NEU MASTER NSG0060-18 User manual

NSG0060-18

Cordless Spray Gun

Technical Data

Max. Viscosity 60 DIN-s

Rated Voltage 20V, DC Max.

Rated Power 243W

Flow Rate 700ml/min

Weight 1.45Kg

1

Danger: re and explosion

Gases volatilized by paint and its solvents can cause

explosions and res. This can lead to property

damage and serious injuries.

Precautions:

• In the work area, exhaust and fresh air must circulate

to prevent ammable gases from accumulating.

• Avoid all ignition sources such as static sparks, open

ames, beacons, hot objects, cigarettes, etc. If you

plug in or unplug the power cord and operatethe

work light switch, it may generate electrical sparks.

• Smoking is prohibited in the spray area.

• Fire extinguishers must be prepared on site

and the re extinguishers are good and effective.

• When working indoors, ensure good ventilation so

that ammable gases can be exhausted timely.

Then the ignition of the combustible gas is avoided by

sparks, which can be generated by the motor of the tool

• When preparing and cleaning components, must follow

the manufacturer's precautions for spraying materials,

solvents, and detergents.

• Do not spray ammable liquids.

• Plastic products are easy to generate static electricity and

it is forbidden toenclose the spray area with plastic products.

Danger: Using unsuitable solvents

can cause an explosion.

The explosion can cause property damage

and serious injury.

Precautions:

• Do not use bleach.

• Do not use halogenated hydrocarbon diluents such

as methylene chloride and 1,1,1-trichlorethylene.

They can react with aluminum and can cause an explosion.

If you are unsure about the material used and the reaction

with the aluminum, contact the supplier of enamel paint.

【Important safety information】

Please read all safety instructions before using appliance. Save these instructions.

Read all safety instructions in the manual to avoid hazards of re, explosion, electric shock, and personal

injury. Familiarize yourself with the correct use of the tool.

This symbol indicates that this may result in death or

serious injury. All related security measures are followed.

Danger: Harmful gases

Paints, solvents, pesticides, and

materials containing toxic substances

volatilize to produce toxic gases that

may be inhaled into the body to cause

nausea, fainting, and poisoning.

Precautions:

• Wear respiratory protection when spraying.

The operator must wear a respirator.

• Wear safety glasses (goggle).

• Protective clothing, gloves and, if necessary, skin protection

creams are required to protect the skin.

Danger: General

It can cause property damage and serious injuries.

Precautions:

• Read the operating instructions carefully and follow the

relevant instructions to avoid danger.

• Observe all local safety instructions, pay attention to

ventilation, re protection and operating instructions.

• Use only manufacturer-approved equipment and

components. Otherwise, it can cause danger.

• Do not use the tool in outdoor on rainy day.

• Wear protective equipment such as goggle, helmet,

clothing etc.

• Never direct the spray gun to people or animals.

2

【Important safety information】

Please read all safety instructions before using appliance. Save these instructions.

Safety instructions of battery pack and charging

1. Prevent unintentional starting. Ensure the switch is in the off-position before connecting to battery pack, picking up or

carrying the appliance.

2. Disconnect the battery pack from the appliance before making any adjustments, changing accessories, or storing appliance.

Such preventive safety measures reduce the risk of starting the appliance accidentally

3. Do not open the battery pack, it can cause short circuit of battery.

4. Do not expose battery pack to high temperature (such as sunlight, etc.), re, water and moisture condition. These may

cause explosion. Do not expose a battery pack or appliance to re or excessive temperature. Exposure to re or temperature

above 130°C may cause explosion.

5. When battery pack is not in use, keep it away from other metal objects, like paper clips, coins, keys, nails, screws

or other small metal objects, that can make a connection from one terminal to another. Shorting the battery

terminals together may cause burns or a re.

6. Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact accidentally occurs, ush with water.

If liquid contacts eyes, additionally seek medical help. Liquid ejected from the battery may cause irritation or burns.

7. Use appliances only with specically designated battery packs. Use of any other battery packs may create a risk of injury and re.

8. Do not use a battery pack or appliance that is damaged or modied. Damaged or modied batteries may exhibit

unpredictable behavior resulting in re, explosion or risk of injury.

9. Recharge only with the charger specied by the manufacturer. A charger that is suitable for one type of battery pack may

create a risk of re when used with another battery pack.

10. Follow all charging instructions and do not charge the battery pack or appliance outside of the temperature range

specied in the instructions. Charging improperly or at temperatures outside of the specied range may damage

the battery and increase the risk of re.

11. Do not modify or attempt to repair the appliance or the battery pack (as applicable) except as indicated in the instructions

for use and care.

12. Have servicing performed by a qualied repair person using only identical replacement parts. This will ensure that the safety of

the product is maintained.

3

Packing List & Components

Battery

pack

Handle

Lock of

tank

Trigger

Gun

assembly

Seal ringNozzle

guard

Nozzle Pattern size

adjust knob

Pattern

Adjusting

knob

Nozzle + Sealing

Wrench Nozzle

unclogging

needle

Brush

Charger

Nut

Viscosity

cup

Flow

regulator

Tank

Air filter

Fanassembly

ring

NO. Name Quantity

1 Gun assembly 1

2 Fan assembly 1

3 Battery pack 1

4 Viscosity cup 1

5 Nozzle + Sealing ring 2 set (ɸ2, 0mm, ɸ3 0mm)

6 Wrench 1

7 Nozzle unclogging needle 1

8 Brush 1

9 Charger 1

4

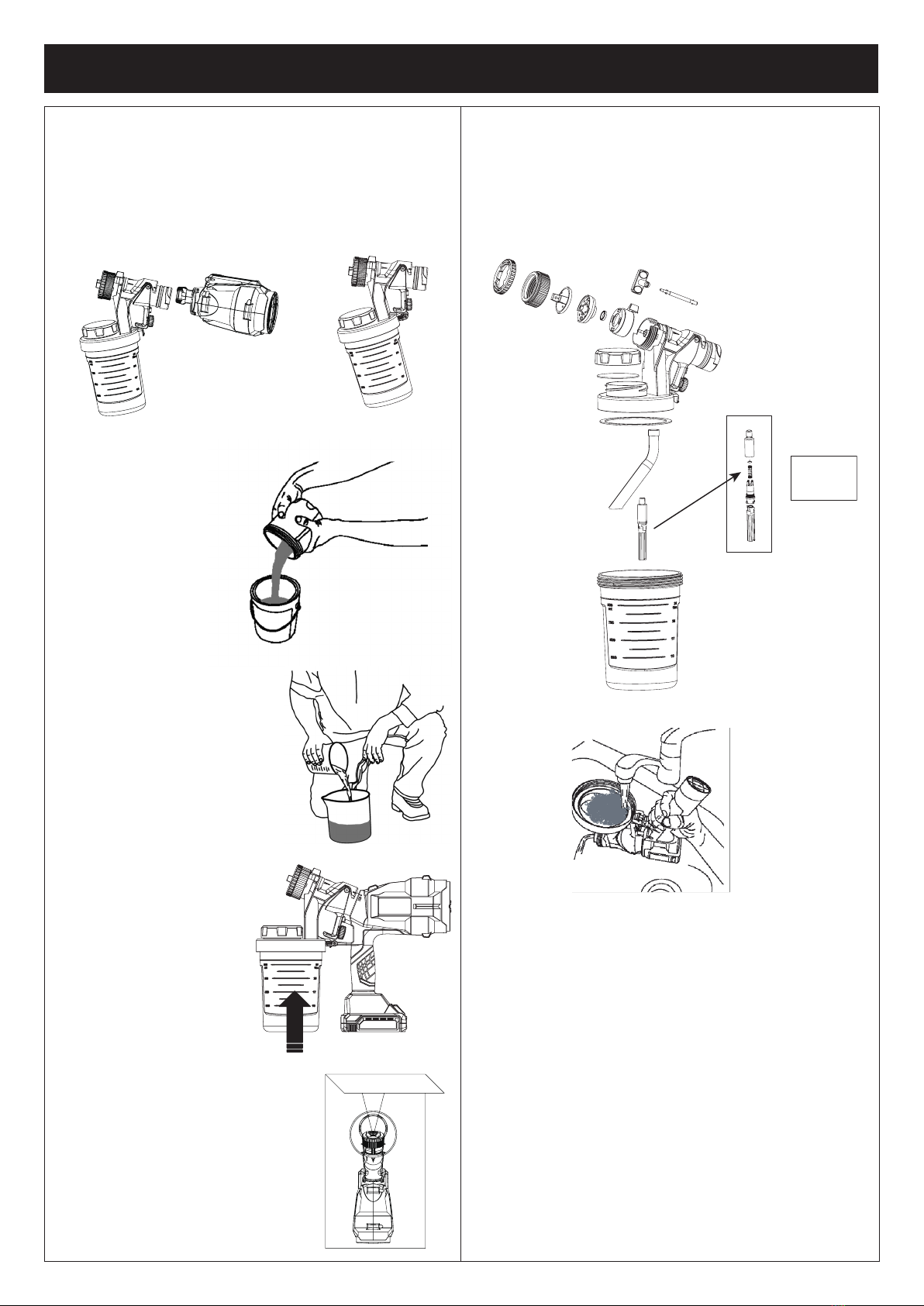

Assembly

Assembly of spray gun

1. Attach fan assembly to gun head rear part as below g

shown and clockwise rotate fan assembly to lock position.

2. Pull the lock of tank up t with hook as shown below.

Spraying material preparation

Before spraying, the spray material is diluted with the solvent

specified by the material manufacturer. Do not use spray

material that exceeds the specied maximum viscosity.

Follow the below instructions:

1. Thoroughly mix the spray material before checking

the viscosity.

2. Completely immerse the viscosity cup into the spray

material except for the hook part.

3. Lift the viscosity cup and record the time start from cup

up-surface left liquid, in seconds, until the liquid in the

viscous cup has owed. This dripping times are

recommended by materials’ manufacturers.

Below is the viscosity dilute guidline of our tool with

manufature specied viscosity.

4. The spray material need to be ltered with a appropriate

wire mesh before ll in tank to prevent large particle

contaminants get nozzle clogged.

Do not spray ammable liquids.

Filling the spraying material

1. Remove the tank from appliance.

2. Pour the diluted ltered spraying material into the tank.

The liquid level does not exceed the the scale line of

the tank.

3. Carefully screw back the liquid-lled tank onto the gun

and tighten. Make sure both tank and rell cap all

tighten enough.

5

Viscosity/ActionViscosity/Action ≥ 60 DIN-s < 60 DIN-s

Material Manufacture

Specied Min Viscosity

Can’t use with our

NSG0060

Dilute to desired and less

than 60 DIN-s viscosity

Material Manufacture

Specied Max Viscosity

Dilute to desired and

less than 60 DIN-s

viscosity

Dilute to desired and less

than 60 DIN-s viscosity

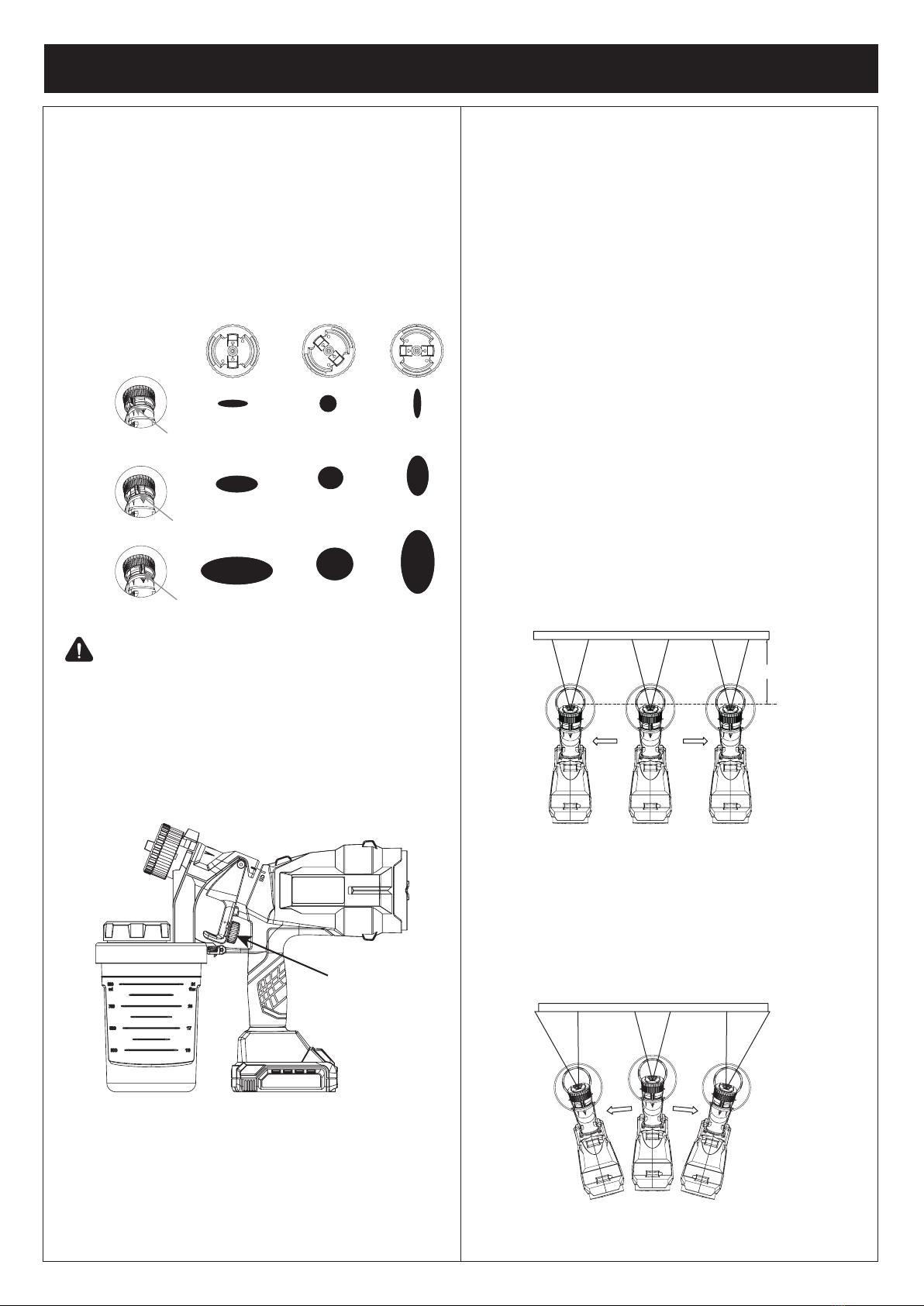

1. By turning the nozzle adjusting knob to get various pattern

in between horizontal oval, vertical oval, round. Users can

adjust accordingly to achieve the ideal spraying results.

2. Users can adjust the spraying size by adjusting the pattern

size control knob.

3. Combine above two steps to achieve the ideal spraying

result, as shown below.

Note: When adjusting the trigger must be released

to avoid danger!

Adjusting ow rate

The flow rate of spray can be adjusted by turning the knob

behind the trigger, clockwise turn ow rate up "+" for thick paint,

counter clockwise turn ow rate down "-" for thin paint as the

mark shown on trigger.

Spraying

The HVLP spray gun (High Volume and Low Pressure) is

a brand new spray system for users. Before first spraying,

the user must do some exercises on the discarded wood or

cardboard to conform.

Spraying

Pretreat the surface to be sprayed

The splash result depends on how smooth and clean the

surface is before spraying. Therefore, pretreat the surface

carefully and keep it dust-free. Cover non-spraying areas.

Correct spraying method

• The spray gun be perpendicular to surface when spraying.

Users can choose a distance of nozzle to surface 2-12 inches

depending on the size of the spray pattern. In general, the

longer distance, the bigger spray pattern.

• Gently press trigger by around 4mm for 1~2 second to

blow air ow rst to build up pressure within the

gun. Then press trigger further to generate paint spray.

• Move the spray gun evenly parallel along the application

surface. A consistent spray gun movements result in

a consistent painting quality.

• Generally, spray twice, the rst spraying may be

slightly thinner, and the second spraying should be

slightly thicker.

• At the end of spraying, hold the spray gun far from the

surface to avoid overspray.

Move the spray gun evenly

• Press and hold the trigger while spraying, and release

the trigger when spraying is nished. When spraying the

next layer, align the nozzle with the bottom edge of the

previous sprayed and allow the edges to slightly

overlap for better spray.

6

Even paint application

✔

50-300mm/2-12in

Thin layer Thin layer

✗

Thick layer

Do not move the spray gun unevenly as shown above.

Horizontal

oval

Vertical

oval

Round

Big

Middle

Small

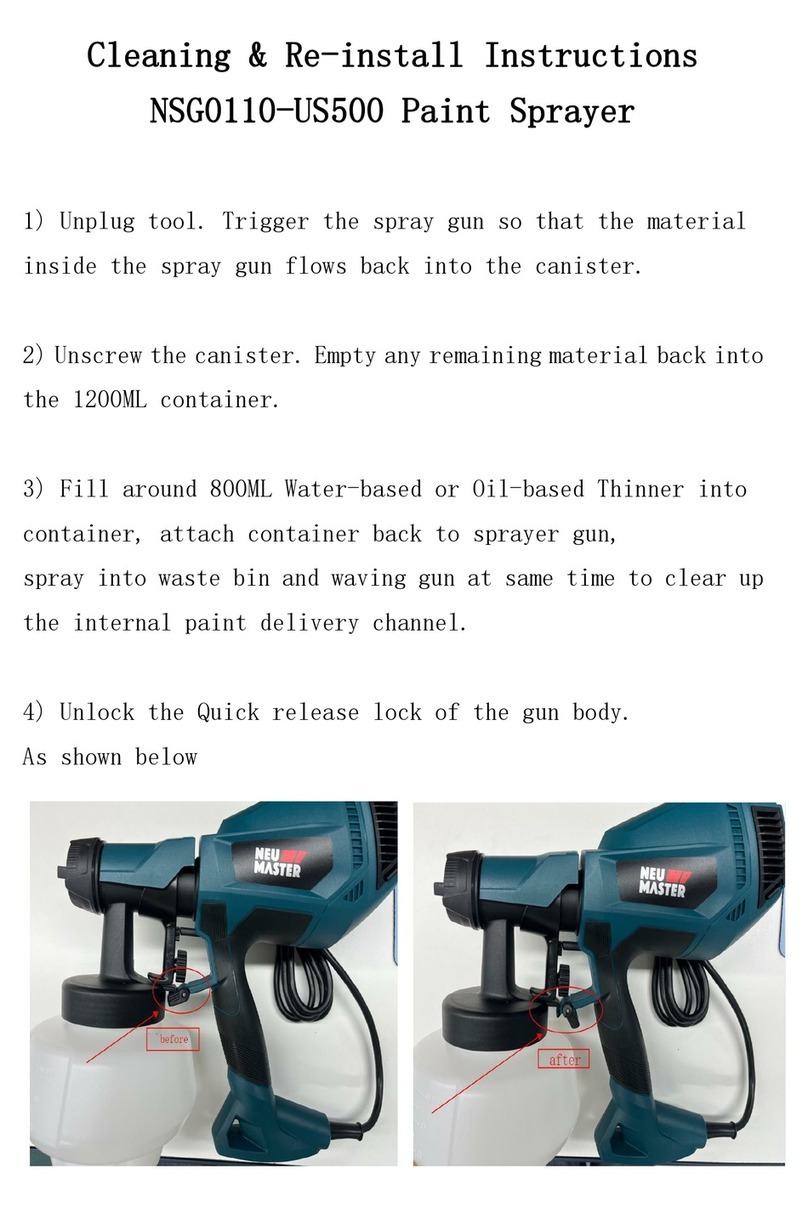

Cleaning

Cleaning the spray gun

Note: Do not immerse the gun in the detergent!

1. Unlock the fan assembly and remove it from the gun

assembly. Align the release latch and pull out the gun.

Press the trigger so that the spray material remaining

the gun ows back into tank.

2. Rotate and remove the tank, empty the residual spraying

material in the tank.

3. For clearing, pour a small

amount of the appropriate

cleaning solution into the

tank (warm soft water for

latex materials; mineral spirits

for oil-based materials)

4. Screw back the tank with the

cleaning solution onto the

spray gun. Attach and lock

fan assembly as per

instruction in page 5.

Attach battery pack back on.

5. Spray cleaning solution for a few

seconds (2-5s) in safety area,

spray for a few seconds again. Then

remove the tank and press the trigger.

6. Wipe and clean the outside of the tank.

7. Turn nut to remove the pattern adjust knob, nut, nozzle

guard, nozzle (sealing ring inside). These are must clean

components after each paint project: nozzle, nozzle sealing

ring, tank sealing ring, suction tube, tank. Other parts need

clear just in case it has paint on them.

8. Washing all these parts with appropriate cleaning solution.

9. Install the removed parts back. Always utilize the

direction/positioning rib.

Note: Never use sharp metal needle or similar to clean the nozzles!

Never use silicone-containing solvent or lubricant to clean the nozzles!

Do not miss the nozzle seal.

10. Check if there is paint on check valve housing. No need

clear it if no paint there. If yes pull the check valve out (Note:

Pull not turn!) for cleaning from tank seat. Turn check valve to

teardown to ve pieces. If user happened turned check valve

and left valve head remain in tank seat, please easily return

valve back in and pull it out as whole. Make sure the rubber

valve put back in right direction with its nipple goes into the see

through hole which can seen from top of the check valve.

7

Check

valve

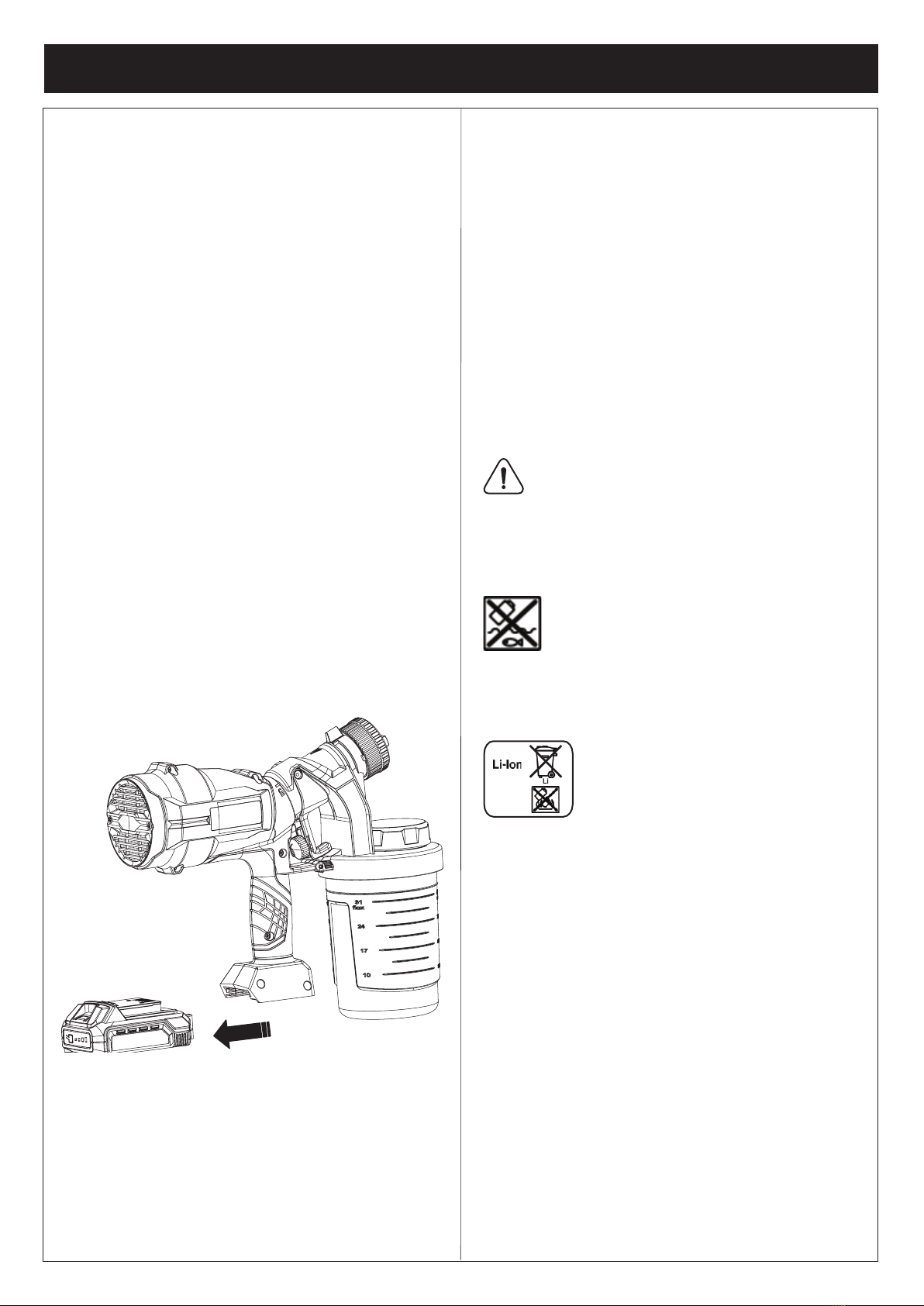

Charging of battery pack

1.

Recharge only with the charger specied by the manufacture.

2. Note: Battery is partially charged by shipping from factory,

User must fully charge the battery pack to ensure the

performance of the spray gun. Battery must remove from

the gun before charging.

3. The lithium-Ion battery pack can be charged at any

percentage of power left without shortening its lifecycle.

Accidently power off charging won’t damage battery pack.

4. Battery pack is equipped with "Electric Cell Protection"

(ECP) to avoid over-discharging. Spray gun will be turn

off once the battery pack is fully discharged.

Do not keep pressing the trigger when the tools

was automatically turned off. This kind of trying press

might damage battery pack.

5. The battery pack is equipped with NTC temperature monitor.

Charging temperature range 0°C to 45°C. Tools can only

work in temperature range from -10°C to 70°C .

Better get battery pack rest for 30 minutes right after

working for the cell to cool down before re-charge.

6. Remove the battery off spray gun if it will not be used

for long time. Remove the battery pack as shown below,

press the release button and pull the battery pack

backward off the spray gun. Do not use excessive

force during this operation.

Transportation

1. Lithium-ion battery packs supplied with the appliance

must be subject to the Dangerous Goods regulations.

Users can not transport the battery pack without

additional protective packaging.

2. However, special packaging and markings are necessary

for handing over to third parties (eg. by air freight or freight

forwarder). So that you must ask the dangerous goods

expert about the delivery of dangerous goods.

3. Make sure that the battery pack is not damaged before

transportation. Guard the exposed terminals and

package the battery pack to avoid electric shock

in the package box.

4. If necessary, consider the relevant national regulations.

Follow the disposal instructions.

Disposal

Environmentally friendly recycling of spray gun,

Battery pack, accessories and package.

Do not disposal spray gun and battery pack into

the household waste!

Battery pack

Li-Ion

Pay attention to the notes in the section

"Transportation"

Battery Pack

8

Maintenance

Trouble Shooting

After using for a period of time, you should check if the

lter is dirty or not. If it is excessively dirty, you need to

replace the lter with the following steps.

1. Remove the battery off the spray gun, and then remove the

lter guard with screw driver.

Problem description

A. Spray with low ow rate or no spray

B. Spraying material drips

C. Bad atomization

D. Spraying uctuation

E. Hanging phenomenon of spray material

F. Over spraying

G. Spray pattern too thin

2. Remove the dirty lter and replace it with a new one.

3. Reinstall the lter guard.

Never operate the spray gun without a lter! The dirt will

be sucked into the appliance and cause a damage.

Reasons

1. Nozzle clogged

2. Suction tube clogged

3. Flow regulator set in low position

4. Suction tube loose

5. Tank loose

6. Filter clogged

1. Nozzle loose

2. Nozzle damaged

3. Nozzle seal damaged

4. Spraying material accumulated in nozzle

1. High viscosity of spray material

2. Highow rate of spray material

3. Flow regulatorset high position

4. Nozzle clogged

5. Filter clogged

6. Low pressure build-up in the tank

1. Spray material is not enough in tank

2. Filter clogged

1. Spray too much material

1.

Short distance between spray gun and surface

2. High ow rate of spray material

1. Move the spray gun too fast

Solutions

1. Clean the nozzle

2. Clean the suction tube

3. Adjust the ow regulator

4. Tighten the suction tube

5. Tighten the tank

6. Replace the lter

1. Tighten the nozzle

2. Replace the nozzle

3. Replace the nozzle

4. Clean the nozzle

1. Dilute the spray material

2. Increase the ow rate

3. Adjust the ow regulator

4. Clean the nozzle

5. Replace the lter

6. Tighten the tank

1. Rell the spray material

2. Replace the lter

1. Increase the ow rate or move the spray

gun faster

1. Increase the distance

2. Decrease the ow rate

1. Increase the ow rate or move the spray

gun slower

9

Filter

Table of contents

Other NEU MASTER Paint Sprayer manuals