Neslab HX Series User manual

Installation, Operation,Installation, Operation,

Installation, Operation,Installation, Operation,

Installation, Operation,

and Maintenance Manand Maintenance Man

and Maintenance Manand Maintenance Man

and Maintenance Manualual

ualual

ual

HX AnalogHX Analog

HX AnalogHX Analog

HX Analog

RecirRecir

RecirRecir

Recirculating Chillerculating Chiller

culating Chillerculating Chiller

culating Chiller

NESLABManualP/N002023

Rev.02/25/92

- 1 -

HX Analog RecirHX Analog Recir

HX Analog RecirHX Analog Recir

HX Analog Recirculating Chillerculating Chiller

culating Chillerculating Chiller

culating Chiller

Installation,Installation,

Installation,Installation,

Installation, Operation,Operation,

Operation,Operation,

Operation, and Maintenance Manand Maintenance Man

and Maintenance Manand Maintenance Man

and Maintenance Manualual

ualual

ual

TT

TT

Tabab

abab

able of Contentsle of Contents

le of Contentsle of Contents

le of Contents

PREFACEPREFACE

PREFACEPREFACE

PREFACE Unpacking ............................................................................................... 3

Warranty ................................................................................................. 3

After-sale Support ................................................................................... 3

SECTION ISECTION I

SECTION ISECTION I

SECTION I

SafetySafety

SafetySafety

Safety Warnings................................................................................................. 4

SECTION IISECTION II

SECTION IISECTION II

SECTION II

General InformationGeneral Information

General InformationGeneral Information

General Information Description .............................................................................................. 5

Specifications.......................................................................................... 6

Cooling Capacity..................................................................................... 7

Pump Capacity ....................................................................................... 8

SECTION IIISECTION III

SECTION IIISECTION III

SECTION III

InstallationInstallation

InstallationInstallation

Installation Site (Air-cooled Units) ........................................................................... 10

Site (Water-cooled Units)...................................................................... 11

Electrical Requirements ........................................................................ 13

Plumbing Requirements........................................................................ 14

Fluids .................................................................................................... 16

Filling Requirements ............................................................................. 17

Pump Purging ....................................................................................... 17

SECTION IVSECTION IV

SECTION IVSECTION IV

SECTION IV

OperationOperation

OperationOperation

Operation Start Up................................................................................................. 18

Refrigeration Control ............................................................................. 18

Flow Control.......................................................................................... 19

Pressure Gauge.................................................................................... 19

Pressure Relief Valve (PD and TU Pumps Only).................................. 20

High Pressure Cutout (Water-Cooled Units Only)................................. 20

- 2 -

SECTION VSECTION V

SECTION VSECTION V

SECTION V

Special FeaturesSpecial Features

Special FeaturesSpecial Features

Special Features Pump Motor Overload Protector ........................................................... 21

Optional Heater Package...................................................................... 22

External Pressure Reducer (Optional) .................................................. 23

Automatic Refill Device (Optional) ........................................................ 24

SECTION VISECTION VI

SECTION VISECTION VI

SECTION VI

MaintenanceMaintenance

MaintenanceMaintenance

Maintenance Service Contracts ................................................................................. 25

Condenser Cleaning ............................................................................. 25

Algae..................................................................................................... 25

SECTION VIISECTION VII

SECTION VIISECTION VII

SECTION VII

ServiceService

ServiceService

Service Pump Strainer (PD and TU Pumps Only) ............................................. 26

Phase Rotation ..................................................................................... 27

Pump Lubrication .................................................................................. 27

SECTION VIIISECTION VIII

SECTION VIIISECTION VIII

SECTION VIII

TroubleshootingTroubleshooting

TroubleshootingTroubleshooting

Troubleshooting Checklist ............................................................................................... 28

Service Assistance ............................................................................... 28

SECTION IXSECTION IX

SECTION IXSECTION IX

SECTION IX

DiagramsDiagrams

DiagramsDiagrams

Diagrams Refrigeration Flow (HX-75 through HX-150) ......................................... 29

Refrigeration Flow (HX-200 through HX-750) ....................................... 29

Pump Flow (CP Pumps) ....................................................................... 30

Pump Flow (PD and TU Pumps) .......................................................... 30

SECTION XSECTION X

SECTION XSECTION X

SECTION X

WarrantyWarranty

WarrantyWarranty

Warranty .............................................................................................................. 31

- 3 -

PrefacePreface

PrefacePreface

Preface

UnpackingUnpacking

UnpackingUnpacking

Unpacking Retain all cartons and packing material until the unit is operated and found to

be in good condition.

If the unit shows external or internal damage, or does not operate properly,

contact the transportation company and file a damage claim. Under ICC

regulations, this is your responsibility.

WarrantyWarranty

WarrantyWarranty

Warranty All NESLAB units are shipped with a warranty card. The top portion of the

card remains with the unit. The bottom portion must be filled out and

returned to NESLAB.

The unit has a warranty against defective parts and workmanship for one full

year from date of shipment. Refer to the last page of this manual for

complete warranty details.

After-sale SupportAfter-sale Support

After-sale SupportAfter-sale Support

After-sale Support NESLAB is committed to customer service both during and after the sale. If

you have questions concerning the operation of your unit or the information

in this manual, contact our Sales Department. If your unit fails to operate

properly or if you have questions concerning spare parts or Service

Contracts, contact our Service Department.

Before calling, please refer to the serial number label on the rear of the case

top to obtain the following information (see Section II, Description for the

serial number label location):

- unit part number

- unit serial number

- 4 -

Section I SafSection I Saf

Section I SafSection I Saf

Section I Safetyety

etyety

ety

WarningsWarnings

WarningsWarnings

Warnings Make sure you read and understand all instructions and safety precautions

listed in this manual before installing or operating your unit. If you have any

questions concerning the operation of your unit or the information in this

manual, contact our Sales Department for assistance (see Preface, After-

sale Support).

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance proceduresPerformance of installation, operation, or maintenance procedures

Performance of installation, operation, or maintenance procedures

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardousother than those described in this manual may result in a hazardous

other than those described in this manual may result in a hazardous

situation and may void the manufacturer’s warranty.situation and may void the manufacturer’s warranty.

situation and may void the manufacturer’s warranty.situation and may void the manufacturer’s warranty.

situation and may void the manufacturer’s warranty.

Transport the unit with care. Sudden jolts or drops can damage theTransport the unit with care. Sudden jolts or drops can damage the

Transport the unit with care. Sudden jolts or drops can damage theTransport the unit with care. Sudden jolts or drops can damage the

Transport the unit with care. Sudden jolts or drops can damage the

refrigeration lines.refrigeration lines.

refrigeration lines.refrigeration lines.

refrigeration lines.

Do not attempt to defeat any of the interlock switches or safetyDo not attempt to defeat any of the interlock switches or safety

Do not attempt to defeat any of the interlock switches or safetyDo not attempt to defeat any of the interlock switches or safety

Do not attempt to defeat any of the interlock switches or safety

features built into the unit.features built into the unit.

features built into the unit.features built into the unit.

features built into the unit.

Observe all warning labels.Observe all warning labels.

Observe all warning labels.Observe all warning labels.

Observe all warning labels.

Never remove warning label.Never remove warning label.

Never remove warning label.Never remove warning label.

Never remove warning label.

Never operate damaged or leaking equipment.Never operate damaged or leaking equipment.

Never operate damaged or leaking equipment.Never operate damaged or leaking equipment.

Never operate damaged or leaking equipment.

Never operate the unit without cooling fluid in the fluid reservoir.Never operate the unit without cooling fluid in the fluid reservoir.

Never operate the unit without cooling fluid in the fluid reservoir.Never operate the unit without cooling fluid in the fluid reservoir.

Never operate the unit without cooling fluid in the fluid reservoir.

Make sure the unit is off before connecting or disconnecting theMake sure the unit is off before connecting or disconnecting the

Make sure the unit is off before connecting or disconnecting theMake sure the unit is off before connecting or disconnecting the

Make sure the unit is off before connecting or disconnecting the

power cord or other cables.power cord or other cables.

power cord or other cables.power cord or other cables.

power cord or other cables.

Always turn off the unit and disconnect the power cord from theAlways turn off the unit and disconnect the power cord from the

Always turn off the unit and disconnect the power cord from theAlways turn off the unit and disconnect the power cord from the

Always turn off the unit and disconnect the power cord from the

power source before performing any service or maintenancepower source before performing any service or maintenance

power source before performing any service or maintenancepower source before performing any service or maintenance

power source before performing any service or maintenance

procedures, or before moving the unit.procedures, or before moving the unit.

procedures, or before moving the unit.procedures, or before moving the unit.

procedures, or before moving the unit.

Always empty the fluid reservoir before moving the unit.Always empty the fluid reservoir before moving the unit.

Always empty the fluid reservoir before moving the unit.Always empty the fluid reservoir before moving the unit.

Always empty the fluid reservoir before moving the unit.

Never operate equipment with damaged power cords.Never operate equipment with damaged power cords.

Never operate equipment with damaged power cords.Never operate equipment with damaged power cords.

Never operate equipment with damaged power cords.

Refer service and repairs to a qualified NESLAB technician.Refer service and repairs to a qualified NESLAB technician.

Refer service and repairs to a qualified NESLAB technician.Refer service and repairs to a qualified NESLAB technician.

Refer service and repairs to a qualified NESLAB technician.

In addition to the safety warnings listed above, warnings are posted

throughout the manual. These warnings are designated by an exclamation

mark inside an equilateral triangle with text highlighted in bold. Read and

follow these important instructions. Failure to observe these instructions

can result in permanent damage to the unit, significant property damage, or

personal injury or death.

- 5 -

Labels

Section II General InfSection II General Inf

Section II General InfSection II General Inf

Section II General Informationormation

ormationormation

ormation

DescriptionDescription

DescriptionDescription

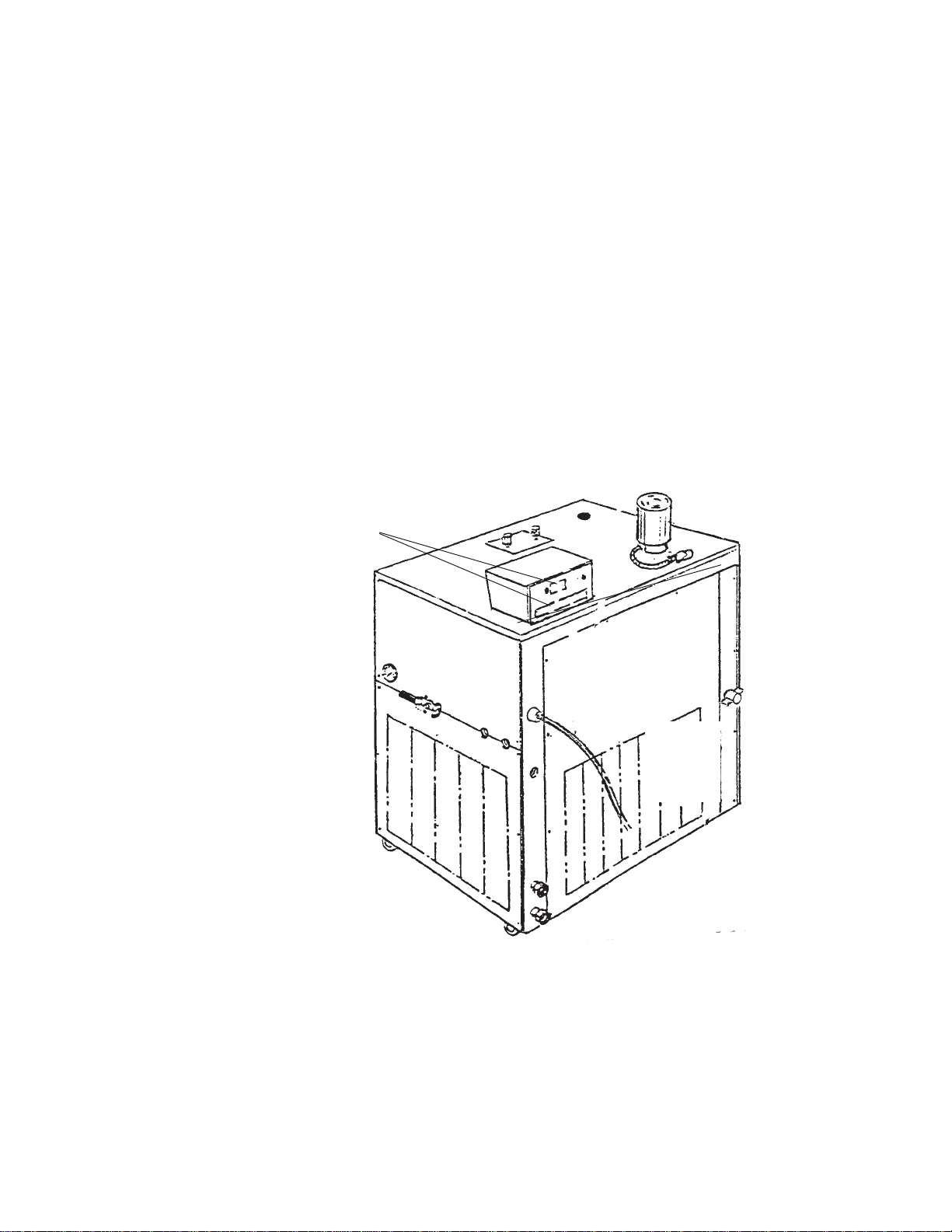

Description The HX Series Recirculating Chiller is designed to provide a continuous flow

of cooling fluid at a constant temperature and volume.

The unit consists of an air-cooled or water-cooled refrigeration system, a

fluid reservoir, a fluid recirculation pump, and a temperature controller.

HX units are available with a large number of options. This manual explains

how to install, operate, and maintain a “standard” HX unit. This manual also

explains some of the available options. Supplemental manuals are supplied

with units equipped with options not covered in this manual.

Throughout the manual, you will be asked to consult the unit’s serial number

label, or the pump identification label, or both, for specific information. Both

labels are located on the rear of the temperature control box.

- 6 -

+5°C to +35°C

±0.1°C

35 ¾ x 23 ¼ x 18 ¾

90.8 x 59.0 x 47.6

5.0

19.0 8.0

30.3

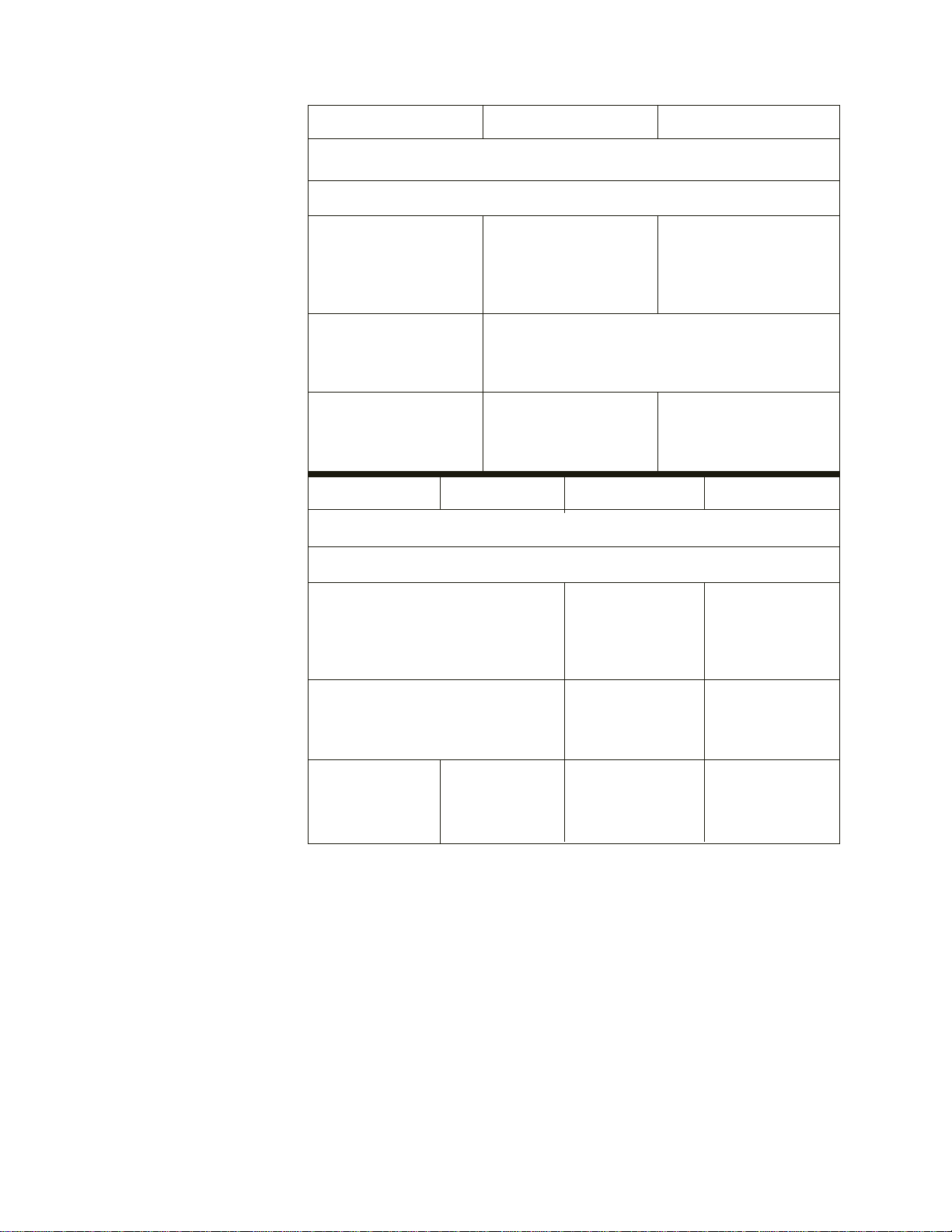

SpecificationsSpecifications

SpecificationsSpecifications

Specifications

HX-75HX-75

HX-75HX-75

HX-75 HX-100HX-100

HX-100HX-100

HX-100 HX-150HX-150

HX-150HX-150

HX-150

Temperature RangeTemperature Range

Temperature RangeTemperature Range

Temperature Range

Temperature StabilityTemperature Stability

Temperature StabilityTemperature Stability

Temperature Stability

Unit DimensionsUnit Dimensions

Unit DimensionsUnit Dimensions

Unit Dimensions

(H x W x D)

Inches

Centimeters

Reservoir VolumeReservoir Volume

Reservoir VolumeReservoir Volume

Reservoir Volume

Gallons

Liters

Shipping WeightShipping Weight

Shipping WeightShipping Weight

Shipping Weight

Pounds

Kilograms

HX-200HX-200

HX-200HX-200

HX-200 HX-300HX-300

HX-300HX-300

HX-300 HX-500HX-500

HX-500HX-500

HX-500 HX-750HX-750

HX-750HX-750

HX-750

Temperature RangeTemperature Range

Temperature RangeTemperature Range

Temperature Range

Temperature StabilityTemperature Stability

Temperature StabilityTemperature Stability

Temperature Stability

Unit DimensionsUnit Dimensions

Unit DimensionsUnit Dimensions

Unit Dimensions11

11

1

(H x W x D)

Inches

Centimeters

Reservoir VolumeReservoir Volume

Reservoir VolumeReservoir Volume

Reservoir Volume

Gallons

Liters

Shipping WeightShipping Weight

Shipping WeightShipping Weight

Shipping Weight

Pounds

Kilograms

320

145

+5°C to +35°C

±0.1°C

15.0

56.8

63 ¾x 46 x 29

162.0 x 116.8 x 73.6

45 7/8 x 33 ¾x 25 ¼

116.5 x 85.7 x 64.1

28.0

106.0 40.0

151.0

471

214 531

241 746

338 971

440

261

118

38 ¼x 26 ¼x 21 ¼

96.8 x 66.7 x 53.6 39 ¾x 26 ¼x 21 ¼

101.0x 66.6 x 53.6

300

136

50 5/8 x 46 x 28 ¾

128.3 x 116.8 x 73.0

1.HX-750 witha water-cooledrefrigeration systemhas thesame dimensionsas theHX-500.

- 7 -

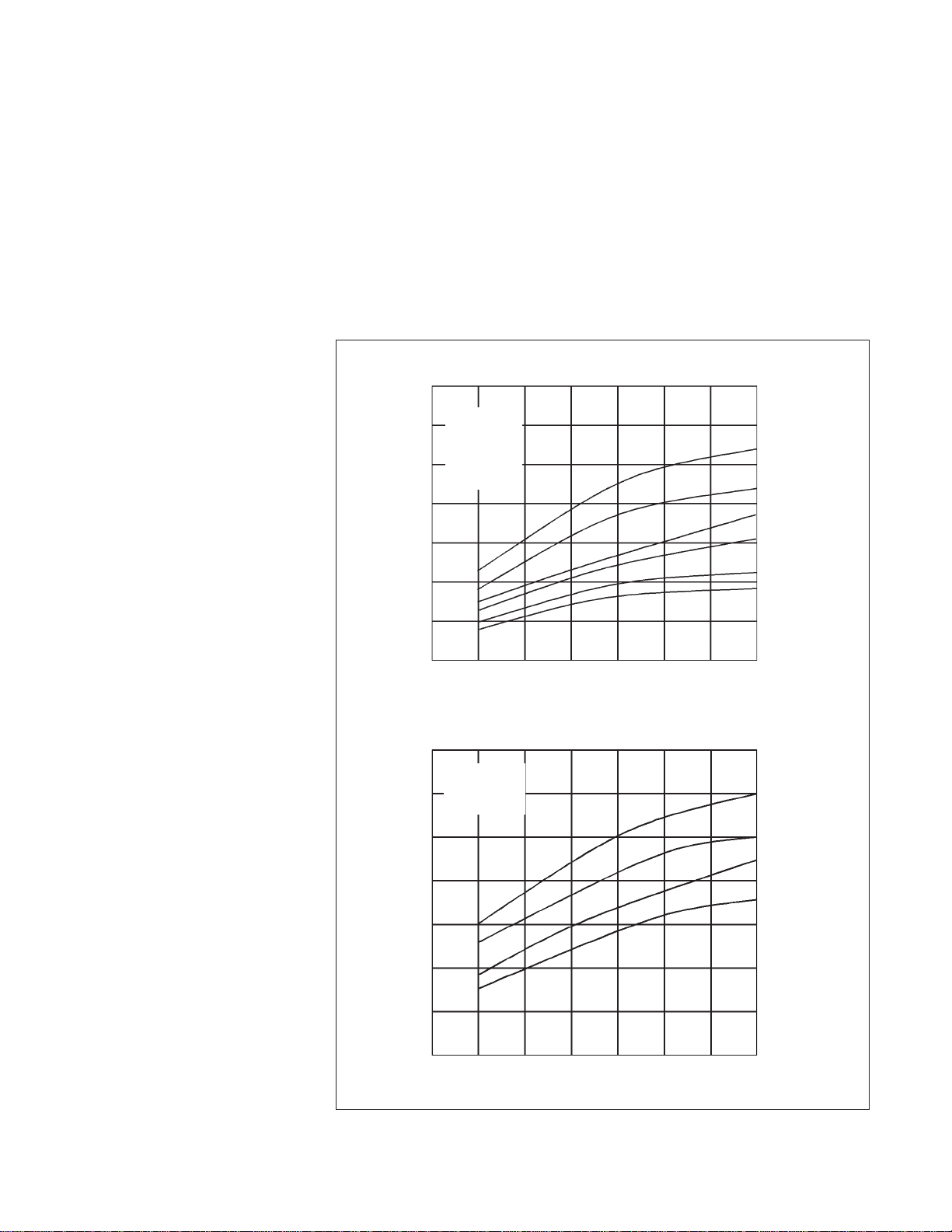

Cooling CapacityCooling Capacity

Cooling CapacityCooling Capacity

Cooling Capacity Cooling capacity will vary depending on fluid temperature, ambient

temperature, and cooling fluid.

Cooling capacities for models HX-75 through HX-750 were obtained under

the following conditions:

1. air-cooled unit operating at +20°C (+68°F) ambient temperature.

2. cooling fluid with specific heat of 1.0 was used for fluid temperatures from

+5°C to +35°C.

FluidTemperature(°C)

FluidTemperature(°C)

CoolingCapacity(Watts)

CoolingCapacity(Kilowatts)

7000

6000

5000

4000

3000

2000

1000

5 1015 20253035

A=HX-150, 60Hz

B=HX-150, 50Hz

C=HX-100, 60Hz

D=HX-100, 50Hz

E=HX-75, 60Hz

F=HX-75, 50Hz

A

B

C

D

E

F

A=HX-300, 60Hz

B=HX-300, 50Hz

C=HX-200, 60Hz

D=HX-200, 50Hz

14

12

10

8

6

4

2

5 1015 20253035

D

C

B

A

HX-75, 100, & 150HX-75, 100, & 150

HX-75, 100, & 150HX-75, 100, & 150

HX-75, 100, & 150

HX-200 & 300HX-200 & 300

HX-200 & 300HX-200 & 300

HX-200 & 300

- 8 -

HX-500 & 750HX-500 & 750

HX-500 & 750HX-500 & 750

HX-500 & 750

FluidTemperature(°C)

A=HX-750, 60Hz

B=HX-750, 50Hz

C=HX-500, 60Hz

D=HX-500, 50Hz

35

30

25

20

15

10

5

A

B

C

D

5101520253035

CoolingCapacity(Kilowatts)

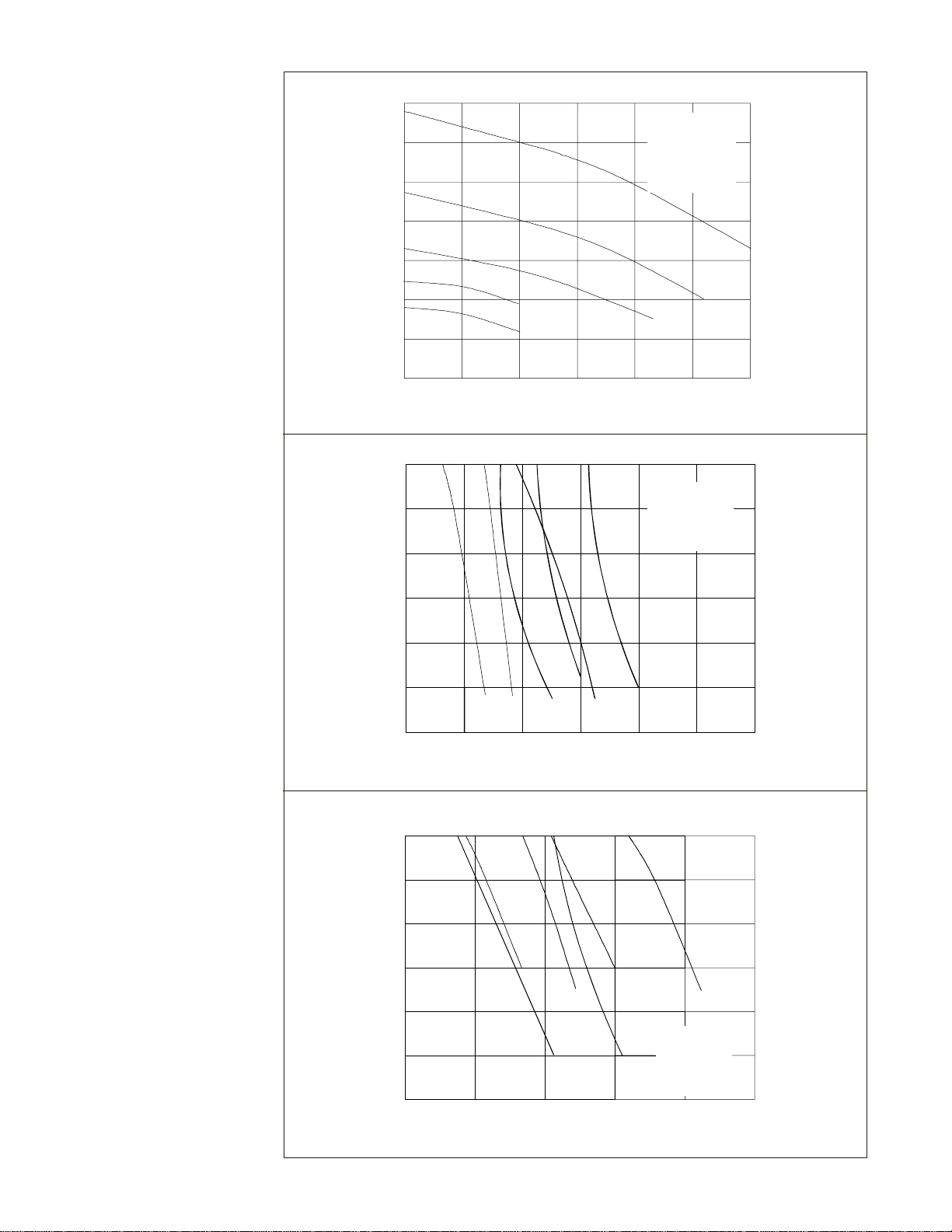

Pump CapacityPump Capacity

Pump CapacityPump Capacity

Pump Capacity HX units are available with one of three standard pump types: positive

displacement (PD), centrifugal (CP), and turbine (TU). Refer to the pump

identification label on the rear of the analog temperature controller to identify

the specific pump in your unit.

PD1, PD2 & TU1PD1, PD2 & TU1

PD1, PD2 & TU1PD1, PD2 & TU1

PD1, PD2 & TU1

A=PD-1, 50Hz

B=PD-1, 60Hz

C=PD-2, 50Hz

D=PD-2, 60Hz

E=TU-1, 50Hz

F=TU-1, 60Hz

AB

D

E

F

C

4.0 60

3.4 50

2.7 40

2.0 30

1.3 20

0.7 10

Bar PSI

12 34 56Gpm

3.8 7.5 11.3 15.1 19 22.7Lpm

FLOW

PRESSURE

- 9 -

C

PRESSURE

51015202530Gpm

18.9 37.9 56.8 60.5 94.6 113.6 Lpm

FLOW

4.7 70

4.0 60

3.4 50

2.7 40

2.0 30

1.3 20

0.7 10

Bar PSI

A

D, E

F

TU-3, 5 & 6TU-3, 5 & 6

TU-3, 5 & 6TU-3, 5 & 6

TU-3, 5 & 6

PRESSURE

AB

D

F

4.0 60

3.4 50

2.7 40

2.0 30

1.3 20

0.7 10

Bar PSI

A=TU-3, 50Hz

B=TU-3, 60Hz

C=TU-5, 50Hz

D=TU-5, 60Hz

E=TU-6, 50Hz

F=TU-6, 60Hz

4 8 12 16 20 24 Gpm

15.1 30.2 45.4 60.5 75.5 91 Lpm

FLOW

CE

PRESSURE

Bar PSI

12 16 20 24 28 Gpm

45.4 60.5 75.5 90.8 106 Lpm

4.0 60

3.4 50

2.7 40

2.0 30

1.3 20

0.7 10

A=TU-7, 50Hz

B=TU-7, 60Hz

C=TU-8, 50Hz

D=TU-8, 60Hz

E=TU-9, 50Hz

F=TU-9, 60Hz

B

A

FLOW

TU-7, 8 & 9TU-7, 8 & 9

TU-7, 8 & 9TU-7, 8 & 9

TU-7, 8 & 9

CD

EF

CPCP

CPCP

CP

A=CP-25, 50Hz

B=CP-25, 60Hz

C=CP-55, 50Hz

D=CP-55, 60Hz

E=CP-75, 50Hz

F=CP-75, 60Hz

B

- 10 -

Section III InstallationSection III Installation

Section III InstallationSection III Installation

Section III Installation

Site (Air-cooled Units)Site (Air-cooled Units)

Site (Air-cooled Units)Site (Air-cooled Units)

Site (Air-cooled Units) The unit should be located in a laboratory or clean industrial environment

where ambient temperatures are inside the range of +55°F to +95°F (+13°C

to +35°C). The unit will retain its full rated capacity in ambient temperatures

to approximately +75°F (+24°C). Above +75°F, reduce the cooling capacity

1% for every 1°F above +75°F, to a maximum ambient temperature of

+95°F. In degrees Celsius, reduce the cooling capacity 1% for every 0.5°C

above +24°C, to a maximum ambient temperature of +35°C.

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, orNever place the unit in a location where excessive heat, moisture, or

Never place the unit in a location where excessive heat, moisture, or

corrosive materials are present.corrosive materials are present.

corrosive materials are present.corrosive materials are present.

corrosive materials are present.

The unit has an air-cooled refrigeration system. It must be positioned so the

air intake and discharge are not impeded. On models HX-75 through HX-

150, air is drawn through the left side of the unit and discharged through the

right and rear. A minimum clearance of 2 feet (0.6 meter) on these three

sides is necessary for adequate ventilation.

On models HX-200 —HX-750, air is drawn through the front of the unit and

discharged through the side and rear. A minimum of 5 feet (1.5 meters) on

all four sides of the unit is necessary for adequate ventilation.

In some applications where space is at a premium, the minimum ventilation

clearance can be compromised. However, consult our Sales Department

before positioning the unit in a location with less minimum clearance than

listed above. Inadequate ventilation will cause a reduction in cooling capacity

and, in extreme cases, compressor failure.

Excessively dusty areas should be avoided and a periodic cleaning schedule

should be instituted (see Section VII, Condenser Cleaning).

Refer to the table below to determine the approximate amount of air intake

required for the unit to retain its full rated capacity. If the air intake does not

meet these standards, cooling capacity will be derated.

HX-75 HX-100 HX-150 HX-200HX-75 HX-100 HX-150 HX-200

HX-75 HX-100 HX-150 HX-200HX-75 HX-100 HX-150 HX-200

HX-75 HX-100 HX-150 HX-200

Air IntakeAir Intake

Air IntakeAir Intake

Air Intake

Cubic feet per minute

Liters per minute

HX-300HX-300

HX-300HX-300

HX-300 HX-500HX-500

HX-500HX-500

HX-500 HX-750HX-750

HX-750HX-750

HX-750

Air IntakeAir Intake

Air IntakeAir Intake

Air Intake

Cubic feet per minute

Liters per minute

600

17000 710

20100 1050

29730 2000

56640

1900

53800 5000

141750 5600

158800

- 11 -

Site (Water-cooled units)Site (Water-cooled units)

Site (Water-cooled units)Site (Water-cooled units)

Site (Water-cooled units)The unit should be located in a laboratory or clean industrial environmentwith

easy access to a facility cooling water supply and a drain.

All units are equipped with castors for easy movement. This allows the unit

to be placed in a small area, as long as there is ample space for the unit to

be moved for access on all four sides. A minimum access clearance of 3

feet (1 meter) on two adjacent sides is recommended.

The facility cooling water supply must meet or exceed the requirements

listed in the table shown on the next page for the unit to operate at its full

rated capacity. If the facility cooling water does not meet these standards,

the cooling capacity will be derated.

As the temperature of the cooling water supply increases, the required flow

rate and pressure of the cooling water supply increases. For example, with a

model HX-150, if the temperature of the cooling water supply is +65°F, the

flow rate must be at least 1.5 gallons per minute, with a pressure differential

of at least 3.5 PSI. However, if the temperature of the cooling water supply is

+85°F, the flow rate must be at least 4.0 gallons per minute, with a pressure

differential of at least 10 PSI.

If the unit is being used with a building water supply, the back pressure of

the drain must be less than the supply pressure.

A water regulating valve, located in the TAP WATER line, regulates the flow

rate of the cooling water supply as it enters the unit. The valve regulates the

flow rate based on the heat load. Flow through the unit stops automatically

when the unit is shut off.

- 12 -

*Estimatedvalues

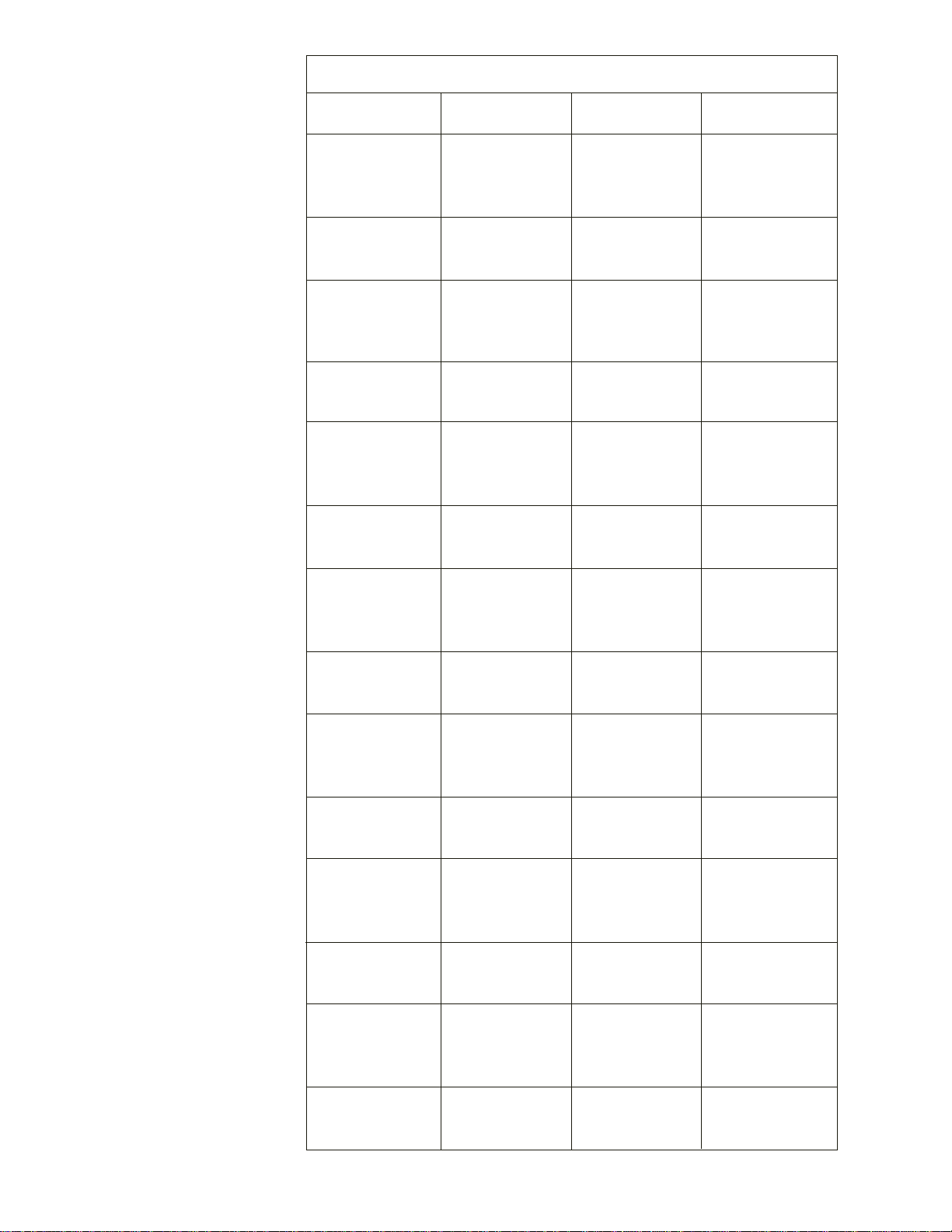

Temperature of cooling water supplyTemperature of cooling water supply

Temperature of cooling water supplyTemperature of cooling water supply

Temperature of cooling water supply

+55°F (+13°C)+55°F (+13°C)

+55°F (+13°C)+55°F (+13°C)

+55°F (+13°C) +65°F (+18°C)+65°F (+18°C)

+65°F (+18°C)+65°F (+18°C)

+65°F (+18°C) +75°F (+24°C)+75°F (+24°C)

+75°F (+24°C)+75°F (+24°C)

+75°F (+24°C) +85°F (+29°C)+85°F (+29°C)

+85°F (+29°C)+85°F (+29°C)

+85°F (+29°C)

HX-75HX-75

HX-75HX-75

HX-75

Flow RateFlow Rate

Flow RateFlow Rate

Flow Rate

Gallons per minute

Liters per minute

Pressure DropPressure Drop

Pressure DropPressure Drop

Pressure Drop

PSI

Bar

HX-100HX-100

HX-100HX-100

HX-100

Flow RateFlow Rate

Flow RateFlow Rate

Flow Rate

Gallons per minute

Liters per minute

Pressure DropPressure Drop

Pressure DropPressure Drop

Pressure Drop

PSI

Bar

HX-150HX-150

HX-150HX-150

HX-150

Flow RateFlow Rate

Flow RateFlow Rate

Flow Rate

Gallons per minute

Liters per minute

Pressure DropPressure Drop

Pressure DropPressure Drop

Pressure Drop

PSI

Bar

HX-200HX-200

HX-200HX-200

HX-200

Flow RateFlow Rate

Flow RateFlow Rate

Flow Rate

Gallons per minute

Liters per minute

Pressure DropPressure Drop

Pressure DropPressure Drop

Pressure Drop

PSI

Bar

HX-300HX-300

HX-300HX-300

HX-300

Flow RateFlow Rate

Flow RateFlow Rate

Flow Rate

Gallons per minute

Liters per minute

Pressure DropPressure Drop

Pressure DropPressure Drop

Pressure Drop

PSI

Bar

HX-500HX-500

HX-500HX-500

HX-500

Flow RateFlow Rate

Flow RateFlow Rate

Flow Rate

Gallons per minute

Liters per minute

Pressure DropPressure Drop

Pressure DropPressure Drop

Pressure Drop

PSI

Bar

HX-750HX-750

HX-750HX-750

HX-750

Flow RateFlow Rate

Flow RateFlow Rate

Flow Rate

Gallons per minute

Liters per minute

Pressure DropPressure Drop

Pressure DropPressure Drop

Pressure Drop

PSI

Bar

0.7* 1.0 1.5 3.0

2.8* 3.7 5.7 11.4

1.5* 2.0 3.5 8.0

0.10* 0.13 0.24 0.55

1.0* 1.5 2.0 3.5

3.7* 5.7 7.6 13.2

2.0* 3.5 5.0 10.0

0.13* 0.24 0.34 0.69

1.0* 1.5 2.5 4.0

3.7* 5.7 9.5 15.1

2.0* 3.5 6.0 10.0

0.13* 0.24 0.41 0.69

1.8* 2.5 3.5 6.0

6.8* 9.5 13.2 22.7

5.0* 6.0 7.0 18.0

0.34* 0.41 0.48 1.24

2.5* 4.0 6.5 11.0

9.5* 15.1 24.6 41.6

6.0* 8.0 13.5 25.0

0.41* 0.55 0.93 1.72

3.5 5.0 8.0 16.0

13.2 18.9 30.3 60.6

13.0 17.0 23.0 57.0

0.89 1.17 1.58 3.93

6.0 8.0 12.5 16.6

22.7 30.3 47.3 62.8

14.0 20.0 28.5 40.0

0.96 1.38 1.96 2.76

- 13 -

Electrical RequirementsElectrical Requirements

Electrical RequirementsElectrical Requirements

Electrical Requirements Refer to the table below to determine electrical requirements of your unit.

Verify the requirements by reviewing the ratings listed on the serial number

label on the rear of the case top or rear of analog temperature controller.

HX-75HX-75

HX-75HX-75

HX-75 HX-100HX-100

HX-100HX-100

HX-100 HX-150HX-150

HX-150HX-150

HX-150

208/230

60

3

200/220 380/420

50 50

3 3

208/230 380/420

60 50

3 3

N/A

VoltsVolts

VoltsVolts

Volts

HertzHertz

HertzHertz

Hertz

PhasePhase

PhasePhase

Phase

PlugPlug

PlugPlug

Plug

HX-200HX-200

HX-200HX-200

HX-200 HX-300HX-300

HX-300HX-300

HX-300 HX-500HX-500

HX-500HX-500

HX-500 HX-750HX-750

HX-750HX-750

HX-750

208/230 220/240

60

50

1 1

NEMA L6-30P or L6-20P

VoltsVolts

VoltsVolts

Volts

HertzHertz

HertzHertz

Hertz

PhasePhase

PhasePhase

Phase

PlugPlug

PlugPlug

Plug NEMA L15-30P or L16-20P

Make sure the voltage of the power source agrees with the unit’s voltage and

frequency rating. The unit is designed to tolerate deviations of ±10% from

the rated line voltage.

Models HX-75 through HX-300 have an 8 foot (2.4 meter) power cord

installed on the unit at the time of shipment.

NOTE:NOTE:

NOTE:NOTE:

NOTE: Custom units equipped with heaters may not have a power cord. See

Section VI, Special Features.

PowerCord(HX-75thruHX-300)

ElectricalConnection

(HX-500 &HX-750)

- 14 -

The unit construction provides extra protection against the risk ofThe unit construction provides extra protection against the risk of

The unit construction provides extra protection against the risk ofThe unit construction provides extra protection against the risk of

The unit construction provides extra protection against the risk of

electric shock by grounding appropriate metal parts. The extraelectric shock by grounding appropriate metal parts. The extra

electric shock by grounding appropriate metal parts. The extraelectric shock by grounding appropriate metal parts. The extra

electric shock by grounding appropriate metal parts. The extra

protection may not function unless the power cord is connected to aprotection may not function unless the power cord is connected to a

protection may not function unless the power cord is connected to aprotection may not function unless the power cord is connected to a

protection may not function unless the power cord is connected to a

properly grounded outlet. It is the user’s responsibility to assure aproperly grounded outlet. It is the user’s responsibility to assure a

properly grounded outlet. It is the user’s responsibility to assure aproperly grounded outlet. It is the user’s responsibility to assure a

properly grounded outlet. It is the user’s responsibility to assure a

proper ground connection is provided.proper ground connection is provided.

proper ground connection is provided.proper ground connection is provided.

proper ground connection is provided.

Models HX-500 and HX-750 are supplied with a disconnect box. Installation

of the cable is the user’s responsibility. Wire the unit in conformance to

local, state, and federal electrical codes. Double check all wiring to make

sure it is properly connected and protected from the elements.

Models HX-200 through HX-750 are equipped with a compressor crankcase

heater. The crankcase heater warms the oil in the compressor and prevents

refrigerant from mixing with the oil. Before start up, the unit must be

connected to its power source for at least 12 hours. This allows time for the

oil to be heated and separate from the refrigerant.

PlumbingPlumbing

PlumbingPlumbing

Plumbing

RequirementsRequirements

RequirementsRequirements

Requirements Air-cooled and water-cooled unitsAir-cooled and water-cooled units

Air-cooled and water-cooled unitsAir-cooled and water-cooled units

Air-cooled and water-cooled units

Before installing the unit to an instrument that previously used tap water as a

cooling fluid, flush the instrument several times to remove any rust or scale

that has built up. Consult the manufacturer of the instrument for a cleaning

fluid recommendation.

The plumbing fittings used to connect the HX to the instrument being cooled

are located on the right side of the unit (labelled SUPPLY and RETURN).

These connections are ¾inch FPT.

Remove the protective plugs from the SUPPLY and RETURN connections.

Connect the SUPPLY fitting to the inlet of the instrument being cooled.

Connect the RETURN fitting to the outlet of the instrument being cooled.

The RESERVOIR DRAIN connection on the rear of the unit is a ½inch FPT

fitting connected internally to the unit’s fluid reservoir. This fitting provides a

means for draining the reservoir. The unit is shipped with a ½inch MPT plug

installed in this fitting. Remove the plug to drain the reservoir.

- 15 -

Two plumbing adapters (¾inch MPT x 5/8 inch hose) are included with the

unit. If the unit is being plumbed to the instrument being cooled using flexible

tubing, install the adapters in the SUPPLY and RETURN plumbing ports. To

prevent leaking, wrap the threads of the adapters with Teflon®sealing tape

before installing them in the plumbing ports. The adapters will accept ½or 5/8

inch ID flexible tubing.

If the unit is "hard plumbed”to the instrument being cooled or to the cooling

water supply, damage can occur if the unit is bumped or jolted from its site.

Provisions should be made to prevent the unit from being moved after

installation. Once the unit is plumbed, secure the locking castors on the

unit’s base. If the unit is located in a heavy traffic area where the possibility

of collision is imminent, it may be necessary to secure the unit to the site

using blocks or mounting brackets.

Flexible tubing, if used, should be heavy wall or reinforced construction. All

tubing should be rated to withstand 110 psi at +35°C. Make sure all tubing

connections are securely clamped. Avoid running tubing near radiators, hot

water pipes, etc. If substantial lengths of tubing are necessary, insulation

may be required to prevent loss of cooling capacity.

Tubing and insulation are available from NESLAB. Contact our Sales

Department for more information (see Preface, After-sale Support).

It is important to keep the distance between the unit and the instrument

being cooled as short as possible, and to use the largest diameter tubing

practical. Tubing should be straight and without bends. If diameter

RESERVOIRDRAIN

SUPPLY

RETURN

- 16 -

reductions must be made, they should be made at the inlet and outlet of the

instrument being cooled, not at the HX.

If substantial lengths of connecting tubing are required, they should be

pre-filled with cooling fluid before connecting them to the unit.

Water-cooled unitsWater-cooled units

Water-cooled unitsWater-cooled units

Water-cooled units

The plumbing connections used to connect the water-cooled condenser in

the HX to the facility cooling water supply are located at the rear of the unit

(labelled TAP WATER and DRAIN). On models HX-75 through HX-300,

these fittings are ½inch FPT. On models HX-500 and HX-750, these fittings

are 1 inch FPT.

Remove the plastic protective plugs from the TAP WATER and DRAIN

connections. Connect the TAP WATER fitting to the facility cooling water

supply. Connect the DRAIN fitting to a drain.

FluidsFluids

FluidsFluids

Fluids The selected cooling fluid must have a viscosity of 50 centistokes or less at

the lowest operating temperature.

Never use flammable or corrosive fluids with this unit. Distilled andNever use flammable or corrosive fluids with this unit. Distilled and

Never use flammable or corrosive fluids with this unit. Distilled andNever use flammable or corrosive fluids with this unit. Distilled and

Never use flammable or corrosive fluids with this unit. Distilled and

deionized water may be aggressive and cause material corrosion.deionized water may be aggressive and cause material corrosion.

deionized water may be aggressive and cause material corrosion.deionized water may be aggressive and cause material corrosion.

deionized water may be aggressive and cause material corrosion.

Please contact NESLAB before subjecting this unit to prolongedPlease contact NESLAB before subjecting this unit to prolonged

Please contact NESLAB before subjecting this unit to prolongedPlease contact NESLAB before subjecting this unit to prolonged

Please contact NESLAB before subjecting this unit to prolonged

exposure to distilled or deionized water.exposure to distilled or deionized water.

exposure to distilled or deionized water.exposure to distilled or deionized water.

exposure to distilled or deionized water.

Tap water is the recommended fluid for operation from +8°C to +35°C.

Below +8°C, a non-freezing solution is required. A 50/50 mixture, by

volume, of water and laboratory grade ethylene glycol is suggested.

Do not use automobile anti-freeze. Commercial anti-freeze containsDo not use automobile anti-freeze. Commercial anti-freeze contains

Do not use automobile anti-freeze. Commercial anti-freeze containsDo not use automobile anti-freeze. Commercial anti-freeze contains

Do not use automobile anti-freeze. Commercial anti-freeze contains

silicates that can damage the pump seals. Use of automobilesilicates that can damage the pump seals. Use of automobile

silicates that can damage the pump seals. Use of automobilesilicates that can damage the pump seals. Use of automobile

silicates that can damage the pump seals. Use of automobile

anti-freeze will void the manufacturer’s warranty.anti-freeze will void the manufacturer’s warranty.

anti-freeze will void the manufacturer’s warranty.anti-freeze will void the manufacturer’s warranty.

anti-freeze will void the manufacturer’s warranty.

For units with extended temperature ranges above +35°C, tap water is the

recommended fluid up to +80°C. Above +80°C, the user is responsible for

the fluid(s) used.

- 17 -

FillingFilling

FillingFilling

Filling

RequirementsRequirements

RequirementsRequirements

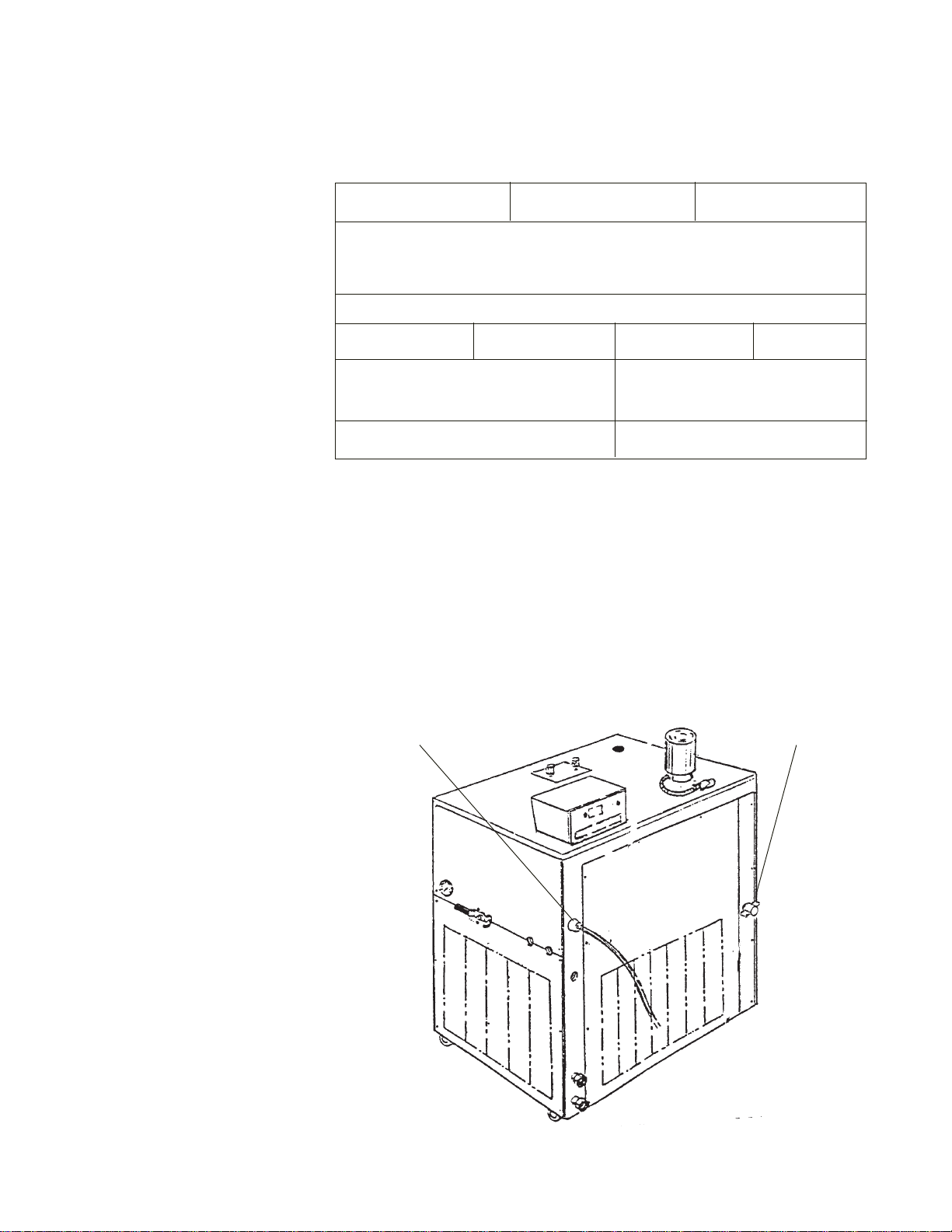

Requirements The reservoir cover is located at the left corner of the case top. Loosen the

thumbscrews and remove the reservoir cover.

Fill the fluid reservoir with cooling fluid to within 1 inch of the top.

The fluid capacity of the instrument being cooled and the recirculation lines

may be significant. To prevent the lowering of the fluid level in the reservoir

below the operating level, have extra cooling fluid on hand to keep the

reservoir filled to within 1 inch of the top.

When the recirculating system is full, replace the reservoir cover.

ReservoirCover

Thumbscrews

Pump PurgingPump Purging

Pump PurgingPump Purging

Pump Purging Models HX-100 through HX-300 with a CP-55 pump may require pump

purging. Refer to the pump identification label on the rear of the control box

to identify the specific pump in your unit.

Pump purging is necessary to purge air trapped in the pump head cavity.

Once the unit is started, open the flow control valve (see Section V, Flow

Control). It there is no flow in the SUPPLY line, or if the flow is restricted,

purging is necessary (see Section 11, Pumps to review the pump flow and

pressure specifications).

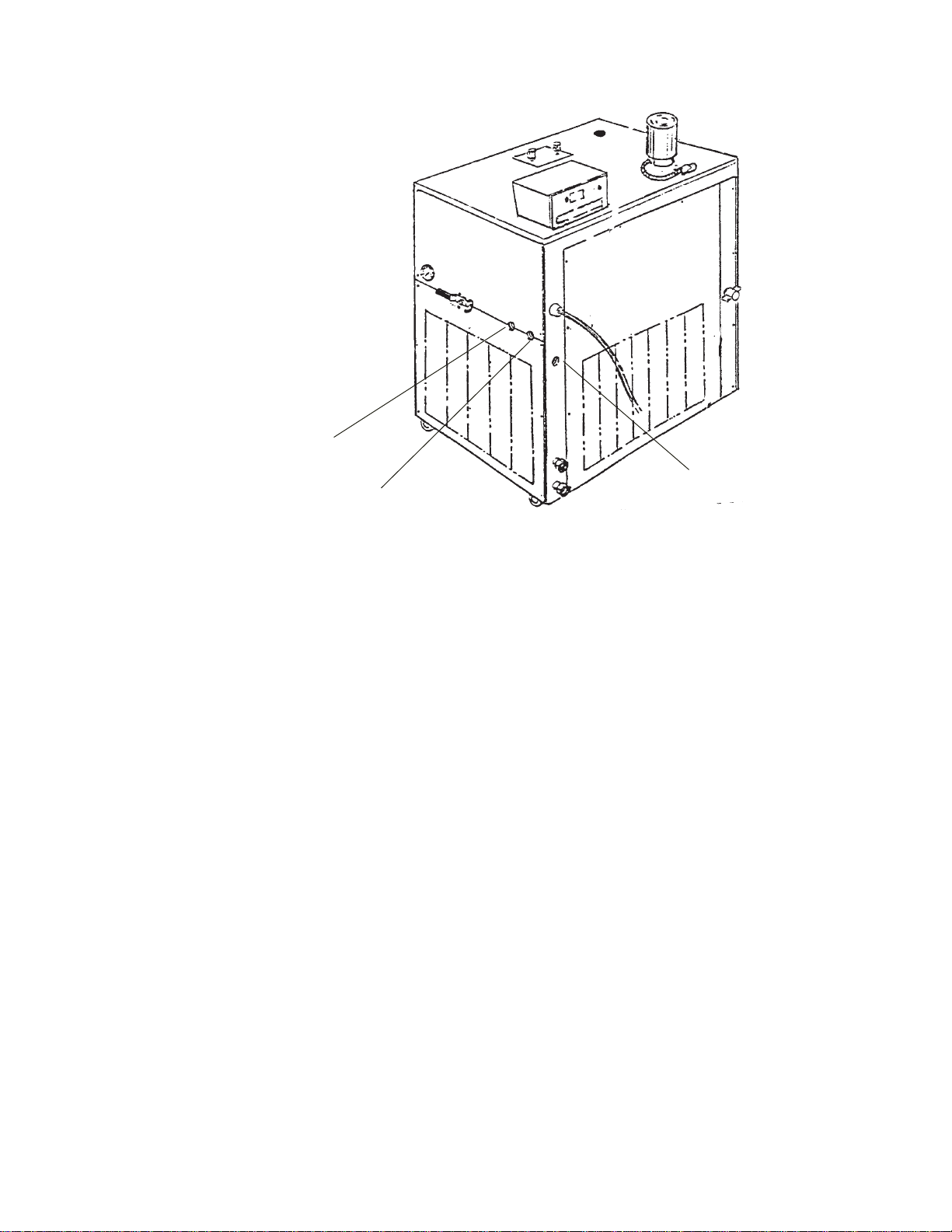

Place a container directly under the purge valve, located on the right side of

the unit, above the SUPPLY and RETURN connections. Start the unit and

open the flow control valve. Turn the PURGE valve about 1/4 clockwise.

After a few moments, cooling fluid should flow from the purge valve.

Once flow is established, close the PURGE valve and the flow control valve.

The pump is now purged and the unit is ready for operation.

Purgevalve

- 18 -

Section IV OperationSection IV Operation

Section IV OperationSection IV Operation

Section IV Operation

Start UpStart Up

Start UpStart Up

Start Up Before starting, check all electrical and plumbing connections and make sure

the recirculating system (the HX, your application, and the recirculation lines)

has been properly filled with cooling fluid.

For water-cooled units — ensure that the facility water is turned on.For water-cooled units — ensure that the facility water is turned on.

For water-cooled units — ensure that the facility water is turned on.For water-cooled units — ensure that the facility water is turned on.

For water-cooled units — ensure that the facility water is turned on.

Models HX-200 through HX-750 are equipped with a compressor crankcase

heater. The crankcase heater warms the oil in the compressor and prevents

refrigerant from mixing with the oil. Before start up, the unit must be

connected to its power source for at least 12 hours. This allows time for the

oil to be heated and separate from the refrigerant.

To start the unit, place the Power On/Off switch in the On position. The

pump and refrigeration system will start, and the POWER indicator will light.

After starting recheck the fluid level, a "top off" may be needed. To shut the

unit off, place the Power switch in the Off position.

When the unit is shut off, wait approximately 5 minutes before restarting.

This allows time for the refrigeration pressures to equalize. If the pressures

are not allowed to equalize, the compressor will short-cycle (clicking sound)

and no cooling will occur.

Refrigeration ControlRefrigeration Control

Refrigeration ControlRefrigeration Control

Refrigeration Control Turn the calibrated dial until the desired temperature aligns with the

reference line.

The refrigeration compressor runs continuously, unless the fluid temperature

exceeds +40°C. A hot gas by-pass system is used to maintain constant

temperature in all units.

The HEAT and COOL indicators, located on the control panel, indicate the

status of the refrigeration system. The HEAT indicator is lit when the unit is

in the hot gas by-pass mode. The COOL indicator is lit when the refrigeration

system is removing heat from the cooling fluid. As the fluid temperature

approaches the temperature setpoint, the indicators cycle on and off to

indicate the duty cycle of the system. The unit can be in COOL or HEAT, but

never both at the same time. A balance between COOL and HEAT controls

the temperature.

- 19 -

Flow ControlFlow Control

Flow ControlFlow Control

Flow Control The flow control handle is connected to a valve that controls the flow rate of

the cooling fluid to the instrument being cooled. The handle is located on the

right side of the unit and is labelled RECIRCULATING FLOW CONTROL.

When the handle is in the “+”position, the valve is open and all possible

cooling fluid is supplied to the instrument being cooled. When the handle is

in the “-”position, the valve is closed and no cooling fluid is supplied to the

instrument being cooled. When the handle is between these two positions,

the flow rate of the cooling fluid is between full flow and no flow. Use a flow

meter on the SUPPLY line to adjust the desired flow rate.

Never “crank”the valve wide open from the closed or slightly openNever “crank”the valve wide open from the closed or slightly open

Never “crank”the valve wide open from the closed or slightly openNever “crank”the valve wide open from the closed or slightly open

Never “crank”the valve wide open from the closed or slightly open

position.position.

position.position.

position.

Pressure GaugePressure Gauge

Pressure GaugePressure Gauge

Pressure Gauge Units with a PD-1, PD-2, or any TU type pump are equipped with a pressure

gauge. Refer to the pump identification label on the rear of the controller to

identify the specific pump in your unit. The RECIRCULATING PRESSURE

gauge is located next to the flow control handle. The gauge indicates the

operating pressure of the system.

FlowControlValve

RECIRCULATINGPRESSUREgauge

This manual suits for next models

7

Table of contents

Popular Chiller manuals by other brands

Carrier

Carrier Flotronic 30GB user manual

CIAT

CIAT LJ 65/75 manual

Galletti

Galletti LCX Series user manual

Fast Chiller

Fast Chiller TT3 user guide

York

York YCAL0043E Series Installation operation & maintenance

Carrier

Carrier AquaSnap 30RAP011-060 Controls, start-up, operation, service, and troubleshooting

ascon

ascon 4AC20C installation manual

AERMEC

AERMEC FCX Direction for use and installation

Thermo Scientific

Thermo Scientific thermoflex Installation, operation and maintanance

SMC Networks

SMC Networks HRSH100-A*-20 Series Operation manual

Scilogex

Scilogex SCIP5-20 operating instructions

1TAC

1TAC 1Hydro user manual