New lift CBM2 User manual

CONTACTORLESS

BRAKE MODULE

MANUAL

Manual CBM2

Hersteller NEW LIFT

Neue elektronische Wege

Steuerungsbau GmbH

Lochhamer Schlag 8

82166 Gräfelng

Tel +49 89 – 898 66 – 0

Fax +49 89 – 898 66 – 300

Mail [email protected]

www.newlift.de

Serviceline Tel +49 89 – 898 66 – 110

Mail [email protected]

Erstausgabe 04.11.2021

Verfasser JW

Letzte Änderung 29.11.2023 / DOS

Freigabe AL

Hardwareversion CBM-5-89-21

Softwareversion V5.6.0.0

Dokumentnummer HB_CBM2_2023-11_v2.0_en

Copyright © NEW LIFT Steuerungsbau GmbH, 2023.

This manual is protected by copyright. All rights, including those of copying,

of reproduction, of translation and of modication, in whole or in part, are

reserved by the publisher.

No part of this description may be reproduced in any form or copied with an

electronic replication system without written permission.

Although great care has been taken in the production of texts and gures, we

cannot be held legally liable for possible mistakes and their consequences.

2

Manual CBM2 3

1 General 5

1.1 Abbreviations, characters and symbols used 5

1.2 Representations 6

1.3 Further information 6

1.4 How to contact us 6

2 Safety 7

2.1 Handling of electronic modules 7

3 Terminals 8

3.1 Connection 8

3.2 Pin Table 9

4 Conguration 10

4.1 Brakemonitoring 10

4.1.1 Contact-basedmonitoring 10

4.2 Motor-PTC 10

4.3 Rectiermode 10

4.4 Explanation of Inputs 11

4.4.1 DRIVE-Signal 11

4.4.2 BRAKE-Signal 11

4.4.3 EVAC-Signal 11

4.4.4 T-Signals 11

4.5 Explanation of Outputs 11

4.5.1 OK-Signal 11

4.5.2 Open-Signal 11

4.5.3 Test-Signal 11

4.6 Control process 12

4.6.1 Normal ride 12

4.6.2 Emergency Stop 12

4.6.3 Brake Test 12

4.6.4 Evacuation 12

4.7 EEPROM 13

4.7.1 Restore factory settings 13

4.8 Surge device Test 13

4.9 CANopen Bootloader 13

5 CANopen 14

5.1 Network Management 14

5.1.1 Node-ID 14

5.1.2 Bit Rate 14

5.1.3 NMT-RX-Events 14

5.2 Sync 14

5.3 Emergency 14

5.4 Heartbeat Producer 15

5.5 Object Dictionary 15

5.5.1 Daten-Types 15

5.5.2 Device Info 16

General

Manual CBM2 5

1 General

The CBM is a module that can control brake coils of all voltages (40-200VDC) and currents (up to 4A)

up to a power of 240VA without protection. It is type-tested according to DIN EN81-20. In addition, it

can perform brake test and evacuation (for machine roomless systems). In addition, other functions are

available, such as the connection of a motor PTC or brake monitoring. The function of the brake circuits

is monitored by a continuous current measurement.

1.1 Abbreviations, characters and symbols used

Abrreviation /

Symbol Meaning

CBM Contactorless Brake Module for elevatior

DRIVE Driving signal from the end of the safety chain

BRAKE Brake signal to open the brake

EVAK Evacuation signal for evacuation in the event of a fault in the system

TEST Test signals for brake test

CANopen CAN interface with CANopen protocol according to CiA Standard Draft

301

►

Activity symbol

Activities described after this symbol must be carried out in the given

order.

• Action step subordinate to the instruction

Safety-relevant information

This symbol is located in front of safety-relevant information.

Information notice

This symbol is located in front of relevant information.

General

6Manual CBM2

1.2 Representations

Representation Meaning

bold ›Terms of switches and control elements

›Input values

italic ›Captions

›References

›Terms of functions and signals

›Product names

bold italc ›Notes

Font LCD ›System messages of the controller

1.3 Further information

The following documents, among others, are available for the FST control system and its components.

›ADM Manual

›EAZ TFT.45.110.210 Manual

›EAZ-256 Manual

›EN81-20 Manual

›FPM Manual

›FST-2XT/s Manual

›FST-2XT MRL Manual

›FST Installation and Commissioning

›FST-3 MIPA

›GST-XT Manual

›LCS Manual

›RIO Manual

›SAM Manual

›UCM-A3 Manual

›Update-Backup-Analysis Manual

These and other current manuals can be found in the download area of our website under Service at

https://www.newlift.de/downloads.html

1.4 How to contact us

If, after referring to this manual, you still require assistance, our service line is there for you

Tel +49 89 – 898 66 – 110

Mail [email protected]

Mon. - Thurs.: 8:00 a.m. – 12:00 p.m. and 1:00 p.m. – 5:00 p.m.

Fr: 8:00 a.m. – 3:00 p.m.

Safety

Manual CBM2 7

2 Safety

All modules of the system may only be operated in a technically faultless condition and in accordance

with the intended use, safety and hazard awareness, observing the instructions, the applicable accident

prevention regulations and the guidelines of the local power supply company.

The safety guidelines of the FST manual and the FST Installation, Commissioning & Ccheck manual apply to

this product.

2.1 Handling of electronic modules

Electrostatic charge

►Leave the electronic module in its original packaging until installation to avoid damage.

►Before opening the original packaging a static discharge must take place!

To do this, touch an earthed metal part.

►Repeat the discharging process regularly while working on electronic modules!

►Provide all unused bus inputs/outputs with a terminator to prevent malfunctions.

Terminals

8Manual CBM2

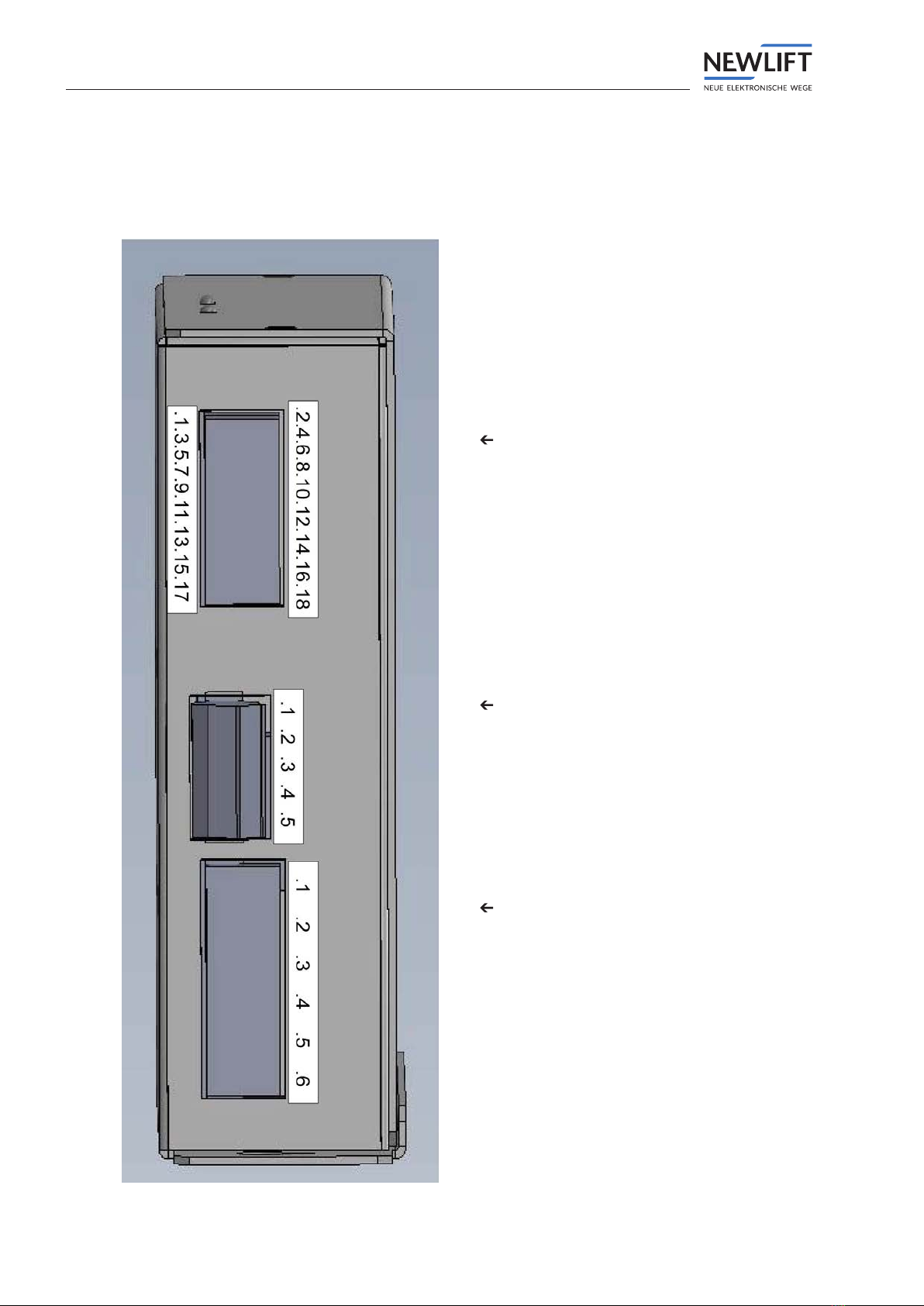

3 Terminals

3.1 Connection

X3: IOs Connector PCB side: Phoenix

Contact MCDN 1,5/ 9-G1-3,81 Mating

Connector cable side: 2x Phoenix

Contact FMC 1,5/ 9-ST-3,81

X5: Power, Overvoltage-Test Connector

PCB side: Phoenix Contact CCA 2,5/

5-G-5,08MatingConnectorcableside:

PhoenixContactSMSTB2,5/5-ST-5,08

X4: DRIVE and Brake-Coils Connector

PCB side: Phoenix Contact GMSTBA

2,5/ 6-G Mating Connector cable side:

Phoenix Contact GMSTB 2,5/ 6-ST

Terminals

Manual CBM2 9

3.2 Pin Table

Clip Name Description Properties

X1.1

PE PowerSupply–230VAC

X1.2

LPowerSupply–230VAC

10ATräge

X1.3

NPowerSupply–230VAC

X1.4

Test Test Switch to simulate Overvoltage

spark

X1.5

Test

Test Switch to simulate Overvoltage

spark

X2.1

Drive

Drive-Signal–48-230VUC 24-230VUC

X2.2

Drive

Drive-Signal–48-230VUC

X2.3

B1+

Brake 1 Coil + 40-200VDC

X2.4

B1- Brake 1 Coil - 0V

X2.5

B2+ Brake 2 Coil + 40-200VDC

X2.6

B2-

Brake 2 Coil - 0V

X3.1

+24V DC

24V – Power Supply for In/Outputs

X3.2

0V(GND)

0V–PowerSupplyforIn/Outputs

X3.3

Brake

Brake-Signal Active High

X3.4

Evac

Evac-Signal Active High

X3.5

T1

T1-Eingang Active High

X3.6

T2

T2-Eingang Active High

X3.7

BM1

BM1-Signal Active High

X3.8

BM2

BM2-Signal Active High

X3.9

CBM_OK

CBMOKOutput(opencollector) Open Collector

X3.10

BRAKE_OPEN BrakeopenOutput(opencollector) Open Collector

X3.11

BRAKE_TEST TestactiveOutput(opencollector) Open Collector

X3.12

0V(GND)

Common pin for CAN-Interface

X3.13

CAN-H

CAN-H(CANopen) CANopen CiA 417

X3.14

CAN-L

CAN-L(CANopen)

X3.15

CAN-H

CAN-H(CANopen)

X3.16

CAN-L CAN-L(CANopen)

X3.17

PTC+ Motor PTC PTCnachDIN44081undDIN

44082

X3.18

PTC- Motor PTC

Configuration

10 Manual CBM2

4 Conguration

Unlike its predecessor, the CBM, the new CBM2 is congured exclusively via CANopen. It follows the

CiA 417 standard. The exact description of the data transfer takes place in CANopen CiA 417,

see „5 CANopen“, page 14.

4.1 Brake monitoring

The brakes are monitored via the brake monitoring contacts of the brakes.

4.1.1 Contact-based monitoring

Here contacts (NO or NC) must be connected to the inputs BM1 and / or BM2. These contacts must

also switch when the brake is activated. Otherwise, the error 0x19 (brake monitoring faulty) is

triggered.

4.2 Motor-PTC

The function of the motor PTC is automatically recognized the rst time it is switched on after resto-

ring the factory settings. If a PTC is then connected, it is activated. In that case, however, the PTC must

not have responded. If no PTC is connected, the function is deactivated. If the function is to be activa-

ted or deactivated during operation, the factory settings must rst be restored!

4.3 Rectiermode

If a voltage of 50V, 100V, 150V or 200V is set, the CBM2 operates in rectier mode. In this case, the

voltage is no longer generated via phase control, but the thyristors are permanently controlled over the

entire half-wave and only operate as a diode. With an input voltage of 230VAC, this results in an output

voltage of 51.75V, 103.5V, 155.25V or 207V. This mode can have a positive effect on the noise develop-

ment of the brake and also the CBMaus. If this function is not desired, a voltage increased or decreased

by 1V can be set.

Configuration

Manual CBM2 11

4.4 Explanation of Inputs

4.4.1 DRIVE-Signal

The DRIVE input can process voltages from 48-230VUC. This means that all common safety circuits

can be connected here. This signal opens two safety contacts in front of and behind the brake coil

and thus prepares the voltage supply for the brakes. If a gear brake is connected and congured, it is

directly energized with the DRIVE signal, since the brake on the gear must rst open.

4.4.2 BRAKE-Signal

The BRAKE signal opens a brake congured as a motor brake. A motor brake is usually mounted

directly on the motor shaft.

4.4.3 EVAC-Signal

The EVAK signal is used for evacuation in the event of a fault. It activates a different measurement of

the input voltage, as the evacuation can also be carried out with a UPS (VI-SY-333 or better) as the

power supply.

Normal travel is not possible when the EVAK signal is activated!

4.4.4 T-Signals

Either the brake test or the evacuation can be carried out with the signals T1 and T2.

In addition, the EEPROM can be re-initialized with the standard values by pressing T1 and T2 during

the boot process

See for details:

see „4.7.1 Restore factory settings“, page 13.

If only T1 is activated during the boot process, the CBM2 enters the bootloader and can receive new

rmware via CANopen.

If only T2 is activated during the boot process, stored errors are deleted.

Detailed description of the signal sequences can be found in:

see „4.6 Control process“, page 12.

4.5 Explanation of Outputs

4.5.1 OK-Signal

The OK output signals that the CBM is active and has no error. This output is only active when both

processors (control and monitor CPU) give their release.

4.5.2 Open-Signal

The open output signals an open brake.

4.5.3 Test-Signal

The test output signals an active brake test.

Configuration

12 Manual CBM2

4.6 Control process

4.6.1 Normal ride

›During normal driving, only the DRIVE and the BRAKE input are activated.

›DRIVE must be applied rst. In this case, if connected, the brake 3 is opened.

›Then BRAKE is applied (there must be no test signal). This opens brake 1 and 2.

›After the ride BRAKE is deactivated again.

›Then rst brake 1 and 2 close. Thereafter, brake 3 is closed.

›Now DRIVE must be deactivated again. The inputs DRIVE and BRAKE are checked with an ABC circuit.

This means that DRIVE must be activated before BRAKE and both signals must be deactivated before

reactivation!

4.6.2 Emergency Stop

In the event of an emergency stop, the DRIVE signal is deactivated rst. This means that all brakes are

applied immediately!

4.6.3 Brake Test

During the brake test, normal travel is rst initiated. If a test signal is already present during this (but-

ton has got stuck), error „0x1A - error inputs“ is set and normal travel is prevented. However, if a test

signal is applied after normal travel has been initiated, the associated brake is applied immediately. The

other brakes remain open.

The brake test is signaled directly to the elevator control via the test output. This must now ensure that

the torque is removed from the frequency converter. As a result, it will deactivate the BRAKE signal.

That is allowed for the brake test. The other brakes remain open anyway. The other brakes only apply

when the DRIVE signal is deactivated.

4.6.4 Evacuation

In order to carry out an evacuation, the EVAC signal must rst be activated. This changes the internal

control of the brakes, since the evacuation can also be carried out with a UPS. Since UPSs that do not

generate a pure sinusoidal voltage (VI-SY-333 or better) are also permitted, the phase control must be

adapted. The brakes are now controlled based on the previously saved operating current.

The DRIVE signal can now be activated. This already opens a transmission brake. The evacuation can

be activated by activating the test 1 and test 2 signals. This is carried out via the congured mode. If the

signals are deactivated again, the brakes are applied again..

Configuration

Manual CBM2 13

4.7 EEPROM

The EEPROM mainly stores data that is required for the CANopen functionality.

In addition, the operating currents of the individual brake coils are stored here. These are necessary to

carry out an evacuation. The default value for all brakes is the equivalent of 0.4A. If this value is still in

the EEPROM and normal travel is triggered, the current values of this normal travel are saved and used

in the following. An evacuation with a CBM in the factory setting without prior normal travel would

result in a current control to 0.4A per brake.

Correct evacuation is possible after a single normal trip.

4.7.1 Restore factory settings

►Switch ON CBM.

►During the start up

•Press buttons T1 and T2

or (if they are not present)

•set a jumper between X2.1 and X2.4 and X2.5.

Since an error occurs in the case at the same time:

►Turn OFF CBM.

►Release the buttons T1 and T2 or remove the jumper.

►Switch ON CBM.

After switching on again, the module is in the factory state.

4.8 Surge device Test

Either a button as a break contact or a wire bridge is connected to terminals X1.4 and X1.5. To test the

triggering of the overvoltage protection device at the voltage input of the CBM2, the connected button

can be pressed or the connected wire bridge can be removed. This causes an internal relay to drop out

at the input of the CBM2 and the output stage that generates the voltage for the brakes. This causes

the brakes to close and the CBM2 detects an undercurrent fault on the brakes. It is therefore no longer

possible to continue your journey.

4.9 CANopen Bootloader

The CBM2 is equipped with a CANopen bootloader that can perform rmware updates as described in

CiA 417. This means that, unlike the CBM1, rmware updates can now be carried out easily in the eld.

When using the CBM2 with the NEWLIFT FST2 lift controller, the rmware can be uploaded via the

FST2 using a USB stick. In addition, you can switch directly to the bootloader by pressing T1 during the

boot process of the CBM2. The CBM2 would then wait for rmware data via CANopen. However, a

specic protocol must be run for this, which is described in a separate manual.

CANopen

14 Manual CBM2

5 CANopen

With the integrated, isolated high-speed CAN ISO-11898 interface, a CANopen protocol according to

CiA 417 is integrated.

5.1 Network Management

The CBM is an NMT slave. An NMT master must make settings on the CBM in accordance with the

NMT protocol.

5.1.1 Node-ID

In the delivery state, the node ID is 125, which corresponds to a non-congured device according

to CiA 417. If an NMT master detects this, it must change the ID to 85-101, which are reserved for

manufacturer-specic IDs. The Node-ID can be changed in Object 0x2001.

5.1.2 Bit Rate

The bit rate is set to 250kbit / s in the delivery state.

5.1.3 NMT-RX-Events

The following NMT-RX events are implemented:

›1/0x01 – Start Node: sets the operational mode

›2/0x02 – Stop Node: sets the stop mode

›128/0x80 – Pre-Operational: sets the pre-operational mode

›129/0x81 – Reset: triggers a reset of the CBM

›130/0x82 – Reset Communication: triggers a reset of the CAN routines

By default, the CBM starts up in pre-operational mode. An NMT master must switch the CBM to opera-

tional mode.

5.2 Sync

The CBM is a SYNC consumer and can receive SYNC objects that were sent via the COB ID 0x080. This

mechanism is used for sending the TPDOs.

5.3 Emergency

In the event of a faulty SDO transfer or another error, an emergency message is sent. This is structured

as follows:

›Byte 0-1: CANopen Error Code

›Byte 2: CANopen Error Register

›Byte 3: -

›Byte 4: Manufacturer-specic error

›Byte 5: Manufacturer-specic error Detail

›Byte 6: Error generated during internal VCC not OK

›Byte 7: Error generated during emergency stop

CANopen

Manual CBM2 15

5.4 Heartbeat Producer

The CBM has a heartbeat endpoint that sends a heartbeat message. In the delivery state the interval

is 3000ms, but can be changed in the range of 500-20000ms. A heartbeat message can contain the

following information:

›0/0x00 - Bootup: CBM is booting

›4/0x04 - Stopped: CBM in Stop Mode

›5/0x05 - Operational: CBM in Operational Mode

›127/0x7F - Pre-Operational: CBM in Pre-Operational Mode

5.5 Object Dictionary

5.5.1 Daten-Types

›0x0001 – boolean

›0x0002 – integer8

›0x0003 – integer16

›0x0004 – integer32

›0x0005 – unsigned8

›0x0006 – unsigned16

›0x0007 – unsigned32

CANopen

16 Manual CBM2

5.5.2 Device Info

›0x1000 – device type; unsigned32;

»constant = 0x414D4243 („CBMA“) if application is running

»constant = 0x424D4243 („CBMB“) if bootloader is running

›0x1001 – error register; unsigned8; read only

›0x1002 – manufacturer status register; unsigned32; read only

›0x1003 – error code register; unsigned32; read only

›0x1009 – manufacturer hardware version; char[4](Ascii); constant

›0x100A – manufacturer software version; char[4](Ascii); constant

»Subindex 0 – Software version

»Subindex 1 – 0x07 GIT version string

›0x1017 – producer heartbeat time; unsigned16; read/write

»Values from 500-20000ms are accepted

* Demand from Master:

COB-ID: 0x600 + NodeID

cs: read=2, write=1

n: read=0, write=2

e: read=0, write=1

s: read=0, write=1

Index: 0x1017

Subindex: 0x0

Data: read=0, write=desired value

* Answer from CBM:

COB-ID: 0x580 + Node-ID

cs: read=2, write=3

n: read=2, write=0

e: read=1, write=0

s: read=1, write=0

Index: 0x1017

Subindex: 0x0

Data: read=actual value, write=0

›0x1018 – identity object

»Subindex 0 – Identity Index; unsigned8; constant = 4

»Subindex 1 – Vendor ID; unsigned32; constant = 0x0057454E

»Subindex 2 – Product Code; unsigned32; constant = 0x324D4243 (“CBM2“)

»Subindex 3 – Revision Number; unsigned32; constant = 0x000000xx where “xx” corresponds to

Revision number in SDO 0x3006 as integer

»Subindex 4 – Serial Number; unsigned32

5.5.3 RPDOs

›0x1400 – RPDO1 Parameter (Controlling)

»Subindex 0 – number of supported entries in this record (here 2); unsigned8; read only

»Subindex 1 – COB-ID used by PDO; unsigned32; read only

»Subindex 2 – transmission type; unsigned8; read only; default=255

RPDO1 is statically mapped to object 0x3016 which is the controlling via CANopen

CANopen

Manual CBM2 17

5.5.4 TPDOs

›0x1800 – TPDO1 Parameter (Errors)

»Subindex 0 – number of supported entries in this record (here 2); unsigned8; read only

»Subindex 1 – COB-ID used by PDO; unsigned32; read only

»Subindex 2 – transmission type; unsigned8; read/write; default=2 (1-240)

»TPDO1 is statically mapped to object 0x301F which is the status of the Errors

›0x1801 – TPDO2 Parameter (Outputs)

»Subindex 0 – number of supported entries in this record (here 2); unsigned8; read only

»Subindex 1 – COB-ID used by PDO; unsigned32; read only

»Subindex 2 – transmission type; unsigned8; read/write; default=1 (1-240)

»TPDO2 is statically mapped:

* Byte 0: Object 0x3014 which is the status of the Outputs

* Byte 1: Object 0x3017 which is the status of the Brake-Coils

›0x1802 – TPDO3 Parameter (Currents)

»Subindex 0 – number of supported entries in this record (here 2); unsigned8; read only

»Subindex 1 – COB-ID used by PDO; unsigned32; read only

»Subindex 2 – transmission type; unsigned8; read/write; default=1 (1-240)

»TPDO3 is statically mapped:

* Byte 0,1: Object 0x3001 which is current of Brake 1

* Byte 2,3: Object 0x3002 which is current of Brake 2

* Byte 4,5: 0 – Compatibility to CBM1

›0x1803 – TPDO4 Parameter (Currents of Brake fallback)

»Subindex 0 – number of supported entries in this record (here 2); unsigned8; read only

»Subindex 1 – COB-ID used by PDO; unsigned32; read only; 0x480 + Node

»Subindex 2 – transmission type; uint8; read only; default=0

»TPDO4 is statically mapped:

* Byte 0,1: Object 0x3001 which is current of Brake 1

* Byte 2,3: Object 0x3002 which is current of Brake 2

»TPDO4 is only transmitted if it is enabled in

* Object 0x2016 Subindex 10

* Object 0x2016 Subindex 1 = 3 and between brake switch off and safety chain opening!

5.5.4 Firmware Update

Firmware update processing; see CiA 302 Part 3: Conguration and program download

›0x1F50 – Program data

›0x1F51 – Program control

›0x1F56 – Program software identication current rmware version; same as 0x100A

›0x1F57 – Flash status identication

›0x6005 – Lock unlock parameters

CANopen

18 Manual CBM2

5.5.5 HerstellerspezischeSDOs

Bei allen SDO-Write-Transfers muss ein Reset durchgeführt werden, bevor die Änderung übernommen wird!

›0x2001 – Node-ID; unsigned8; read/write

Can be set from 85 to 101. A new uncongured Device is set to 125.

›0x2002 – Bitrate; unsigned8; read/write

»Bitrates implemented:

* 0 = 20kbit/s

* 1 = 50kbit/s

* 2 = 125kbit/s

* 3 = 250kbit/s (default)

* 4 = 500kbit/s

* 5 = 800kbit/s

›0x2003 – Lift-ID; unsigned8; read/write

Can be set from 0 (default) to 7

›0x2004 – Controlling Mode; unsigned8, read/write

»Read: 0x0X

»Write: 0x7300000X (the Ascii-Values of the character “s” need to be appended)

* Modes implemented:

0x0 = Controlling with IO (Conguration-Values extracted from DIP-Switches)

0x1 = Controlling with CANopen (Conguration-Values extracted from internal EEPROM)

›0x2011 – Voltages of the brakes; uint8; read/write

»Subindex 0: Number of entries = 2 (read only)

»Subindex 1: Voltage Brake 1

»Subindex 2: Voltage Brake 2

Voltages can be set from 40 to 200. A new uncongured Device is set to 0.

›0x2012 – Brake Modes; char[4]; read/write

»Subindex 0: Number of entries = 2 (read only)

»Subindex 1: Mode Brake 1

»Subindex 2: Mode Brake 2 Mode can be set to 0 (gear brake) or 1 (motor brake).

»Subindex 3: Connection Brake 1

»Subindex 4: Connection Brake 2

Connection can be set to 0 (only one coil) or 1 (two coils in series)

›0x2013 – Power reduction level of the brakes; char[4]; read/write

»Subindex 0: Number of entries = 2 (read only)

»Subindex 1: Reduction Level Brake 1

»Subindex 2: Reduction Level Brake 2

Reduction Level can be set from 50 to 100%. A new uncongured Device is set to 0.

›0x2014 – Power reduction time of the brakes; char[4]; read/write

»Subindex 0: Number of entries = 2 (read only)

»Subindex 1: Reduction Level Brake 1

»Subindex 2: Reduction Level Brake 2 Reduction Time can be set to 0, 3-10 or 255.0 means direct

Power Reduction, 255 means never reduce Power. A new uncongured Device is set to 0.

›0x2015 – Power Stage; char[4]; read/write

»Values implemented: 0 = Off 1 = On (default)

0x0 = OFF

0x1 = ON

CANopen

Manual CBM2 19

›0x2016 – Brake monitoring; read/write

»Subindex 0: Number of entries = 11 (read only)

»Subindex 1: uint8

* 0 = Off

* 1 = On, Contact-Type NO

* 2 = On, Contact-Type NC

* 3 = On, contactless

»Subindex 2: Counter Brake 1; uint16; Default: 100; Range: 20-1000

»Subindex 3: Current Offset Brake 1; uint16; Default: 50mA; Range: 5-500mA

»Subindex 4: Delay Monitoring after switch off; uint16; Default: 50ms; Range: 50-500ms

»Subindex 5: Counter Brake 2; uint16; Default: 100; Range: 20-1000

»Subindex 6: Current Offset Brake 2; uint16; Default: 50mA; Range: 5-500mA

»Subindex 7: Delay Monitoring after switch off; uint16; Default: 50ms; Range: 50-500ms

»Subindex 8: Start Tests; uint8; write only;

* 11 = leave brake 1 open after ride

* 12 = leave brake 2 open after ride

* 31 = leave Brake 1 closed

* 32 = leave Brake 2 closed

»Subindex 9: enables self-teach mode; writing a ‘1’ enables the self-teach mode; this measures the

counter values and adjusts the current offset for best results; as long as you read the value “1”

here, the self-teach mode is active; after self-teach mode has nished, the controller needs to read

the values to overtake them in the parameters! If counter values are 0 after self-teach Mode, self-

teaching was not possible! In that case parameters need to be adjusted manually or contactless

monitoring is not possible with these brakes. Contactless brake monitoring is switched off then

automatically; uint8

»Subindex 10: enables/disables sending of TPDO4 between brake switch off and safety chain ope-

ning; uint8

»Subindex 11: changes the interval of the sending of TPDO4 between 5 and 20ms; Default=10ms;

uint8

›0x2017 – Evacuation times; unsigned16; read/write

»Subindex 0: Number of entries = 2 (read only)

»Subindex 1: Evacuation pulse duration

»Subindex 2: Evacuation period duration

»Values can be set from 50-10000ms; Default: Pulse=200ms, Period=2000ms

When setting Strobe and Period to the same value, brakes are always open till evacuation is active!

›0x2019 – One Halfwave Mode; uint8; read/write

»Values implemented:

0x0 = Off

0x1 = On

›0x2020 – Delay switch off Gear-Brake; unsigned16; read/write

Can be set from 100 to 1000ms. Default is 1000ms

›0x2021 – Load-Check Pulse; uint16, read/write

Can be set from 50 to 1000ms. Default is 200ms. 0 switches off this function.

›0x2022 – CANopen Errors; uint8; read/write

»Values implemented:

0 = only Errors are transmitted which lead to shutoff (default)

1 = all Errors are transmitted

CANopen

20 Manual CBM2

›0x2023 – Delay Periods for MosFET-Tests; uint8; read/write

»Subindex 0: Number of entries = 2 (read only)

»Subindex 1: Delay periods HS-MF-Test, Number of periods for delaying the HS-MF-Test after

Switchoff and EEPROM-Write-Cycles

»Subindex 2: Delay periods HS-MF-Test, Number of periods for delaying the LS-MF-Test after the

HS-MF-Test

Can be set from 5 to 200. Default is 5(100ms).

›0x2024 – continuous contactless Brake monitoring; uint16, read/write

»Subindex 0: Number of entries = 8 (read only)

»Subindex 1: Counter Brake 1; Default: 0; Range: 20-1000; 0= continuous monitoring Off

»Subindex 2: Current Offset Brake 1; Default: 50mA; Range: 20-500mA

»Subindex 3: Delay Monitoring after switch on; Default: 2000ms; Range: 1000-5000ms

»Subindex 4: Counter Brake 2; Default: 0; Range: 20-1000; 0= continuous monitoring Off

»Subindex 5: Current Offset Brake 2; Default: 50mA; Range: 20-500mA

»Subindex 6: Delay Monitoring after switch on; Default: 2000ms; Range: 1000-5000ms

»Subindex 7: Delay for start Test after switch on; Default: 5000ms; Range: 2000-10000m

»Subindex 8: Start Tests; uint8; write only;

* 21 = close Brake 1 after delay

* 22 = close Brake 2 after delay

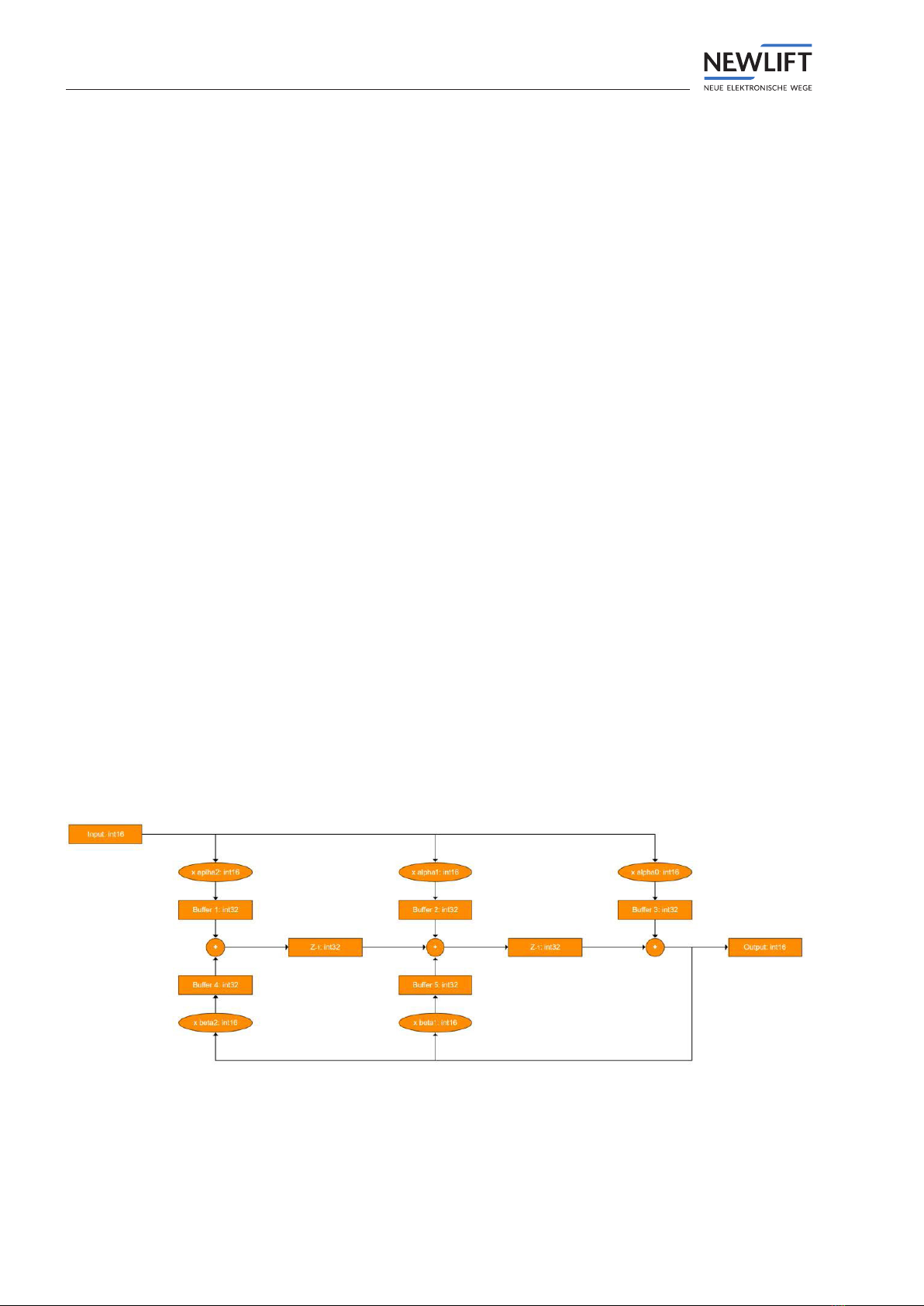

›0x2025 – IIR-Filter 2nd Order for Currents; Default: Butterworth with fg= 100 Hz and A= 1, 0

»Subindex 0: Number of entries = 6 (read only

»Subindex 1: Power of 2; uint8; Default: 10; Range: 6-12

»Subindex 2: alpha[0]; int16; Default: 47; Range: -32768 - +32767

»Subindex 3: alpha[1]; int16; Default: 94; Range: -32768 - +32767

»Subindex 4: alpha[2]; int16; Default: 47; Range: -32768 - +32767

»Subindex 5: beta[1]; int16; Default: 1339; Range: -32768 - +32767

»Subindex 6: beta[2]; int16; Default: -504; Range: -32768 - +32767

»Filter structure

Table of contents

Other New lift Control Unit manuals

Popular Control Unit manuals by other brands

Sagem

Sagem MO300 M2M Application note

VAT

VAT 650 Series Installation, operating, & maintenance instructions

Siemens

Siemens WATCHDOG-Modul ET 200iSP Product information

Grundfos

Grundfos CIM 200 Functional profile and user manual

LOXONE

LOXONE Miniserver Go quick start guide

Cumberland

Cumberland SP-MODULE user manual

Elkron

Elkron IT500CLOUD user manual

Emerson

Emerson Anderson Greenwood 727 Series Installation and maintenance instructions

Espressif Systems

Espressif Systems ESP32-S2-SOLO-2 user manual

Peak

Peak PCAN-MicroMod FD Digital 1 user manual

Gemu

Gemu 410 Installation, Operating and Maintenance Instructions for the Installer and the User

Beckhoff

Beckhoff EK9500 Documentation