NEU MASTER NSG0070-US500 User manual

INSTRUCTIONS MANUAL

Electric Spray Gun

NSG0070-US500

WARNING: READ INSTRUCTIONS MANUAL BEFORE USING PRODUCT.

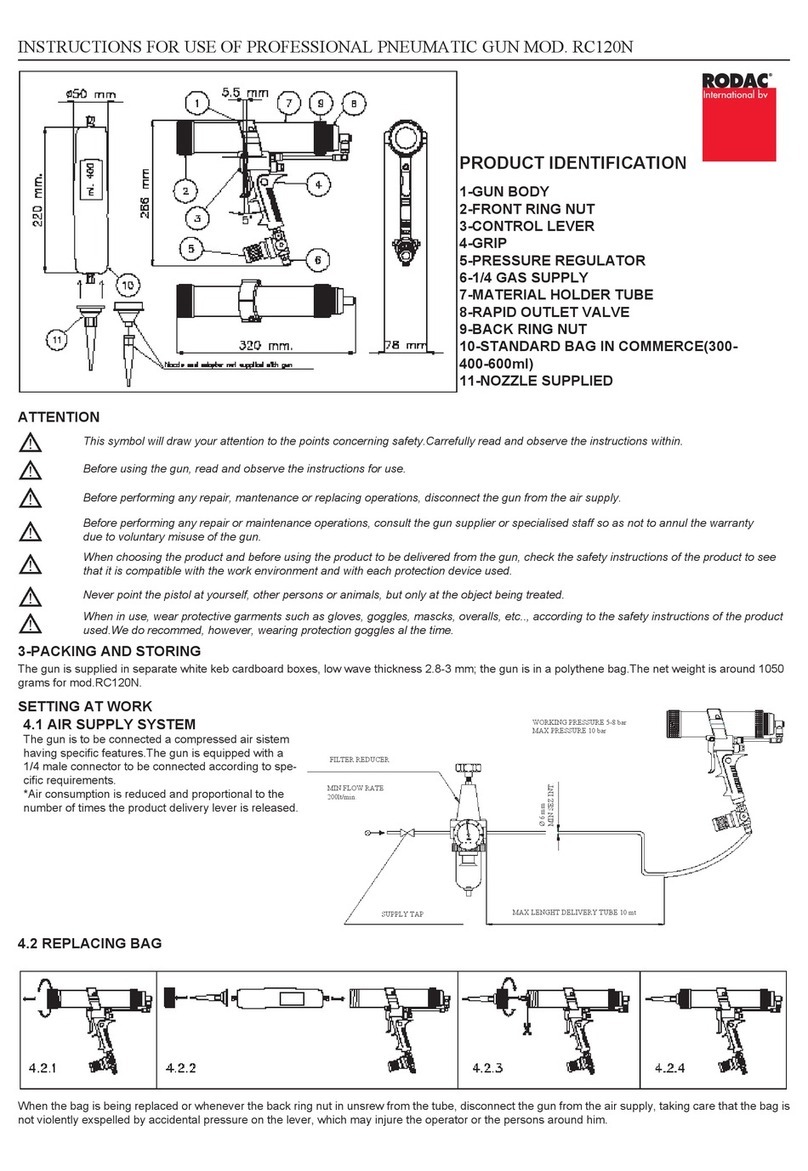

FIG. A

FIG. A1

FIG. A2

FIG. B

FIG. C

FIG. D

FIG. F

FIG. E FIG. E1

FIG. G

FIG. H FIG. H1

FIG. I

FIG. J

FIG. K

FIG. L

50 to 300mm

FIG. M

FIG. N

FIG. O

FIG. P

FIG. Q

FIG. R

FIG. Q1

FIG. S

27

90°

9

FIG. T

FIG. T1

FIG. U1

ENGLISH ENGLISH

noitcurtsniehtdnatsrednudnadaeR

manual.

Fire hazard.

Explosion hazard.

Respiratory hazard.

Electric shock hazard.

SAVE THESE INSTRUCTIONS:

To reduce the

risks of fire or explosion, electrical shock and

the injury to persons, read and understand all

instructions included in this manual. Be familiar

with the controls and the proper usage of the

equipment.

To avoid these risks, take the following

preventions:

►Exhaust and fresh air introduction must be

provided to keep the air within the spray area

►Avoid all ignition sources such as static

electricity sparks, open flames, pilot lights, hot

objects, lit tobacco products, and sparks from

connecting and disconnecting power cords or

working light switches.

►Fire extinguisher equipment shall be present

and working.

►Keep area clean and free of paint or solvent

►Follow the material and solvent manufacturer’s

safety precautions and warnings.

►Do not spray flammable or combustible

materials near an open flame or sources of

ignition such as lit tobacco products, motors, and

electrical equipment.

►Know the contents of the spray materials

and their cleaning solvents. Read all Material

Safety Data Sheets (MSDS) and container

labels provided with the spray materials and

solvents. Follow the spray material and solvent

manufacturer’s safety instructions.

than 60ºC (140ºF). Flashpoint is the temperature

(see coating supplies).

Wa rning! Ex p losion ha z ard due to

incompatible materials. Severe injury or

property damage can occur.

To avoid these risks, take the following

preventions:

► Do not use bleach.

►Do not use halogen a ted hydrocarb o n

solvents such as methylene chloride and 1,1,1

- trichloroethane. They are not compatible with

aluminum and may cause an explosion. If you

are unsure of a material’s compatibility with

aluminum, contact your coating supplier.

Warning! Hazardous vapors.

yarpS

slairetamrehtodna,stnevlos,slairetam

niemocrodelahnifilufmrahebnac

contact with the body. Vapors can cause

severe nausea, fainting, or poisoning.

To avoid these risks, take the following

preventions:

► Use a respirator or mask if vapors can be

inhaled.

Read all instructions supplied with the mask to

be sure it will provide the necessary protection.

► Wear protective eyewear.

► Wear protective clothing as required by

coating manufacturer.

Warning! Electric shock hazard. May

cause severe injury.

To avoid these risks, take the following

preventions

►Keep electrical cord plug and sprayer trigger

free from spray material and other liquids. Never

hold cord at plug connections to support cord.

Failure to observe may result in an electrical

shock.

►Never immerse electrical parts in water or any

other liquid. Wipe the exterior of the sprayer with

a damp cloth for cleaning. Always make sure the

sprayer is unplugged before taking it apart for

cleaning.

► Do not expose unit to rain or wet conditions.

►Do not abuse the cord. Never use the cord to

carry the unit or pull the plug from an outlet. Keep

cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately.

Warning! General. To Reduce the risk of

severe injury or property damage.

To avoid these risks, take the following

preventions:

►Do not aim the gun at, or spray any person,

including self, or animal.

► Do not spray outdoors on windy days

►Wear protective clothing to keep spray

material off skin and hair.

► Hose may become hot and cause skin burn.

► Follow all appropriate local, state, and national

operation.

►Always use appropriate gloves, eye protection

and a respirator or mask when spraying, thinning,

mixing, pouring, or cleaning.

►Do not operate or spray near children. Keep

children away from equipment at all times. Keep

sprayer out of the reach of children.

►Do not overreach or stand on an unstable

support. Keep effective footing and balance at all

times.

► Stay alert and watch what you are doing.

It is important for you to read and understand this

manual. The information it contains relates to

protecting YOUR SAFETY and PREVENTING

PROBLEMS. The symbols below are used to

help you recognize this information.

Danger! Indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

Warning! Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

Caution! Indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

Notice! Used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

The following are explanations of important

safety hazard pictorials in this manual.

TECHNICAL DATA

IMPORTANT SAFETY INSTRUCTIONS

SAFETY GUIDELINES - DEFINITIONS GENERAL SAFETY WARNINGS

Rated Current 4.0A

Water Flow Rate 900ml/min

Max. Viscosity 100 DIN-s

(runout time: 100seconds)

Nozzle Size

Φ2.5mm /

Φ2.0mm /

Φ3.0mm

Canister Capacity 1200ml

►

This product is intended for household use only.

Warning! Fire or explosion

hazard. Solvent and spray material fumes can

explode or ignite. Severe injury or property

damage can occur.

lock (#19) and snap onto the hook on the edge of

Cleaning brush

Switch trigger lever

Spray gun unit

ENGLISH ENGLISH

►Do not operate the unit when fatigued or

►Read all instructions and safety precautions

fo r equ ipment and s pray ma t eria l b efore

operating any equipment.

►Hearing protection is recommended for

extended use.

Warning! Some spray materials contain

chemicals known to the State of California to

cause cancer, birth defects or other reproductive

harm. To reduce your exposure wear appropriate

safety equipment such as face masks, gloves,

and other appropriate protective equipment.

Please review and follow the safety precautions

on the paint container.

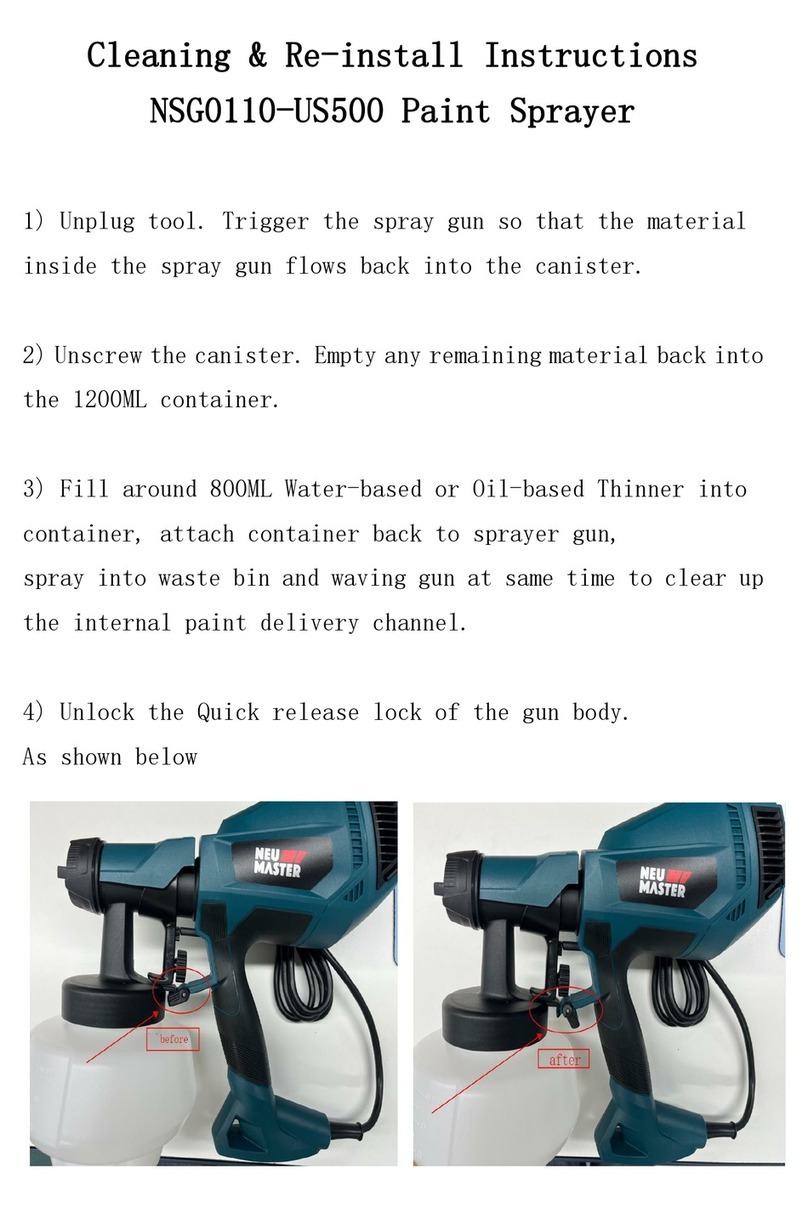

FEATURES (Fig. A, Fig. A1, Fig. A2 )

1.

2. Power unit

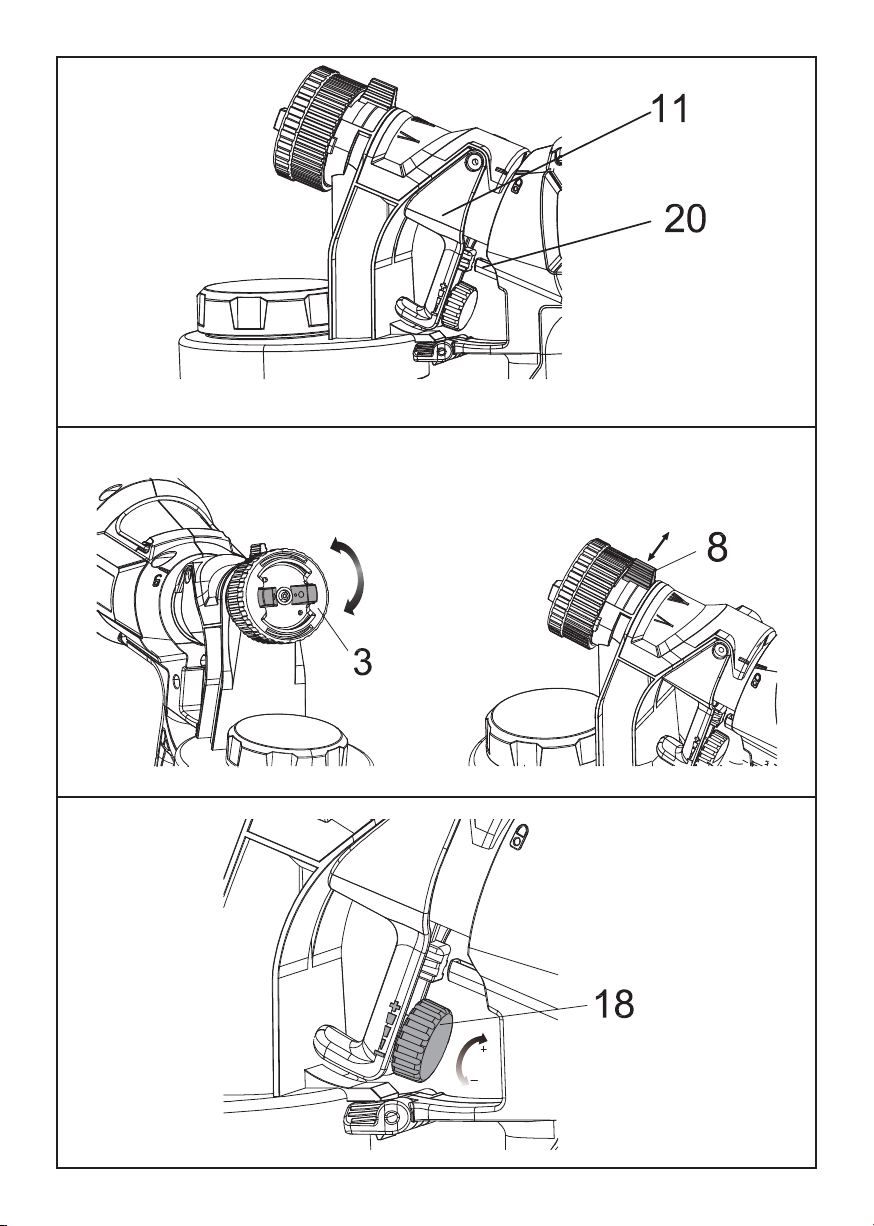

3. Smart nozzle selector

4. Tip collar

5. Air cap

6. Nozzle (Φ2.0mm/Φ2.5mm/Φ3.0mm)

7. Y-type seal ring

8. Spray width lever

9. Spray tip

10. Spray unit housing

11. Trigger

12.

13. Sealing linear

14. O-ring

15. Pickup tube

16. Check valve assembly

16.1 Check valve sleeve 1

16.2 Check valve

16.3 Spring

16.4 Check valve sleeve 2

16.5 Valve extension

17. Canister

18.

Flow control knob

19. Quick release lock

20.

21.

22.

Filter

23.

Filter cover

24.

Viscosity cup

25.

Cleaning needle

26. Spray tip key

Warning! Be sure to use appropriate

protective gear and unplug unit.

Warning! Make sure area is well ventilated

Aligning the pickup tube (Fig. B)

The pickup tube (#15) needs to be aligned in the

direction toward the front of the canister ( Fig. B).

This will ensure you spray as much material as

Make sure the pickup tube is assembled tight

in place.

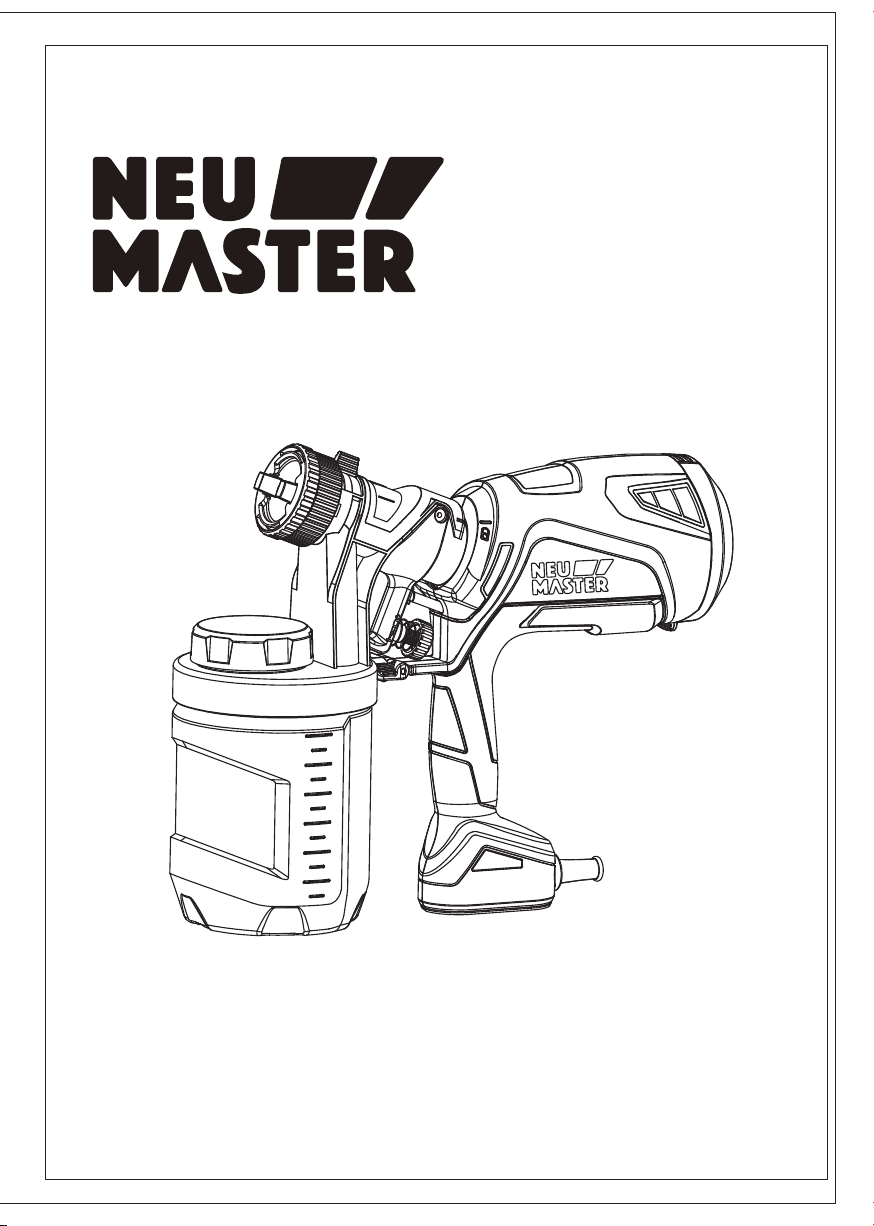

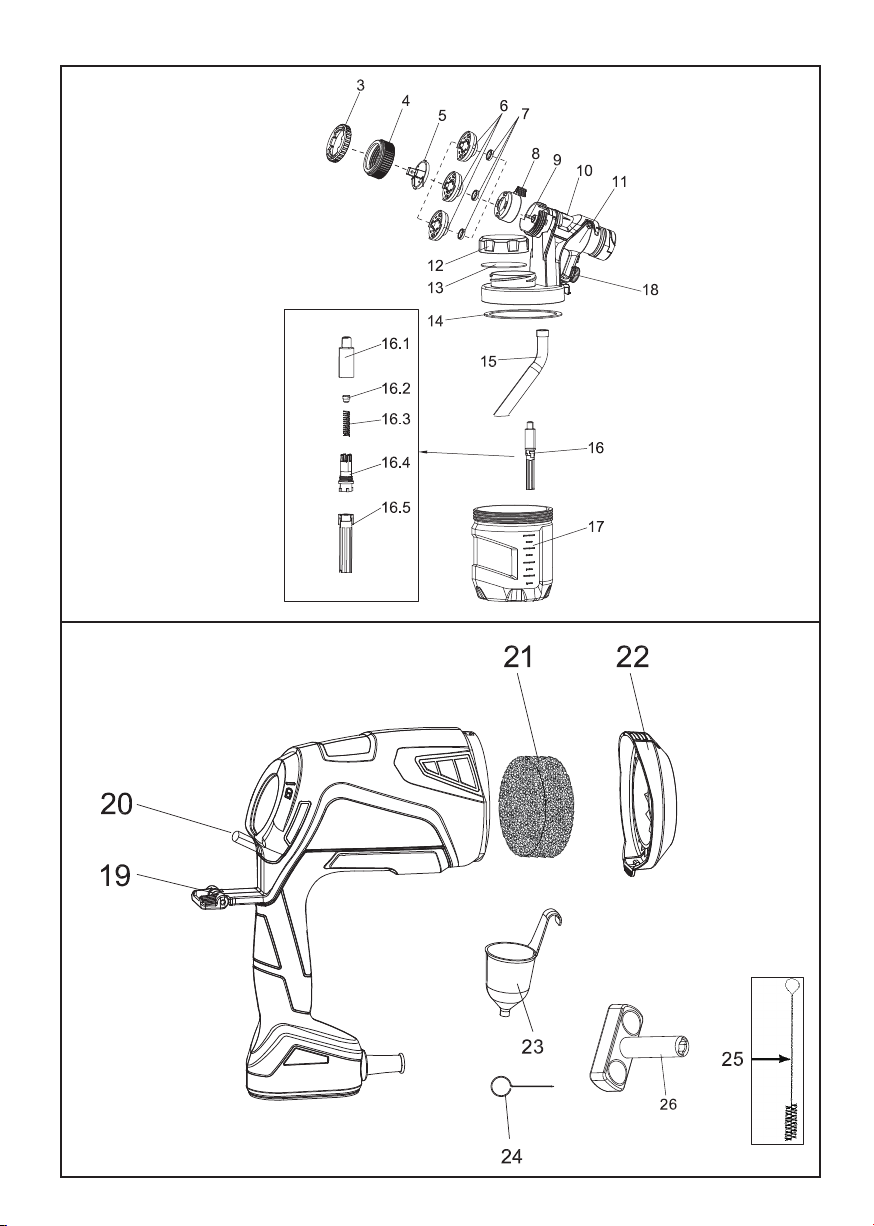

Attaching spray unit to the handle ofgun

Align the marking line on the spray unit with the

icon of unlock, then rotate the spray gun handle

anticlockwise until stop. Rotate the quick release

canister lid.

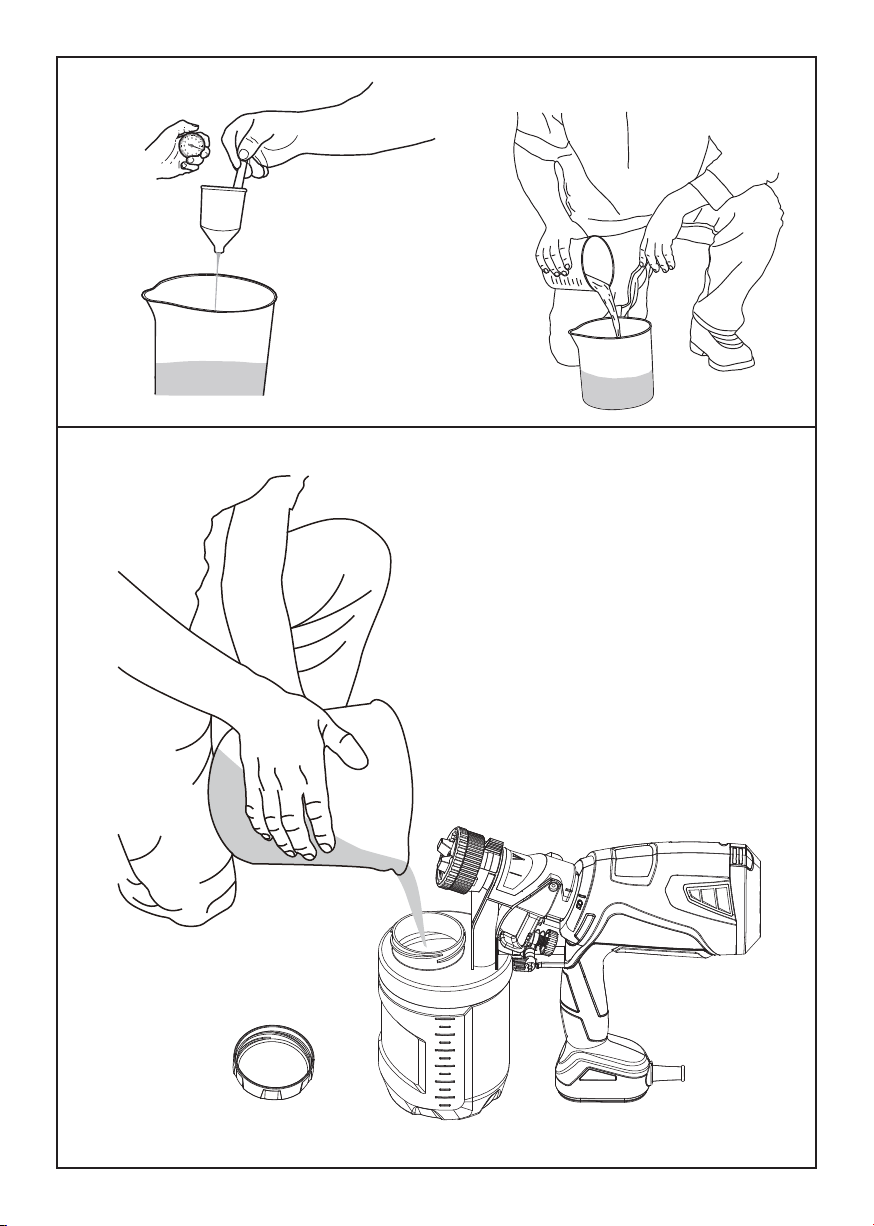

Liquid material preparation (Fig. E1 and E2)

Tip: Make sure the type of material you use can

be cleaned with either mineral spirits or paint

thinner (for oil-based paints) or a warm water

and soap solution (for water soluble paints like

latex). Use rag during pouring , mixing , and

testing of materials to be sprayed to

portect your floors and anything else in the

ying area that you wish to remain untouched

ebotdeenyamdey

arpsgniebdiuqilehT

thinned (diluted) before starting. When

thinning, use the proper liquid thinner

recommended on the container by the material

manufacturer..

Warning!: Do not use materials with a

A viscosity test cup is provided to determine the

“runout time” of the material being used.

►Before measuring for the proper viscosity, stir

the material thoroughly.

►Dip the viscosity cup into the material being

►With the cup held over the material container,

measure the amount of time it takes for the

being a constant stream out of the bottom of

the cup (100 seconds or less) . This is

the “runout time”. Refer to the thinning table for

information on the thinning required for different

materials.

►If material needs thinning, add the appropriate

liquid, thinning material recommended by the

manufacturer

►It is possible to spray latex paint with this

unit, however, the required thinning may exceed

material manufacturer’s recommendation. Thin

latex paint so that it runs through viscosity cup

within100 seconds. The operator should consider

the type of application and final location of the

ELECTRICAL SAFETY

SET - UP

EXTENSION CORD

Type of

cable

Up to 5

metres

from 5 to

10 metres

Paralel 2x 1.0 mm22x 1.5 mm2

onerofereht;detalusnielbuodsilootsihT

earth wire is required. Always check that the

power supply corresponds to the voltage on the

rating plate.

tsumti,degamadsidrocylppusehtfI►

be replaced by the manufacturer or an authorised

Service Centre in order to avoid a hazard.

►When using the tool outdoors, only use

extension cables intended for outdoor use. A

suitable rated extension cable of up to 30 M can

be used without loss of power.

►Electric safety can be further improved by

using a high sensitivity.

(Fig. E)

(Fig. E1).

Use only a 3-blade grounding plug and a

3-slot receptacle that will accept the plug on the

product. Make sure your extension cord is in good

condition. When using an extension cord, be sure

to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and

overheating. If an extension cord is to be used

after the cord type designation. For example, a

designation of SJTW-A would indicate that the

cord would be appropriate for outdoor use. For

proper size cords see chart.

Guide for extension cord usage:

project when spraying a material that requires

more than 100 seconds to run through the

viscosity cup.

power unit C)(Fig.

viscosity

the tool.

ffonrutotreggirtehtesaeleR.lootehtnonrutot)02#(

the switch inside the tool by the switch trigger lever

Squeeze to press the trigger (#11), trigger will actuate

(More than

(Less than

ENGLISH ENGLISH

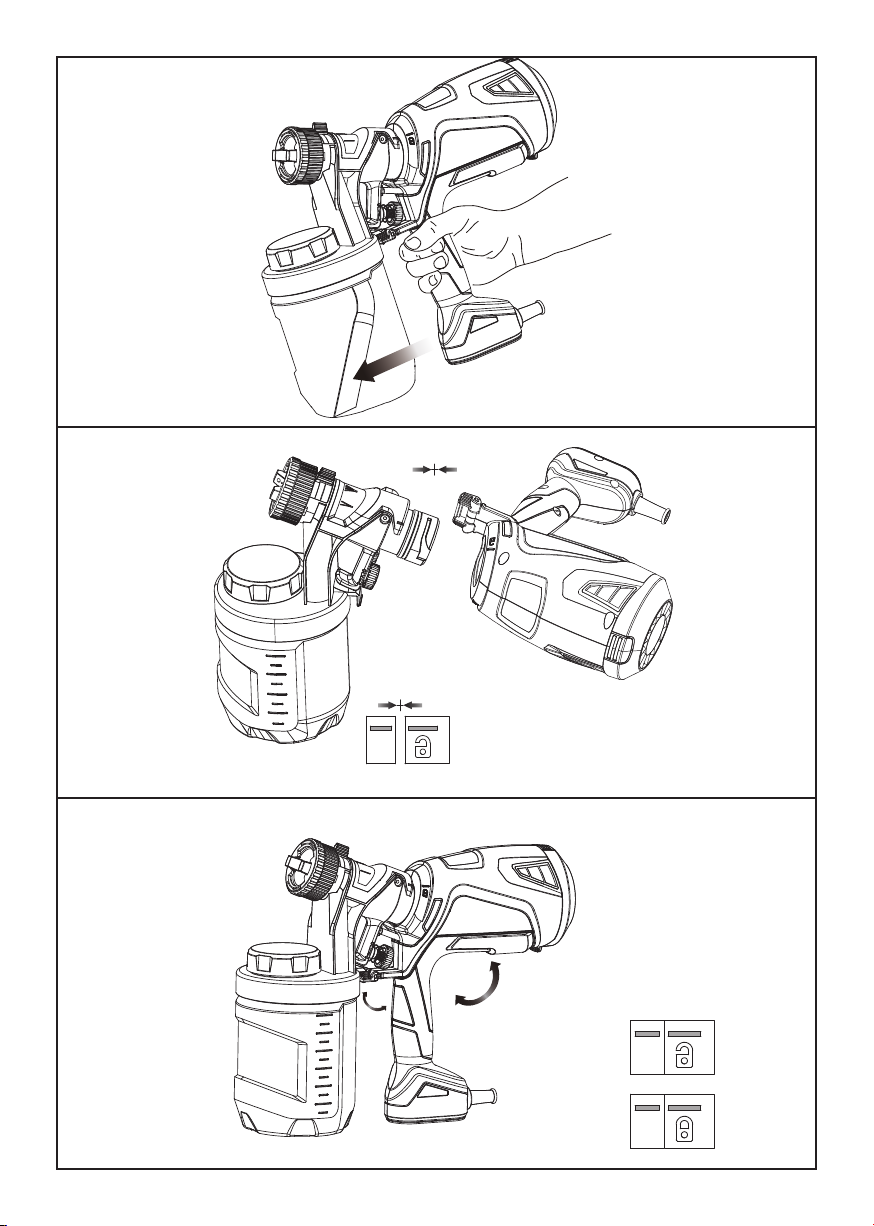

FILLING THE CANISTER (FIG. F)

►Check to make sure that the canister is

completely screwed onto the sprayer.

►Stand the sprayer firmly on a smooth and

horizontal surface

►Pour the properly thinned and strained

material to be sprayed into the canister (Fig. F).

►Clean any residual liquid from the threads or

sides of the canister and sprayer.

►Starting the threads evenly, screw the lid

completely onto the top of canister. Check the

lid to make sure it is threaded on squarely and

completely before picking up the sprayer.

ON / OFF SWITCH (Fig. G)

SMART SELECT NOZZLE SELECTION (Fig. H,

Fig. H1)

There are three spray patterns to choose from:

- Vertical Flat Jet

- Horizontal Flat Jet

- Circular Jet

To select Vertical Flat Jet , turn

the air cap (#5) to horizontal

direction by turning the smart

nozzle selector (#3) clockwise

until stop.

To select Horizontal Flat Jet,

turn the air cap(#5) to vertical

direction by turning the smart

n o z z l e s e l e c t o r ( # 3 ) a n t i -

clockwise until stop.

To select Circular

Jet, turn the Spray

Width Lever (#8)

t o t h e i c o n o f

Minimum.

Note: Spray nozzle can only be assembled in

one direction that the notch of the nozzle(#6)

m u s t ali g n w i t h t h e s k i r t o n s p r a y u n i t

housing(#10). Refer to Fig. T1 for proper

assembly.

Warning! Risk of injury. Never point the

sprayer at any part of the body. Never pull the

trigger while adjusting the spray setting.

ADJUSTING WIDTH OF SPRAY PATTERN (Fig.

H1)

By turning the Spray Width Lever (#8) between

the Minimum marking and Maximum marking,

the width of the spray patterns can be adjusted

accordingly.

PREPARATION TIPS

►Always stir and strain the material thoroughly

before use.

►With any spraying job you should always

ensure that you have properly prepared the

are free from dust, dirt, rust and grease. Lightly

pressure wash decks or exterior surfaces and

ensure that they are dry before spraying.

►Even though HVLP sprayers have very little

overspray, it is recommended that you mask

all edges and other areas and use drop cloths

to protect your floors and anything else in the

spraying area that you wish to remain untouched.

► Skin that forms on the top of paint can clog the

sprayer. Remove skin before mixing. Strain with

to remove any impurities that could clog system.

►Before starting have gloves, paper towels,

rags etc. available for unexpected spills.

OPERATION

THINNING TABLE

SPRAY MATERIAL RUNOUT TIME

Clear and semi-

transparent

stains and sealers

Oil based primers,

varnishes and

polyurethane

No thinning required

seconds runout)

Solid color water

based stains

Water based or

latex paints

May require thinning

seconds runout)

Note: Not recommended for textured paint

Vertical narrow jet for

horizontal coating

direction

Horizontal narrow jet

for vertical coatiang

direction

Vertical wide jet for

horizontal coating

direction

Horizontal wide jet

for vertical coating

direction

Small-medium

size surface

Large size

surface top

coating

Initial coatings,

corners, edges,

and hard to reach

locations

Small circular jet

Application Spray Width Lever #8 Air Cap #5 Spray Jet Pattern

100

100

2

ENGLISH ENGLISH

FLOW CONTROL KNOB (Fig. I)

The flow control knob(#18) regul ates t he

amount of liquid that can be sprayed. Turning

the flow knob clockwise increases the flow of

liquid. Turning the knob counter anti-clockwise

Tip: Always test the spray pattern on scrap

control knob on the highest flow setting. If less

flow is desired, dial the flow control knob anti-

thicker materials should be sprayed with the

flow control knob on high flow setting. Thinner

►Practice spraying on a piece of scrap material

such as cardboard to test your spray pattern and

become familiar with the flow control feature of

the sprayer.

►Ensure surface to be sprayed is free of dust,

dirt, and grease.

►Ensure spray area is clean and free of dust

that could be blown onto newly sprayed surfaces.

► Cover any areas not intended to be sprayed.

►Always spray from a minimum of 50mm to a

maximum of 300mm (Fig. J).

►A commonly used method for spraying a large

surface is the “crisscross” pattern. This is done

by spraying in horizontal strips and then crossing

over these strips with vertical strips (Fig. L).

►To get an even spray distribution, always keep

your arm at the same distance (Fig. J) from the

surface you are spraying and avoid moving your

wrist (Fig. K).

►Maintain smooth and consistent speed which

will help avoid inconsistencies. Begin spraying

after the pass has begun and release trigger

before stopping the pass.

►Avoid spraying too heavily in any one area.

Several lighter coats are better than one heavy

coat which can lead to running and dripping.

Remember that the flow control knob regulates

the amount of liquid that can be sprayed. Turning

the flow knob clockwise increases the flow

of liquid. Turning the knob counterclockwise

decreases the flow of liquid. If runs or drips do

occur, have a dry paint brush on hand to smooth

them out.

►Turn the power unit off and place the sprayer

in the built-in dock of the power unit when not

spraying for any length of time.

cleaning solution.

cleaning solution (Fig. M). Screw on the canister

back the sprayer.

►Plug in the cord and turn on the power unit.

►Spray the cleaning solution through the

sprayer onto scrap material for 2 to 3 seconds

(Fig. O).

►Turn the power unit off, unplug the cord.

► Unscrew the canister from the sprayer.

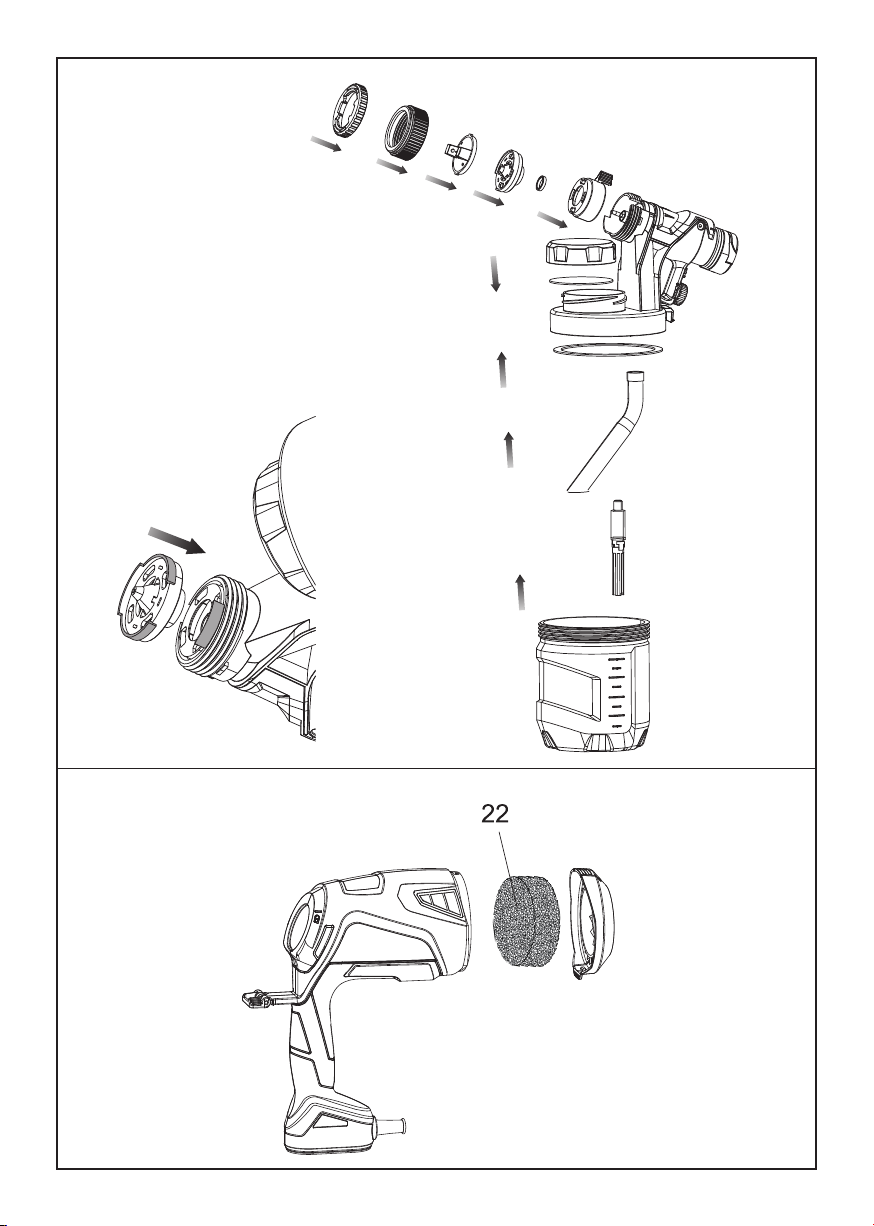

►Remove the o-ring(#14), pickup tube(#15),

check valve (#16), and quick refill lid(#12) from

the sprayer. Clean the parts with the cleaning

brush in the appropriate cleaning solution (Fig. P).

Note: When removing the check valve, twist the

check valve clockwise and then pull it out.(Fig P

insert)

►Unscrew the tip collar (#4) and remove all

the parts of the spray nozzle(#3,#4,#5,#6,#7.#8)

from the sprayer.

Remove the spray tip(#9) from the sprayer ( Fig.

Q1). Clean all parts with the cleaning brush in the

appropriate cleaning solution (Fig. Q, Fig.Q1).

Be sure to clean around check valve with brush

(Fig. Q insert).

►If using water based material, clean the

sprayer by running water through pickup tube

inlet as shown in Fig. R. If using oil based

materials, clean pickup tube inlet with the

appropriate cleaning solution.

Repeat until sprayer is completely clean.

► Dry all parts thoroughly.

► Properly dispose of cleaning solution.

►Place a drop of household oil into the inside

of the sprayer from the hole for assembling the

spray tip (Fig. S).

► Reassemble sprayer (Fig. T).

Note: Spray nozzle can only be assembled in

one direction that the notch of the nozzle(#6)

m u s t alig n w i t h t h e s k i r t o n s p r a y u n i t

housing(#10). Refer to Fig. T1 for proper

assembly.

Note: The spray tip must be assembled in

the sprayer with the bumps on the spray tip in

vertical direction

Note: Assemble the pickup tube(#15) and check

on the sprayer.

►Wrap the air hose around the power unit and

put all accessories back into place.

Use only mild soap and damp cloth to clean the

power unit. Never let any liquid get inside the

power unit; never immerse any part of the power

unit into a liquid.

Important! To assure product SAFETY

and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this

manual) should be performed by authorized

service centers or other qualified service

personnel, always using identical replacement

parts.

by pulling the

bottom side of the filter cover (#22) and remebe it.

Remove the filter as shown in Fig.U1 and

Important! Never operate the power unit

in and interfere with the function of the power

unit.

Warning! Be sure to use appropriate

protective gear.

►Do not use materials with a flashpoint

higher than 60°C( 140°F) . Flashpoint is the

temperature that a fluid can produce enough

vapors to ignite (see coating supplier).

►Make sure clean up area is well ventilated and

►Always s pray o utdoor s whe n sp rayi ng

cleaning solution through sprayer.

► Do not submerse power unit.

►Use drop cloths during pouring, mixing, and

viscosity testing of materials to be sprayed to

protect your floors and anything else in the

spraying area that you wish to remain untouched.

►To begin cleaning:

►Turn the power unit off, unplug the cord.

►Unscrew the canister from the sprayer and

pour any remaining liquid back into the original

container (Fig. M).

►Pour a small amount of the appropriate

cleaning solution into the canister (Fig. N).

- Warm soapy water for water based materials

- Manufacturers recommended cleaning solution

for oil based materials

►Screw on the canister back to the sprayer

securely and vigorously shake the sprayer.

►Unscrew the canister and properly dispose of

DEVELOPING THE PROPER

SPRAYING TECHNIQUE

CLEANING

MAINTENANCE

ENGLISH ENGLISH

PROTECTING THE ENVIRONMENT

STORAGE TROUBLESHOOTING

ACCESSORIES

Make sure unit is clean and dry before storing.

Store unit indoors in a dry location. To prevent

damage, wrap the electrical cord so that it is not

crimped during storage.

Recommended accessories for use with your

product are available from your local dealer or

authorized service center.

Warning! The use of any accessory not

recommended for use with this product could be

hazardous.

Separate collection. This product must

not be dispos e d o f with nor m a l

day

that

your

product

needs

replacement, or if it is of no further use to you, do

not dispose of it with household waste. Make this

product available for separate collection.

Separate collection of used products

and packaging allows materials to be

recycled and used again. Re-use of

recycled materials helps prevent environmental

pollution and reduces the demand for raw

materials. Local regulations may provide for

separate collection of electrical products from

the household, at municipal waste sites or by the

retailer when you purchase a new product.

TROUBLE! MATERIAL RUNS OR DRIPS.

WHAT’S WRONG? WHAT TO DO…

Spraying too much material. knob.

Spraying too slowly. Increase speed of application.

Spraying too close. Increase distance from surface.

Viscosity too thin. Check dilution recommendation.

TROUBLE! MATERIAL DRIPS FROM NOZZLE

WHAT’S WRONG? WHAT TO DO…

Nozzle loose Screw nozzle tight

Nozzle breaks Change

Y-type seal ring of nozzle breaks Change

Material accumulated /clog inside nozzle Clean

TROUBLE! TOO MUCH OVER SPRAY.

WHAT’S WRONG? WHAT TO DO…

Sprayer too far from surface. Reduce distance to surface.

Too much material being sprayed.

TROUBLE! LITTLE OR NO MATERIAL BEING RELEASED.

WHAT’S WRONG? WHAT TO DO…

Spray nozzle/tip clogged. Clean nozzles.

Y-type seal ring of nozzle missing Add seal ring to nozzle and assemble in place

Pickup tube loose or clogged. Check tube.

Canister loose Screw canister tightly in place

Flow control knob setting too low.

Air inlet blocked

Material too thick. Thin material per manufacturer recommendation.

TROUBLE! MATERIAL BEING SPRAYED IS SPLATTERING

WHAT’S WRONG? WHAT TO DO…

Viscosity of material is too high. Thin material per manufacturer recommendation.

TROUBLE! ATOMIZATION IS TOO COARSE

WHAT’S WRONG? WHAT TO DO…

Viscosity of material too high. Thin material per manufacturer recommendation.

Flow control knob setting too high Decrease ow control setting

Material accumulated /clog inside nozzle Clean

Air inlet blocked Clean or change air lter

Canister loose Screw canister tightly in place

Quick rell lid loose Screw quick rell lid tight in place

TROUBLE! SPRAYER PULSATES.

WHAT’S WRONG? WHAT TO DO…

Air lter clogged Clean or change air lter

Material in canister almost empty. Rell canister.

Canister loose Screw canister tightly in place

Quick rell lid loose Screw quick rell lid tight in place

TROUBLE! SPRAY MATERIAL DOES NOT COVER PROPERLY

WHAT’S WRONG? WHAT TO DO…

Flow control knob setting too low. Increase ow control setting

Clearance to target area too large Reduce spray distance

Too few spray paths sprayed over target area Apply more spray paths sprayed over target area

Viscosity of material too high. Thin material per manufacturer recommendation.

ENGLISH ENGLISH

Table of contents

Other NEU MASTER Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Echo

Echo MS-300 Operator's manual

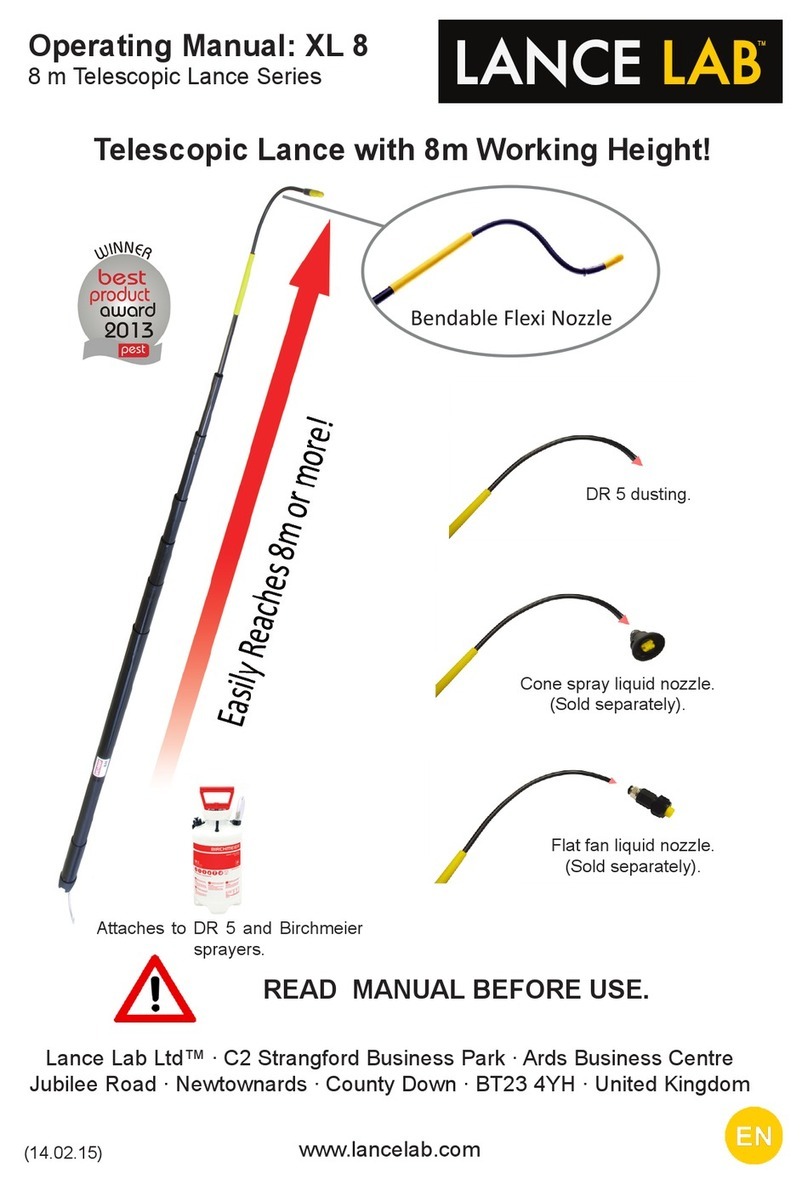

Lance Lab

Lance Lab 8 m Telescopic Lance Series operating manual

BE Ag & Industrial

BE Ag & Industrial AGRI EASE 90.700.100 Operations & parts manual

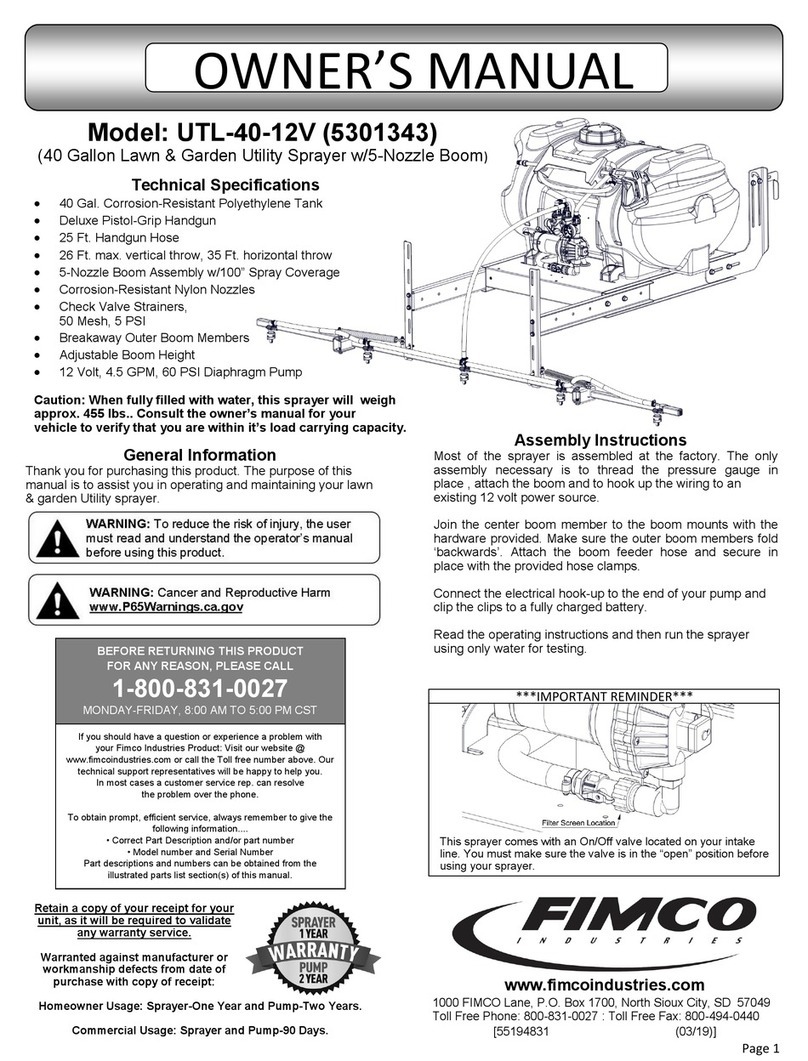

Fimco

Fimco UTL-40-12V owner's manual

swissmex

swissmex 547195 Operator's manual

Fimco

Fimco LG-3025 Assembly and operation instructions

Anest Iwata

Anest Iwata WA 200 Installation, use & maintenance instruction manual

Fimco

Fimco LAWN GUARD LWN-GRD-4 owner's manual

GUSMER

GUSMER GAP Pro operating manual

MaxiMist

MaxiMist SprayMate TNT HVLP ST610EU Instruction manual and users guide

WAGNER

WAGNER 558019 operating manual

WERKU

WERKU WK500480 Original instructions