New Focus Vortex 6000 Series User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Newport / New Focus 6000 Vortex at our website: Click HERE

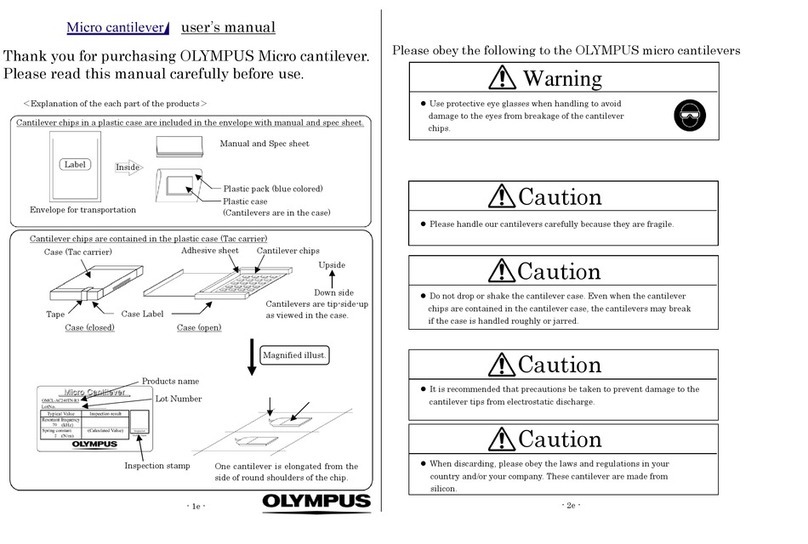

USER’S GUIDE

6000 Vortex Series

Tunable Diode Laser

U.S. Patents #5,319,668 & #5,995,521 and

European Patent #0 693 231 B1

Use of controls or adjustments, or performance of procedures

other than those specified herein, may result in hazardous

radiation exposure.

TM

5215 Hellyer Ave. • San Jose, CA 95138-1001 • USA

phone: (408) 284–6808 • fax: (408) 284–4824

e-mail: contact@newfocus.com • www.newfocus.com

Vortex6000.book Page 1 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Warranty

New Focus, Inc. guarantees its Vortex lasers to be free of material and workmanship defects for

one year from the date of shipment or 3,000 hours of operation, whichever comes first. This

warranty is in lieu of all other guarantees expressed or implied and does not cover incidental or

consequential loss.

Please note that each Vortex laser is custom built to the user’s exact wavelength specification.

Because of the custom nature of this product, returns are accepted only within 30 days from the

date of purchase and are subject to a restocking fee of 50% of the original cost.

Products described in this document are covered by U.S. Patents #5,319,668 and #5,995,521 and

European Patent #0 693 231 B1.

Information in this document is subject to change without notice.

Copyright 2002, 2001–1998, New Focus, Inc. All rights reserved.

The and logos, and NEW FOCUS, Inc. are registered

trademarks and Vortex is a trademark of NEW FOCUS, Inc. Littelfuse and Slo-Blo are registered

trademarks of Littelfuse, Inc.

Document Number 600013 Rev. H

Vortex6000.book Page 2 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series Contents • 3

Contents

User Safety 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Using the Safety Interlock . . . . . . . . . . . . . . . . . . . . . . . . . 7

Getting Started 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Unpacking the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Setting Up the Laser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Starting the Vortex for the First Time . . . . . . . . . . . . . .11

General Operation 13

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

What’s Inside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mounting the Laser Head . . . . . . . . . . . . . . . . . . . . . . . . .14

Using the Front-Panel Controls . . . . . . . . . . . . . . . . . . .15

Turning on the Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Selecting an Operating Mode . . . . . . . . . . . . . . . . . . . . . 17

Displaying and Setting the Laser Parameters . . . . . . .19

Restoring Local (Front-Panel) Control . . . . . . . . . . . . .20

Modulating the Laser Output . . . . . . . . . . . . . . . . . . . . . 20

Reading an Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Vortex6000.book Page 3 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4 • Contents NEW FOCUS, Inc.

Constant-Power Mode 25

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Preparing to Use Constant-Power Mode . . . . . . . . . . .25

Operating in Constant-Power Mode. . . . . . . . . . . . . . .26

Computer Control 29

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Using the IEEE-488 Interface . . . . . . . . . . . . . . . . . . . . . .29

Using the RS-232 Interface. . . . . . . . . . . . . . . . . . . . . . . .30

Restoring Local (Front-Panel) Control . . . . . . . . . . . . .31

Understanding the Command Types . . . . . . . . . . . . . .31

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Command Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Command Definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Principles of Operation 49

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

General Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Changing the AC-Voltage Selection 53

Customer Service 55

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Technical Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix I: Physical Specifications 57

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Laser Head and Mounting Bracket. . . . . . . . . . . . . . . . .58

Appendix II: RS-232 Connector Wiring 59

Index 61

Vortex6000.book Page 4 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series User Safety • 5

User Safety

Introduction

Your safe and effective use of this product is of utmost importance to

us at New Focus. Please read the following laser safety information

before attempting to operate the laser.

Laser Safety

The laser radiation emitted from this unit may be harmful. Always

follow these precautions:

• Avoid direct exposure to the beam.

• Avoid looking at the beam directly.

• Be aware of and follow the warnings on the safety labels (examples

are shown on page 6).

• To completely shut off power to the unit, turn off the keyswitch.

The

Power

button on the front of the controller controls power to

the laser diode; even when the power to the diode is off, power is

still being supplied to the laser head for temperature control.

• Do not open the laser head or controller.

Diode-laser power at the wavelengths shown in the following table could be

accessible inside the laser head. There are no user-serviceable parts inside the

laser head or controller. Unauthorized opening of the head or controller will

void the warranty and may result in misalignment of the laser cavity and/or

irreparable damage to the internal components.

Vortex6000.book Page 5 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6 • User Safety NEW FOCUS, Inc.

The following table contains a list of wavelength ranges and maximum

internal powers accessible inside the different model laser heads. Look

at the label on top of your laser head for its model number and its

specific wavelength.

The actual output power and wavelength range of your laser will only be a fraction

of the internal diode power and wavelength range shown here.

Label Identification

The aperture and danger labels shown here pertain to different

wavelength laser heads. Depending on your specific wavelength

requirements, other labels similar to those shown may be used.

Figure 1:

Labels on the

front and top of

the laser head

Model Wavelength Range Max. Power

6003 350–500 nm 10 mW

6005 600–645 nm 15 mW

6009 630–710 nm 30 mW

6013 710–800 nm 70 mW

6017 760–905 nm 100 mW

6021 830–1180 nm 100 mW

6025 1100–1480 nm 30 mW

6027 1350–1650 nm 50 mW

6029, 6029-Power 1380–1710 nm 50 mW

6031 1550–1900 nm 25 mW

6033 1610–2400 nm 100 mW

Note:

Note:

Note:

Note:

External-Cavity Diode Laser

Wavelengths :

Model Number :

Serial Number :

Manufactured :

This product conforms to the applicable requirements of

21 CFR 1040.10 and 1040.11 at the date of manufacture.

VORTEXTM

AVOID EXPOSURE

LASER LIGHT EMITTED

FROM THIS APERTURE

AVOID EXPOSURE

INVISIBLE LASER RADIATION

EMITTED FROM

THIS APERTURE

Front of laser head Aperture labels Certification label

Vortex6000.book Page 6 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series User Safety • 7

Figure 2:

Labels on the back

of the laser head

Using the Safety Interlock

The safety interlock connector on the back of the Vortex controller is

provided for external safety systems. The system is shipped with a

jumper across the interlock terminals. Do not remove this jumper

unless you are using the safety interlock feature; the laser will not emit

light unless the interlock circuit is closed. The circuit carries 15-V DC.

Back of laser head Danger labels

Vortex6000.book Page 7 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8 • User Safety NEW FOCUS, Inc.

Vortex6000.book Page 8 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series Getting Started • 9

Getting Started

Introduction

This section outlines the basic steps needed to start using your Vortex

laser system, including information on unpacking the system and brief

set-up and starting notes. For more detailed information on how to

operate the instrument, refer to the “General Operation” chapter

beginning on page 13.

Unpacking the System

Carefully unpack the Vortex laser system. Compare the contents

against the packing slip and inspect them for any signs of damage. If

parts are missing or you notice any signs of damage, such as dented or

scratched covers, or broken knobs, please contact New Focus

immediately.

For orders with multiple heads, up to 3 heads may be shipped in the same

container.

Save the shipping container and packing material for future shipping

needs.

Check that the power module on the back of the controller is set for the

proper AC line voltage (see page 53 for information on checking and

changing the voltage).

Note:

Note:

Note:

Note:

Vortex6000.book Page 9 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10 • Getting Started NEW FOCUS, Inc.

Setting Up the Laser

1. Mount the laser head:

The laser head is shipped with a mounting

bracket already attached. This bracket also serves as a heatsink to

avoid overheating the laser head. Mount the laser head/bracket in a

stable position with the output aperture pointing towards an

appropriate beam block. Output-beam height is two inches. See

page 14 for details on mounting techniques.

2. Position the controller:

Position the controller within a cable

length of the laser head (about five feet). Make sure that the side and

rear vents of the controller are not blocked. The controller

keyswitch should be off (position “

0

”).

3. Connect the head and controller:

Connect the controller to the

laser head with the 26-pin D-connector laser cable provided.

Use

only

the supplied New Focus laser cable to connect the controller to

the laser head. To ensure proper and safe operation of the laser,

secure the cable to the laser head and controller using the captive

attachment screws in the cable’s D-connectors.

Figure 3:

Controller to Laser

Head Connection Frequency

Modulation

Current

Modulation

Auxillary

Input Laser

Interlock

IEEE 488

RS232

Laser Cable

26 Pin

D-Connector

26 Pin

D-Connector

120Vac

~

Vortex6000.book Page 10 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series Getting Started • 11

4. Connect the power cord:

Attach the power cord to the controller

and plug it into a wall outlet.

This instrument is configured at the factory for the line voltage and frequency

appropriate for your country. If you are unsure of how your unit is configured,

see “Changing the AC-Voltage Selection” on page 53.

5. Optically isolate the laser:

Take precautions to prevent back

reflections into the laser head. Isolation can be achieved by angling

your optics or with the use of an optical isolator. The degree of

isolation required depends on how you are using the laser; contact

New Focus technical support for help with your particular

application.

Starting the Vortex for the First Time

The following section takes you through the basic steps of starting up

and shutting down the laser. The controls and functions are described

in more detail in the following chapter.

Figure 4:

Vortex Front Panel

1. Turn on the system:

Turn the keyswitch to “ON” (position “

|

”).

The system will start up in constant-current mode with the current

set to 0 mA, and the system ID will scroll across the display.

After turning the keyswitch, allow the system a minimum of 20 minutes to

reach a stable temperature before turning on the laser diode (step 4).

Once the keyswitch is turned on, the system can be operated

remotely through the IEEE-488 (GPIB) or RS-232 ports. Refer to

the “Computer Control” chapter beginning on page 29 for details.

Note:

Note:

45.0 mA

GPIB Address Baud Rate

Display SetPower Mode Local

TM

Note:

Note:

Vortex6000.book Page 11 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

12 • Getting Started NEW FOCUS, Inc.

2. Set the operating mode:

An LED on the front panel will indicate

the system’s operating mode: constant-current or constant-power.

To change modes, press the

Mode

button.

You will need to use an external photodetector to operate the

Vortex in constant-power mode. See “Selecting an Operating

Mode” on page 17 for details on the different modes, or the

“Constant-Power Mode” chapter beginning on page 25 for details

on setting up and using the laser in constant-power mode.

3. Set the operating current or power:

Press the

Display

button

until the current, “0.0 mA” (for constant-current mode), or the

power, “0.0%” (for constant-power mode), is displayed. If the

Set

button is not already lit, press it to enable the adjustment knob.

Turn the knob to set the current or power.

To prevent damage to the laser diode, the factory has limited the maximum

current to the operating current listed on the Acceptance Test Data Sheet.

4. Activate the laser:

Push the

Power

button to activate the laser

power. The button will flash for 5 seconds before current flows

through the diode.

Laser light should now be emitting from the aperture.

Laser radiation emitted from this unit may be harmful. Avoid direct exposure

to the beam.

5. Turn the laser off:

To minimize the risk of power surges

damaging the laser diode, push the

Power

button to turn off the

laser when it is not in use (the LED on the button will turn off) and

before shutting down the system. Turn the keyswitch off (position

“

0

”) to shut down the entire system.

Note:

Note:

Vortex6000.book Page 12 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series General Operation • 13

General Operation

Overview

The Vortex is a robust, narrow-linewidth, laser source. The system

consists of a laser controller, a laser head, and a laser cable. Each Vortex

laser head contains head-specific information so that it can be used

with any Vortex laser controller. This modular design allows you to

switch wavelengths simply by changing the laser head (heads are

available separately). The system can be operated manually, using the

front-panel controls, or remotely, using one of the computer interfaces.

What’s Inside

The Vortex laser is an external-cavity diode laser (ECDL) based on the

Littman-Metcalf design (see “Principles of Operation” on page 49). The

customer-selected wavelength is set and stabilized at the factory using

external optics, a diffraction grating, a mirror, and precision temper-

ature control. Fine wavelength tuning without mode hops is achieved

by rotating the mirror around a fixed rotation point using a piezo-

electric actuator. Laser output power is controlled by an ultra-low-

noise current source.

The controller contains the electronics for laser-current, laser-

temperature, and piezo-voltage control, as well as digital-interface

electronics. A dimensional drawing of the controller is located in

“Appendix I: Physical Specifications” on page 57. The temperature of

the laser cavity is set at the factory for optimum laser performance and

is not adjustable by the user, although you can read the temperature

using the computer interface (see “Computer Control” on page 29). The

Vortex6000.book Page 13 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

14 • General Operation NEW FOCUS, Inc.

laser current controls the optical output power. The piezo voltage

controls the laser wavelength (frequency). Both of these parameters

can be adjusted through the front-panel controls, the computer

interface, or the back-panel BNC connectors.

Mounting the Laser Head

Proper mounting of the laser head is essential for stable wavelength

operation. The output wavelength is strongly dependent on the

temperature of the laser cavity, which is actively stabilized using a

thermoelectric cooler (TEC). The TEC utilizes the laser-head housing as

a heat reservoir. For this reason, the mount for the laser head needs to

provide a good thermal path away from the laser head. The mounting

bracket included with each laser head provides such a path when it is in

contact with a large thermal mass, such as an optical table.

The laser head can be mounted with or without the enclosed mounting

bracket (shipped attached to the laser head). Dimensional drawings of

the laser head and the mounting bracket are shown in Appendix I on

page 58. The mounting bracket is designed for use with metric (25-mm

spacing, M6) or English (one-inch spacing, 1/4-20) breadboards. If you

are mounting the laser head without the included mounting bracket,

take steps to ensure it has an adequate thermal heat sink.

Setting the Beam Height

The laser beam height is one inch (25.4 mm) from the bottom of the

laser head. The mounting bracket adds one additional inch (25.4 mm)

to the beam height. To raise the beam height, additional risers are

available from New Focus (model number 6001).

Optically Isolating the Laser

After mounting the laser head, take precautions to prevent back

reflections into the laser aperture. Isolation can be achieved by angling

your optics or with the use of an optical isolator. The degree of

isolation required depends on how you are using the laser; contact New

Focus technical support for help with your particular application.

Vortex6000.book Page 14 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series General Operation • 15

Using the Front-Panel Controls

The Vortex has two control options, local and remote. In local mode,

the front panel provides control of the laser system. In remote mode,

you control the laser over the computer interface (IEEE-488 or RS-232).

Whenever the Vortex receives a command over the computer interface,

it automatically deactivates most of the front-panel controls (the

Local

button, which restores local control, and the

Power

button and power

keyswitch all remain active). For information on using computer

control, see page 29.

The controls on the front panel (Figure 5) allow you to switch system

operating modes and to read and set the laser current, laser power,

piezo voltage (which controls the laser wavelength), and computer-

interface parameters.

Figure 5:

Controller front

panel

1. Display:

The display shows the various laser parameters, as well as

errors and system-identification information.

2.

Constant Current

Indicator:

This indicator is lit when the laser is

set for constant-current mode.

3.

Constant Power

Indicator:

This indicator is lit when the laser is set

for constant-power mode.

45.0 mA

12435

12

1110

1413

98876

GPIB Address Baud Rate

Display SetPower Mode Local

TM

Vortex6000.book Page 15 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

16 • General Operation NEW FOCUS, Inc.

4.

Addressed

Indicator:

This indicator is lit whenever the controller

is communicating over the computer interface (see the “Computer

Control” chapter beginning on page 29).

5.

Remote

Indicator:

This indicator is lit whenever the controller is

under computer control, via either the IEEE-488 (GPIB) or the RS-

232 interface. (See “Computer Control” on page 29.)

6. Power Keyswitch:

Controls AC power to the entire laser system,

including the temperature circuit in the laser head.

7.

Power

Button:

Turns on and off current to the laser diode.

8.

Mode

Button:

Switches the laser between constant-current and

constant-power modes (power to the laser diode must be off to

switch modes).

Constant-power mode requires an external beamsplitter and

photodetector. See the “Constant-Power Mode” chapter beginning

on page 25 for details.

9.

Display

Button:

Changes the display to show laser current, laser

power, piezo voltage, or auxiliary input voltage.

10.

Set Button: Activates/de-activates the adjustment knob so you can

adjust the displayed laser parameter (the properties you can

control depend on the operating mode).

11. Adjustment Knob: When activated by the Set button, this knob is

used for all adjustments of laser and system parameters.

12. Local Button: Returns the controller to local (front-panel) control

when the driver is in remote (computer) control.

13. GPIB Address Button: Displays the GPIB (IEEE) address setting. See

“Using the IEEE-488 Interface” on page 29 for more information.

14. Baud Rate Button: Displays the RS-232 baud-rate setting. See

“Using the RS-232 Interface” on page 30 for more information.

Vortex6000.book Page 16 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series General Operation • 17

Turning on the Power

Before turning on the system for the first time, check that the AC line

voltage indicator on the back of the controller matches the voltage you

are using (see page 53).

To turn on the Vortex:

1. Turn the power keyswitch on the front panel clockwise (to the “|”

position).

This turns on AC power for the entire laser system, including the

temperature circuit in the laser head.

2. Wait at least 20 minutes after turning on the keyswitch to allow the

laser head to reach a stable temperature.

3. Press the Power button on the controller front panel to allow

current to flow to the laser head. The button will flash during the

five -second safety delay before the current is activated. The button

will remain lit while current is flowing to the laser diode.

The diode will not emit laser light until the current is set high enough to meet

the threshold current.

Before turning off the system, you should first turn off power to the

laser diode by pressing the Power button.

Selecting an Operating Mode

The Vortex laser-current driver operates in either constant-current

mode or constant-power mode. Constant-current mode results in

narrower laser linewidth while constant-power mode results in the

lowest intensity fluctuations. The constant-current or constant-power

indicator on the controller display will indicate the active mode.

Constant-Current Mode

When operating in constant-current mode, the controller maintains a

stable set current with the low-noise current driver. This results in a

narrow laser linewidth.

Note:

Note:

Vortex6000.book Page 17 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

18 • General Operation NEW FOCUS, Inc.

While in constant-current mode, you can adjust the diode current and

laser wavelength (piezo voltage). To change one of these parameters

from the front panel, display the current (mA) or piezo voltage (V),

press the Set button so it is lit, and turn the adjustment knob. The laser

power is not adjustable in this mode; the power is read from the back

facet of the laser diode, and is only accurate to within about 20% of the

true laser output power.

Each laser head is designed and built for a specific operating current

and has a factory-limited maximum current level to prevent possible

damage to the laser diode. This current limit also limits the maximum

power output from the laser head.

Constant-Power Mode

When operating in constant-power mode, the controller adjusts the

laser current to maintain a stable output power. Only power and laser

frequency (piezo voltage) can be varied in constant-power mode. The

laser power displayed in this mode is given in terms of a percentage of

maximum auxiliary input signal.

Constant-power mode requires use of an external beamsplitter and a

photodetector to measure the laser power and provide an electrical

signal for the internal feedback circuit.

See the “Constant-Power Mode” chapter beginning on page 25 for

details on setting up and using the Vortex in constant-power mode.

Setting the Operating Mode

The Constant Current and Constant Power LEDs on the front panel (see

Figure 5 on page 15) indicate which mode is active.

To change the mode:

1. Make sure the power to the laser head is off.

If the LED in the Power button is lit, then the laser head is on: press

the Power button to turn off the laser power.

2. Press the Mode button to switch modes. The mode indicator on the

front panel will change to show the newly selected mode.

Vortex6000.book Page 18 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6000 Vortex Series General Operation • 19

3. Press the Power button to re-activate the laser head.

In order to use the Vortex in constant-power mode, you will need to

use a beamsplitter and a photodetector (see “Constant-Power Mode” on

page 25 for details).

Displaying and Setting the Laser Parameters

Use the front panel to display either the set value or the actual

operating value of the laser parameter you want: current, laser power,

piezo voltage (which controls wavelength), or auxiliary input voltage.

The operating mode (constant-current or constant-power) determines

which parameters you can adjust.

1. Press the Display button to view the parameter you want. The units

on the display indicate which parameter is active:

• Laser current is displayed as “x.x mA.”

• Laser power is displayed as “x.x mW” in constant-current

mode and as “x.x%” when in constant-power mode. In

constant-current mode, the power is read from the back of the

laser-diode, and is therefore only accurate to approximately

20% of the true laser output power.

• Piezo voltage is displayed as “x.x V.” This is a direct readout of

voltage to the piezoelectric actuator that controls the

wavelength. Increasing the voltage decreases the wavelength

(increases the frequency). The voltage range is 0–117.5 V.

• Auxiliary input is displayed as “aux x.xx” (not adjustable).

2. Switch the Set button on or off, depending on the value you want

to see. If the LED in the Set button is lit, then the display will show

the set value of the parameter; if the LED is not lit, then the display

will show the operating value.

If the LED does not go on, then you cannot adjust the displayed

value. For example, in constant-current mode you can’t adjust the

power and in constant-power mode you can’t adjust the current.

3. To adjust the set value for the parameter, enable the Set button and

turn the adjustment knob.

Vortex6000.book Page 19 Tuesday, February 19, 2002 3:25 PM

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

12

Table of contents

Other New Focus Measuring Instrument manuals