Neptune Technology EMP User manual

How to Set Up a SCADAmetrics®Signalizer with the

Neptune®C&I MACH 10®

The following document provides information related to the configuration and use of the

SCADAmetrics Signalizer™ industrial output module (IOM) with Neptune’s C&I MACH 10 ultrasonic

water meter. For further troubleshooting or additional information specific to The Signalizer™

product, contact SCADAmetrics at 636.405.7101, via email at jim@scadametrics.com, or online at

www.scadametrics.com.

The Signalizer IOM Product Overview

The Signalizer from SCADAmetrics is an industrial output module that serves as an interface

between water meters and building management systems for the purpose of control and

automation. It simultaneously provides a 4-20mA rate-of-flow signal and digital pulse signals based

on intercepted encoder signals from the meter.

Module Dimensions (inches): 5 x 4.5 x 1.275

Figure 1

2

Quick Start Guide

Initial Set-Up

1. Attach the water meter’s three (3) encoder wires to Signalizer terminals 1,2,3.

2. AMR/AMI (if applicable) - Attach the endpoint’s three (3) encoder wires to Signalizer terminals 4,5,6.

3. 4-20mA (if applicable) - Connect the output signal to PLC/Controller: Terminals 7(+) and 8(-).

a. Important: The Signalizer™ provides loop power. The user must not add an additional loop

excitation power supply, or else damage to the unit will result.

4. Pulse Output (if applicable) Connect the signal to the PLC/Controller: Terminals 9 and 10.

a. Important: The pulse output is a solid state, dry-contact type. 500mA max, 60V max. Circuit

must be current limited by external means.

5. Alarm (if applicable) Connect the output signal to the PLC/Controller:

a. If Signalizer should lose communication with the meter (i.e. cut cable, Signalizer powered off),

the alarm contact will close.

b. Important: The alarm output is a solid state, dry-contact type. 500mA max, 60V max. Circuit

must be current limited by external means.

6. Set the DIP Switches per the C&I MACH 10 Recommended DIP Switch Settings on page 5.

7. Connect DC voltage source to the Signalizer’s ultra-wide power supply input (V+/V- terminal block).

A 24VDC power supply with galvanic isolation is recommended.

Figure 2

3

Installation & Connectivity

Install Location

Install the unit near a power source capable of providing 9-36VDC. When installing the module,

please ensure that the total encoder cable length from the MACH 10 meter to the Signalizer, plus the

length from the Signalizer to the endpoint does not exceed 500ft. If the total cable length is to be

greater than 20ft or if the Signalizer is to be installed in proximity of motors or Variable Frequency

Drives (VFD), then shielded/single point grounded extension cable is recommended. If an endpoint is

connected to the Signalizer, it is recommended to use as short a length of wire as possible, 6 feet to

10 feet being preferred.

The Signalizer is not a water-proof design, therefore it will need to be installed in a dry location. If a

water-proof installation is required, The Signalizer can be installed within a NEMA-6P, IP-68

enclosure (available separately from SCADAmetrics).

Powering the Device

Connect DC voltage source to the Signalizer’s ultra-wide power supply input (V+/V- terminal block;

see Figure 2). A 24VDC power supply with galvanic isolation is recommended, but not required. An

external AC/DC converter (Model MDR-20-24) is available separately from SCADAmetrics. It operates

at 120vAC/24vDC, 20 W.

The Signalizer requires 9-36Vdc/1.5W external power. However, the module’s 4-20mA output signal

does not require an additional loop excitation DC power supply. The pass-thru function to AMR/AMI

does not require DC power and will remain operational in the event DC power is lost or removed

from the module.

Meter Terminal Block Hookup

The following table provides the appropriate Neptune meter connections to the output module.

Terminal

Function

Neptune Color

1

Meter Clock

Black

2

Meter Data

Red

3

Meter Ground

Green

Table 1

1-3

4-6

7-8

9-10

11-12

Figure 3

4

AMR/AMI Terminal Block Hookup

The following table provides for compatible endpoint connections to the output module.

Terminal

Function

Neptune

Endpoint

w/Std

Cable

Neptune

(or other)

Endpoint

w/Nicor

Cable

Neptune

(or other)

MIU w/Itron

Cable

Sensus, Badger,

Mueller, Zenner,

Master-Meter,

Metron-Farnier, RG3,

Kamstrup Endpoints

Elster AMCO

Endpoint

4

Utility AMI Clock

Black

Red

Black

Red

White|Green

5

Utility AMI Data

Red

Green|White

Red

Green|White

Red

6

Utility AMI

Ground

Green Black White|Shield Black Black

Table 2

*Alternative color coding: Manufacturers occasionally substitute a WHITE wire for a GREEN wire.

IMPORTANT: Utility AMI/AMR Terminal Block Hookup (Terminals 4-5-6): Apply color-coding that

pertains to the manufacturer of the AMI/AMR endpoint (or manufacturer of the specialty cable, such

as Nicor or Itron).

Signal Terminal Block Hookup

The following table provides connections for respective signal options to destination system.

Terminal

Function

Notes

7*

4-20mA +

Settable Range via DIP

Switches

8*

4-20mA -

9

Pulse +

Solid State Dry Contact (N-O)

500mA Max, 60v Max

10

Pulse -

11

Alarm +

Solid State Dry Contact (N-O)

500mA Max, 60v Max

12

Alarm -

Table 3

*Important: The Signalizer output module provides loop power, therefore, there is no need to add an

additional loop excitation power supply.

LED Indicator

After powering the module, the following LED indications may be observed:

•The Upper Yellow ‘Heartbeat’ LED should light up YELLOW with an

OCCASIONAL BLINK, signifying that the Signalizer is working.

•The Upper Green ‘Meter OK’ LED should light up SOLID GREEN, signifying

that the meter has been successfully detected; if the meter is not detected,

then the ‘Meter OK’ LED will emit a fast (10Hz) blink.

•The Lower Yellow LED will follow the Pulse Output (LED ON = Contact

Closure).

•The Lower Green LED will light up SOLID GREEN during periods when

Positive Flow is Detected.

Upper

LEDs

Lower

LEDs

Figure 4

5

Neptune C&I MACH 10 Recommended Settings

Neptune registers do not require any special pre-programmed

factory settings. The following DIP Switch Settings (Table 4)

should be configured for use with the C&I MACH 10 meter (sizes

3-12”). Note: DIP Switches 9-16 are labeled 1-8 on The Signalizer as

well, but positioned as the last 8 switches moving left-to-right.

C&I MACH 10 Recommended DIP Switch Settings

Setting DIP

3" 4" 6" 8" 10" 12"

1

ON ON ON ON ON ON

2

OFF OFF OFF OFF OFF OFF

3

4

5

ON ON ON ON ON ON

6

OFF OFF OFF OFF OFF OFF

7

ON ON ON ON ON ON

Pulse Speed 8

9

OFF OFF ON ON ON ON

10

OFF OFF OFF OFF OFF OFF

11

OFF OFF OFF OFF OFF OFF

12

OFF OFF OFF OFF OFF OFF

13

ON ON OFF OFF OFF OFF

14

ON OFF ON ON OFF ON

15

ON OFF OFF OFF ON OFF

16

OFF ON ON ON ON OFF

OFF = Normal (8th digit), ON = Low (7th digit)

Encoder

Resolution

(US Gallons)

20mA Flow

Rate

C&I MACH 10

Encoder

Protocol

Registration

Units

OFF = Gallons, OFF = Cubic m; ON = Cubic ft, ON = Acre ft

OFF = Gallons, OFF = Cubic ft; ON = Cubic m, ON = Acre ft

Encoder

Sample Period

Table 4

Encoder Protocol

Set DIP Switch (1) to ONand (2) to OFF tooperate with Neptune protocol.

Registration Units

The Signalizer can be set toGallons, Cubic Meters, Cubic Feet, and Acre Feet. See Table 4 above and

set according topreference.

Encoder Sample Period

The recommended sampling period for TheSignalizer and C&I MACH 10is 300 seconds. The

Signalizer’s sampling period can be adjusted via DIP Switch (5-7), however it is important to

familiarize yourself with how the sample period will affect the battery life expectancy ofthe C&I

MACH 10(see Sampling Period vs. Battery Life Expectancy section for moredetail).

IMPORTANT: Using a sample period less than 300s will reduce the C&I MACH 10’s expected 10-year

battery lifeand impact the battery warranty.

1-8

9-16

Figure 5

6

Pulse Speed

The Signalizer’s pulse speed can be set to accommodate preferred SCADA or BMS system settings.

Set DIP switch (8) to OFF for Normal Speed (8th digit) and ON for Low Speed (7th digit). Each time the

respective register digit changes, a pulse is generated.

Encoder Resolution

The Signalizer can be set to accommodate the appropriate encoder resolution for the respective C&I

MACH 10 meter size. The following settings are recommended for an 8-digit resolution on a

C&I MACH 10:

U.S Gallons

•For sizes 3” and 4”, set DIP Switches (9-12) all to OFF for a register resolution of (x1).

•For sizes 6” to 12”, set DIP Switch (9) to ON and (10-12) to OFF for a register resolution of (x10).

Cubic Feet

•For sizes 3” and 4”, set DIP Switches (11) to ON and (9-10, 12) to OFF for a register resolution of

(x0.1) in Cubic Feet.

•For sizes 6” to 12”, set DIP Switches (9-12) all to OFF for a register resolution of (x1) in

Cubic Feet.

Cubic Metres

•For sizes 3” and 4”, set DIP Switches (9,11) to ON and (10,12) to OFF for a register resolution of

(x0.01) in Cubic Metres.

•For sizes 6” to 12”, set DIP Switches (11) to ON and (9-10, 12) to OFF for a register resolution of

(x0.1) in Cubic Metres.

20mA Flow Rate

The Signalizer can be set to match or closely match the maximum operating flow of each size meter.

The Signalizer’s maximum flow options range from 20 gpm to 18,000 gpm. Refer to the DIP Settings

reference at end of this document or on the product label to see maximum flow rate options. See

the 20mA Flow Rate Row in Table 4 above to select the option that best suits your application based

on the C&I MACH 10’s size and respective maximum flow rate.

Sampling Period vs. Battery Life Expectancy

The C&I MACH 10’s expected battery life of 10 years is based

on the meter’s typical operational parameters as well as

providing AMR/AMI readings every 15 minutes.

When operating in conjunction with The Signalizer, setting the

output module’s sampling period at too frequent of a rate can

result in a less-than-expected battery life. Therefore it is highly

recommended to set the Signalizer sampling period between

300 seconds and 900 seconds when connecting The Signalizer

to a C&I MACH 10 meter.

Sampling periods below 300 seconds will result in the C&I MACH 10 battery having a life expectancy

less than 10 years and will impact the meter’s battery warranty. Note: Applying power to the Signalizer

output module does not provide additional power to the meter or prevent battery degradation.

Sampling Period

C&I MACH 10

Estimated Battery

Life

5 secs 2 years

10 secs 3 years

15 secs 4 years

30 secs 7 years

60 secs 9 years

300 secs 10 years

600 secs 10 years

900 secs 10 years

7

DIP Switch Settings Reference

The following DIP Switch settings (Figure 6) can also be found on the module’s rear cover. These are

general setting options and are not specific to the C&I MACH 10. Refer to Table 4 in the Neptune

C&I MACH 10 Recommended Settings section for specific configuration of a C&I MACH 10.

Figure 6

PSD CI MACH 10 and SCADAMETRICS 09.21 © Copyright 2021, Neptune Technology Group Inc. Neptune is a registered trademark

of Neptune Technology Group Inc.

Table of contents

Popular Control Unit manuals by other brands

Dewetron

Dewetron DAQP-CFB2 Technical reference manual

Watts

Watts LFTWHG2 Series installation instructions

power automation

power automation PA 8000 installation instructions

Fracarro

Fracarro MOD-WL16 operating instructions

Axel Larsson

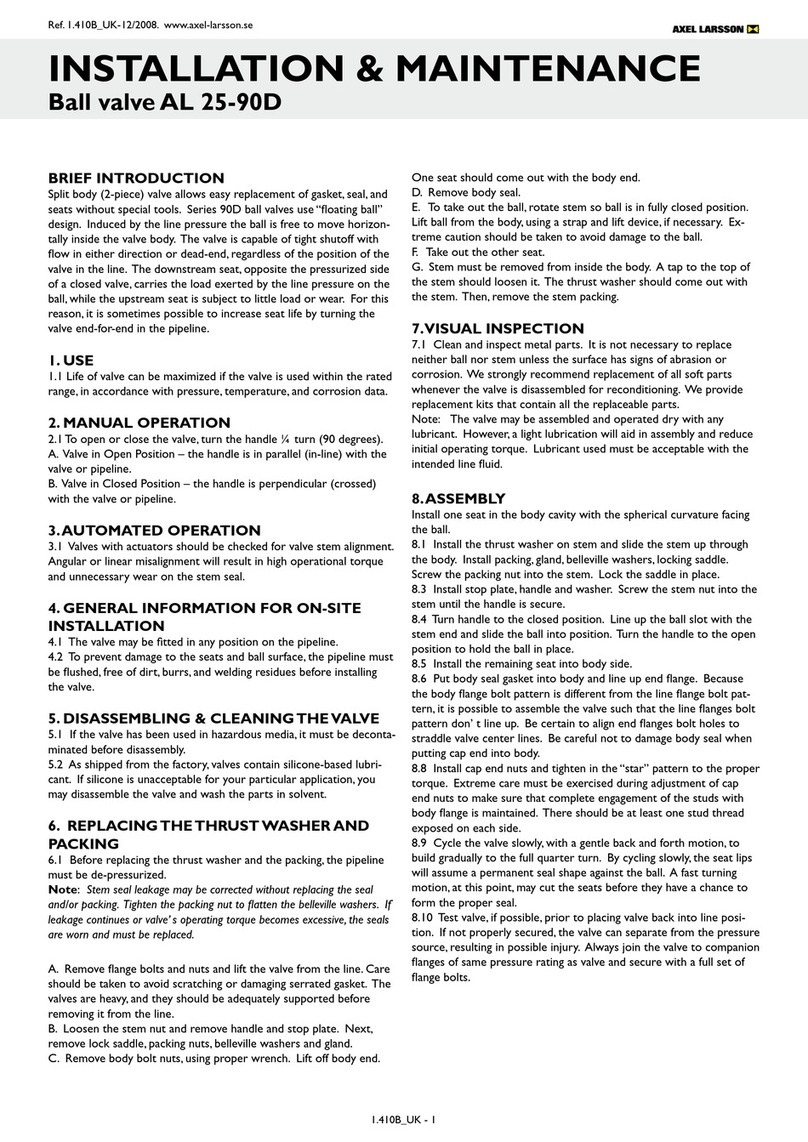

Axel Larsson AL 25-90D Installation & maintenance

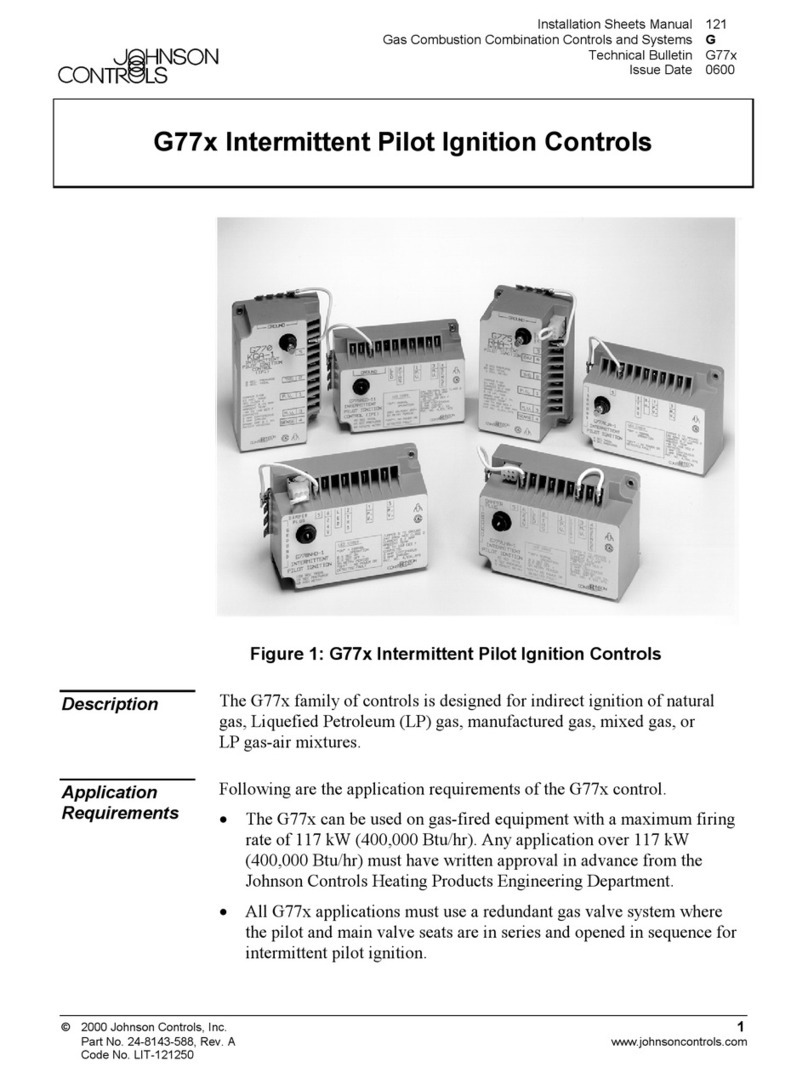

Johnson Controls

Johnson Controls G77 Series Technical bulletin

Laird

Laird BT900-SA-0x Hardware integration guide

DROPSA

DROPSA nano Progressive USER OPERATION AND MAINTENANCE MANUAL

National Instruments

National Instruments NI 9775 CALIBRATION PROCEDURE

KinCony

KinCony KC868-H8w Device user manual

Ei Electronics

Ei Electronics Ei100MRF instructions

Grafik Eye

Grafik Eye 3100 Installer's guide