UPSIDE-DOWN MICRO-EMITTERS HANDBOOK 9

MICRO-SPRINKLER/EMITTER SELECTION

B. Water distribution uniformity

It is of vital importance that the irrigation water is distributed as evenly as possible throughout the irrigated

area. Properly designed micro-sprinklers/emitters enable greater distribution uniformity.

• Good distribution uniformity contributes to

higher yield and a higher quality crop.

• Poor distribution uniformity reduces yield and

crop quality and may damage the soil/substrate.

Netafim™ conducts rigorous tests to assess the distribution uniformity capacity of its micro-sprinklers/

emitters. The following is a brief summary of these testing procedures.

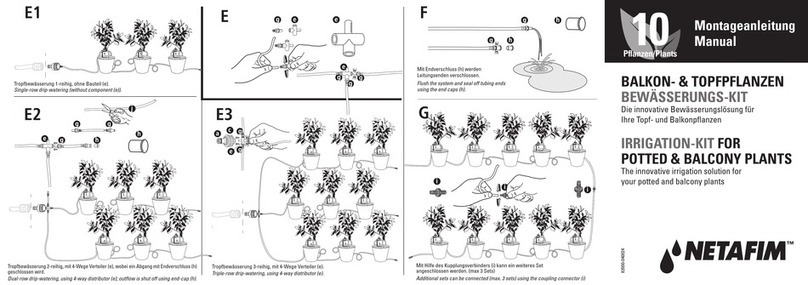

The water distribution uniformity survey: Setup and data collection

1.

A 4 X 4 micro-sprinklers/emitters grid (16 micro-sprinklers/emitters) is set up according to the planned

layout - spacing between micro-sprinklers/emitters

in the same distribution pipe and spacing between

distribution pipes.

ATTENTION

The survey must be conducted on a flat,

leveled and obstruction-free area.

Nine rectangular areas, each defined by 4 micro-

sprinklers/emitters at its four corners are produced.

2.

The center area is selected and a grid pattern

of rain gauges or catch cans is set up, with the

following distances between them each-

• 0.5 meter or less on both axes for

micro-sprinklers/emitters (flow rate ≥ 30 l/h)

• 0.25 meter or less on both axes for

micro-sprinklers/emitters (flow rate < 30 l/h)

ATTENTION

All the catch cans must be identical and placed in a leveled and stable position.

3.

The system is operated for 1 hour under normal operating conditions.

ATTENTION

The effect of wind on distribution uniformity is unpredictable.

For an accurate measurement, the system must not be operated under windy conditions.

4.

The level of the water collected in each gauge or can is measured and their results (in mm) noted as a

list, from the highest to the lowest.

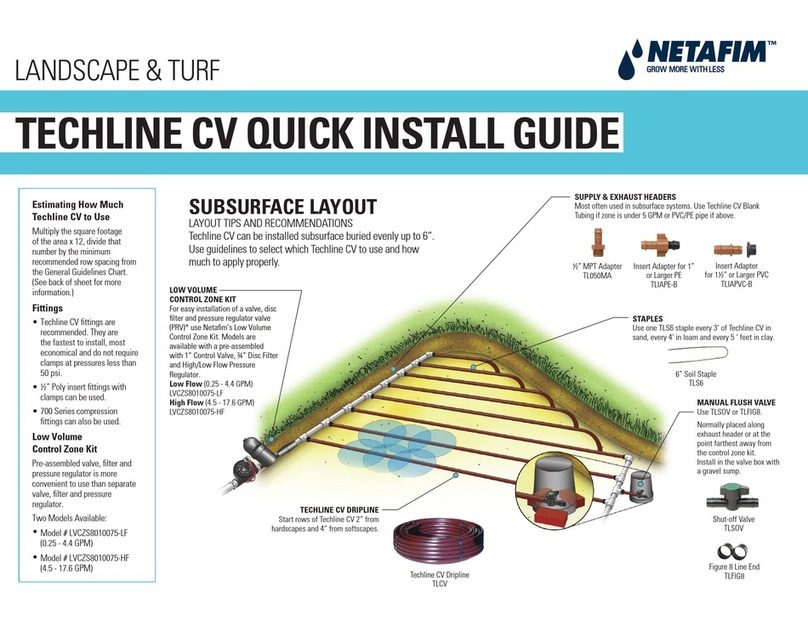

Emitter

Catch cans

Distribution

pipe