Trane CGAH 115 Owner's manual

Other Trane Chiller manuals

Trane

Trane RTAA-70 Operating and safety instructions

Trane

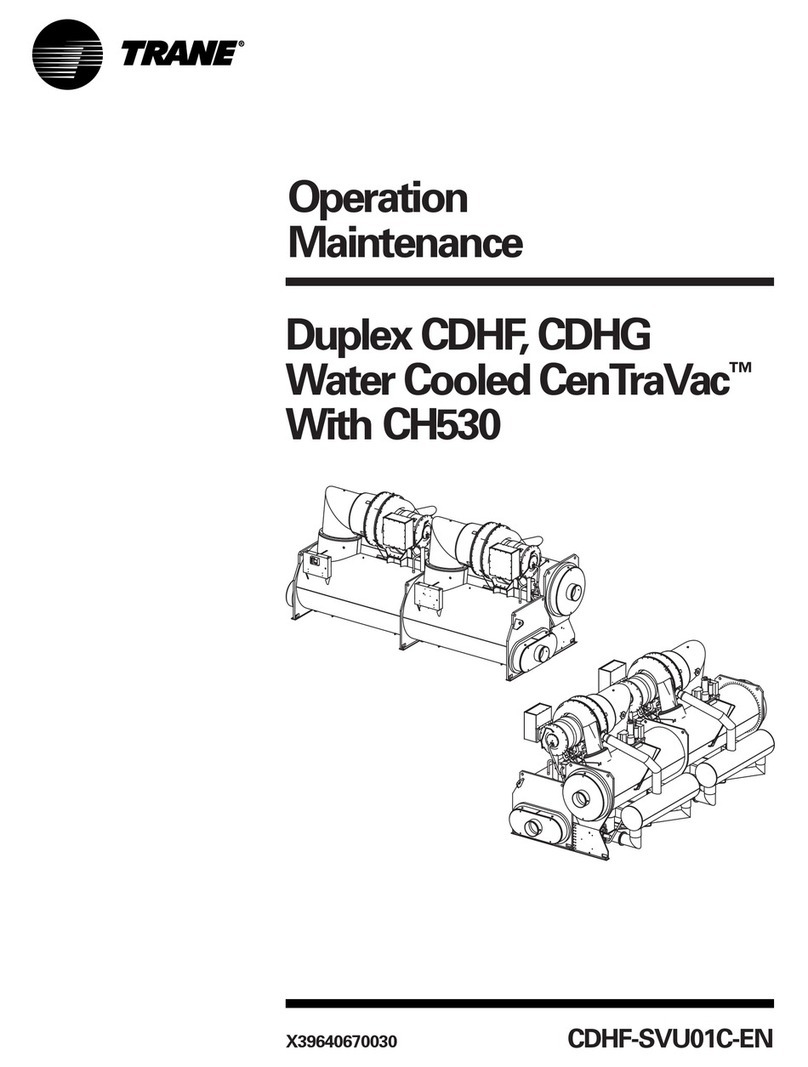

Trane CenTraVac Duplex CDHF Troubleshooting guide

Trane

Trane Thermafit TACW Installation and operating instructions

Trane

Trane TCK024B1 Owner's manual

Trane

Trane 4PXCBU36BS3HAC Assembly instructions

Trane

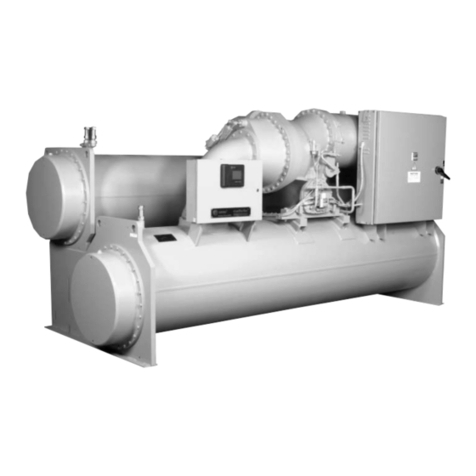

Trane CGWF Owner's manual

Trane

Trane CVGF500 Instruction manual

Trane

Trane CenTraVac Configuration guide

Trane

Trane AquaStream CGWN 205 Owner's manual

Trane

Trane R Series Guide

Trane

Trane SINTESIS ADVANTAGE CGAF Series Owner's manual

Trane

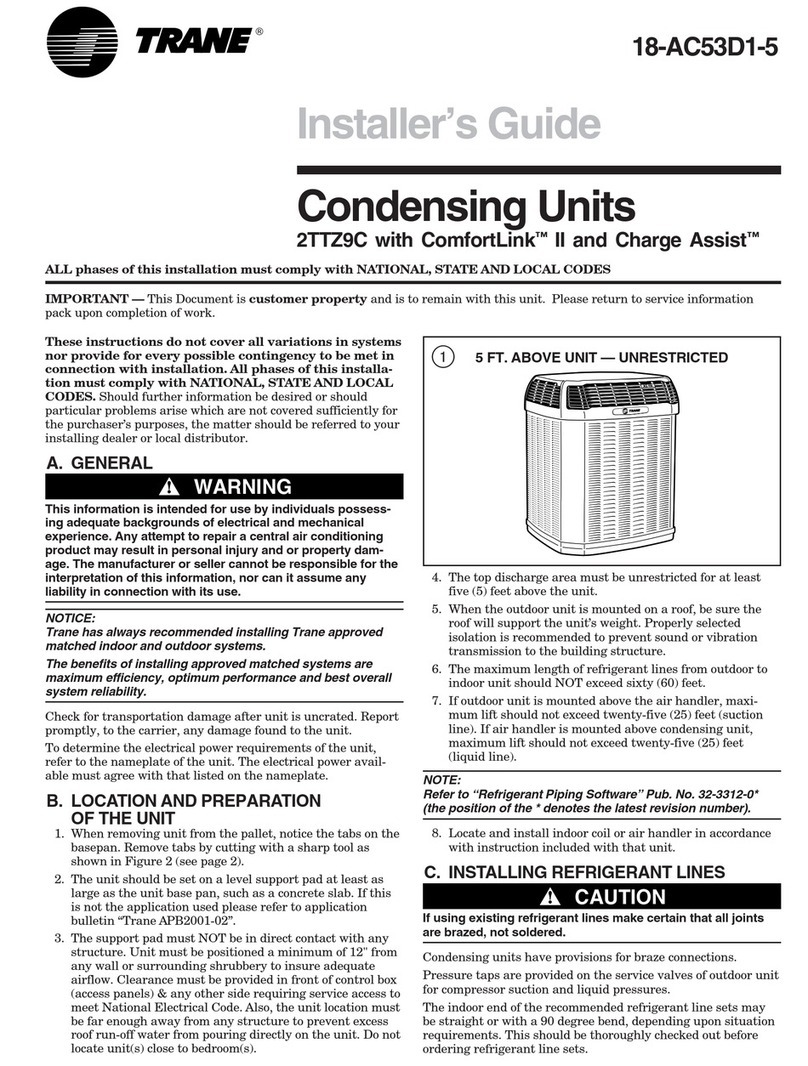

Trane 2TTZ9C Assembly instructions

Trane

Trane PRGD series Installation and operating instructions

Trane

Trane 4TXCB004DS3HCC Assembly instructions

Trane

Trane Maxxum HCCA Series Owner's manual

Trane

Trane CITY RTSF Series User manual

Trane

Trane 4YCZ5024F1060A User manual

Trane

Trane Manhattan Gen II Installation and operating instructions

Trane

Trane BAYGARD310 Series User manual

Trane

Trane R Series Owner's manual

Popular Chiller manuals by other brands

Aqua Optima

Aqua Optima Corona Instructions for use

York

York YGWH 115 Installation, commissioning & operation

Galletti

Galletti PERFORMA MPE Series Technical manual

SMC Networks

SMC Networks HRR Series manual

Daikin

Daikin EWAQ016CAW Installation and operation manual

Moffat

Moffat Friginox TSR-11SC Specification sheet