Source Mode the HVPS maintains the preset current while voltage is determined by

the load. If output voltage does not exceed the max limit of 14kV the HVPS will maintain the

preset current.

3 Rev. 1 10/06/2020

Current Mode example settings. The current limit was set to 33mA and HV to 14kV. After

connecting the clean load cell, the HVPS was operating at 33mA current and HV floating around

12kV. With the same settings and dirty load cell connected, the HVPS

was operating with 33mA current, but HV increased to 12.5kV to maintain 33mA current.

2.3 Burns-In Mode.

In normal operation the HVPS is exposed to occasional overload conditions caused by arcing in

the load cells. The HVPS monitors the rate and duration of overload conditions and shut down if

overload condition persists.

New load cells may be contaminated with remnants of machining process and may cause

excessively high rate of arcing for first few hours of operation which may cause the HVPS to

shut down prematurely. To prevent this unnecessary shutdown the Burn In mode was introduced.

When Burn In mode is activated (by pressing the Burn In ON/OFF switch), the HVPS will not

shut down in response to persistent overload condition for 3 hours period.

In Burn-In mode the protection algorithm, which monitors rate and duration of overloads and

shuts down the HVPS if overload persists is suspended for 3 hours.

The Burn In mode can be terminated before 3-hour timer expires by pressing the Burn In

ON/OFF switch.

During Burn In cycle the display alternates between standard Voltage and Current readings

and Burn In cycle message.

4 Rev. 1 10/06/2020

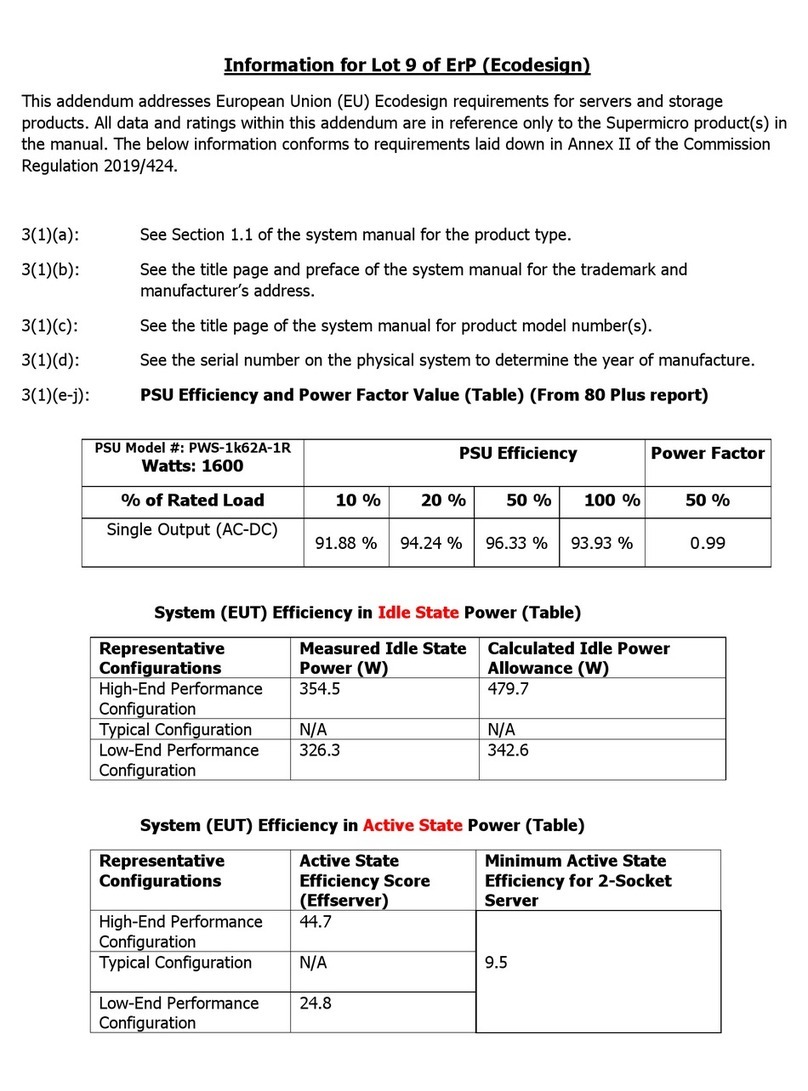

POWER FACTOR

CORRECTOR

RESONANT POWER

CONVERTER

HV MULTIPLIER

CURRENT FEEDBACK

VOLTAGE FEEDBACK

L

NGND

Universal Input

120 - 240 VAC

14kV

7kV

INTELLIGENT

CONTROLLER

VOLTAGE OR

CURRENT TRIM

VOLTAGE MONOTOR

CURRENT MONITOR

STATUS LEDs

POWER TRANSFORMER

MODULE

HIGH

VOLTAGE

ADJUST

HV

GOOD

RELAY

CURRENT

LIMIT

ADJUST

HV_OFF

ISOLATED

RS-485 or Modbus

I MONITOR

V MONITOR

Burn in

On/ off

Fig.1 HV Power Supply Block Diagram

5 Rev. 1 10/06/2020

3.0 Installation and safety

The HV Power Supply must be mounted indoors, protected from weather

Elements, in a location easily accessible by operating service personnel.

The HV Power Supply is equipped with universal input; power factor corrected (PFC)

AC/DC power supply and can operate from 120VAC or 240VAC power lines.

The maximum current draw is 4 Amp from 120 VAC line and 2.0 Amp from 240VAC

line. Use these numbers to select proper wire gage as per applicable standards.

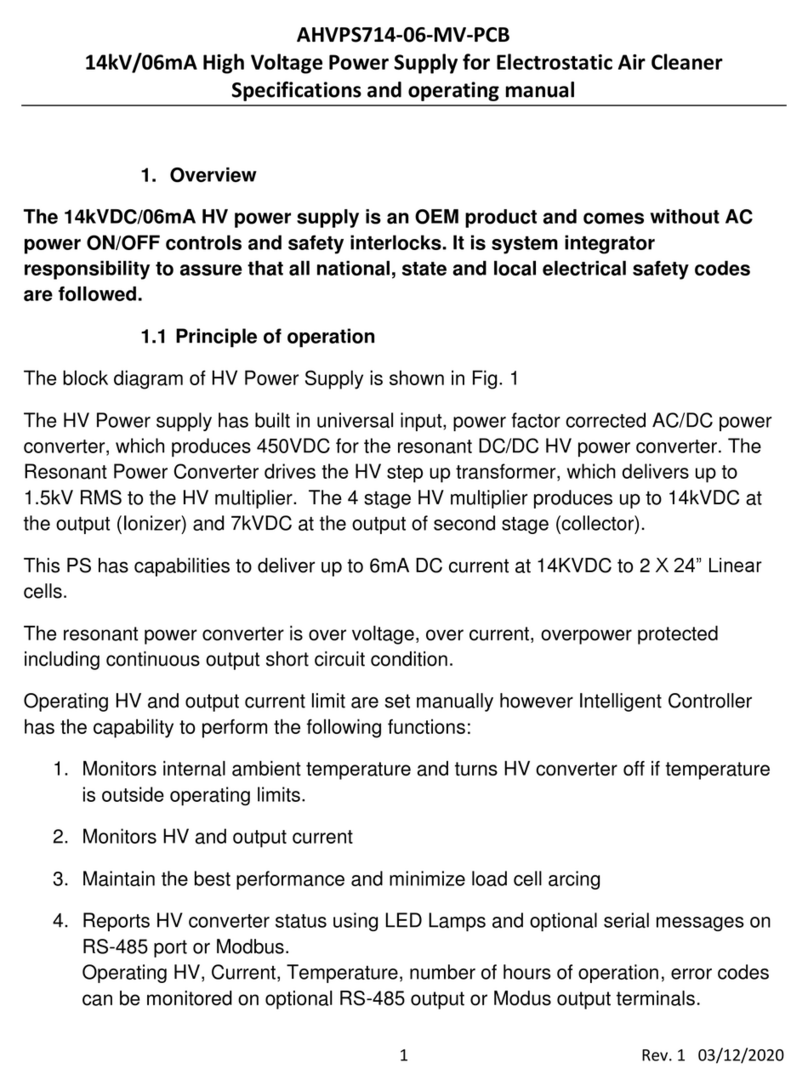

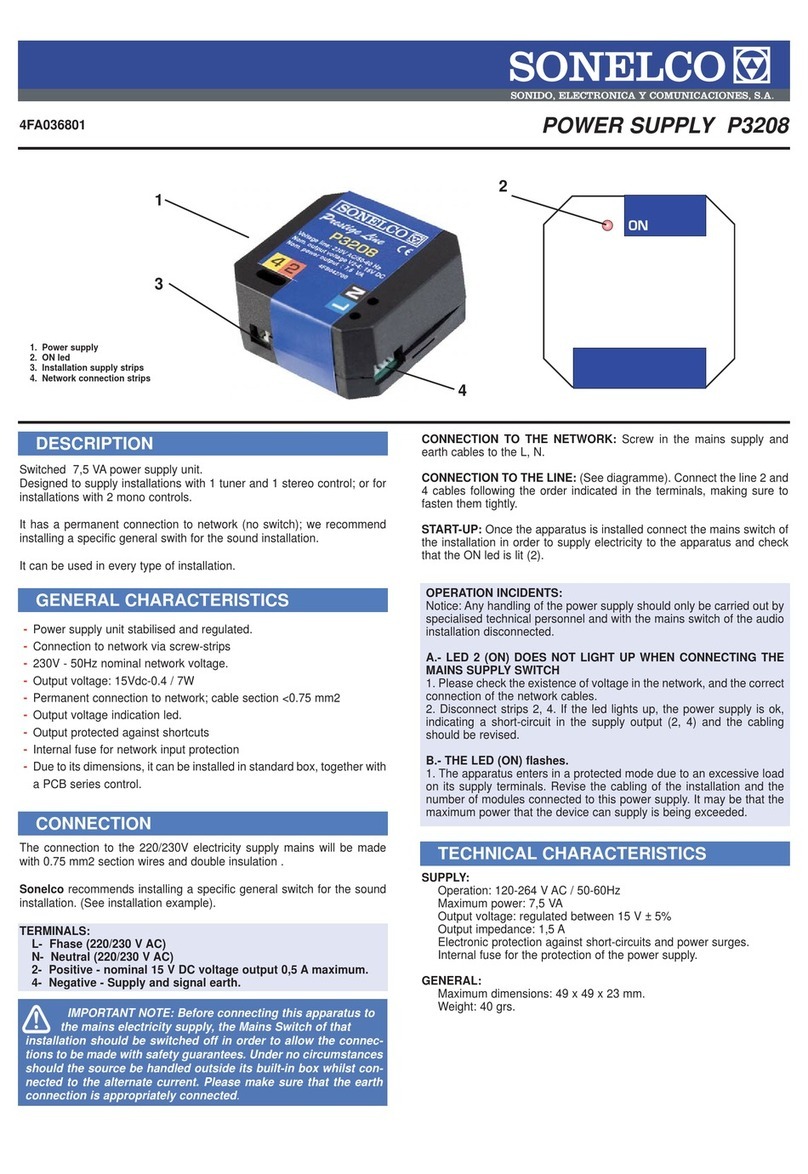

The connection diagram of HV Power Supply is shown in Fig.2 All connections are

made to terminals on the Main Board.

The HV Multiplier has two outputs:

Ionizing Voltage –Labeled as 14kVDC

Collector Voltage –Labeled as 7kVDC

The HV and current adjustment trim pots and status LEDs are located at the edge of

the Main Board as well as AC power input, HV Good Relay and RS-485 serial port.

4.0 Field wiring connections

These instructions are for qualified personnel only. To reduce the risk of electric

shock, do not perform any servicing other than contained in the instructions

unless you are qualified to do so. All wiring must be installed according to

national, state and local codes.

The HV Power Supply requires the following field connections:

1. AC line connection including safety GND (J10, highlighted in green)

2. HV Connection (7kV and 14kV terminal studs, highlighted in red)

3. HV Good Relay contacts (J1, highlighted in green)

4. RS-485 / Modbus communication port (J12, highlighted in green)

5. HV GND and AC GND (corner mounting screws to carrier plate)

6 Rev. 1 10/06/2020

5. Start - up

WARNING!!! HIGH VOLTAGE - RISK OF ELECTRIC SHOCK

Check load cells specifications and number of cells connected before adjusting

the HV and current limits. Instructions below are to operate the HV Power supply

in Voltage Source Mode. Consult factory if Current Source Mode is preferred.

1. Turn the HV Adjust trim pot to the minimum (fully CCW position) and Current

Limit trim pot to the maximum (Fully CW position)

2. Turn AC power on.

WARNING HV comes on as soon as AC power is applied.

Power On LED (Green) and HV On LED (Yellow) should turn On.

Fault LED (red) should stay Off. If Fault LED, comes on follow instruction in

Service/troubleshooting manual.

3. Adjust slowly HV by turning the trim pot clockwise until HV Good LED (Blue)

turns On and output current reaches required value.

Output current adjustment is based on the type and number of load cells connected to

the HV supply. Typical settings are 1mA per cubic foot of load cell.

To facilitate installation and initial adjustment The HV and load current can be monitored

on PC running any ASCII data terminal or Lab View application.

This concludes powering up/adjusting the HV power supply.

7 Rev. 1 10/06/2020

HV TRANSFORMER

HV MULTIPLIER

FAULT

HV

GOOD

POWER ON 7KV

14KV

2

3

1

AC

INPUT

HV GND

HV ADJUST

Min. Max.

Air cleaner 14 kV HV power supply

Connections, indicators and controls

PFC AC/DC

POWER

SUPPLY

RESONANT

POWER

CONVERTER

LINE

NEUTRAL

1

2

3

RS-485

PORT

GND

A B

CURRENT

LIMIT

ADJUST

Min. Max.

2

1

HV

GOOD

RELAY

GND

HV ON

HV

GND

CONNECTION

J 10

INTELLIGENT

CONTROLLER

J 12

J 1

I MONITOR

V MONITOR

Burn in

On/ off Burn in

On/ off

Fig.2 Connections, Indicators and Controls

8 Rev. 1 10/06/2020

6. Specifications

1. Power Input:

a. Voltage: Universal voltage input 120 –240VAC

b. Current: 4A @ 120VAC, 2 Amp at 240VAC

c. Frequency: 50/60HZ

d. Power: < 500W

e. Power Factor : > 0.90

f. Operating efficiency: 82% typical

2. HV Output:

a. Voltage: IONIZER adjustable 7.0 to 14.0 kV DC

COLLECTOR adjustable 3.5 to 7.0kV DC

b. Current: 40mA max at 10kV or 33mA at max 12KVDC

Current limit adjustable 1mA to 40mA

3. Temperature:

Operating: 0 to 50 deg C

Storage: -40 to +80 deg C

4. Overload/Fault protection

a. Automatic shut down when load current exceeds 33mA load at 12KVDC.

Automatic and soft restart when overload condition is removed.

b. Fast control loop (Fast Clamp) keeps the output below 15kV when HV load is

disconnected and when main regulation loop fails.

c. Voltage and Current Faults

d. The recovery from fault condition caused by voltage or current outside the operating

window is monitored and timed by two fault counters - Fault Counter 1 and Fault

Counter 2. Refer to protection flow chart.

e. When voltage or current fault happens, unit restarts automatically after 2 sec delay

and displays error message. The internal Fault Counter 1 is incremented. After 10

9 Rev. 1 10/06/2020

restarts, HV shuts down for 1 min, Fault Counter # 2 is incremented, and Fault

Counter # 1 is cleared.

This process may repeat 3 times (until Fault Counter 2 content exceeds 3) and then

the HV is turned off permanently.

So, the unit allows 5 x 10 = 30 faults with 2 sec recovery time after each fault

and additional 1 min recovery after every 10 faults.

With persisting voltage and/or current type faults it will take ~ 4min before unit shuts

down permanently.

To restart the unit from the permanent shutdown condition input AC power must be

recycled.

Temperature Fault

Recovery process from over temperature condition is not using Fault Timers. When

internal temperature exceeds +60C unit turns HV Off waits until temperature drops below

+60C and restarts. Unit will not start if internal temperature is above +60C

7.0 Intelligent Controller

Microcontroller based, comprising status LED and optional communication port

- Monitors output current, HV and temperature.

- Monitors internal ambient temperature and shuts down the HV when

temperature is outside operating limits

- Counts hours of operation

- Optional Isolated RS-485 or Modbus port outputs Voltage, Current,

Temperature, Hours of operation, Faults alerts.

- Custom protocol using Lab View Application or standard ASCII characters

output to be used with Hyper Terminal or similar serial terminal software.

The simplified flowchart, Status LEDs functionality and serial protocol details are

shown in the Appendix A.

Safety features

- HV ON warning LED

- Dry contacts to signal HV GOOD (contacts closed when HV within operating window)

10 Rev. 1 10/06/2020

8.0 Connectivity

a. Inputs:

120V to 240VAC, Live and Neutral on terminal strip, Earth Ground, #6 Lug on

chassis

b. OUTPUTS:

- Ionizer Voltage, Collector Voltage - # 10 Lugs on # 10 studs.

- High Voltage Return - #6 Lug on chassis

- 250VAC/10Amp dry contacts to indicate HV GOOD condition

- Isolated RS-485 or Modbus port

c. INDICATORS: On Controller PCB and remote PCB

LED Blue Indicator: HV Good (for remote LED terminal)

LED Green Indicator: Input Power On

LED Yellow Indicator: HV ON

LED RED Indicator: FAULTS

The complete functionality of LED indicators and Relay output logic is shown in Appendix A,

Table 1

9.0 Mechanical Specifications

All PCB electrical & components must be mounted in custom metal enclosure with fan

on one side and ventilation levers on other side to create air circulations inside the box.

The PS PCB must be mounted in the enclosure with min of 2” distance from metal surface on all

sides.

Proposed enclosure dimensions 12” W x 15” L x 6” H

Proposed PCB’s will be mounted on Aluminum plate dimensions

11.30” W x 13” L x 0.125” thickness

11 Rev. 1 10/06/2020

10.0 Agency Approvals

rUL, or ETL, optional

11.0 Manufacturer’s Marking:

P/N, Date code, serial #

Appendix A

#

System

Status

BLUE LED -

HV Good,

GREEN LED

- AC Supply

is ON

RED LED

FAULT

YELLOW

LED HV

ON

Relay - Dry

Contact NO

1

System

Good

ON

ON

OFF

ON

ON - dry

contact closed

2

Temp fault

OFF

ON

ON

OFF

OFF - dry

contact open

3

Overload

fault

OFF

ON

2 Flashes &

pause

ON

OFF - dry

contact open

4

Over

voltage

fault

OFF

ON

3 Flashes &

pause

OFF

OFF - dry

contact open

5

System

shutdown

for

10min due

to

OFF

ON

Flashes

continuously

OFF

OFF - dry

contact open

Continues

arcing

below

10KV.

Table1. LED Indicators and Relay output logic

12 Rev. 1 10/06/2020

RS-485 Serial port protocol or Modbus protocol

RS-485 / Modbus is available on J12 terminal block

J12-1 RS-485 NON_INV (A)

J12-2 GND

J12-3 RS-485 INV (B)

Data Format.

Voltage [kVx10] Current [mAx10] Temp [C] Hrs. of operation Fault

142 66 32 300 0

Fault codes:

0No Fault

1Over voltage

2Over current

3Overload (arcing)

4Temperature too high

5HV ON/OFF fault

Table of contents

Other Allanson Power Supply manuals