4

EFlow Kit Installation Guide

December 2017

GROW MORE WITH LESS®

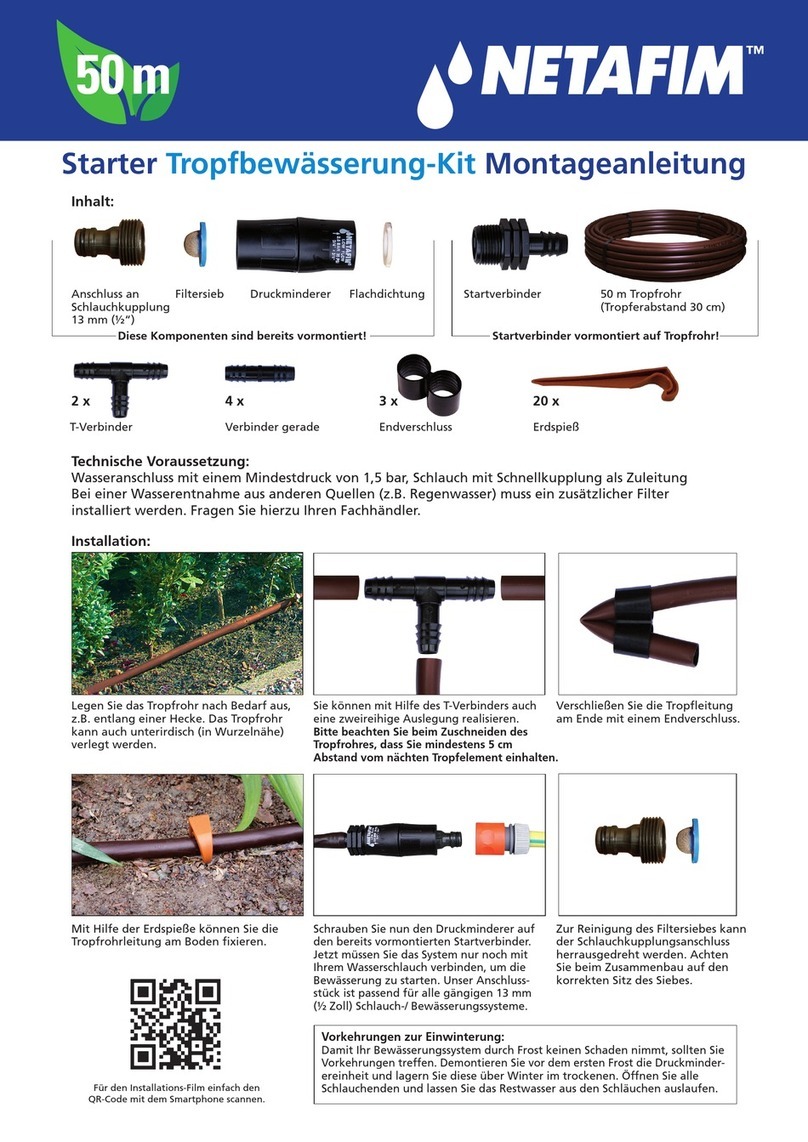

FILTER ASSEMBLY

The 25mm Arkal Disc Filter is used to protect the system from

contamination of debris. It has a 130 micron ltration element

inside that requires cleaning periodically (see maintenance and

servicing). The Techlter is also required to provide the system

with trace elements of Triuralin. This chemical prevents roots

from blocking drippers. A Techlter is not required for

EFlow CNL XR and EFlow AS XR kits.

1. Assuming the outlet of the treatment plant is a 25mm male

thread, use a 25mm ratchet clamp to connect the 25mm

LDPE to the treatment plant with the 25mm Nut & Tail tting.

2. Using the ratchet clamp again, connect the 25mm Arkal Disc

Filter (black) to the 25mm LDPE with 25mm Nut & Tail ttings.

3. Now use the ratchet clamp to connect the 25mm Techlter

(black) to 25mm LDPE using 25mm Nut & Tail ttings.

IMPORTANT:

The arrow on the lter indicates the direction of ow

Filters should be installed facing down as shown in illustration

The Arkal Disc Filter is to be installed upstream of Techlter

If installing multiple zones, tees are to be installed after the

ltration system (Tees are provided in the ‘Add-on’ kit only).

The lter system is to be contained within the rectangular

valve box provided.

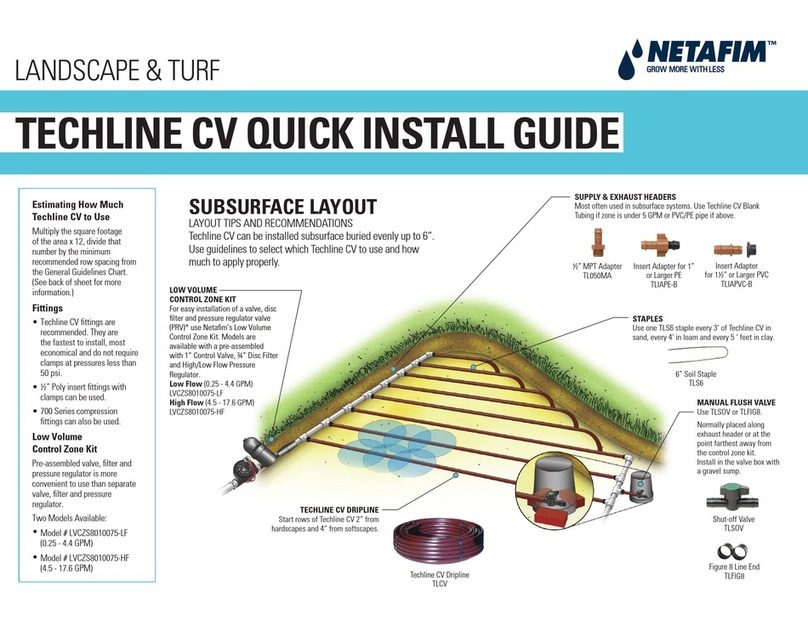

ZONE ASSEMBLY

1. Using the 25mm LDPE from the Filter Assembly, you need

to create a header assembly that runs perpendicular to the

dripperline. This will be buried below the surface in

Sub surface Dripperline Installations between

100mm and 200mm.

2. Attach the 25mm End Connectors to the end of the header

assembly using a 25mm ratchet clamp.

3. Using the punch tool, insert holes into the 25mm LPDE at lateral

spacings. With the ratchet clamp, attach the dripperline into

the Start Connectors and insert the tting into the hole on the

25mm LDPE. Ensure the tting and initial section of dripperline

remains perpendicular to the 25mm LDPE.

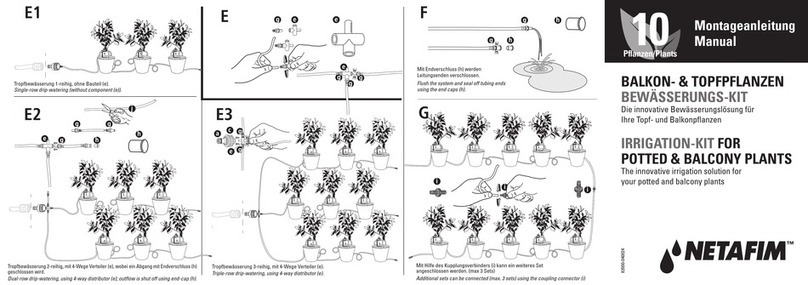

4. Using 25mm LDPE, install the Flush Manifold opposite the

header assembly.

5. Repeat the installation of Start Connectors between the

dripperline and LDPE for the Flush Manifold.

6. Insert the 25mm End Connectors at the highest end of the

Flush Manifold using a 25mm ratchet clamp.

FLUSH VALVE

The Flush Valve is used to clear any debris out of the system

during routine maintenance. The Flush Valve is located at the

lowest end of the Flush Manifold.

1. Screw the 25mm threaded elbow into the male Manual Flush

Valve. Be sure to apply thread tape (thread tape not provided).

2. Connect the threaded elbow to the 25mm LDPE Flush

Manifold using a 25mm ratchet clamp.

3. Install the Manual Flush Valve at 90° to the surface, ensuring

the lilac cap is level with the nish grade of the soil.

ASSEMBLY