Installation

Installation Installation

Installation

Toreducetheriskofelectricshock,reand

explosion,allelectricalwiringmustbedonebya

qualiedelectricianandcomplywithalllocalcodes

andregulations.

Power Power

PowerRequirements Requirements

Requirements

SeeDriverInstallationmanualforinstructionsfor

powerrequirements.

Connect Connect

ConnectPower Power

Power

SeeDriverInstallationmanualforinstructionsto

connectpower.

Grounding Grounding

Grounding

Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

Sprayer: Sprayer:

Sprayer:Systemisgroundedthroughthepower

cord.

Fluid Fluid

Fluidhoses: hoses:

hoses:Useonlyelectricallyconductivehoses

withamaximumof210ft.(64m)combinedhose

lengthtoensuregroundingcontinuity.Check

electricalresistanceofhoses.Iftotalresistance

togroundexceeds25megaohms,replacehose

immediately.

Spray Spray

Spraygun: gun:

gun:Groundthroughconnectiontoaproperly

groundeduidhoseandpump.

Fluid Fluid

Fluidsupply supply

supplycontainer: container:

container:Groundtheuidsupply

container.Followlocalcode.

Object Object

Objectbeing being

beingsprayed: sprayed:

sprayed:Groundtheobjectbeing

sprayed.Followlocalcode.

Solvent Solvent

Solventpails pails

pailsused used

usedwhen when

whenushing: ushing:

ushing:Followlocal

code.Useonlyconductivemetalpails,placedon

agroundedsurface.Donotplacethepailona

non-conductivesurface,suchaspaperorcardboard,

whichinterruptsgroundingcontinuity.

To To

Tomaintain maintain

maintaingrounding grounding

groundingcontinuity continuity

continuitywhen when

whenushing ushing

ushingor or

or

relieving relieving

relievingpressure: pressure:

pressure:Holdthemetalpartofthespray

gun/dispensevalvermlytothesideofagrounded

metalpail,thentriggerthegun/valve.

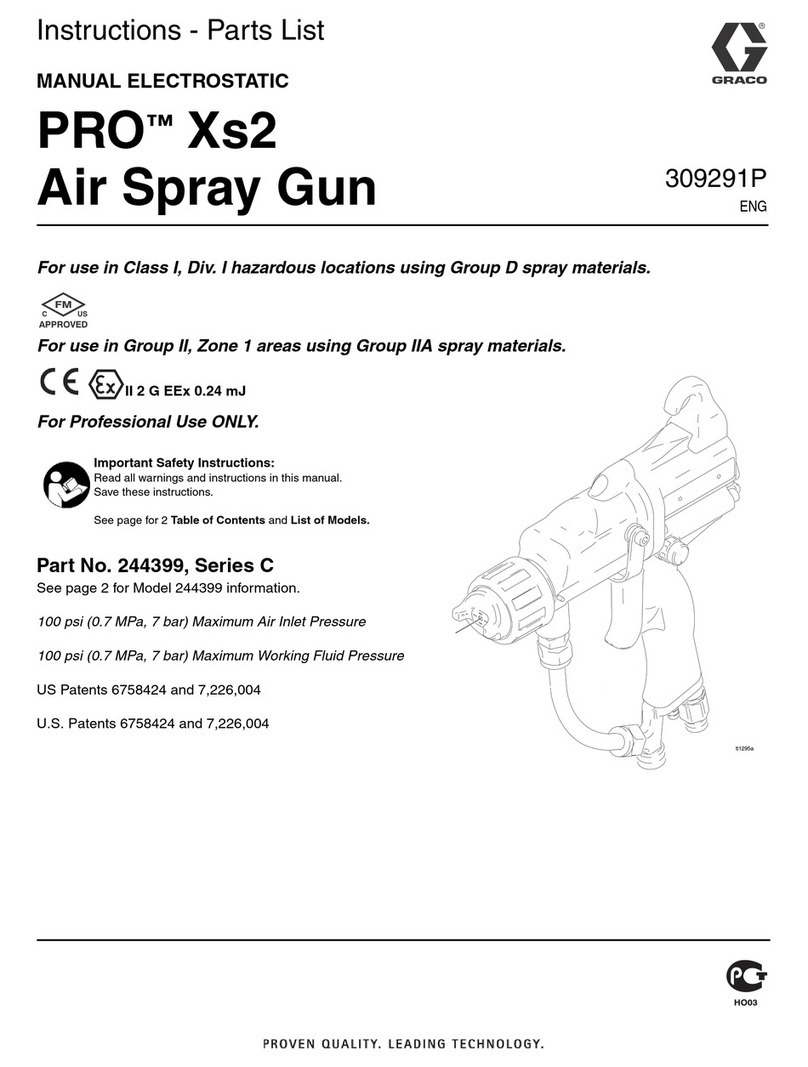

1.Loosenthegroundscrew(Y)andattachaground

wire(Gracopart244524–notsupplied).Tighten

thegroundscrewsecurely.Connecttheother

endofthegroundwiretoatrueearthground.

NOTE: NOTE:

NOTE:Twogroundterminalsareprovidediflocal

coderequiresredundantgroundingconnections.

2.Groundtheobjectbeingsprayed,uidsupply

container,andallotherequipmentinthe

workarea.Followyourlocalcode.Useonly

electricallyconductiveairanduidhoses.

3.Groundallsolventpails.Useonlymetalpails(5

gallon(19liter)metalpail,Gracopart101108

–notsupplied),whichareconductive,placed

onagroundedsurface.Donotplacepailon

anon-conductivesurface,suchaspaperor

cardboard,whichinterruptsgroundingcontinuity.

8 3A8126B