New Focus 3501 User manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Model 3501 User’s Manual

Optical Chopper

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

Contents

351007 Rev. B

3

4

6

8

9

21

22

24

41

43

45

I Warranty

II Introduction

III Safety and

Preparation for Use

IV Quick Start

V Operation

VI Rack Mount Kit

VII Computer Control

VIII Command Summary

IX Troubleshooting

X AC Operating

Voltages

XI Specifications

Is a registered trademark of

New Focus, Inc.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

I

Warranty

New Focus, Inc. guarantees the chopper head to be free of defects for 90 days

from the date of shipment. All other parts of the Model 3501 Optical Chopper

are guaranteed to be free of defects for one year from the date of shipment.

This is in lieu of all other guarantees, expressed or implied, and does not

cover incidental or consequential loss.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4

The Model 3501 Optical Chopper is designed to interrupt light paths in optical

experiments at frequencies from 4 Hz to 6.4 kHz. Both single and dual beam

experiments can be performed across a broad range of chopping frequencies.

The chopper has a crystal controlled frequency synthesizer that serves as an

internal reference frequency for locking the chopper to a particular chopping

frequency. Reference frequencies can also be provided through the Sync Input

to allow the chopper to lock to an external source. A block diagram of the

optical chopper system is shown in Figure 1.

Several measures ensure that jitter and drift of the chopping frequency is

reduced to a minimum. Precision photo-etched wheels are mounted on a

high quality DC motor. The motor head has a photo-sensor for monitoring

the chopping frequency of the outer part of the wheel (Fouter). The chopper

controller then actively stabilizes the motor speed to match the desired chop-

ping frequency. This technique minimizes phase noise at the chopping fre-

quency and provides for long-term stable chopping with a minimum of fre-

quency drift.

Figure 1 shows a block diagram of the Model 3501 Optical Chopper system.

Programmable divide/multiply circuitry allows for harmonic or subharmonic

locking of the chopper to the reference frequency. In addition, the phase of

the chopping frequency may be varied over a -180 to +179 degree range with

respect to the reference frequency. A variety of TTL level outputs are available

for use in triggering lock-in amplifiers, oscilloscopes, photon counters or box-

car averagers.

II

Introduction

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

The chopping frequency, as well as a number of other operating parameters,

can be viewed on the front panel display, and cursor keys provide easy adjust-

ment of operating parameters. From the front panel the user can store and

recall up to nine instrument set-ups. An IEEE-488 interface provides remote

operation of all instrument functions.

The chopper head can be mounted on a 1/2”-diameter post or bolted directly

to a standard optical bench. The Model 3501 Optical Chopper is supplied with

four chopper wheels and a wheel cover. The Model 3510 Rack Mount Kit, an

accessory that is sold separately, enables the chopper controller to be mounted

in a rack (see Page 21).

Optical Trigger Motor

Chopping Head

Phase

Shifter

Ext V

4 Hz - 6.4 KHz

Micro-

processor

Front

Panel +/-

H/S

Norm

Out 1

Out 2

f Outer

f Synch

f Outer

Out 1

Out 2

Synch

Out

Int

Synch In Subharmonic

Divide by 1 to 15

Internal Frequency

Synthesizer

Harmonic

Multiplier 1 to 15

Motor

Controller

Divide by 7 Divide by 6

IEEE-488

Fig. 1

Block diagram of the Model 3501 Optical Chopper.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6

Mounting the Chopper Head

The Model 3501 Optical Chopper head may be secured to standard optical

benches using 1/4-20 or M6 bolts. The bolts pass through the mounting plate

perpendicular to the plane of the optical bench. The chopper head can be

rotated off-axis by loosening the 1/4-20 set screws on the side of the motor

mount. Do not over-tighten the set screws.

The Model 3501 Optical Chopper head may also be mounted on standard

optical bench rods. First loosen the two 1/4-20 set screws which secure the

mounting plate to the head. Remove the mounting base. Insert the 1/4-20

knob (supplied with the chopper) into the base of the head. This knob is

inserted into the same hole occupied by the dowel on the mounting plate.

Slide the motor mount onto the optical bench rod and tighten the knob. Do

not over-tighten the knob.

Mounting the Wheel

Remove power from the control unit before attempting to change the chopper

wheel. Secure the chopper head to a work surface. Remove the four 4-40

screws that secure the retaining cap over the wheel, while taking care not to

bend the wheel. Install the replacement wheel, retaining cap and 4-40 screws.

Do not over-tighten the screws.

Control Cable

Connect the 6-wire cable from the connector at the side of the chopper head to

the MOTOR connector at the back of the control unit.

WARNING: Do not connect or disconnect the chopper head while the control

unit is powered or damage to components may occur. Always shut off the

instrument and allow the motor to stop before disconnecting the cable.

III

Safety and

Preparation

for Use

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

Line Voltage Selection

The instrument may be damaged if operated with the line voltage selector set

at the wrong voltage or with the wrong fuses installed in the power entry

module. When the instrument ships from the factory, it will be programmed

for the standard AC voltage in the user’s country. To select a different operat-

ing voltage refer to the AC Operating Voltages section (Page 43).

Grounding

The line cord is a three-wire power cord for connection to the power mains

and a protective ground. The chassis is connected to the protective ground to

reduce the risk of electric shock. To avoid potential electrical shock, use only

mains that provide a protective ground.

Wheel Hazard

WARNING: The moving wheel may inflict injury. The operator should

assure the safety of personnel who may be exposed to this hazard.

Safety is important! The chopper wheel can cause injury if it is touched while

rotating. This is especially critical if you find yourself reaching into your opti-

cal set-up with the lights off. You may want to use the chopper wheel cover to

reduce the chance of injury.

Environment

The Model 3501 Optical Chopper may be operated in an ambient of 0 to 40

degrees C. It is recommended to avoid direct sunlight on the LED display.

WARNING: Hazardous voltages, capable of causing death, are present inside

this instrument. Do not operate the instrument with the covers removed.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8

Before operating the Model 3501 Optical Chopper, please review the previous

section to make sure the chopper is ready for use.

1. Mount the chopper head securely on an optical bench.

2. Mount the 42/30 wheel on the head. Avoid bending the wheel. The wheel

should be free to turn without contact to the optical sensor or nearby

equipment.

3. Connect the cable between the chopper head and the connector marked

MOTOR on the back panel of the control unit.

4. Check that the correct line voltage has been selected and the proper fuse

inserted into the mains power entry module at the back panel of the con-

trol unit. Connect the instrument to the power mains.

5. After insuring the safety of nearby personnel, switch on the instrument.

6. Recall instrument set-up “0” (factory default setting). Press SET until

“RECALL” is lit. Press the up/down arrow keys until “0” appears in the

display window. Press the left or right arrow key to recall set-up “0”.

7. The instrument will lock at 84 Hz within 1 minute.

8. To choose a particular chopping frequency, press the Set key until the

FREQ LED is lit, and then use the up/down arrows keys to adjust the

chopping frequency.

IV

Quick Start

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

This section describes operation of the chopper, starting with an overview of

the front panel functions. This is followed by a description of the chopper

back panel and the chopper head.

V

Operation

Sync

Input

Wheel Sync

Measure

Set Power

Mode

Synthesizer

Output F Outer

60

42/30

7/5

2

V ext.

EXT

+

EXT

-

INT

SYNC IN

F outer

OUT 1

OUT 2

UNLCK

DEG

kHz

Hz

ACT

FREQ

PHASE

H

S

RECALL

STORE

IEEE

H/S

+

/

-

NORMAL

NEW FOCUS, Inc.

Made in USA

3501 Optical Chopper

Fig. 2

Front panel of the Model 3501 chopper controller.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10

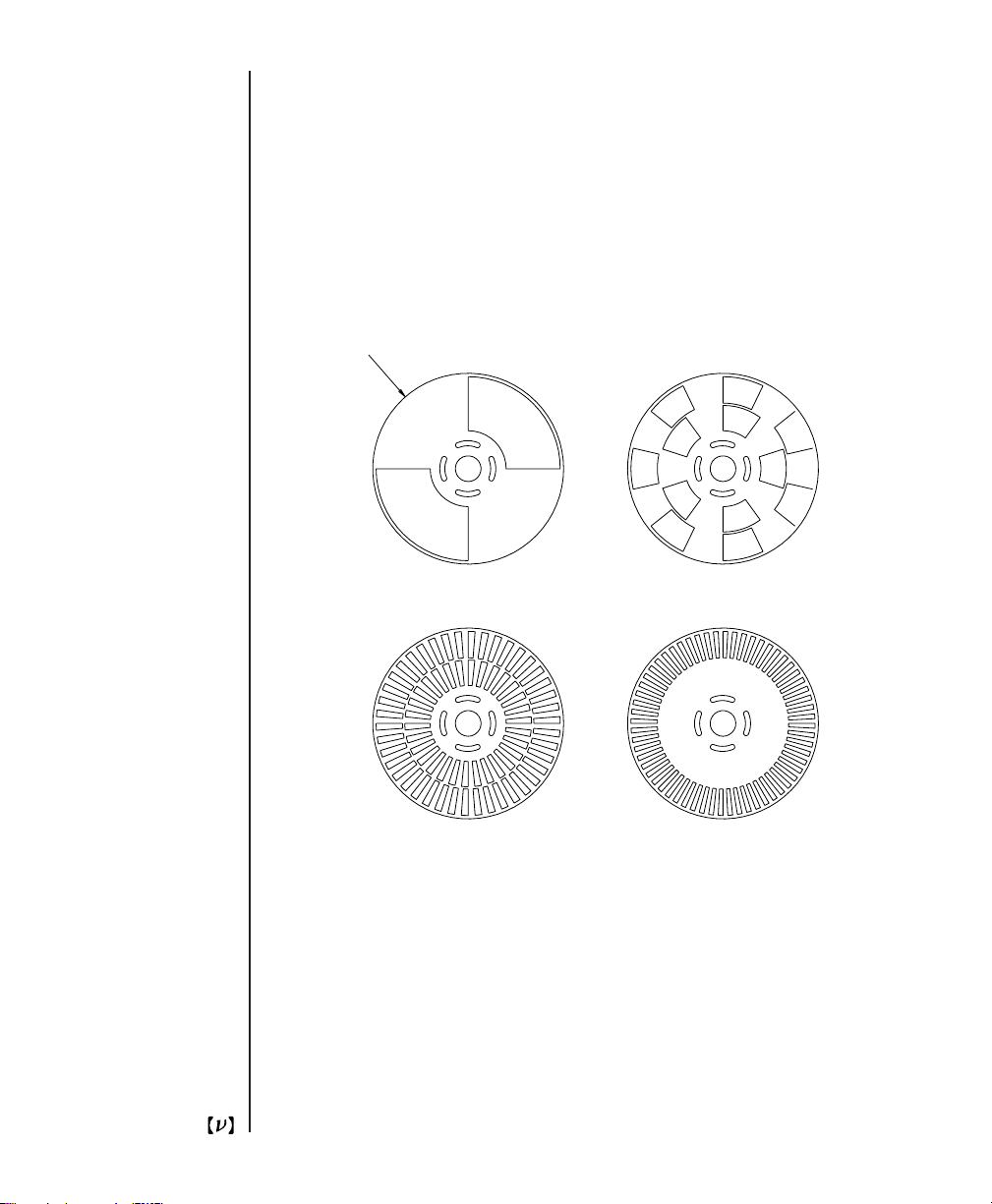

Wheel

The user may select from single or double slot wheels to perform single or

dual path experiments. Different wheel apertures may be selected to accom-

modate the chopping frequency of interest. The table below summarizes

wheel choices and chopping frequency ranges.

Wheel Type Lowest Frequency Highest Frequency

(slots) (Fouter) (Fouter)

60 120 Hz 6.40 kHz

42/30 84 Hz 4.48 kHz

7/5 14 Hz 746 Hz

2 4 Hz 213 Hz

Fouter is the chopping frequency as measured by an optical pick-up on the

chopper head. If a wheel has two sets of slots, Fouter refers to the chopping

frequency of the slots on the outer edge of the wheel.

To change the wheel type, push the Wheel key until the LED lights under the

desired wheel type.

Sync

The user may synchronize the chopping frequency to the chopper's internal

synthesizer (INT), or the rising edge (EXT+) or falling edge (EXT-) of an

externally-supplied Sync Input signal. When Vext is selected, the user may

drive the motor directly with an analog voltage applied at Vext on the back

panel. When using Vext or INT, a signal applied to the Sync Input has no

effect on the chopper.

To change the Sync source, press the Sync key until the LED under the desired

Sync source lights.

Front Panel

Operation

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

Mode

The Mode setting changes the reference signals available at OUT1 and OUT2

on the back panel as follows:

Mode Fouter OUT1 OUT2

H/S [H/S]·Fsync [H/S]·Fsync [H/(7·S)]·Fsync

+/- Fsync Fouter - Finner Fouter + Finner

NORMAL Fsync 5·Fouter Finner

To change the Mode, push the Mode key until the LED under the desired

Mode lights.

Fouter is the chopping frequency of the outer set of slots as measured by an

optical pick-up on the chopper head. Finner is the chopping frequency of the

inner set of slots. For wheels with only one set of slots Fouter is the chopping

frequency, and Finner is not defined.

Fsync is the frequency of the Sync source. In INT Sync mode, Fsync is the fre-

quency of the chopper's internal frequency synthesizer. In EXT+ or EXT- Sync

mode, Fsync is the frequency of the externally supplied signal at the Sync

Input.

Set

The Set key selects which instrument parameter is modified by the cursor

keys. Press SET until the LED lights under the desired parameter. The up

arrow and down arrow keys will then change the parameter value. In some

cases, the left arrow and right arrow keys select the significant digit to be

modified.

FREQ The user may set the synthesizer frequency depending on the Sync

source selected. When EXT-, EXT+ or Vext sync has been selected, the fre-

quency may range from 4.00 Hz to 99.9 kHz.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

12

When INT Sync is selected, the synthesizer frequency will be restricted to the

working range of the particular chopping wheel. In H/S mode this range will

be modified by the setting of H and S. In this case, the range limits may be

calculated as follows:

Fupper = Fouter [highest] · (S/H) and

Flower = Fouter [lowest] · (S/H),

where S,H = 1 - 15.

Setting FREQ The synthesizer frequency may be set to three significant

digits. The significant digit to be modified may be selected by the left arrow

and right arrow keys. The magnitude of the digit may be changed with the up

arrow and down arrow keys. If the display overflows or underflows, the display

will change the Hz/kHz LEDs and the decimal point to maintain three signifi-

cant digits of resolution.

PHASE The phase delay may be set from +179.0° to -180.0°. The phase

shift is always referred to the chopping frequency Fouter. In NORMAL and +/-

modes Fouter = Fsync. In H/S mode Fouter = [H/S]·Fsync.

When the phase adjustment is active, the DEG LED will be lit. The left arrow

and right arrow keys select the significant digit to be modified, and this digit

will blink. The up arrow and down arrow keys change the magnitude of the

digit.

H In H/S mode the user may lock the chopper to a harmonic of the sync

frequency. H is set to the harmonic of interest. Use the up arrow and down

arrow keys to set H from 1 to 15.

SThe user may lock the chopper to a subharmonic of the sync frequency. S

is set to the subharmonic of interest. Use the up arrow and down arrow keys to

set S from 1 to 15. S and H may be set in any combination. Changing S only

has an effect when the chopper is in H/S mode.

STORE The user may store an instrument set-up in one of two ways. First,

the control unit will retain the control settings when the power is removed.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

13

When power is restored, the instrument will recall the last control settings used.

Second, the user may utilize one of nine programmable instrument set-ups.

To store an instrument set-up press the Set key until STORE is lit. Then, use

the up arrow and down arrow keys to select instrument set-ups 1-9. Press the

left arrow or right arrow key to store the instrument’s settings at the selected

instrument set-up. The display will blink to indicate that the storage process

is complete. Location 0 is reserved for the factory default settings: 42/30

wheel, internal sync, normal mode, 84 Hz, IEEE address 12.

RECALL The user may recall instrument set-ups in one of two ways. First,

the control unit will retain the control settings when the power is removed.

When power is restored, the instrument will recall the last control settings

used.

Second, the user may utilize one of ten programmable instrument set-ups. To

recall a previously stored instrument set-up, use the up arrow and down

arrow keys to select instrument set-ups 0-9. Press the left arrow or right arrow

key to recall the selected instrument set up. The display will blink when the

recall process is complete. Location 0 is reserved for the factory default set-

tings.

Default settings Recalling set-up ‘0’ will restore the instrument to the

factory default settings: 42/30 wheel, internal sync, normal mode, 84 Hz,

IEEE address 12.

IEEE The user may select the Model 3501’s device address on the IEEE-488

bus. The factory default setting is 12. Use the up arrow or down arrow key to

change the device address.

Measure

The Measure key selects which frequency measurement—OUT1, OUT2,

Fouter or Fsync—is displayed on the front panel. The instrument will contin-

ue to measure and update the display until another function key is pressed.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

14

To change the Measure parameter, press the Measure key until the LED lights

under the desired parameter.

Sync Input

The user may connect a TTL level sync frequency at the Sync Input. EXT+ or

EXT- sync must be selected and the frequency must remain within the limits

defined above in the FREQ section. The UNLCK LED will blink if the Sync

Input frequency is outside the limits.

Synthesizer Output

The instrument provides the user with a TTL level square wave output for use

in experiments. The Synthesizer Output frequency is adjusted by setting the

FREQ parameter from the front panel or via IEEE-488. With INT sync active,

the frequency will be limited as given above in the FREQ section. With EXT+,

EXT- or Vext, the Synthesizer Output ranges from 4.00 Hz to 99.9 kHz.

Fouter

The instrument provides the user with a TTL level square wave generated

from an optical pick-up on the chopper head.

ACT

The ACT LED indicates when the IEEE-488 interface is busy.

UNLCK

The red UNLCK LED indicates when the chopper is not synchronized to an

internal or external sync frequency. The UNLCK LED will blink when an

external sync frequency exceeds the limits for a particular wheel.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

15

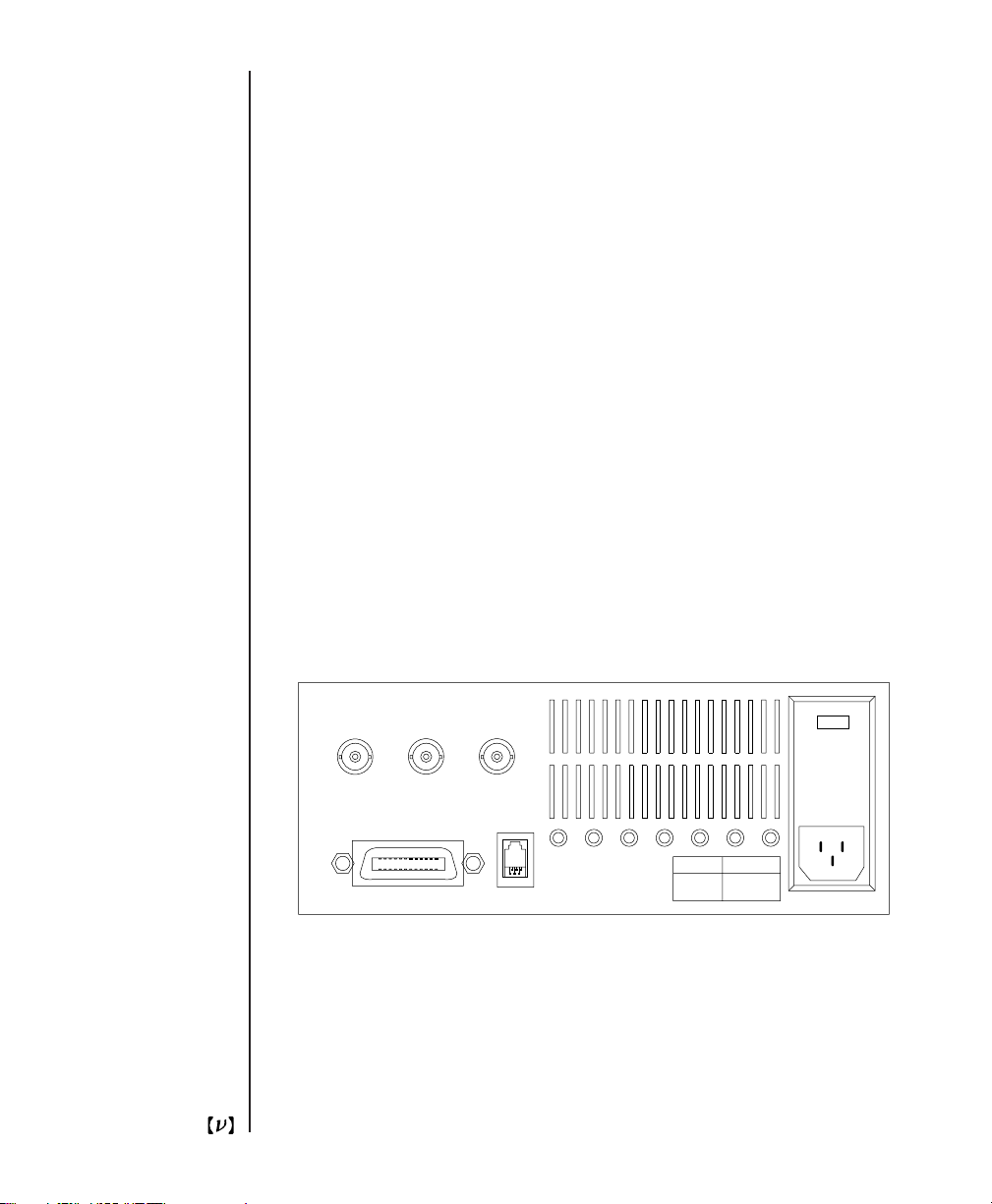

OUT 1 OUT 2 V ext

TTL TTL -10V=100%

IEEE-488 MOTOR

WARNING: High voltage

inside. Refer to qualified

technician for service.

VOLTS AC SLO-BLO FUSE

100-120

220-240

0.4 AMP

0.2 AMP MADE IN THE U.S.A.

120 Vac

Fig. 3

Back panel of the chopper controller.

OUT1

The function of the OUT1 output depends on the instrument’s operating

mode. In H/S mode, the instrument provides a TTL level pulse at fre-

quency [H/S]·Fsync. In +/- mode the frequency at OUT1 is

Fouter - Finner, and in NORMAL mode the frequency is 5·Fouter.

OUT2

The function of the OUT2 output depends on the instrument’s operating

mode. In H/S mode, the instrument provides the user with a TTL level

pulse at frequency [H/(7·S)]·Fsync. In +/- mode the frequency at OUT2

is Fouter+Finner, and in NORMAL mode the frequency is Finner.

Back Panel

Operation

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

16

Vext

When Vext sync is selected, the user may drive the chopper motor directly with

a DC input voltage. 0 to -10 V DC corresponds to 0 to 100% of the highest

motor speed.

MOTOR

Use the supplied cable to connect the chopping head to the chopper controller

at the back panel.

IEEE-488

The instrument may be programmed remotely via IEEE-488. Use a standard

cable to connect the instrument to the host computer system.

Power entry module

The AC power is connected at the power entry module on the back panel. The

line voltage and power cord have been chosen at the factory to match the

country of consignment. If it is necessary to change the mains voltage, con-

sult the section on AC Operating Voltages (Page 43).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

17

5.74 " (145.8)

5.48" (139.2)

4.03" (102.4)

0.50" (12.7)

2.25" (57.1)

5.00" (127.0)

2.88" (73.2)

2.00" (50.8)

Fig. 4

Chopper head with wheel cover.

Chopper Head Cable

The cable that connects the control unit to the chopper head is a six conduc-

tor reverse RJ11 type IDC telephone cable. Connect the cable from the connec-

tor on the side of the chopper head to the MOTOR connector on the back

panel of the control unit. The instrument has been tested with cable lengths

up to 25 feet, but the chopper is supplied with a shorter cable. Replacement

cables and longer cables may be purchased from electronics parts suppliers

such as Digi-Key (Part # H2662-14-ND).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

18

Mounting the Chopper Head

The Model 3501 Optical Chopper head may be secured to standard optical

benches using 1/4-20 or M6 bolts. The bolts pass through the mounting plate

perpendicular to the plane of the optical bench. This mounting method pro-

vides the advantage of allowing the wheel to be rotated off-axis by loosening

the 1/4-20 set screws on the side of the motor mount. Do not over-tighten the

set screws.

The Model 3501 Optical Chopper head may also be mounted on standard

optical bench rods. First loosen the two 1/4-20 set screws that secure the

mounting plate to the head. Remove the head. Insert the 1/4-20 knob into

the base of the head. This knob is inserted into the same hole occupied by the

dowel on the mounting plate. Slide the head onto the optical bench rod and

tighten the knob. Do not over-tighten the knob.

Chopper Motor

The operating life of the chopper motor is limited. Long term use of the

motor at high speed will result in faster wear and shorter life. Contact New

Focus for details about replacing the motor, if this becomes necessary.

Mounting the Wheel

Remove power from the control unit before attempting to change the chopper

wheels. Secure the chopping head to a work surface. Remove the four 4-40

screws that secure the retaining cap over the wheel, while taking care not to

bend the wheel. Install the replacement wheel, retaining cap and 4-40 screws.

Do not over-tighten the screws.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

19

Diameter 4.50" (114.3 mm)

2 Slot

42/30 Slot 60 Slot

7/5 Slot

Fig. 5

The four chopper wheels that are supplied with the chopper.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of contents