CONTENTS

STANDARD ACCESSORIES ..................................................................................................................................... 1

OPTIONALS ................................................................................................................................................................ 1

SAFETY PRECAUTIONS .......................................................................................................................................... 2

PRIOR TO USE............................................................................................................................................................................2

SAFETY SYMBOLS ....................................................................................................................................................................2

NOTATIONS USED IN THE INSTRUCTION MANUAL....................................................................................... 4

NOTATIONS.................................................................................................................................................................................4

INFORMATIONAL NOTES .......................................................................................................................................................4

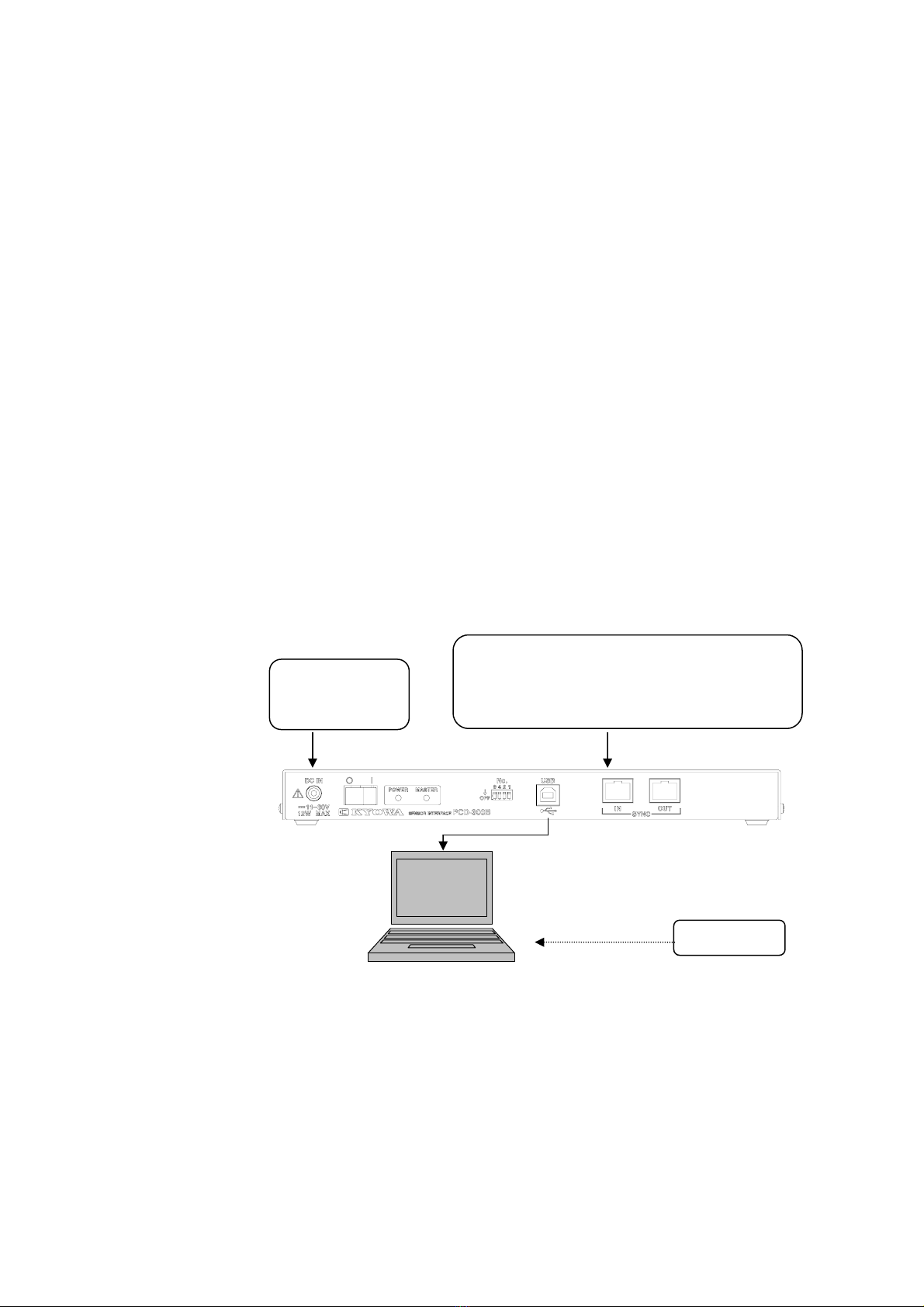

1. OUTLINE OF THE PRODUCT ............................................................................................................................. 5

1-1 OUTLINE OF THE PRODUCT ...........................................................................................................................................5

1-2 SYSTEM CONFIGURATION ..............................................................................................................................................6

2-1 FRONT PANEL......................................................................................................................................................................7

2-2 REAR PANEL ........................................................................................................................................................................8

3. SYSTEM INSTALLATION................................................................................................................................... 10

3-1 CONNECTING AC POWER SUPPLY ..............................................................................................................................10

3-2 CONNECTING DC POWER SUPPLY ..............................................................................................................................11

3-3 SETTING PCD NO. .............................................................................................................................................................12

3-4 CONNECTING SENSORS..................................................................................................................................................14

3-4-1 Input Adapter Types and Features...............................................................................................................................14

3-4-2 Input Adapter Connection Method ..............................................................................................................................15

3-4-3 Connection Method .......................................................................................................................................................17

3-5 MOUNTING/DEMOUNTING INPUT ADAPTER ...........................................................................................................20

3-6 CONNECTING MULTIPLE PCD-300B UNITS ...............................................................................................................21

3-7 CONNECTING TO THE PC...............................................................................................................................................22

3-8 POWER ON/OFF.................................................................................................................................................................23

3-9 INSTALLILNG USB DRIVER............................................................................................................................................23

3-10 SELF TEST.........................................................................................................................................................................23

4.TROUBLESHOOTING .......................................................................................................................................... 24

5. TECHNICAL INFORMATION ............................................................................................................................ 25

5-1 USING STRAIN GAGE HAVING GAGE FACTOR OTHER THAN 2.00 .....................................................................25

5-2 USING EXTENSION CABLE.............................................................................................................................................25

5-3 SPECIAL TERMS................................................................................................................................................................26

6. SPECIFICATIONS ................................................................................................................................................ 27

6-1 SPEIFICATIONS .................................................................................................................................................................27

6-2 OUTSIDE DRAWING .........................................................................................................................................................30