Read Before Use

1. Before use, please check if the electric supply is 220V /50Hz

(110V/60Hz for some area), and also make sure there is air filter cotton in

the base air filter, not blocked.

2. DO NOT overfill the solution tank above its Max. volume 2 L to prevent

overflow. If the air filter cotton is wet, please wait until it gets dried before

turning on.

3. The motor speed is fixed, please do not detach or change the motor

rotation. Only the water-soluble liquid can be used. Make sure there is no

impurities to keep the air filter unblocked.

4. Please power off when the following circumstances happen .

The machine exposed to the rain or gets wet; the motor ceased to work;

the obvious change in the voice of motor; solution leakage; the motor

doesn't work when turned on or other dangerous situations.

5. Must use proper personal protective equipment while using fogger.

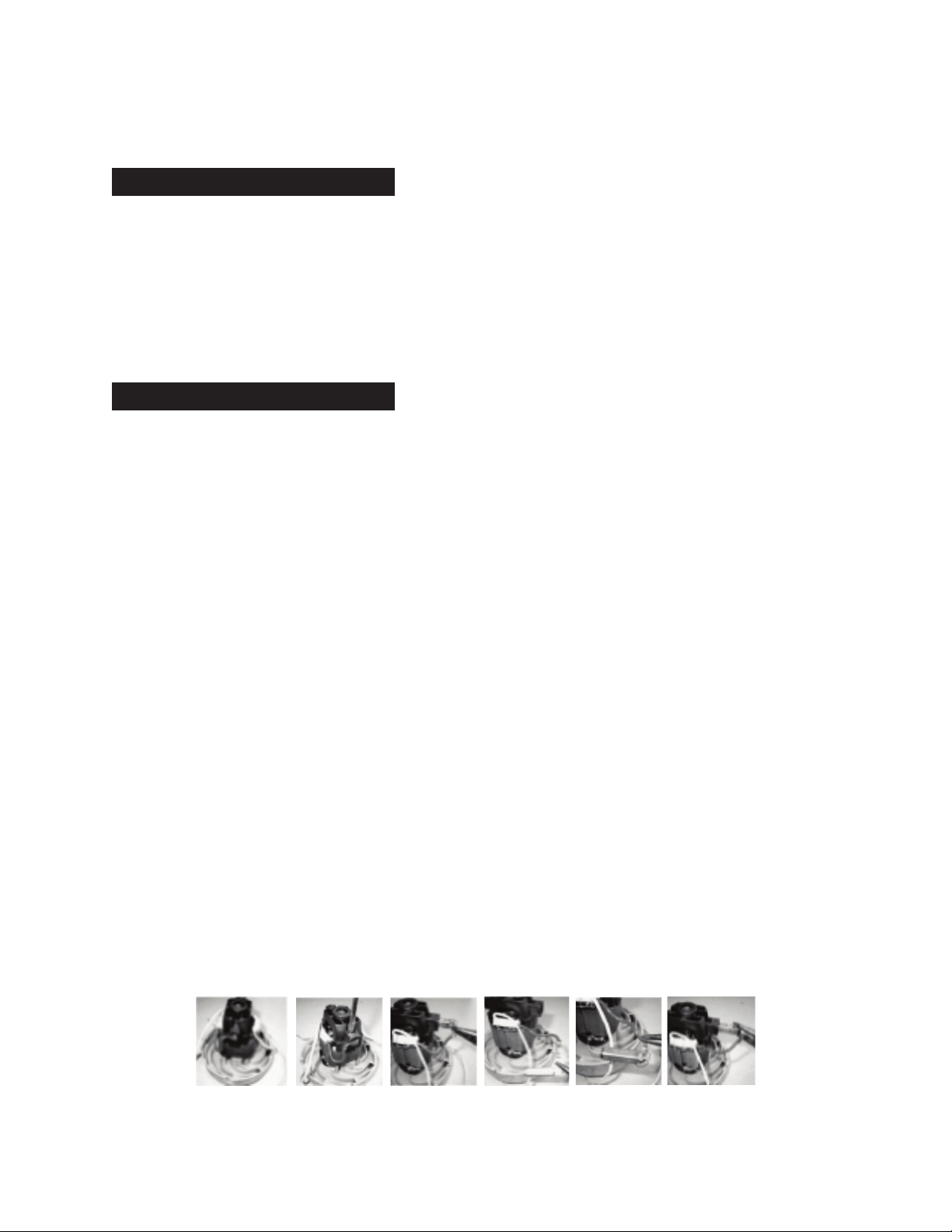

6. After use, please clean the fogger of any residual solution. Fill with clean

water, remove the spray nozzle, then turn on to spray for 2 to 3 minutes.

Wipe dry and store the machine. Store fog sprayer in a dry, warm location

out of the reach of chldren.

7. Do not use the machine in the rain. Do not plug or unplug with wet hands.

The machine should not be stored near any flammable, explosive articles,

or high temperature sites. Do not pull the electric wire violently from plug to

avoid damages. Do not turn on/off frequently to avoid damage to the motor.

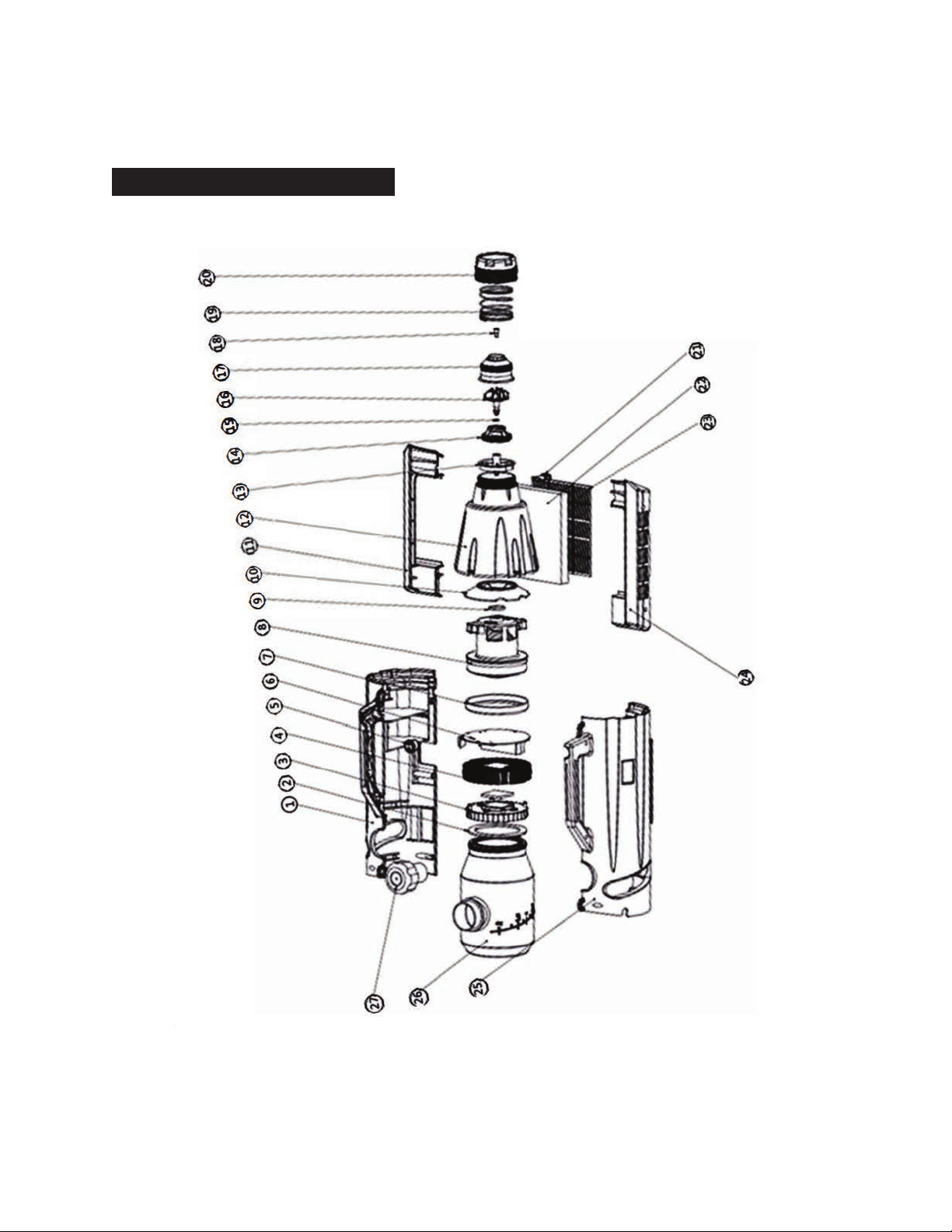

8. If you hear any unusual sounds, turn off and call professional technician to

check. Do not disassemble the machine privately.

01