Neptune NXP-M User manual

Neptune stepper motor-driven diaphragm pump

NXP-M and NXP-P

Operating instructions

Read the operating manual!

The user is responsible for installation and operation related mistakes!

Table of Contents 3

Subject to technical changes.

Neptune stepper motor-driven diaphragm pump NXP-M and NXP-P Operating instructions

Table of Contents

1 Notes for the Reader ..........................................................4

1.1 General non-discrimination......................................................4

1.2 Explanation of the signal words ................................................4

1.3 Explanation of the warning signs ..............................................4

1.4 Identification of warnings.........................................................4

1.5 Instruction for action identification ...........................................4

2 Safety .................................................................................5

2.1 General warnings.....................................................................5

2.2 Hazards due to non-compliance with the safety instructions .....6

2.3 Working in a safety-conscious manner .....................................6

2.4 Personal protective equipment.................................................6

2.5 Personnel qualification.............................................................6

3 Intended use ...................................................................... 8

3.1 Notes on product warranty .......................................................8

3.2 Intended purpose.....................................................................8

3.3 Device revision ........................................................................8

3.4 Principles ................................................................................8

3.5 Prohibited dosing media...........................................................8

3.6 Foreseeable misuse.................................................................8

4 Product description .........................................................10

4.1 Properties..............................................................................10

4.2 Scope of delivery ...................................................................10

4.3 Structure of the dosing pump .................................................10

4.4 Function description ..............................................................11

4.5 Rating plate ...........................................................................11

4.6 Conveying characteristics ......................................................12

5 Technical data..................................................................13

5.1 Delivery capacity data............................................................13

5.2 Operating conditions and limits ..............................................13

5.3 Electrical specifications .........................................................14

5.4 Other data .............................................................................14

6 Dimensions ......................................................................15

6.1 NXP-M/P 68 through 285 .......................................................15

6.2 NXP-M/P 375, 540, and 810...................................................16

7 Installing the Dosing Pump.............................................. 17

7.1 Set up information .................................................................17

7.2 Installation examples .............................................................17

8 Hydraulic installations..................................................... 18

8.1 Design of the system..............................................................18

8.2 System piping........................................................................19

8.3 Aligning the dosing head ........................................................19

8.4 Hydraulic connections............................................................19

8.5 Connecting a leakage drain....................................................21

8.6 Connecting the dosing head venting facility ............................21

8.7 Hydraulic accessories ............................................................21

9 Electrical installation.......................................................24

9.1 Principles ..............................................................................24

9.2 Description of connection sockets ..........................................25

10 Control..............................................................................27

10.1 Operating elements of the control NXP-M .............................27

10.2 Operating elements of the control NXP-P ..............................27

10.3 Password protection ............................................................28

11 Operation..........................................................................30

11.1 Commissioning the dosing pump..........................................30

11.2 NXP-P: Operating modes......................................................31

11.3 External On / Off via Release input ........................................32

11.4 Decommissioning the dosing pump......................................33

11.5 Shutting down in an emergency ...........................................33

11.6 Storage ...............................................................................33

11.7 Transportation......................................................................33

11.8 Disposal of old equipment....................................................33

12 Maintenance ....................................................................34

12.1 Maintenance intervals..........................................................34

12.2 Tighten up dosing head bolts................................................34

12.3 Change the diaphragm.........................................................35

12.4 Clean suction and discharge valves ......................................35

13 Troubleshooting ...............................................................36

13.1 Type of fault .........................................................................36

14 Spare parts.......................................................................39

14.1 Diaphragm spare parts kits ..................................................39

14.2 Dosing head spare parts kits including valves.......................39

15 Delivery characteristic curves.........................................40

16 Index.................................................................................41

Notes for the Reader

Instruction for action identification

4

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

1 Notes for the Reader

These Operating instructions contain information and behaviour rules for

safe and designated operation of the dosing pump NXP-M and NXP-P.

Observe the following principles:

nRead the entire operating manual prior to starting-up the device.

nEnsure that everyone who works with or on the dosing pump has read

the operating instructions and follows them.

nKeep the operating instructions for the entire service life of the dosing

pump.

nPass on the operating instructions to any subsequent owner of the

dosing pump.

1.1 General non-discrimination

In this operating manual, only the male gender is used where grammar

allows gender allocation. The purpose of this is to make the text easy to

read. Men and women are always referred to equally. We would like to

ask female readers for understanding of this text simplification.

1.2 Explanation of the signal words

Different signal words in combination with warning signs are used in this

operating manual. Signal words illustrate the gravity of possible injuries if

the risk is ignored:

Signal word Meaning

DANGER Refers to imminent danger. Ignoring this sign may

lead to death or the most serious injuries.

WARNING

Refers to a potentially hazardous situation.

Failure to follow this instruction may lead to death

or severe injuries.

CAUTION

Refers to a potentially hazardous situation.

Failure to follow this instruction may lead to

minor injury or damage to property.

NOTE Refers to a danger which, if ignored, may lead to

risk to the machine and its function.

Table 1: Explanation of the signal words

1.3 Explanation of the warning signs

Warning signs represent the type and source of a danger:

Warning sign Type of danger

Danger point

Danger from electrical voltage

Danger from corrosive substances

Danger from potentially-explosive substances

Danger from automatic startup

Danger of damage to machine or functional

influences

Table 2: Explanation of the warning signs

1.4 Identification of warnings

Warnings are intended to help you recognise risks and avoid negative

consequences.

This is how warnings are identified:

Warning sign SIGNAL WORD

Description of danger.

Consequences if ignored.

ðThe arrow signals a safety precaution to be taken to eliminate

the danger.

1.5 Instruction for action identification

This is how pre-conditions for action are identified:

üPre-condition for action which must be met before taking action.

@A resource such as a tool or auxiliary materials required to perform

the operating instructions.

This is how instructions for action are identified:

èSeparate step with no follow-up action.

1. First step in a series of steps.

2. Second step in a series of steps.

4Result of the above action.

üAction completed, aim achieved.

Safety

General warnings 5

Subject to technical changes.

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

2 Safety

2.1 General warnings

The following warnings are intended to help you to eliminate the dangers

that can arise while handling the dosing pump. Risk prevention measures

always apply regardless of any specific action.

Safety instructions warning against risks arising from specific activities

or situations can be found in the respective sub-chapters.

DANGER

Mortal danger from electric shock!

Wrongly connected or located cables or damaged ones can injure you.

ðConnect the device only to a SCHUKO socket outlet protected by a

ground fault circuit interrupter (GFCI).

ðReplace damaged cables without delay.

ðDo not use extension cables.

ðDo not bury cables.

ðSecure cables to avoid being damaged by other equipment.

DANGER

Danger to life through explosions!

The use of dosing pumps without ATEX certification in a potentially

explosive atmospheres can result in potentially-fatal explosions.

ðNever use the dosing pump in potentially explosive areas.

WARNING

Danger from unsuitable materials

The materials of the dosing pump and hydraulic parts of the system

must be suitable for the dosing medium that is used. Should this not

be the case, the dosing media may leak.

ðMake sure that the materials you are using are suitable for the

dosing medium.

ðMake sure that the lubricants, adhesives, sealants, etc. that you

use are suitable for the dosing medium.

WARNING

Caustic burns or other burns through dosing media!

While working on the dosing head, valves and connections, you may

come into contact with dosing media.

ðUse sufficient personal protective equipment.

ðRinse the dosing pump with a liquid (e.g. water) which does not

pose any risk. Ensure that the liquid is compatible with the dosing

medium.

ðRelease pressure in hydraulic parts.

ðNever look into open ends of plugged pipelines and valves.

WARNING

Danger of automatic start up!

After connecting the mains supply, residual dosing media in the

dosing head can spray out.

ðBefore connecting the mains supply, connect the dosing lines.

ðCheck that all the screw connections have been tightened

correctly and are leak-proof.

CAUTION

Danger when changing the dosing medium.

Changing the dosing media can provoke unexpected reactions,

damage to property and injury.

ðClean the dosing pump and the system parts in contact with the

media thoroughly before changing the dosing medium.

CAUTION

Increased risk of accidents due to insufficient qualifica-

tion of personnel!

Dosing pumps and their accessories may only be installed, operated

and maintained by personnel with sufficient qualifications. Insufficient

qualification will increase the risk of accidents.

ðEnsure that all action is taken only by personnel with sufficient and

corresponding qualifications.

ðPrevent access to the system for unauthorised persons.

Safety

Personnel qualification

6

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

2.2 Hazards due to non-compliance with the safety

instructions

Failure to follow the safety instructions may endanger not only persons,

but also the environment and the device.

The specific consequences can be:

nfailure of vital functions of the dosing pump and the system,

nfailure of required maintenance and repair methods,

ndanger for individuals through dangerous dosing media,

ndanger to the environment caused by substances leaking from the

system.

2.3 Working in a safety-conscious manner

Besides the safety instructions specified in this operating manual, further

safety rules apply and must be followed:

naccident prevention regulations,

nsafety and operating provisions,

nsafety provisions for handling dangerous substances (mostly the

safety data sheets to dosing media),

nenvironmental protection provisions,

napplicable standards and legislation.

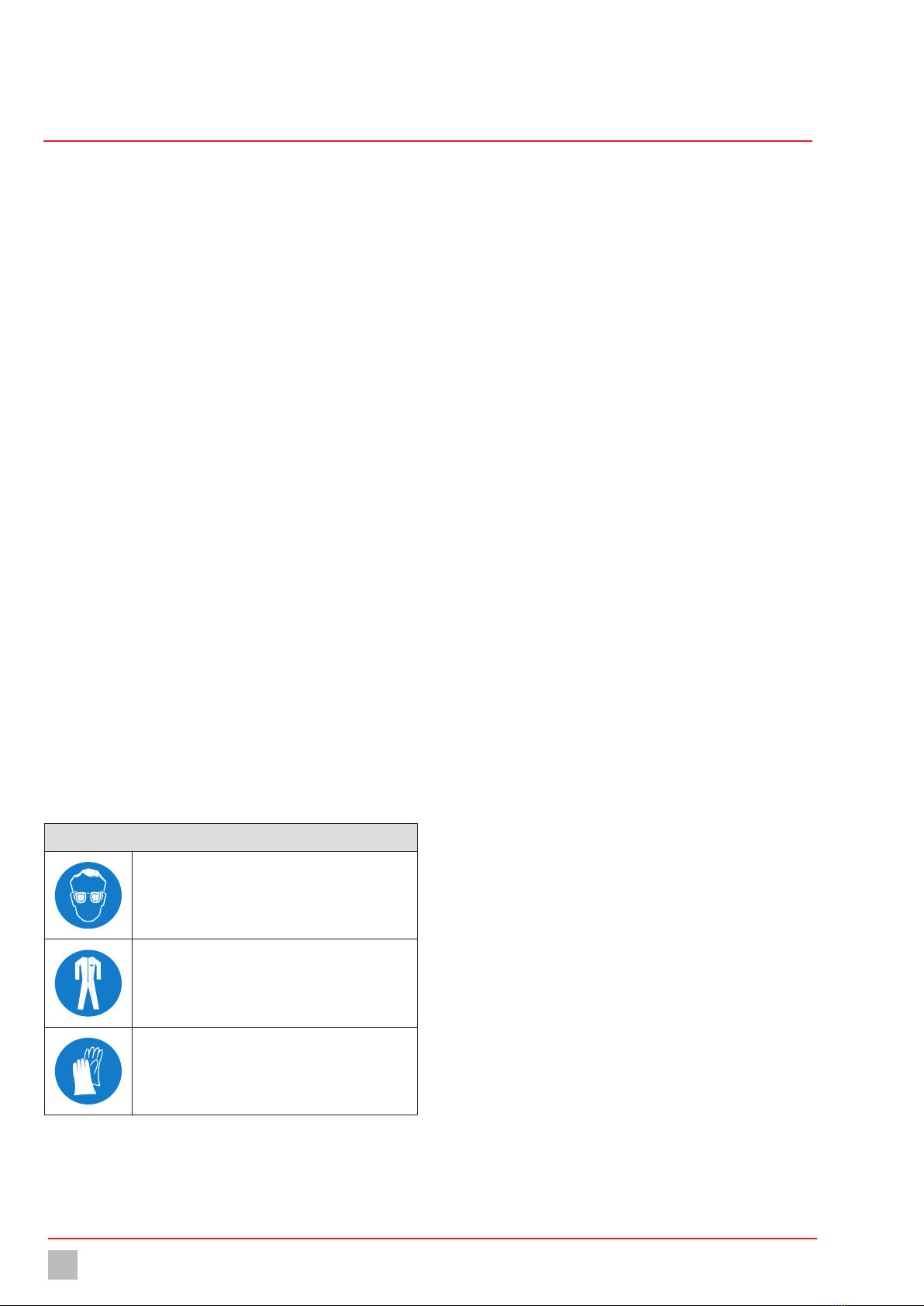

2.4 Personal protective equipment

Based on the degree of risk posed by the dosing medium and the type of

work you are carrying out, you must use corresponding protective

equipment. Read the Accident Prevention Regulations and the Safety

Data Sheets to the dosing media find out what protective equipment you

need.

You will require the minimum of the following personal protective

equipment:

Personal protective equipment required

Protective goggles

Protective clothing

Protective gloves

Table 3: Personal protective equipment required

Wear the following personal protective equipment when performing the

following tasks:

ncommissioning,

nworking on the dosing pump while running,

nshutdown,

nmaintenance work,

ndisposal.

2.5 Personnel qualification

Any personnel who work on the dosing pump must have appropriate

special knowledge and skills.

Anybody who works on the dosing pump must meet the conditions below:

nattendance at all the training courses offered by the owner,

npersonal suitability for the respective activity,

nsufficient qualification for the respective activity,

ntraining in handling of the dosing pump,

nknowledge of safety equipment and the way this equipment functions,

nknowledge of this operating manual, particularly of safety instructions

and sections relevant for the activity,

nknowledge of fundamental regulations regarding health and safety

and accident prevention.

All persons must generally have the following minimum qualification:

ntraining as specialists to carry out work on the dosing pump

unsupervised,

nsufficient training that they can work on the dosing pump under the

supervision and guidance of a trained specialist.

Safety

Personnel qualification 7

Subject to technical changes.

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

These operating instructions differentiate between these user groups:

2.5.1 Specialist staff

Thanks to their professional training, knowledge, experience and

knowledge of the relevant specifications, specialist staff are able to

perform the job allocated to them and recognise and/or eliminate any

possible dangers by themselves.

2.5.2 Trained persons

Trained persons have received training from the operator about the tasks

they are to perform and about the dangers stemming from improper

behaviour.

In the table below you can check what qualifications are the pre-condi-

tion for the respective tasks. Only people with appropriate qualifications

are allowed to perform these tasks!

Qualification Activities

Specialist staff nAssembly

nHydraulic installations

nElectrical installation

nMaintenance

nRepairs

nCommissioning

nTaking out of operation

nDisposal

nFault rectification

Trained persons nStorage

nTransportation

nControl

nFault rectification

Table 4: Personnel qualification

Intended use

Foreseeable misuse

8

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

3 Intended use

3.1 Notes on product warranty

Any non-designated use of the product can compromise its function or

intended protection. This leads to invalidation of any warranty claims!

Please note that liability is on the side of the user in the following cases:

nThe dosing pump is operated in a manner which is not consistent with

these operating instructions, particularly the safety and handling

instructions and the chapter 3 “Intended use“ on page 8.

nIf people operate the product who are not adequately qualified to carry

out their respective activities.

nNo original spare parts or accessories of Neptune are used.

nUnauthorised changes are made to the device by the user.

nThe user uses different dosing media than those indicated in the

order.

nThe user does not use dosing media under the conditions agreed with

the manufacturer such as modified concentration, density, tempera-

ture, contamination, etc.

3.2 Intended purpose

The dosing pump NXP-M and NXP-P is intended for the following

purpose: the conveying and dosing of liquids.

3.3 Device revision

This operating manual applies to the following devices:

Device Month / year of

manufacture

Firmware

NXP-M 08/2016 onwards

NXP-P 08/2016 onwards From 01:59

Table 5: Device revision

3.4 Principles

nBefore delivery, the manufacturer inspected the dosing pump and

operated it under specific conditions (with a specific dosing medium

with a specific density and temperature, with specific pipe dimen-

sions, etc.) Since these conditions differ at every location of usage,

the delivery capacity of the dosing pump should be measured by

gauging it at the operating company's installation. For details on the

approximate values and the capacity of the dosing pump, refer to the

chapter 15 “Delivery characteristic curves“ on page 40.

nComply with the information regarding the operating and environmen-

tal conditions (see chapter 5 “Technical data“ on page 13).

nAny restrictions regarding the viscosity, temperature and density of

dosing media must be followed. You must only use dosing media at

temperatures above freezing point or below the boiling point of the

respective medium.

nThe materials of the dosing pump and hydraulic parts of the system

must be suitable for the dosing medium that is used. In this connec-

tion, note that the resistance of these components can change in

dependence on the temperature of the media and the operating

pressure.

i

Information on the suitability of materials combined with

different dosing media can be found in the Compatibility Chart

of Neptune.

The information in this resistance list is based on information

from the material manufacturers and on expertise obtained by

Neptune from handling the materials.

As the durability of the materials depends on many factors,

this list only constitutes initial guidance on selecting material.

In all cases, test the equipment with the chemicals you use

under operating conditions.

nThe dosing pump is not intended for outdoor use unless appropriate

protective measures have been taken.

nAvoid leaks of liquids and dust into the casing and avoid direct

exposure to sunlight.

nYou must never operate dosing pumps in a potentially explosive

atmosphere if they do not have corresponding nameplates or an

appropriate EU Declaration of Conformity for potentially explosive

atmospheres.

3.5 Prohibited dosing media

The dosing pump must not be used for these media and substances:

nGaseous media,

nradioactive media,

nsolid substances,

ncombustible media,

nall other media that are not suitable for delivery using this dosing

pump.

3.6 Foreseeable misuse

Below, there is information about the applications of the dosing pump or

associated equipment that are not considered to be intended use. This

section is intended to allow you to detect possible misuse in advance and

to avoid it.

Intended use

Foreseeable misuse 9

Subject to technical changes.

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

Foreseeable misuse is assigned to the individual stages of the product

lifetime:

3.6.1 Incorrt assembly

nUnstable or unsuitable bracket

nDosing pump bolted wrongly or loosely

3.6.2 Incorrect hydraulic installation

nSuction and pressure lines dimensioned incorrectly

nUnsuitable connection of the pipes due to wrong material or

unsuitable connections.

nSuction and pressure lines mixed-up

nDamage to threads due to them being tightened too much

nBending of pipelines

nNo free return flow of the pressure relief valve

nExcessive demand due to the pressure differences between the

suction and discharge valves

nThrough-suction at installation without back-pressure valves

nDamage due to undamped acceleration mass forces

nExceeding the admissible pressure on the suction and discharge sides

nUsing damaged parts

3.6.3 Incorrect electrical installation

nConnecting the mains voltage without a protective earth

nUnsecured mains or one that does not conform to standards

nNot possible to immediately or easily disconnect the power supply

nWrong connecting cables for mains voltage

nDosing pump accessories connected to wrong sockets

nDiaphragm monitoring not connected or defective

nProtective earth removed

3.6.4 Incorrect start-up

nStart-up with damaged system

nShut-off valves closed at commissioning

nClosed suction or pressure line, e.g. due to blockages

nPersonnel was not informed before the start-up

nSystem was recommissioned after maintenance without all the

protective equipment and fixtures, etc. being reconnected

nInadequate protective clothing or none at all

3.6.5 Incorrect operation

nProtective equipment not functioning correctly or dismantled

nModification of the dosing pump without authority

nIgnoring operational disturbances

nElimination of operational disturbances by personnel without

adequate qualifications

nDeposits in the dosing head due to inadequate purging, particularly

with suspensions

nBridging the external fuse

nOperation made more difficult due to inadequate lighting or machines

that are difficult to access

nOperation not possible due to dirty or illegible display of the dosing

pump

nDelivery of dosing media for which the system is not designed

nDelivery of particulate or contaminated dosing media

nInadequate protective clothing or none at all

3.6.6 Incorrect maintenance

nCarrying out maintenance during ongoing operation

nCarrying out work that is not described in the operating manual

nNo adequate or regular inspection of correct functioning

nNo replacement of damaged parts or cables with inadequate

insulation

nNo securing against reactivation during maintenance work

nUsing cleaning materials that can cause reactions with the dosing

media

nInadequate cleaning of the system

nUnsuitable purging medium

nUnsuitable cleaning materials

nDetergents left in system parts

nUsing unsuitable cleaning equipment

nUsing the wrong spares or lubricants

nContaminating the dosing medium with lubricant

nInstalling spare parts without following the instructions in the

operating manual

nBlocking venting orifices

nPulling off sections of the plant

nContamination at installation without a dirt trap

nMixing up the valves

nMixing up the sensor lines

nNot reconnecting all the lines

nDamaging or not installing all the seals

nNot renewing seals

nNot paying attention to safety data sheets

nInadequate protective clothing or none at all

3.6.7 Incorrect decommissioning

nNot completely removing the dosing medium

nDismantling lines while the dosing pump is running

nDevice not disconnected from the power supply

nUsing the wrong dismantling tools

nInadequate protective clothing or none at all

3.6.8 Incorrect disposal

nIncorrect disposal of dosing media, operating resources and other

materials

nNo labelling of hazardous substances

Product description

Structure of the dosing pump

10

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

4 Product description

4.1 Properties

The NXP-M and NXP-P is a stepper motor-driven diaphragm dosing pump

that is used when precise dosing results are required.

They are characterized by the following properties:

nOutput range from 0.68 – 8.10 gph, up to 290 psig

nPower supply 110—240 V, 50/60 Hz, IP65, 25 W

nMicroprocessor-controlled drive

nIntegrated dosing head ventilation (only NXP-M/P 68 through 285 with

plastic dosing head)

nSuitable for wall and floor mounting

nMaterial finishes PVC, PP, PVDF and stainless steel

nRelease input for external start/stop

Also with NXP-P:

nPulse input (increase and reduction)

nLevel input with early warning and main alarm

nStroke frequency can be precisely adjusted via the keyboard

nGraphic display

nCalculation wizard for pulse operation available online

4.2 Scope of delivery

Please compare the delivery note with the scope of delivery.The

following items are part of the scope of delivery:

nDosing pump NXP-M and NXP-P,

nOne set each of hose clamping connections for the suction and

discharge sides for hoses with diameters of 4/6 mm, 1/4 x 3/8” (made

of PVC, PP and PVDF),

nCovering caps electrical connections:

1 for NXP-M

3 for NXP-P,

nConductive rubber band for electrical contacts:

1 for NXP-M (in connection port 1)

2 for NXP-P (in connection ports 1 and 3),

nMains cable,

nOperating instructions,

nInspection report and test certificate (optional),

nAccessory kit (optional).

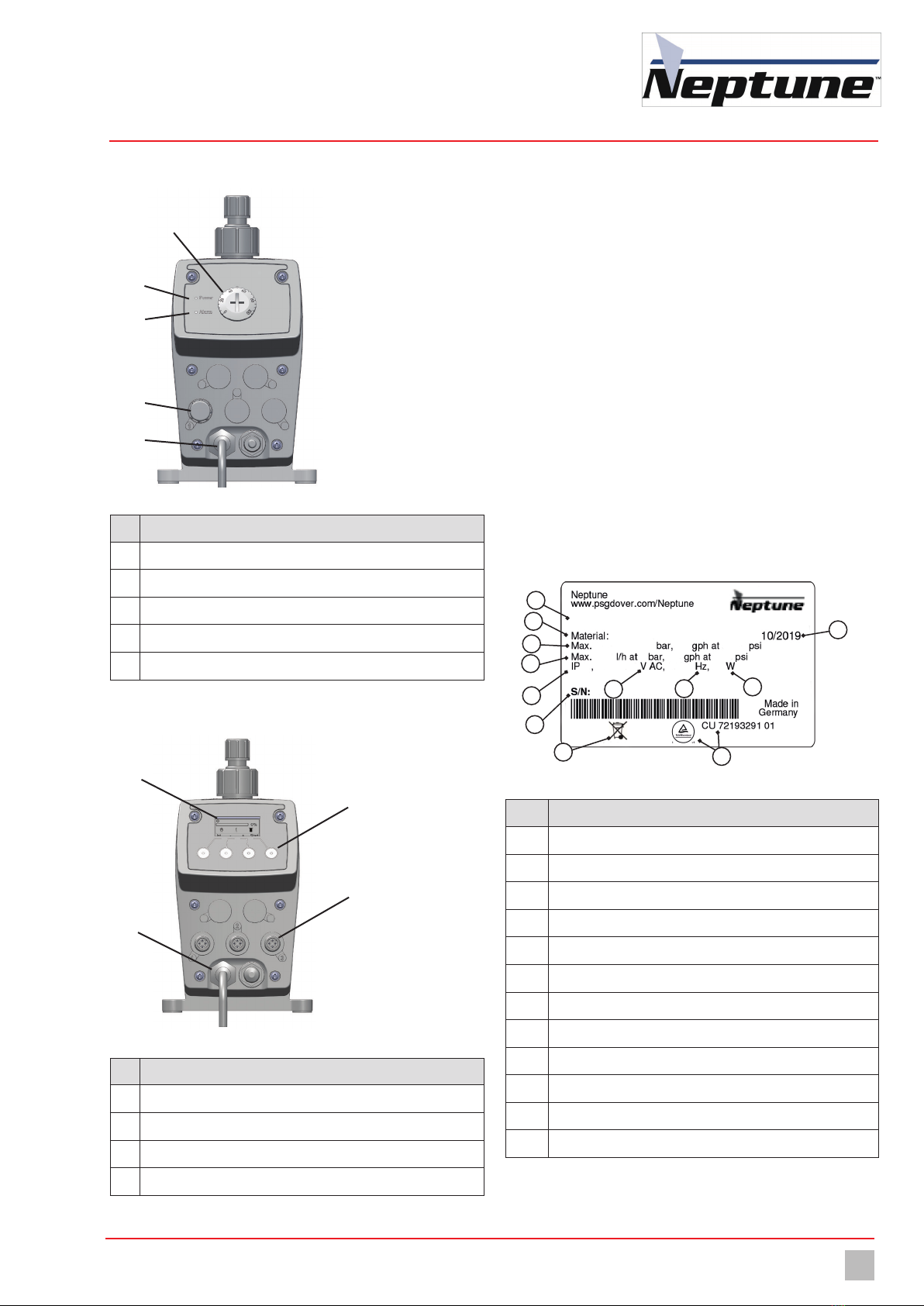

4.3 Structure of the dosing pump

4.3.1 General Overview

a

b

c

Fig. 1: General Overview

No. Description

1Dosing head

2Drive unit

3Control box

Table 6: General Overview

4.3.2 Dosing head

a

c

d

b

Fig. 2: Dosing head

No. Description

1Valve and connection on the discharge side

2Integrated dosing head ventilation (only NXP-M/P 68 through 285

with plastic dosing head)

3Arrow indicating the direction of throughflow of the dosing

medium (plastic version only)

4Valve and connection on the suction side

Table 7: Dosing head

Product description

Rating plate 11

Subject to technical changes.

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

4.3.3 Control element of the NXP-M

Fig. 3: Dosing pump control NXP-M

No. Description

1Stroke frequency setting

2Power LED

3Alarm LED

4Release input for external start/stop

5Mains cable for power supply

Table 8: Designation of components

4.3.4 Control element of the NXP-P

a

b

d

c

Fig. 4: Dosing pump control NXP-P

No. Description

1Graphic display

2Multifunction keys on the contol unit for operator inputs

3Connection ports for external operation

4Mains cable for power supply

Table 9: Designation of components

4.4 Function description

Dosing pumps are positive displacement pumps. They are used if

precisely defined delivery of a medium is necessary.A constant volume

per stroke or time is delivered.

The system delivers or meters the dosing medium by means of a

repeated sequence of suction strokes followed by pressure strokes. This

results in a pulsing flow.

If the dosing pump is in the suction stroke phase, the diaphragm is pulled

into the rear final position. Due to the resulting vacuum in the dosing

head, the discharge valve closes, the suction valve opens and dosing

medium flows from the suction line into the dosing head.

If the dosing pump is in the pressure stroke phase, the diaphragm is

moved into the front final position. Due to the pressure in the dosing head,

the suction valve closes and the dosing medium flows through the

discharge valve from the dosing head into the pressurised pipe.

4.5 Rating plate

There is information on the equipment about safety or the product's way

of functioning. The information must stay legible for the duration of the

service life of the product.

Fig. 5: Rating plate NXP-M and NXP-P

No. Description

1Product, type, nominal size

2Maximum delivery capacity at average pressure

3Maximum delivery capacity at maximum pressure

4Protection class

5Voltage supply

6CSA certificate

7WEEE label

8 Frequency

9Power consumption

10 Serial number

11 Month / year of manufacture

12 Material of the dosing head / seals

Table 10: Rating plate

a

b

c

d

e

NXP 11

10

2

1

45

6

7

89

12

3

Product description

Conveying characteristics

12

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

4.6 Conveying characteristics

The design of the dosing pump enables it to perform the pressure and suction stroke at different speeds. For low supply rates, for example, the dosing

pump performs the suction stroke at the maximum speed and adjusts the speed of the pressure stroke to match the desired supply rate.This produces

a constant supply stream, which gives you a low-pulsation, smooth dosing.

Fig. 6:

Settings

100 % delivery rate Time

50 % delivery rate Time

10 % delivery rate Time

Pressure stroke

Suction stroke

Selecting available dosing programs

Technical data

Operating conditions and limits 13

Subject to technical changes.

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

5 Technical data

5.1 Delivery capacity data

Please note that some of this data only represents guide values. The actual capacity of a dosing pump depends on various factors. For approximate

values of the delivery capacity at different pressures, refer to chapter 15 “Delivery characteristic curves“ on page 40.

Information Value

NXP-M and NXP-P Size

M68/P68 M140/P140 M285/P285 M375/P375 M540/P540 M810/P810

Delivery capacity at max. backpressure

gph 0.68 1.4 2.85 3.75 5.4 8.10

ml/stroke 0.22 0.57 1.19 1.52 2.27 3.41

Max. delivery pressure psig 290 (232*) 232 145 88 74 44

Delivery capacity at average backpressure

gph 0.7 1.59 2.98 3.88 5.6 8.2

ml/stroke 0.28 0.63 1.26 1.60 2.36 3.44

Average delivery pressure psig 145 116 72 44 36 22

Max. stroke frequency min-1 150

Table 11: Output data

* with a PVC design.

5.2 Operating conditions and limits

Information Value NXP-M and NXP-P Size

Approved ambient temperature °F 41 – 113 (with PVC components 41 – 104)*

Relative humidity %max. 90

Max. sound pressure level dB(A) 51 – 56

Max. supply pressure mbar 800

Viscosity limits mPa∙s 300** / 1000***

Adjustable dosing range %0 – 100

Table 12: Operating conditions and limits

* Use of the dosing pump at ambient temperatures below 41 °F must be checked individually. In such cases, please contact the manufacturer.

** With a viscosity of ~300 mPa∙s and above, you must use spring-loaded valves.

*** If the viscosity of the medium is larger than 1000 mPa·s, the use of the dosing pump must be checked individually. In such cases, please contact the

manufacturer.

5.2.1 Approved media temperature

Information Value NXP-M and NXP-P (all sizes)

Dosing head made of PVC °F 32 – 95

Dosing head made of PP °F 32 – 140

Table 13: Approved media temperature

Technical data

Other data

14

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

Information Value NXP-M and NXP-P (all sizes)

Dosing head made of PVDF °F 32 – 176

Dosing head made of stainless steel (1.4571) °F 32 – 176

Table 13: Approved media temperature

5.3 Electrical specifications

Information Value NXP-M and NXP-P (all sizes)

Voltage supply 110 – 240 V AC, -10% / +5%, 50/60 Hz

Power consumption W 25

Table 14: Electrical specifications

5.4 Other data

Information Value

NXP-M and NXP-P Size

M68/P68 M140/P140 M285/P285 M375/P375 M540/P540 M810/P810

Weight (with dosing head made of PVC, PP,

PVDF) Ib 4.85 approx.

Weight (with dosing head made of stainless

steel (1.4571)) Ib 7.27 approx.

Diameter of diaphragm in 1.299 1.535 2.125

Electrical cable ft 5.9 ft (with mains plug)

Protection class IP65 (with covering caps on the connections)

Insulation class F

Valve connection G5/8 male

Valve size DN3 DN4

Table 15: Other data

15

Subject to technical changes.

Neptune stepper motor-driven diaphragm pump NXP-M and NXP-P Operating instructions

Dimensions

6 Dimensions

6.1 NXP-M/P 68 through 285

~3~1.7

~ 2.3

~ 7.09

4.72 L

L

~ 10.23

~8.07

3.94

4.57

Ø

3.15

2.76

Ø

0.26

Fig. 7: Dimensioned drawing of NXP-M/P 68 through 285 with dosing head made of PVC, PP or PVDF (all dimensions in inch)

~9.33"

~7.95"

~ 3.15"

~ 0.67"

LL

~ 4.72"

~7.08"

~ 2.32"

2.76"

Ø

0.25

3.94"

4.57"

Ø

3.15"

Fig. 8: Dimensioned drawing of NXP-M/P 68 through 285 with dosing head made of stainless steel (1.4571) (all dimensions in inch)

Hose clamp connector Material Scale Nominal width L

NXP-M68 and NXP-P68

PVC / PP / PVDF 4/6 mm DN4 31

Stainless steel 4/6 mm DN4 50

NXP-M/P 140 and 285

PVC / PP / PVDF

4/6 mm DN4 31

1/4x3/8" 1/4" 34

Stainless steel (1.4571) / PVDF 4/6 mm DN4 50

16

Neptune stepper motor-driven diaphragm pump NXP-M and NXP-P Operating instructions

Dimensions

6.2 NXP-M/P 375, 540, and 810

~ 3.31~ 0.69

LL

~ 2.1

~ 7.12

2.76

Ø

0.26

Ø

3.31

3.94

4.57

~ 9.33

~ 7.93

Fig. 9: Dimensioned drawing of NXP-M/P 375,540, and 810 with dosing head made of PVC, PP, PVDF or stainless steel (1.4571) (all dimensions in mm)

Hose clamp connector Material Scale Nominal width L

NXP-M/P 375,540, and 810

PVC / PP / PVDF

4/6 mm DN4 31

1/4x3/8" 1/4" 34

Stainless steel (1.4571) / PVDF 4/6 mm DN4 50

~ 5.2 (stainless steel)

Installing the Dosing Pump

Installation examples 17

Subject to technical changes.

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

7 Installing the Dosing Pump

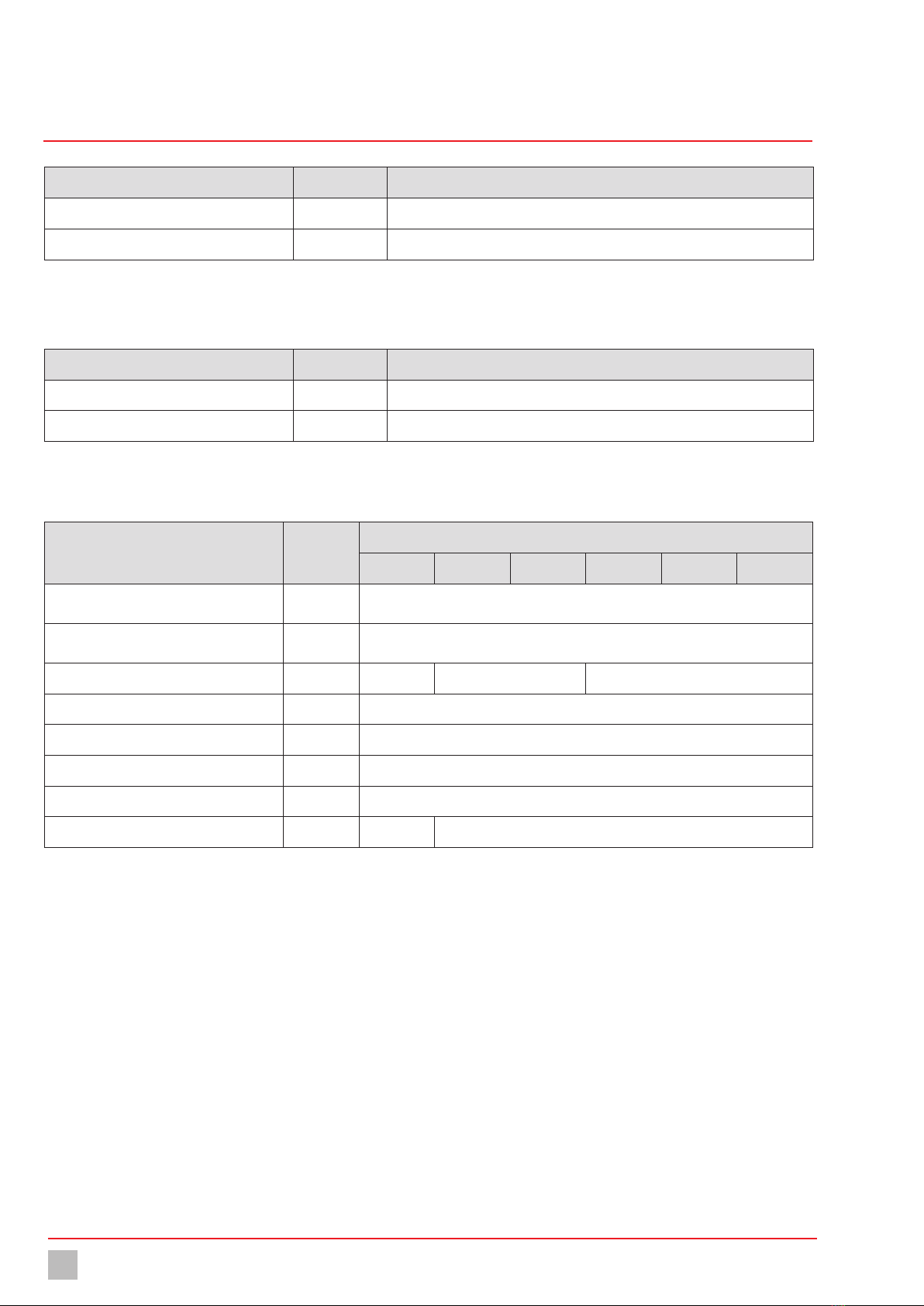

DANGER

Mortal danger from electric shock!

Electrically conductive liquid can enter pump housings, cable screw

connections and mains connectors.

ðMake sure that all protective measures comply at least with the

requirements of protection class IP65.

ðAlways set up the dosing pump such that water cannot enter the

housing.

CAUTION

Danger of personal injury and material damage!

A dosing pump that is difficult to access represents a danger due to

incorrect operation and faulty maintenance.

ðInstall the dosing pump such that it is accessible at all times.

Especially the oil level glass, the oil inlet and the oil drain.

7.1 Set up information

When installing, follow the basic principles below:

nThe valves must be vertical: Discharge valve at top, suction valve at

bottom. in this connection, pay attention to the arrow on the dosing

head. The dosing head must be aligned such that the arrow points

vertically upwards.

nYou should install the dosing pump at a convenient height for

operation.

nIt must not be installed under the ceiling.

nThe frame of foundation for fixing the dosing pump must not be

subjected to jolts. The pump must be vibration-free and stable.

nThere must be enough free space in the area of the dosing head and

the suction and discharge valves for these parts to be easily

dismantled if required. The entire space requirement for installation

and maintenance is approximately 1 m².

nThe distance from the sides of the dosing pump to the wall or other

dosing pumps or equipment must be at least 3 cm. There must be a

guaranteed flow of circulating air.

nThe maximum ambient temperature must be complied with, see

chapter 5.2 “Operating conditions and limits“ on page 13. If

necessary, radiant heat from surrounding equipment must be

screened.

nAvoid exposure to direct sunlight.

nThe dosing pump is not intended for use out of doors unless

appropriate protective measures have been taken to prevent dust and

water from entering the housing.

nFor the dimensions of the fastening holes, refer to chapter 6

“Dimensions“ on page 15.

nThe tightening torque for the fastening bolts is 1.5 – 2 Nm.

7.2 Installation examples

7.2.1 Installation on a wall console

Fig. 10: Installation on a wall console

To reduce the structure-borne noise, the dosing pump is bolted to the wall

bracket using rubber elements. The materials necessary for this are

included with the wall bracket.

7.2.2 Installation on the wall

Fig. 11: Installation on the wall

The dosing pump can be mounted to the floor or directly to the wall

without the need for additional elements. Turn the dosing head appropri-

ately to ensure the flow direction of the medium through the dosing head.

Hydraulic installations

Design of the system

18

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

8 Hydraulic installations

In this chapter, you will find information about the hydraulic parts of a

system that you should install or that can install additionally. In many

cases, you must install hydraulic accessories to be able to use all the

functions that the dosing pump offers, to guarantee functional safety or to

achieve a high level of dosing precision.

WARNING

Caustic burns or other burns through dosing media!

A diaphragm rupture, blocked pressure lines or the use of material not

suitable for the dosing medium can result in the discharge of dosing

medium. Depending on the type and hazardousness of the dosing

medium, this can result in injury.

ðWear the recommended personal protective equipment.

ðMake sure that the materials you are using are suitable for the

dosing medium.

ðMake sure that the lubricants, adhesives, sealants, etc. that you

use are suitable for the dosing medium.

ðInstall a leakage drain.

ðInstall pressure relief valves.

CAUTION

Danger of personal injury and material damage!

High peak pressures can lead to piping vibrating and cause them to

snap. This can result in injury from piping or escaping dosing media.

ðInstall pulsation dampeners.

NOTE

Damage to drives due to overloading

The pressure conditions between the suction and discharge sides

must be balanced; otherwise, overloading can result. This can lead to

uncontrolled dosing processes, damage to the piping and to the

dosing pump.

ðEnsure that the pressure on the discharge side is at least 15 psig

than on the suction side.

NOTE

Locking of threads

Stainless steel and plastic parts (particularly those made of PVC) that

are bolted together in a detachable connection (e.g. the dosing head

and the valves) can lock. This makes them difficult to release.

ðBefore bolting, grease the corresponding parts with a lubricant

(e.g. PTFE spray). Ensure that the lubricant is compatible with the

dosing medium.

8.1 Design of the system

nThe dosing pumps technical data (see chapter 5 “Technical data“ on

page 13) must be taken into account and the plant s layout must be

set up appropriately (e.g. pressure loss when rating the lines with

regard to their nominal diameter and length).

nThe entire system and its integrated dosing pump must be designed

in such a way that an escaping dosing medium (due to the failure of

wearing parts such as the diaphragm, or burst hoses) does not lead to

permanent damage to system parts or the premises.

nThe leakage opening of the dosing head must be visible so that you

can detect a diaphragm rupture. It must be possible for the outflow

from the leakage drain to be on a free downwards gradient.

nIf you use hazardous dosing media, the installation must be designed

such that no disproportionately high consequential damages arise

due to dosing media escaping.

nTo avoid dosing errors after the end of the process, the dosing pump

must be locked hydraulically.

nTo allow you to easily inspect the pressure conditions in the system,

you should provide connections for pressure gauges close to the

suction and discharge valves.

Hydraulic installations

Hydraulic connections 19

Subject to technical changes.

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

8.2 System piping

nThe system piping must not exert any force on the connections and

valves of the dosing pump.

nThis means that steel piping should be connected to the dosing pump

by means of flexible pipe sections.

nThe nominal diameters of the pipework and the installed fittings

should be rated the same as or greater than the nominal diameters of

the dosing pump's suction and discharge valves.

nThe suction line should be kept as short as possible.

nYou should avoid intertwined hoses.

nAvoid loops, since air bubbles can collect.

8.3 Aligning the dosing head

a

b

c

Fig. 12: Aligning the dosing head

When connecting the dosing lines to the dosing pump, you must observe

the direction of through-flow (see arrow 2). The dosing head must be

aligned vertically. The alignment can be changed in 90° intervals.

The suction valve (3) must always point downwards. Accordingly, arrow

(2) and pressure valve (1) always point upwards. This is irrespective of the

positioning of the dosing head to the drive.

8.4 Hydraulic connections

8.4.1 Connecting hose clips

Choose the hose connection according to the condition of the hose

(material, inner diameter, wall thickness) in order to ensure maximum

pressure resistance.

8.4.1.1 Size 4/6

a

b

c

d

e

a

b

c

d

e

4/6 6/9

Fig. 13: Hose clips 4/6 and 6/9 (internal and external diameters in mm)

Perform the following working steps:

1. Cut the hose (1) to the appropriate length neatly and at an exact right

angle.

2. Place a gasket that is suitable for the dosing medium between the

connection (5) and the valve.

3. Screw the connecting piece to the dosing pump's valve using the

union nut (2).

4. Thread the union nut (3) and the clamping ring (4) onto the hose.

5. Plug the hose all the way in to the grommet of connection piece.

6. Push the clamping ring onto the grommet of connection piece and

screw it to the union nut.

7. Carry out the same procedure with the connection to the dosing

pump's other valve.

üHose clip connected.

Hydraulic installations

Hydraulic connections

20

Stepper motor-driven diaphragm dosing pump NXP-M and NXP-P Operating instructions

8.4.1.2 Size 6/12

a

b

c

d

Fig. 14: Hose clip 6/12 (internal and external diameter in mm)

Size 6/12 hose clips only have a union nut. It clamps the hose onto the

grommet of the connection piece and at the same time fastens on the

dosing pump's valve.

Perform the following working steps:

1. Cut the hose (1) to the appropriate length neatly and at an exact right

angle.

2. Place a gasket that is suitable for the dosing medium between the

connection (4) and the valve.

3. Push the union nut (2) and the cutting ring (3) over the hose. Press

the end of the hose onto the grommet of connection piece.You can do

this more easily by moistening the end of the hose on the inside or

applying some lubricant to the grommet in the cone area. You should

push at least two thirds of the hose onto the grommet of the

connection piece.

4. Push the cutting ring over the hose into the cone area on the

grommet of connection piece.

5. Screw the union nut onto the valve of the dosing pump.

üHose clip connected.

8.4.2 Making the glue-in connection

a

b

Fig. 15: Glue-in connection

Perform the following working steps:

1. Cut the PVC tube to length.

2. Push the union nut (1) onto the tube.

3. Stick the bonded coupling sleeve (2) to the tube (follow the

instructions of the adhesive manufacturer).

4. Screw the union nut onto the valve of the dosing pump. Use a gasket

that is suitable for the dosing medium.

üGlue-in connection made.

8.4.3 Making the cemented connection

a

b

Fig. 16: Cemented connection

Perform the following working steps:

1. Cut the tube to length.

2. Cut the thread (2) onto the end of the tube.

3. Push the union nut (1) onto the tube.

4. Seal the thread.When choosing your sealing material, take into

account its resistance to material, temperature and pressure.

5. Screw the union nut onto the valve of the dosing pump. Use a gasket

that is suitable for the dosing medium.

üCemented connection made.

i

Under normal conditions, you only need to screw the hydraulic

connections finger-tight. However, due to the material settling,

the pre-tension of the screw connection can slacken. This

means that you must re-tighten the screw connection before

carrying out commissioning.

This manual suits for next models

1

Table of contents

Other Neptune Water Pump manuals

Neptune

Neptune NPVS150 Assembly instructions

Neptune

Neptune 500 Series Instruction manual

Neptune

Neptune 7000 Series Owner's manual

Neptune

Neptune MP7100 Owner's manual

Neptune

Neptune VTF Installation instructions

Neptune

Neptune 560 Series Instruction Manual

Neptune

Neptune Apex WAV User manual

Neptune

Neptune NSP-M User manual

Popular Water Pump manuals by other brands

VS

VS ZJ Series Operating instruction

Flo King

Flo King Permacore Reusable Carbon Bag Disassembly. & Cleaning Instructions

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Milton Roy

Milton Roy PRIMEROYAL instruction manual

Tesla

Tesla 4OL Installation and operating instructions

Crane

Crane Barnes SGV 2 HP Installation and operation manual