NEU MASTER N3020 User manual

N3020

CN

EN

DE

FR

IT

ES

PT

RU

JP

ID

SAVE THIS INSTRUCTION MANUAL FOR FUTURE PEFERENCE.

电动喷枪

Electric Spray Gun

Elektrische Spritzpistole

Pistolet à peinture électrique

Pistola a spruzzo elettrica

Pistola de pulverización eléctrica

Pistola de pulverização elétrica

Электрический распылитель

電動スプレーガン

Pistol semprot listrik

Important Safety •Read all safety inform n before

opera the equipment. Save these

To reduce the risks of fire or explosion, electrical shock and the injury to persons, read and understand all inst included in this manual. Be

familiar with the controls and proper usage of the equipment.

Indicates a hazardous situa on which, if not avoided,

could result in death or serious injury.

HAZARD: EXPLOSION OR FIRE

Solvent and paint fumes can explode or ignite.

Severe injury or property damage can occur.

PREVENTION:

•Provide extensive exhaust and fresh air introduc n to keep the air

within the spray area free from n of

flammable vapors.

•Avoid all igni on sources such as sta c electric

sparks, open flames, pilot lights, electrical

appliances, and hot objects. Con or

power cords or working light

switches can make sparks.

•Do not smoke in spray area.

•Fire sher must be present and in good working order.

•Use only outdoors in a well-ve ed area. Flammable vapors are

heavier than air. The turbine contains arcing parts that emit sparks and can

ignite vapors.

•Follow the material and solvent manufacturer’s warnings and

•Do not use materials with a flashpoint below 70°F

(21°C). Flashpoint is the temperature that a fluid can produce enough

vapors to ignite (see coa g supplier).

•Plas c can cause sta c sparks. Never hang plas c to enclose the spray

area. Do not use drop cloths when spraying flammable materials.

HAZARD: EXPLOSION HAZARD DUE TO

INCOMPATIBLE MATERIALS.

Will cause property damage or severe injury.

PREVENTION:

•Do not use materials containing bleach or

chlorine.

•Do not use halogenated hydrocarbon solvents such as bleach,

mildewcide, methylene chloride and 1,1,1--trichloroethane. They are not

compa e with aluminum.

•Contact your coa g supplier about the compa lity of

material with aluminum.

HAZARD: HAZARDOUS VAPORS

Paints, solvents, insec cides, and other

materials can be harmful if inhaled or come in

contact with the body. Vapors can cause

severe nausea, fa g, or poisoning.

PREVENTION:

•Use a respirator or mask if vapors can be

inhaled. Read all instruc ons supplied with

the mask to be sure it will provide the

necessary prote .

•Wear eyewear.

•Wear clothing as required by coa g manufacturer.

HAZARD: GENERAL

Can cause severe injury or property damage.

PREVENTION:

•Read all instruc ons and safety before

equipment.

•Follow all appropriate local, state, and codes

governing ven a , fire preven on, and

•Use only manufacturer authorized parts. User assumes all

risks and liabili es when using parts that do not meet the

minimum specifica s and safety devices of the turbine

manufacturer.

•Do not spray outdoors on windy days.

•Wear clothing to keep paint off skin and hair.

•Never aim spray gun at any part of the body.

Household use only. Intended for outdoor use ONLY with

materials having flashpoint above 70oF (21oC).

2

Technical Data

Double insula n

Voltage

Frequency

Power

Nozzle Size

Max. Viscosity

Max. Spraying Pressure

Flow Rate

Container Capacity

Nozzle Material

120V~

60Hz

3.0A

Φ2.5mm (/Φ1.8mm/Φ1.0mm)

60DIN-s

0.1-0.2Bar

700ml/min

800ml

Copper Nozzle

ImportantSafetyInformation•Readallsafetyinformationbefore

operatingtheequipment.Savetheseinstructions

ImportantElectricalInformation

1.Thetoolplugmustfitintothesocket.Theplugmaynotbemodifiedinanyform.Donotuseadaptorplugstogetherwithprotective‐earthedtools.

Unmodifiedplugsandsuitablesocketsreducetheriskofanelectricshock.

2.Avoidphysicalcontactwithearthedsurfacessuchaspipes,heatingelements,stovesandrefrigerators.Theriskthroughelectricshockincreasesif

yourbodyisearthed.

3.Keeptheequipmentawayfromrainandmoisture.Theriskofanelectricshockincreasesifwaterpenetrateselectricalequipment.

4.Donotmisusethemainsleadbycarryingthetoolbythelead,hangingitfromtheleadorbypullingontheleadtoremovetheplug.Keepthelead

awayfromheat,oil,sharpedgesormovingtoolparts.Damagedortwistedleadsincreasetheriskofanelectricshock.

5.Ifyouworkoutdoors,useonlyextensionleadsthatareapprovedforoutdooruse.Theuseofanextensionleadthatissuitableforoutdoorsreduces

theriskofanelectricshock.

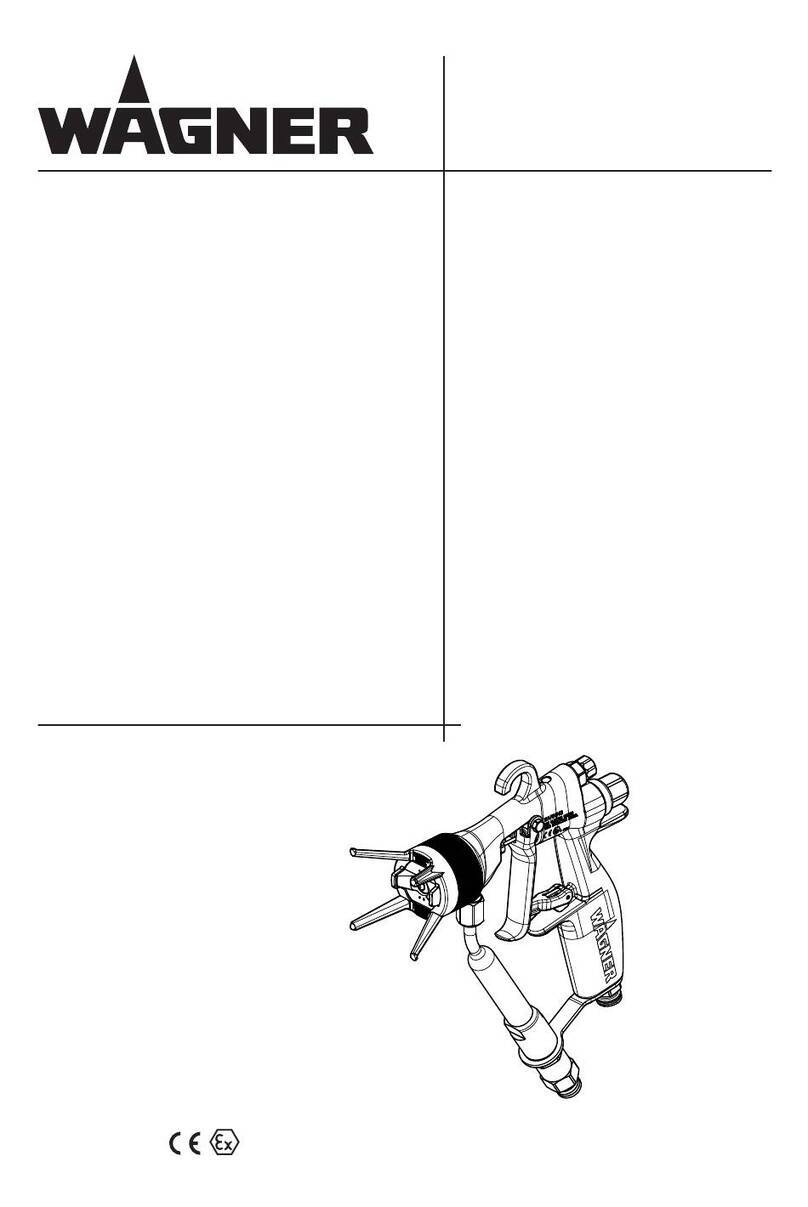

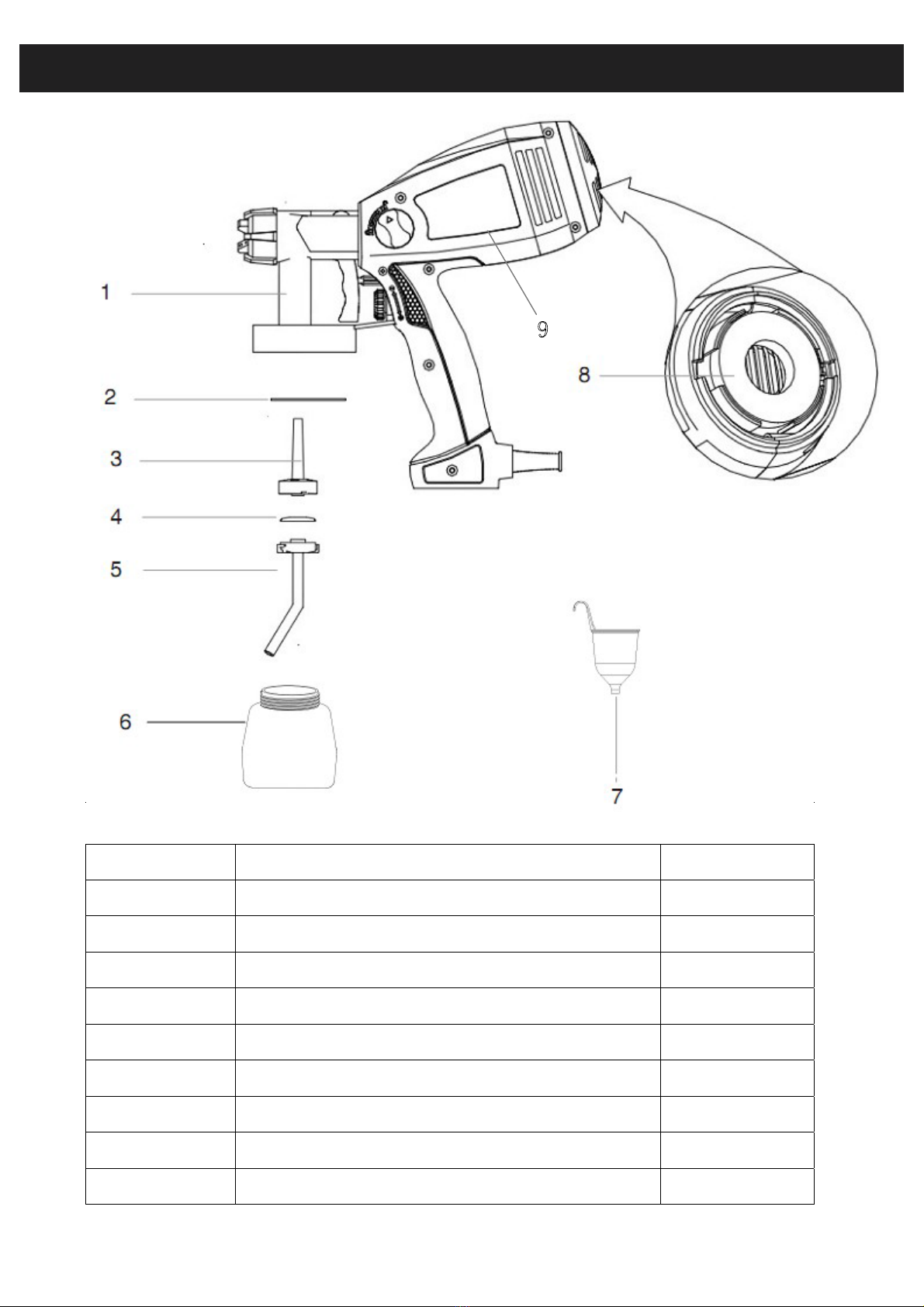

Components

ComponentsCompoC

3

Filter

housing

Nut Aircap

Viscositycup

Seal

Nozzle

Trigger

Material

adjustment

knob

Handle

container

AirCompressor

Assembly

Setup

1.TurnbothknobsonbothsidesoftheAirCompressorAssemblytothe

“Unlock”position,andInsertthespraygunintotheAirCompressor

Assemblyintoplace,

2.TurnbothknobsonbothsidesoftheAirCompressorAssemblytothe

“Lock”positiontolockthetwopiecesintoplace.

AligningtheSuctionTube

Ifyouaregoingtobesprayinginadownwarddirection,

theangledendofthesuctiontubeshouldbepointing

towardthefrontofthegun.

Ifyouaregoingtobesprayinginanupwarddirection,

theangledendofthesuctiontubeshouldbepointing

towardtherearofthegun.

Bypointingthesuctiontubeintheproperdirection,you

willnothavetorefillthecontainerasoften..

MaterialPreparation

Beforespraying,thematerialbeingusedmayneedtobe

thinnedwiththepropersolventasspecifiedbythe

materialmanufacturer.Neverexceedthethinning

advicegivenbythecoatingmanufacturer.

Donotusematerialswithaflashpointbelow70°F

(21°C).Followtheinstructionsbelow.

1.Stirthesprayingmaterialthoroughlybeforemeasuring

viscosity.

2.Diptheviscositytestcupcompletelyintothespraying

material.

3.Holdthetestcupupandmeasurethetimeinsecondsuntil

theliquidemptiesout.Thistimeisreferredtobelowas

RunoutTime.

ThinningChart

MaterialRunoutTime

1)Oilenamel25‐40

2)Oilbasedprimer30‐45

3)OilstainNothinningrequired

4)ClearsealerNothinningrequired

5)PolyurethaneNothinningrequired

6)Varnish20‐50

Materialtobesprayedshouldalwaysbestrainedtoremoveany

impuritiesinthepaintwhichmayenterandclogthesystem.Impuritiesin

thepaintwillgivepoorperformanceandapoorfinish.

MATERIALFLASHPOINTMUSTBE70°F(21°C)OR

HIGHER.

FillContainer

1.Unscrewthecupfromthespraygun.

2.Afterthematerialhasbeenproperlythinnedandstrained,

fillthecontainertothetopoftheneck.

3.Carefullyscrewthecupbackontothespraygun.

4

Spraying

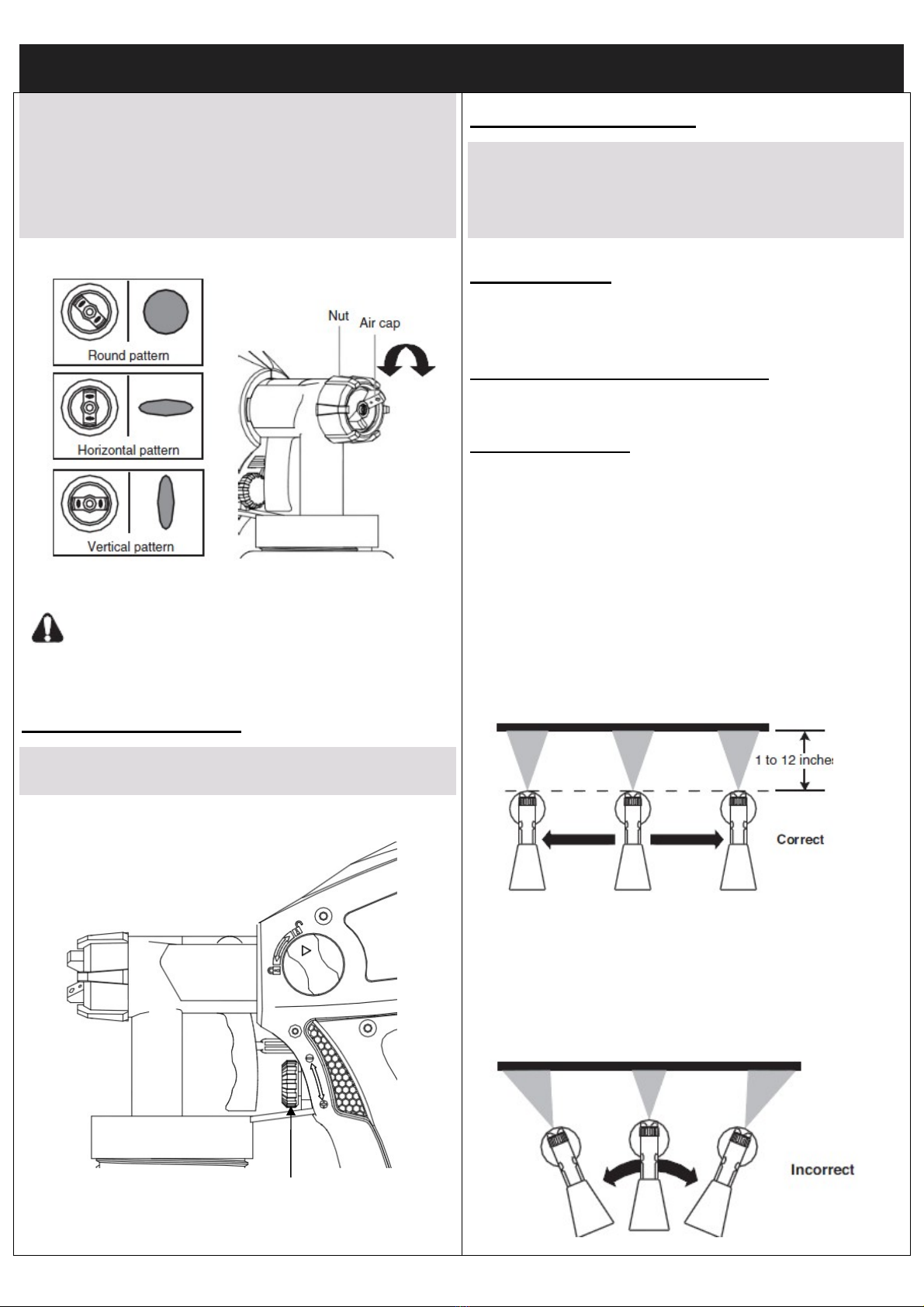

Thespraypatternshapeisadjustedbyturningtheears

oftheaircaptoeitherthevertical,horizontal,or

diagonalpositions.Thepositionsoftheaircapandthe

correspondingspraypatternshapesareillustratedbelow.

Testeachpatternandusewhicheverpatternissuitable

foryourapplication.

NEVERtriggerthegunwhileadjustingtheearson

theaircap.NEVERpointthespraygunatanypart

ofthebody.

MaterialFlowAdjustment

Setthematerialvolumebyturningtheregulatorbehindthetriggerofthe

spraygun.

ProperSprayingTechnique

IfsprayingwithanHVLPspraysystemisnewor

unfamiliartoyou,itisadvisabletopracticeonapieceof

scrapwoodorcardboardbeforebeginningonyour

intendedworkpiece.

SurfacePreparation

Allobjectstobesprayedshouldbethoroughlycleanedbefore

sprayingmaterialonthem.Areasnottobesprayedmay,in

certaincases,needtobemaskedorcovered.

SprayAreaPreparation‐outdooruseonly

Thesprayareamustbecleanandfreeofdustinordertoavoidblowing

dustontoyourfreshlysprayedsurface.

HowtoSprayProperly

•Positionthespraygunperpendiculartoandone(1)ormoreinchesfrom

thespraysurface,dependinguponthespray

patternsizedesired.

•Sprayparalleltothesurfacewithsmoothpassesata

consistentspeedasillustratedbelow.Doingthiswillhelp

avoidirregularitiesinthefinish(i.e.runsandsags).

•Alwaysapplyathincoatofmaterialonthefirstpassand

allowtodrybeforeapplyingasecond,slightlyheaviercoat.

•Thecloseryoursprayeristotheobjectbeingsprayedthe

lowertheoverspray.

Evencoatthroughout

Keepstrokesmoothandatanevenspeed

•Whenspraying,alwaystriggerthespraygunafterspray

passhasbegunandreleasetriggerbeforestoppingthe

pass.Alwayskeepthegunpointedsquarelyatthespray

surfaceandoverlappassesslightlytoobtainthemost

consistentandprofessionalfinishpossible.

LightcoatHeavycoatLightcoat

Donotflexwristwhilespraying.

5

Cleanup

CleaningtheSprayGun

Specialcleanupinstructionsforusewith

flammablesolvents(musthaveaflashpointabove

70ºF(21ºC):

•Alwaysflushspraygunoutside.

•Areamustbefreeofflammablevapors.

•Cleaningareamustbewell‐ventilated.

•DONOTSUBMERGEAirCompressor!

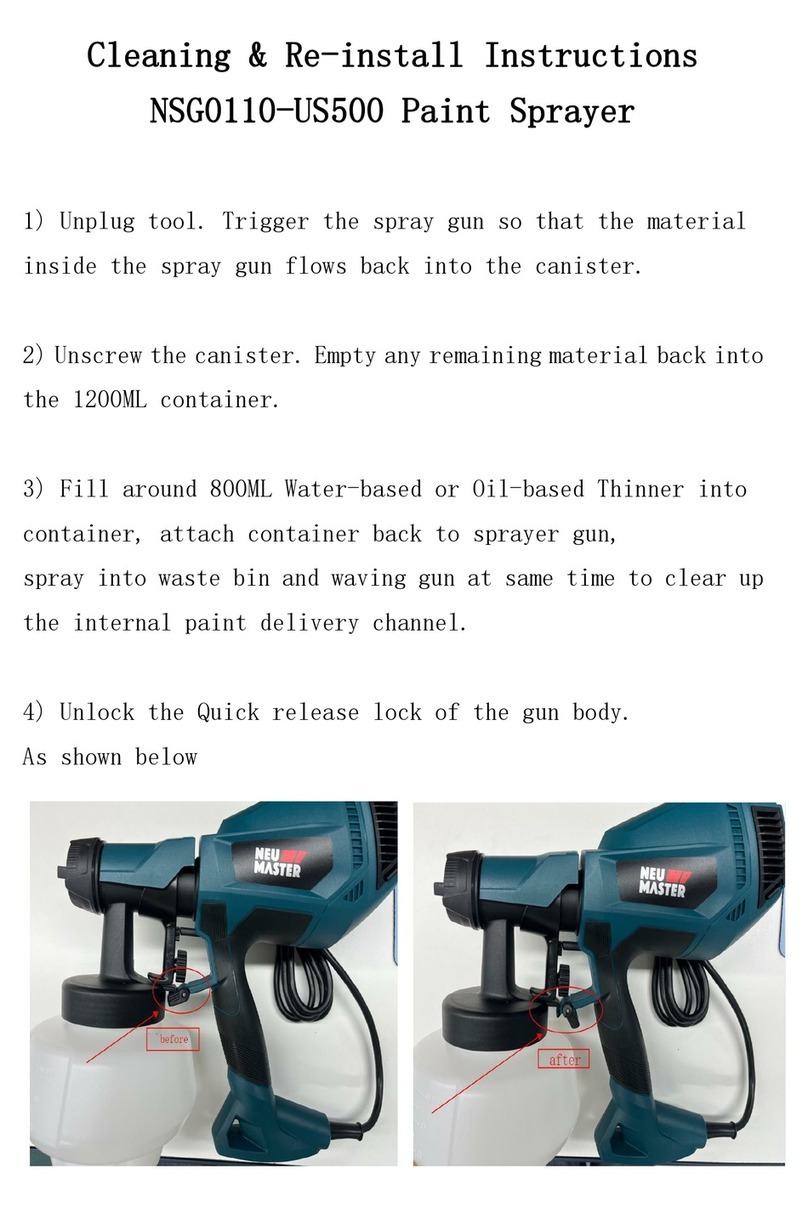

1.Unplugthespraygun,and

triggerthespraygunsothat

thematerialinsidethespray

gunflowsbackintothe

container.

2.Unscrewthecontainer.

Emptyanyremainingmaterial

backintothematerial

container.

3.Pourasmallamountofthe

appropriatecleaningsolution

intothecup(warm,soapy

waterforlatexmaterials;

mineralspiritsforoil‐based

materials).Cleancupand

properlydisposeof

cleaningsolution.

4.RefillthecupwithNEW

cleaningsolution.

5.Attachthecuptothegunand

pluginthesprayer.

6.Spraythesolutionthroughthe

gunfortwosecondsinasafe

area.Sprayagainfortwo

seconds.Unplugthespray

gun,andtriggerthespraygun

sothatthematerialinsidethe

spraygunflowsbackintothe

container.

7.Wipetheexteriorofthecup

andgununtilclean.

8.Unscrewthenutand

removetheaircap

andnozzle.

9.Cleanthecontainer,

suctiontube,aircap

andnozzlewitha

cleaningbrushand

theappropriate

cleaningsolution.

Nevercleannozzleorairholesinthespraygunwith

sharpmetalobjects.Donotusesolventsorlubricants

containingsilicone.

10.Turnbothknobsonbothsides

oftheAirCompressorAssembly

tothe“Unlock”position,pulland

separatethespraygunfromthe

AirCompressorAssembly.

11.(a)Cleantherearofthespray

gunwiththeappropriatecleaning

solution.

(b)Turnthesuctiontube

anti‐clockwiseandpullthesuction

tubedownwardtodisassembleit

fromthespraygun.Thencleanthe

suctiontubewiththeappropriate

cleaningsolution.

Attention!TheSealRing(4)betweenSuctionTube1(3)andSuctionTube

2(5)mustbeputbackintoplaceaftercleaning.Otherwise,somepaintin

thecontainerwillbesuckedintotheairductandinterferewiththe

functionoftheunit.

6

(a)

(b)

Maintenance

YoushouldinspecttheairfilterintheAirCompressorAssemblytoseeifit

isexcessivelydirty.Ifitisdirty,followthestepsbelow

toreplaceit.

1.Unplugthespraygun.Remove

thefiltercoverwithatool

(suchasaflatscrewdriver)

2.Removethedirty

filtersandreplace

withnewones.

3.Securethecoverbackontotheturbine.

Neveroperateyourunitwithouttheairfilters.Dirtcould

besuckedinandinterferewiththefunctionoftheunit.

Troubleshooting

Problem

A.Littleornomaterialflow

B.Materialleaking

C.Atomizationistoocoarse

D.Sprayjetpulsates

E.Patternrunsorsags

F.Toomuchoverspray

G.Patternisverylightand

splotchy.

Cause

1.Nozzleclogged.

2.Suctiontubeclogged.

3.Materialvolumesettingturnedtoolow(‐).

4.Suctiontubeloose.

5.Nopressurebuildupincontainer.

6.Airfilterclogged.

1.Nozzleloose.

2.Nozzleworn.

3.Nozzlesealworn.

4.Materialbuild‐uponaircapandnozzle

1.Viscosityofmaterialtoohigh.

2.Materialvolumetoolarge.

3.Materialvolumesettingtoohigh(+).

4.Nozzleclogged.

5.Airfilterclogged.

6.Toolittlepressurebuild‐upincontainer.

1.Materialincontainerrunningout.

2.Airfilterclogged.

1.Applyingtoomuchmaterial.

1.Guntoofarfromsprayobject.

2.Toomuchmaterialapplied.

1.Movingthesprayguntoofast

Solution

1.Clean.

2.Clean.

3.Increasevolumesetting(+).

4.Insert.

5.Tightencontainer.

6.Change.

1.Tighten.

2.Replace.

3.Replace.

4.Clean.

1.Thin.

2.Decreasevolumesetting(‐).

3.Decreasevolumesetting(‐).

4.Clean.

5.Change.

6.Tightencontainer.

1.Refill.

2.Change.

1.Adjustmaterialfloworincrease

movementofspraygun.

1.Reducedistance.

2.Decreasevolumesetting(‐).

1.Adjustmaterialflowordecrease

movementofspraygun.

7

filters

Parts List

8

9

Number Part Descripon Quanty

1 Sprayer Assembly 1

1

1

1

1

1

1

1

1

2Container Seal

3Sucon Tube 1

4 Seal Ring

5Sucon Tube 2

6Container

7Viscosity Cup

8 Air Filter

9Air Compressor Assembly

Table of contents

Other NEU MASTER Paint Sprayer manuals