Step 4. After a suspended ceiling

has been installed or the finish coat

has been applied to a fixed ceiling

(as applicable), slide on the outer

piece of the Escutcheon until it

comes in contact with the ceiling. Do

not lift the ceiling panel out of its nor-

mal position.

In the case of the outer piece of the

Deep Ceiling Escutcheon, hold the

outer piece in contact with the mount-

ing surface (ceiling), and then rotate

the inner piece approximately 1/4

turn with respect to the outer piece,

to hold the Deep Escutcheon firmly

together.

Care &

Maintenance

The Model S170 must be maintained

and serviced in accordance with the

following instructions:

NOTES

Absence of the outer piece of an es-

cutcheon, which is used to cover a

clearance hole, may delay the time

to sprinkler operation in a fire situ-

ation.

Before closing a fire protection sys-

tem main control valve for mainte-

nance work on the fire protection sys-

tem which it controls, permission to

shut down the affected fire protec-

tion systems must be obtained from

the proper authorities and all person-

nel who may be affected by this ac-

tion must be notified.

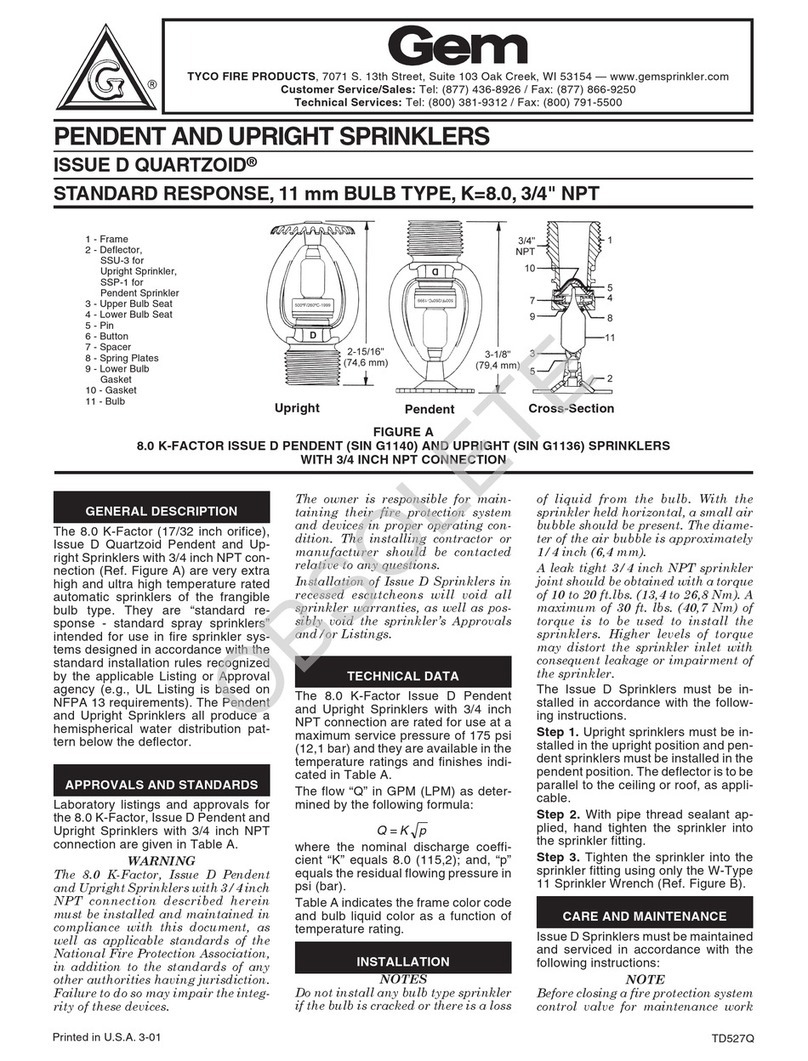

A Vent Hole is provided in the Bulb

Seat (Ref. Figure 2) to indicate if the

Dry Sprinkler is remaining dry. Evi-

dence of leakage from the Vent Hole

is an indication that there may be

weepage past the O-ring seal and,

therefore, it is an indication that the

sprinkler needs to be removed for de-

termining the cause of leakage (e.g.

an improper installation or an ice

plug). The fire protection system con-

trol valve must be closed and the

system drained before removing the

sprinkler.

Sprinklers which are found to be

leaking or exhibiting visible signs of

corrosion must be replaced.

Automatic sprinklers must never be

shipped or stored where their tem-

perature will exceed 100°F/38°C and

they must never be painted, plated,

coated, or otherwise altered after

leaving the factory. Modified sprin-

klers must be replaced. Sprinklers

that have been exposed to corrosive

products of combustion, but have not

operated, should be completely

cleaned by wiping the sprinkler with

a cloth or by brushing it with a soft

bristle brush.

Care must be exercised to avoid

damage - before, during, and after

installation. Sprinklers damaged by

dropping, striking, wrench twist/slip-

page, or the like, must be replaced.

Also, replace any sprinkler that has

a cracked bulb or that has lost liquid

from its bulb (Ref. Installation Sec-

tion).

The owner is responsible for the in-

spection, testing, and maintenance

of their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any

other authorities having jurisdiction.

The installing contractor or sprinkler

manufacturer should be contacted

relative to any questions.

It is recommended that automatic

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service.

Limited

Warranty

Products manufactured by Tyco Fire

Products are warranted solely to the

original Buyer for ten (10) years

against defects in material and work-

manship when paid for and properly

installed and maintained under nor-

mal use and service. This warranty

will expire ten (10) years from date

of shipment by Tyco Fire Products.

No warranty is given for products or

components manufactured by com-

panies not affiliated by ownership

with Tyco Fire Products or for prod-

ucts and components which have

been subject to misuse, improper in-

stallation, corrosion, or which have

not been installed, maintained, modi-

fied or repaired in accordance with

applicable Standards of the National

Fire Protection Association, and/or

the standards of any other Authori-

ties Having Jurisdiction. Materials

found by Tyco Fire Products to be de-

fective shall be either repaired or re-

placed, at Tyco Fire Products’ sole

option. Tyco Fire Products neither as-

sumes, nor authorizes any person to

assume for it, any other obligation in

connection with the sale of products

or parts of products. Tyco Fire Prod-

ucts shall not be responsible for

sprinkler system design errors or in-

accurate or incomplete information

supplied by Buyer or Buyer’s repre-

sentatives.

IN NO EVENT SHALL TYCO FIRE

PRODUCTS BE LIABLE, IN CON-

TRACT, TORT, STRICT LIABILITY

OR UNDER ANY OTHER LEGAL

THEORY, FOR INCIDENTAL, INDI-

RECT, SPECIAL OR CONSEQUEN-

TIAL DAMAGES, INCLUDING BUT

NOT LIMITED TO LABOR

CHARGES, REGARDLESS OF

WHETHER TYCO FIRE PRODUCTS

WAS INFORMED ABOUT THE POS-

SIBILITY OF SUCH DAMAGES,

ANDINNOEVENTSHALLTYCO

FIRE PRODUCTS’ LIABILITY EX-

CEED AN AMOUNT EQUAL TO THE

SALES PRICE.

THE FOREGOING WARRANTY IS

MADE IN LIEU OF ANY AND ALL

OTHER WARRANTIES EXPRESS

OR IMPLIED, INCLUDING WAR-

RANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICU-

LAR PURPOSE.

Ordering

Information

Ordering Information:

1. When placing an order, indicate

the full product name. Please include

the quantity, model, response charac-

teristic, style of escutcheon, tempera-

ture rating, finish, and order length.

Dry Sprinklers are furnished based

upon Order Length as measured

from the face of the ceiling to the

face of the sprinkler fitting in which

the individual sprinkler is to be in-

stalled. After the measurement is

taken, round it to the nearest 1/4

inch increment.

2. W-Type 7 Sprinkler Wrench.

Patents:

U.S.A. Patent Number 5,188,185 is

applicable to the Model S170 Dry

Pendent Sprinklers.

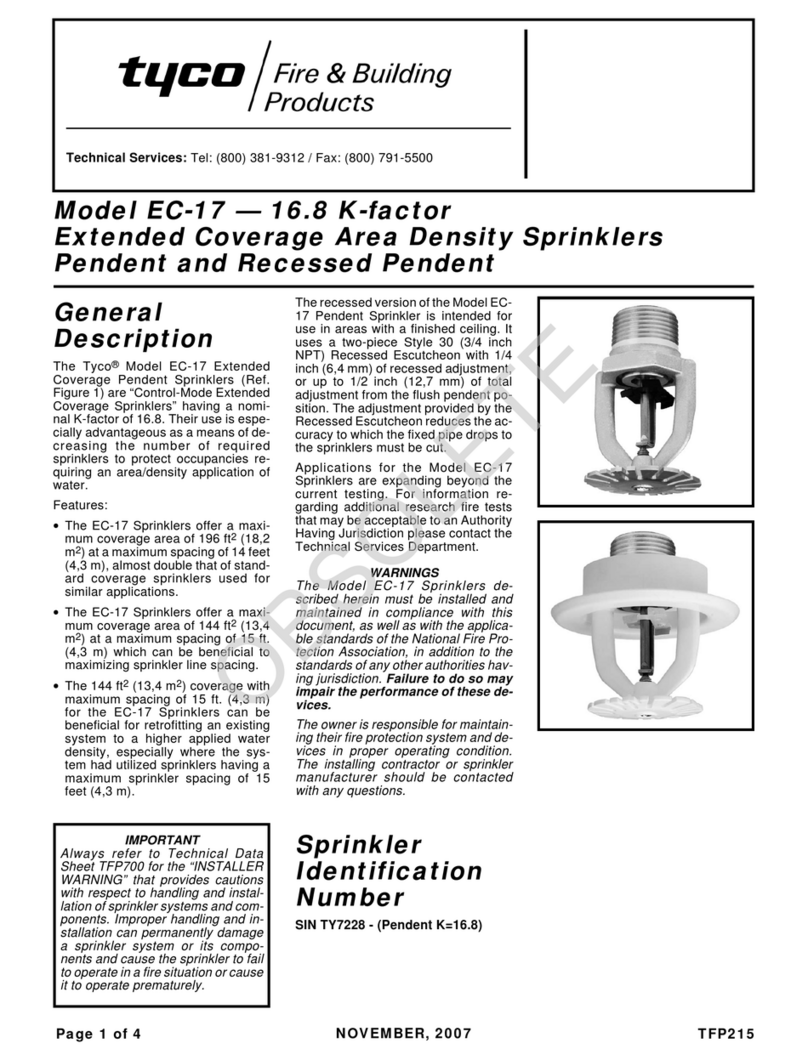

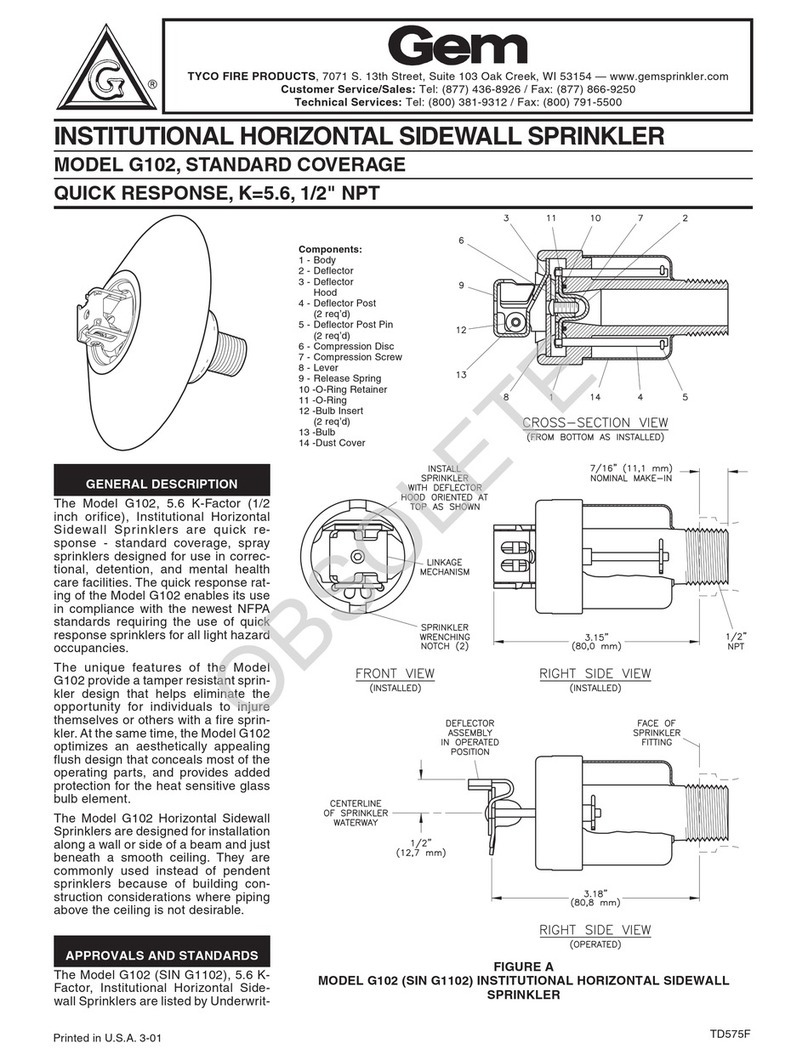

Figure 3

W-Type 7 Sprinkler

Wrench

RECESS

WREN

H

ENSURE ENGAGEMENT WITH

PUSH WRENCH IN TO

SPRINKLER WREN

HIN

AREA

Printed in U.S.A. 3-01