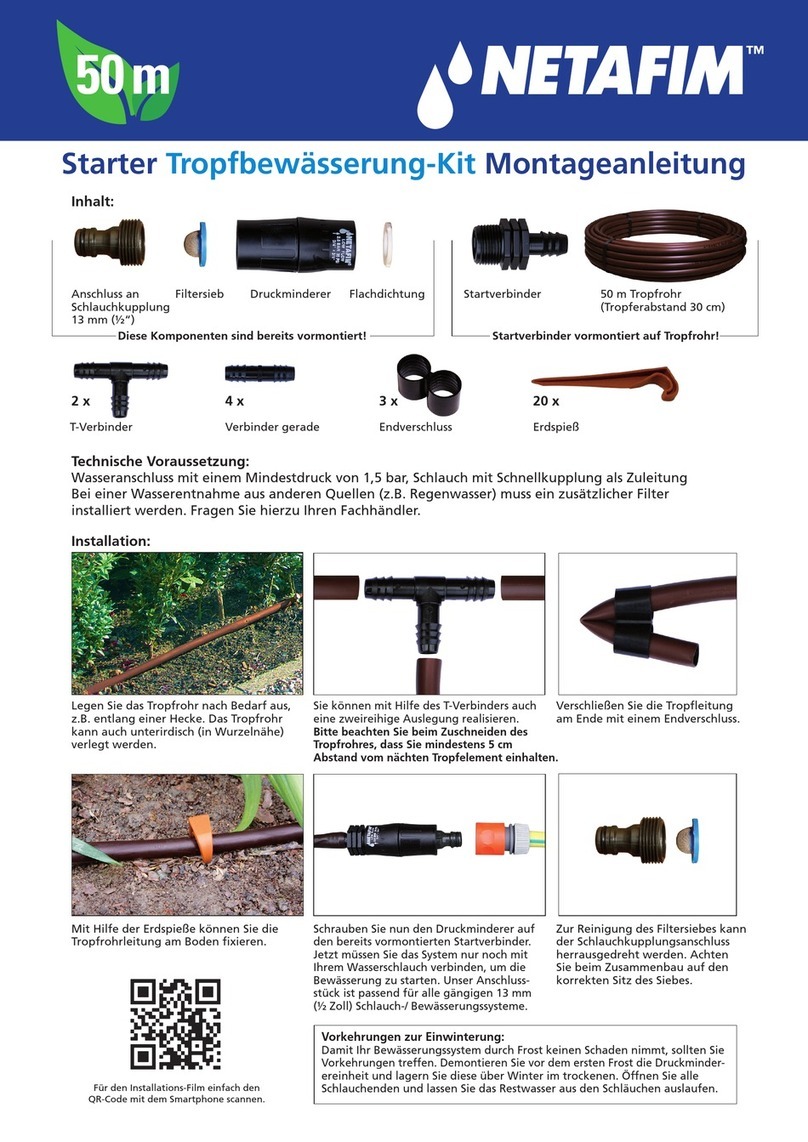

Netafim TECHLINE AS Guide

Other Netafim Irrigation System manuals

Netafim

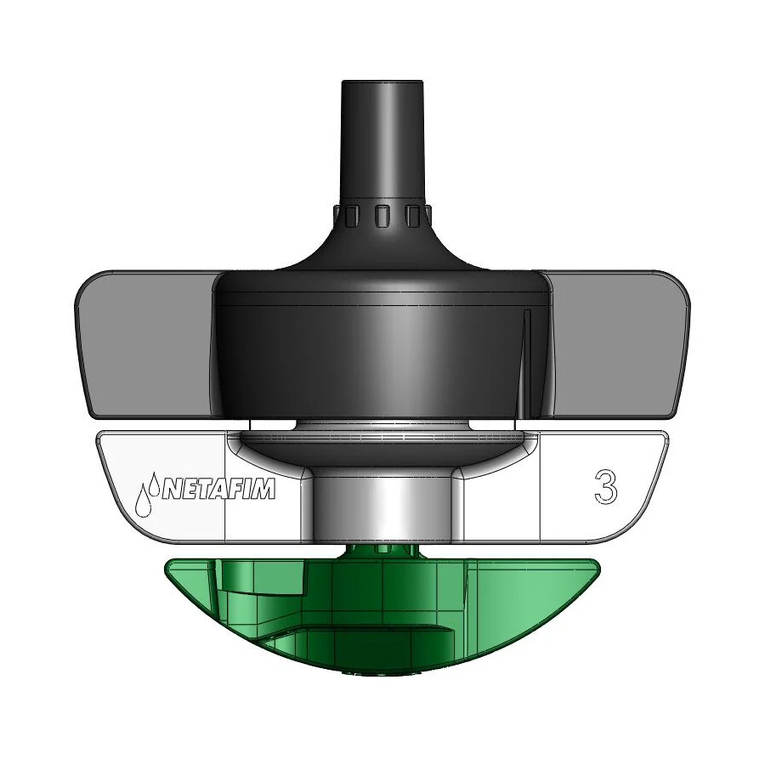

Netafim GYRONET TURBO User manual

Netafim

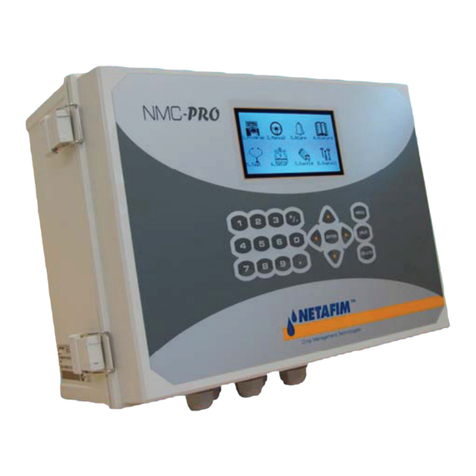

Netafim nmc-pro User manual

Netafim

Netafim EFLOW CNL XR User manual

Netafim

Netafim D-Net 6550 User manual

Netafim

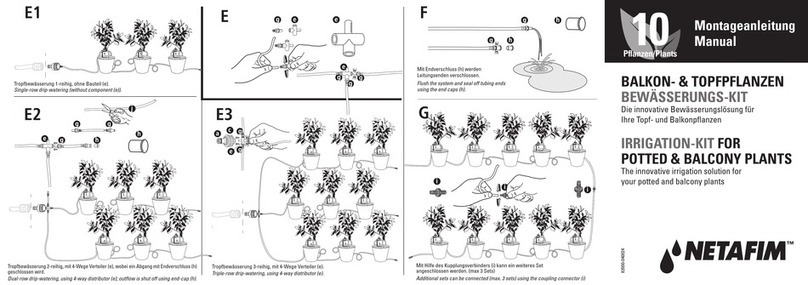

Netafim SMART & GREEN 429854 User manual

Netafim

Netafim NETBEAT User manual

Netafim

Netafim SPINNET User manual

Netafim

Netafim D-Net 8550 User manual

Netafim

Netafim nmc-pro User manual

Netafim

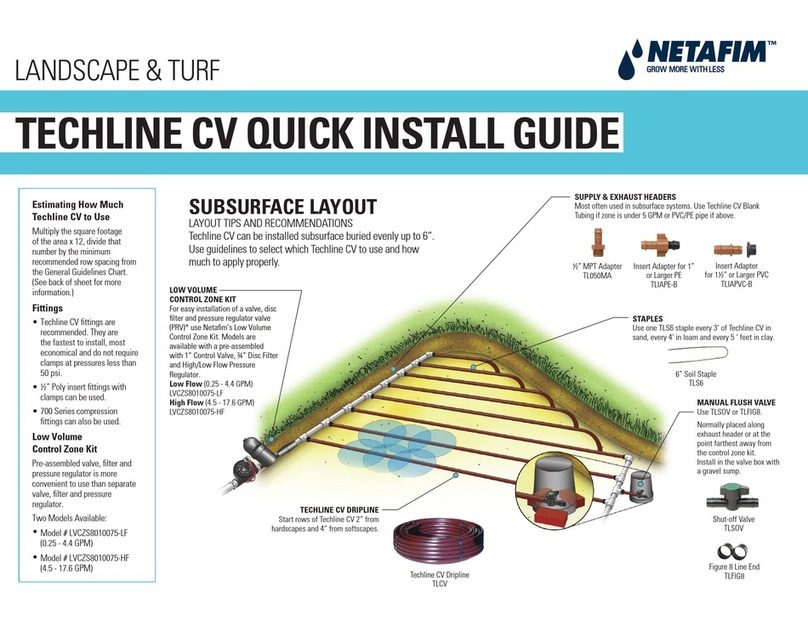

Netafim TECHLINE CV User manual

Popular Irrigation System manuals by other brands

Tyco Fire Product

Tyco Fire Product Star Galaxy SGQR instruction manual

Tyco Fire Product

Tyco Fire Product CENTRAL A instruction manual

Oral Care Technologies

Oral Care Technologies Hydro Floss Instructions for use

Reliable

Reliable F1-300 quick start guide

Tyco Fire Product

Tyco Fire Product Gem F892 instruction manual

Irrigation-Mart

Irrigation-Mart KIT-GK100-RV-B quick start guide