TO

THE

OWNER:

The warranty coverage that

is

extendedto yourmachine

is

explainedin the Warranty and Limitation

of

Liability

form.

Yourdealerwill provide you witha copy

of

the warranty and retain acopywhich youhave

signed. Afteryou readthe warranty, askyour dealer

to

explainany points that you may not understand.

The machine was designedto powerand propel itself. It is intendedto move material inthe normal and

customary applications.

Do notmodify oralterorpermit anyone else

to

modify oralterthis machine orany

of

its components

mechanical function with

first

consulting anauthorizedNew HollandConstruction

dealer.

If

youhave any

questions regarding machine modifications, contactNew HollandConstruction,

245

E.

NorthAve., Carol

Stream, IL 60188.

Your

safety andthe safety

of

those around you dependuponthe care and goodjudgmentyouuse while

operatingthis equipment. Readthe safetyprecautions

carefully.

Afteryouhave operatedthe machine for

50

hours, take yourmachine andthis manual to your selling dealer.

He

will performthe factory recommended 50-hour service.

You

will be responsible

for

the cost oflubri-

cants, fluids, filters and otheritems replaced

as

part

of

normal maintenance. Priorto taking the machine

to

your sellingdealer for service, it is recommendedthat you contact them to determine any other charges for

whichyou may

be

responsible.

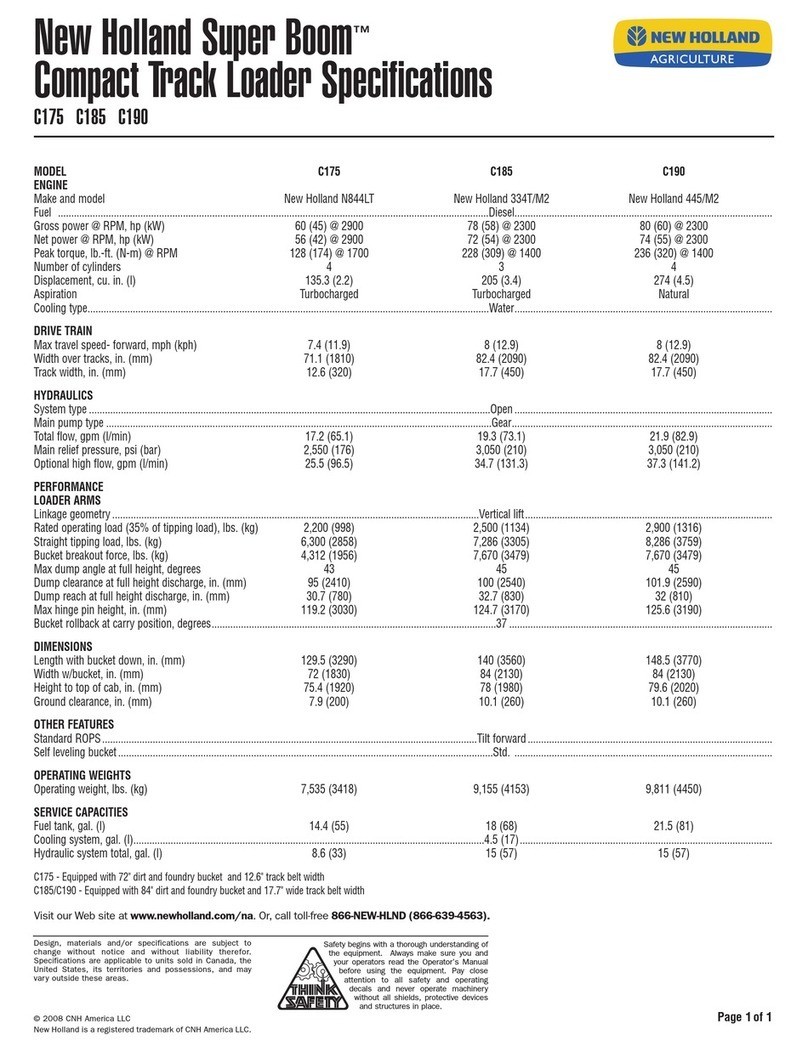

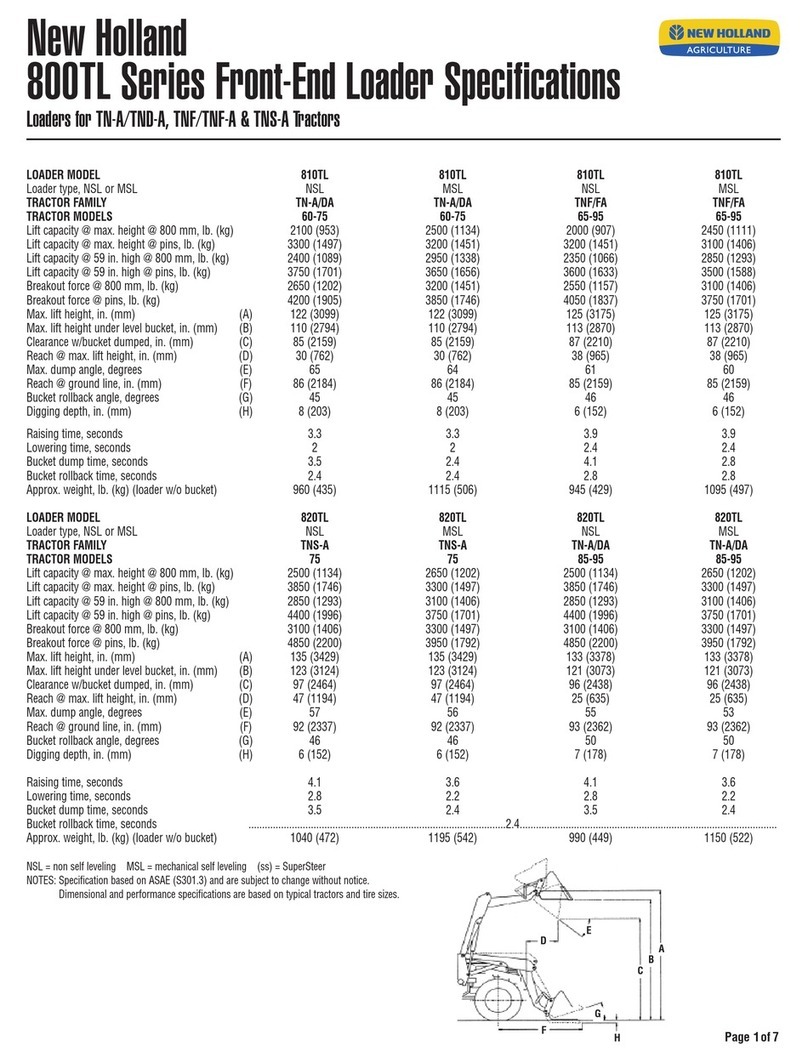

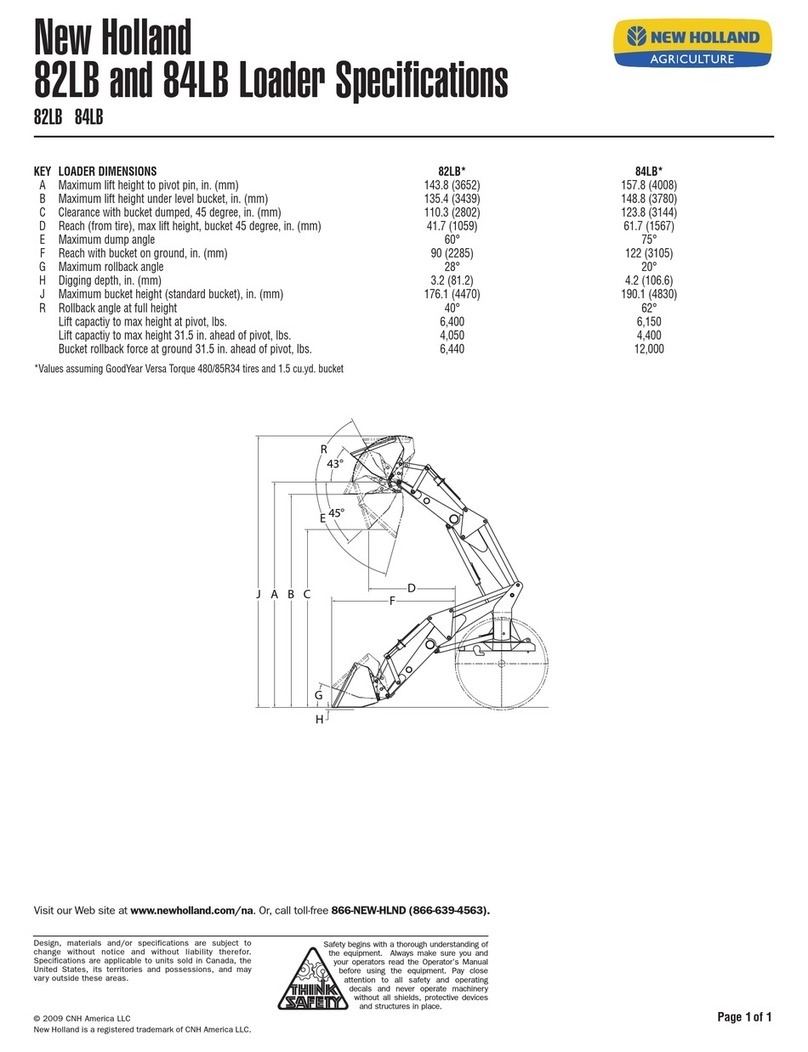

All data given inthis book

is

subjectto product variations. Dimensions andweights

are

approximate only

and the illustrations

do

notnecessarily showmachines in standard condition. Forexact information about

anyparticularmachine, please consultyourNewHollandConstruction dealer.

CAUTION: THIS SYMBOLIS USED THROUGHOUTTHIS

BOOK

WHENEVER

PERSONAL SAFETYIS INVOLVED. TAKE TIME TO READAND FOLLOWTHE

INSTRUCTIONS. BE CAREFUL!

CAUTION: PICTURES IN THIS MANUAL

MAY

SHOWPROTECTIVE SHIELDINGOPEN

ORREMOVEDTOBETTERILLUSTRATEAPARTICULARFEATUREORADJUSTMENT.

BE CERTAIN,HOWEVER, TOCLOSE

OR

REPLACEALL SHIELDINGBEFORE

OPERATINGTHE MACHINE.

IMPROVEMENTS

NewHolland Construction

is

continually strivingto improve its products.

We

reserve the right

to

make

improvements orchanges when it becomespractical and possible

to

do

so,

without incurring any obligation

to

make changes oradditions

to

the equipment soldpreviously.

©1999 NEW HOLLAND CONSTRUCTION

Find manuals at https://best-manuals.com