New lift FST-2s User manual

Replacing FST-2s with FST-2XTs

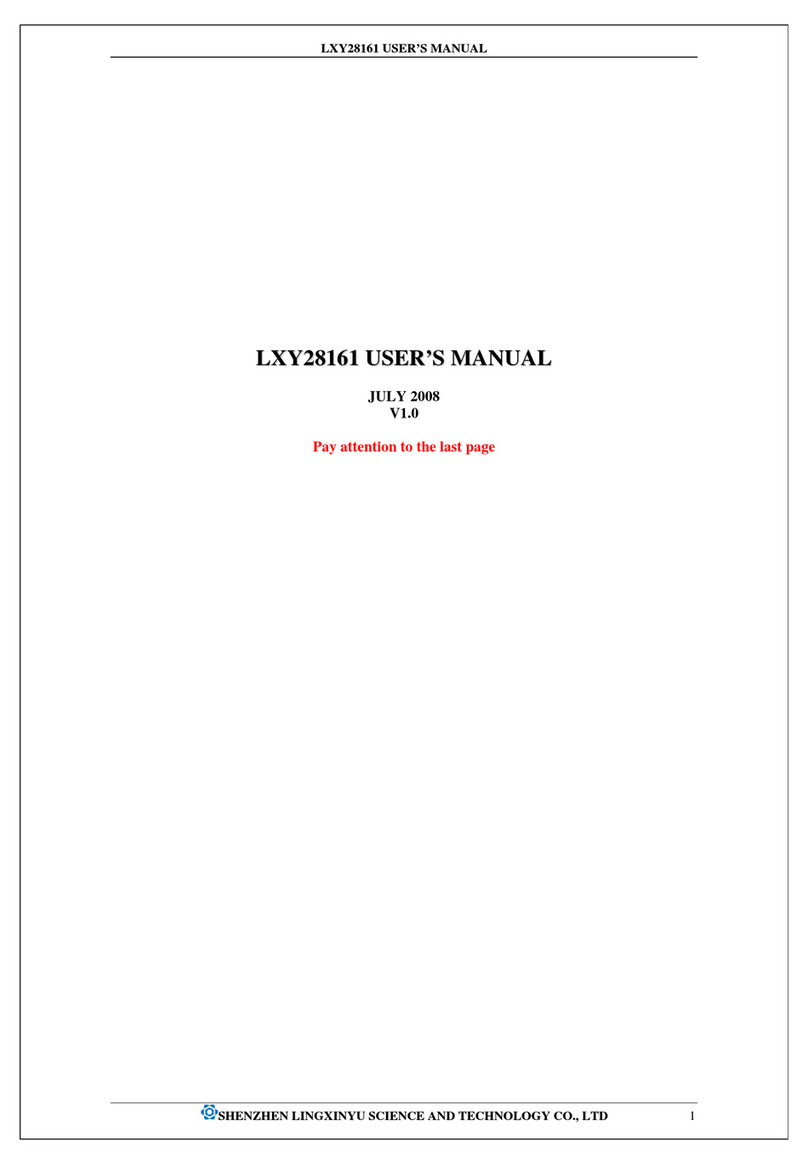

MANUAL

FST-2s

X37

X23

X17

X16

K37 K38 K39 K40

J131

J133

J135

J137

X111

X7/JTAG

J1/SERVICE

VORSICHT!

Explosionsgefahr bei

unsachgemäßem Austausch

der CR2430 Lithium-Batterie.

Entsorgung nur nach

Betriebsanleitung.

X2/GST-2s

K37: FK-SET

K38: Option1/FK-RESET

K39: Option2/GG-SET

K40: Option3/GG-RESET

J2

K23

K22

K21

K20

X19

X14

Notruf

X32

X21

X20

K7 K8 K9 K10 K11

FST-2s V2.Xc

K12 K1 K2 K3 K4 K0 K5 K6

Serien-

nummer

GEBER-B

GEBER-A

Zone

0

11

X2

K23

J131

J135

J136

X41X7

GESCHLOSSEN

>A<

01

Enter

Drive

Shift

F1 F2

AA

B

A

EVAC

AUX

FUNC Select

11

SKZU

SP

TKA

TKB

TKC

NHLT

FKNH

X5 X6 X3

BR

TEST R1/R2

1 0

S1000 S141 S140

S143/S207 S206 S205

S25

S998

IN

OUT

E

S

F

X2

HHT

1 2

X4

123 4 5678 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24

X1

K37

K38 X30

1

K22

K21

K20

X16

K14

X17

X19

X14

X21

X20

K13

X18 X24 X25 X26

K7

K6

K5

K0

K4

K3

K2

K1

K12

K11

K10

K9

K8

J133

14:03 : 02

1 3 4 6 7 8 2 3 5 6 7

1 2 3 4 5 6 7 8 129 10 11 14 15 16 1713

1 2 3 4 5 6 7 8 129 10 11

1234 21 1 2 3 4 1 2 3 4 5 6 7 8 9

1

1 2 3 4

84

91213 11 10 7 6 5

X15

1 2 3 40

3 2 X13 14

2 3 4 5 6 2 3 4 2 3X23 X27 X28

2 3 41

65

D22 X32

FST-2XTs

>

SAFETY CCT CLOSED

>AX< >BX< '''@'''

0 0 13:06:56

ManualforreplacingFST-2swithFST-2XTs

Manufacturer NEWLIFTSteuerungsbauGmbH

LochhamerSchlag8

82166Graefelfing

Tel +49 89 – 898 66 – 0

Fax +49 89 – 898 66 – 300

Mail [email protected]

www.newlift.de

Service line Tel +49 89 – 898 66 – 110

Mail [email protected]

Date of issue 21.12.2015

Author AL/DSI

Release AL

Hardware version FST-2XTs:51-00-3.1-FST_2XTs_MAIN

FST-2s:V2.8

Software version V2.000-0111

Doc. No. hb_Austausch_FST-2saufFST-2XTs_2016-03_en

Copyright ©NEWLIFTSteuerungsbauGmbH,2016

Thismanualisprotectedbycopyright.Allrights,includingthoseofcopying,of

reproduction,oftranslationandofmodification,inwholeorinpart,arereservedby

thepublisher.

Nopartofthisdescriptionmaybereproducedinanyformorcopiedwithan

electronicreplicationsystemwithoutwrittenpermission.

Althoughgreatcarehasbeentakenintheproductionoftextsandfigures,we

cannotbeheldlegallyliableforpossiblemistakesandtheirconsequences.

ManualforreplacingFST-2swithFST-2XTs 3

Content

1 General 5

1.1 Abbreviations, characters and symbols used 5

1.2 Further information 5

1.3 How to contact us 5

1.4 General safety regulations 6

1.4.1 Applicablestandardsandguidelines 6

1.4.2 Electromagneticcompatibility(EMC) 6

1.4.3 Handlingelectronicassemblies 6

2 FST-2XTs compared to FST-2s 7

3 FST jumpers 9

4 Terminal strips 13

4.1 Overview of terminal strips relevant to replacement 13

4.2 Adaptation table 17

5 Replacing FST-2s with FST-2XTs 18

5.1 Data transfer 18

5.1.1 DatatransferviaLONbus 18

5.1.2 Datatransferviaserialinterface(alternative) 20

5.2 Removal 22

5.3 Installation 22

5.4 Function tests 23

5.5 Information on EN81-1/2:1998 + A3:2009 25

5.5.1 FunctionUCM-A3 25

5.6 Waste disposal 26

5.7 Appendix 26

4 ManualforreplacingFST-2swithFST-2XTs

General

Abbreviations,charactersandsymbolsused

ManualforreplacingFST-2swithFST-2XTs 5

1 General

This manual is intended to simplify the replacement of the FST-2s circuit board with the FST-2XTs circuit board.

► Read this manual carefully and observe the FST-2s/XTs Installation & Commissioning manual as well as the

included circuit diagrams and jumper settings for the circuit boards before beginning the replacement.

► After replacing, perform the tests listed under certicates “FST-2XTs 51 00 - notices” on pages 1 and 3.

► Update the documents of the lift system on-site as well as other documents that may be present at the “desi-

gnated entity”. A check of the parameters and functions transferred from the FST-2s circuit board or of the

NEW LIFT factory parameter set is the responsibility of the person who performs the replacement.

As assistance here, the test actuations as described in the FST-2XT or FST-2XTs Installation & Commissioning

manual under 6.7.4 are to be performed. The FST-2XTs circuit board is generally compatible with the FST-2s

circuit board. There are, however, additional functions resulting from further developments, relating to the EN81-

1/2:1998 + A3:2009 A3 in particular, that are to be observed.

1.1 Abbreviations, characters and symbols used

EAZ position indicators

Delivery condition

Settings that are supplied as standard are marked with an asterisk .

► Activity symbol:

Activities described after this symbol must be carried out in the given order.

Safety-relevant information

This symbol is located in front of safety-relevant information.

Information notice

This symbol is located in front of relevant information.

1.2 Further information

The following documents, among others, are available for the FST control system and its components:

› FST Installation & Commissioning

› FST manual

› ADM manual

› FPM manual

› SAM manual

› EAZ-256 manual

› EAZ-LCD and EAZ-VFD manual

› Fire recall manual

These and other current manuals can be found in the download area of our website under Service at http://

www.newlift.de/en/service/download

1.3 How to contact us

If, after referring to this manual, you still require assistance, our service line is there for you:

Tel +49 89 – 898 66 – 110

Mail [email protected]

Mon. - Thurs.: 8:00 a.m. – 12:00 p.m. and 1:00 p.m. – 5:00 p.m.

Fr: 8:00 a.m. – 3:00 p.m.

General

Generalsafetyregulations

6 ManualforreplacingFST-2swithFST-2XTs

1.4 General safety regulations

The FST-2XTs microprocessor control must only be operated in perfect working condition in a proper manner,

safely and in compliance with the instructions, the valid accident prevention regulations and the guidelines of

the local power company.

The safety guidelines of the FST manual and the FST Installation and Commissioning manual always apply.

1.4.1 Applicable standards and guidelines

All FST-2XTs microprocessor controls satisfy:

› the safety guidelines for the construction and installation of passenger and goods passenger lifts (DIN EN 81

Part 1 and 2).

› the conditions for the erection of high voltage installations with nominal voltages up to 1 kV (DIN VDE 0100).

› the contact protection measures in the machine room (VDE 0106).

› the data sheet on safety measures for the installation, maintenance and commissioning of lift systems (ZH

1/312).

1.4.2 Electromagnetic compatibility (EMC)

An accredited inspection authority has inspected the FST control system and its components in accordance with

the standards, thresholds and severity levels named in EN 12015/1995 and EN 12016/1995.

The FST control system and its components are:

› immune to electrostatic discharge (EN 61000-4-2/1995)

› immune to electrostatic elds (EN 61000-4-3/1997)

› immune to fast transient disturbances (EN 61000-4-4/1995)

The electromagnetic disturbance eld strengths created by the FST control system and its components do not

exceed the permissible thresholds. (EN 55011/1997).

1.4.3 Handling electronic assemblies

► Keep the electronic assembly in its original packaging until installation.

► Touch a grounded piece of metal before opening the original packaging to discharge any static electric

charge on the electronic assembly.

► During work on electronic assemblies, periodically repeat this discharge procedure.

► Fit all bus inputs and outputs that are not in use with a terminator except slot X3.

FST-2XTs compared to FST-2s

Generalsafetyregulations

ManualforreplacingFST-2swithFST-2XTs 7

2 FST-2XTs compared to FST-2s

The FST-2XTs is nearly fully compatible with the FST-2s.

► Note the improvements and expansions listed in the following!

Improvements and expansions

› Adoption of the FST-2XT properties

MMI (man-machine interface - keyboard/display), processor structure, connectivity (USB, CAN Open LIFT,

Ethernet), NEW LIFT Guide (online conguration aid).

› Emergency mode monitor

The emergency mode monitor for emergency release for the lift attendant was integrated in the display of the

FST-2XTs.

› Auxiliary mode control (AUX)

Auxiliary mode control switches S21/S22 were grouped together in a single cam switch.

› Keypad

The keypad has the full functionality of the FST-2XT keypad.

› BUS connector plugs

Bus connectors X3, X5 and X6 were repositioned for easier use.

› Connectivity

Interface expansion to Ethernet, Mini USB, USB 2.0, CAN Open LIFT

› Operating elements of the lift attendant panel

»The operating elements in the lift attendant panel area were, in part, implemented as pressure mats.

»Adjacent to the pushbuttons, LEDs have been added as button acknowledgement.

»LED illuminated ->button pressed, function active

»LED off - > button not pressed, function not active

»Function button “F1” (currently without function) and the selection buttons for controlling external

safety devices for protected area safeguarding for shaft head and shaft pit were added to the previous

operating elements (brake release button A/B, anti creep device, evacuation switch, brake test key

switch and shaft door reset button).

› Improved visual signalling.

»The LEDs, IN/OUT (BUS trafc), safety circuit inputs and 24VDC power supply for shaft bus (X5/6) are

now located directly on the front panel.

»Upon actuation of the evacuation switch, the LED of the toggle ashes in sync with the acoustic message.

FST-2XTs compared to FST-2s

Generalsafetyregulations

8 ManualforreplacingFST-2swithFST-2XTs

Note the following important changes

› Terminal strips X1, X23, X24, X25, X27, X28

Due to expanded functionality, the plugs listed above have been changed.

► For detailed information, see 4.1 Overview of terminal strips relevant to replacement.

► Reconnect wires of these terminal strips according to 4.2 Adaptation table.

All terminal strips not listed can be connected unchanged to the FST-2XTs.

› Group controller circuit board for FST-2s “GSTs”

The GSTs group controller circuit board has been discontinued; the GST-XT is available as a replacement.

› DRM-contactor monitoring

The positively driven, normally closed contacts of the brake activation relay located on the FST-2XTs are now

also integrated in the contactor monitoring. The normally closed contacts that are integrated in the safety circuit

remain included unchanged as with the FST-2s.

› Drive monitoring input

Input X1:21 was implemented as motor monitoring as with the FST-2XT.

FST jumpers

Generalsafetyregulations

ManualforreplacingFST-2swithFST-2XTs 9

3 FST jumpers

FST-2XT jumper J1: service jumper

This jumper must always remain open.

FST-2XTs jumper J1: encoder - incremental / CAN Open LIFT

Function J1

Incremental 24V 1-2

CANopen Lift ground 2-3

FST-2XT and FST-2XTs jumper J2: load measurement inputs

Function J2

Switched GND for load measurement inputs 1-2

Switched +24 V for load measurement inputs 2-3

FST-2XTs jumper J3: encoder - incremental / CAN Open LIFT

Function J3

Incremental 5V 1-2

CANopen Lift 24V 2-3

FST-2XTs jumper J4: encoder - incremental / CAN Open LIFT

Function J4

Incremental track A 1-2

CANopen Lift channel L 2-3

FST-2XTs jumper J5: encoder - incremental / CAN Open LIFT

Function J5

Incremental track A negated 1-2

CANopen Lift channel H 2-3

FST-2XT and FST-2XTs jumper J90: shielding X9

This jumper is in the open position on delivery. Set only after consulting with NEW LIFT.

The shielding of service-PC cable X9 is connected to PE or GND potential with J90.

Function J90

Shielding of the connecting cable on PE 1-2

Shielding of the connecting cable on GND 2-3

Shielding of the connecting cable insulated open

FST jumpers

Generalsafetyregulations

10 ManualforreplacingFST-2swithFST-2XTs

FST-2XT and FST-2XTs jumper J100: shielding X43

This jumper is in the open position on delivery. Set only after consulting with NEW LIFT.

The shielding of modem cable X10 is connected to PE or GND potential with J100.

Function J100

Shielding of the connecting cable on PE 1-2

Shielding of the connecting cable on GND 2-3

Shielding of the connecting cable insulated open

FST-2XT and FST-2XTs jumper J110: shielding X11

This jumper is in the open position on delivery. Set only after consulting with NEW LIFT.

The shielding of DCP cable X11 is connected to PE or GND potential with J110.

Function J110

Shielding of the connecting cable on PE 1-2

Shielding of the connecting cable on GND 2-3

Shielding of the connecting cable insulated open

FST-2XT and FST-2XTs J120: shielding X12

The shielding of encoder cable X12 is connected to PE or GND potential with J120.

Function J120

Shielding rotary encoder cable on PE 1-2

Shielding rotary encoder cable on GND 2-3

FST jumpers

Generalsafetyregulations

ManualforreplacingFST-2swithFST-2XTs 11

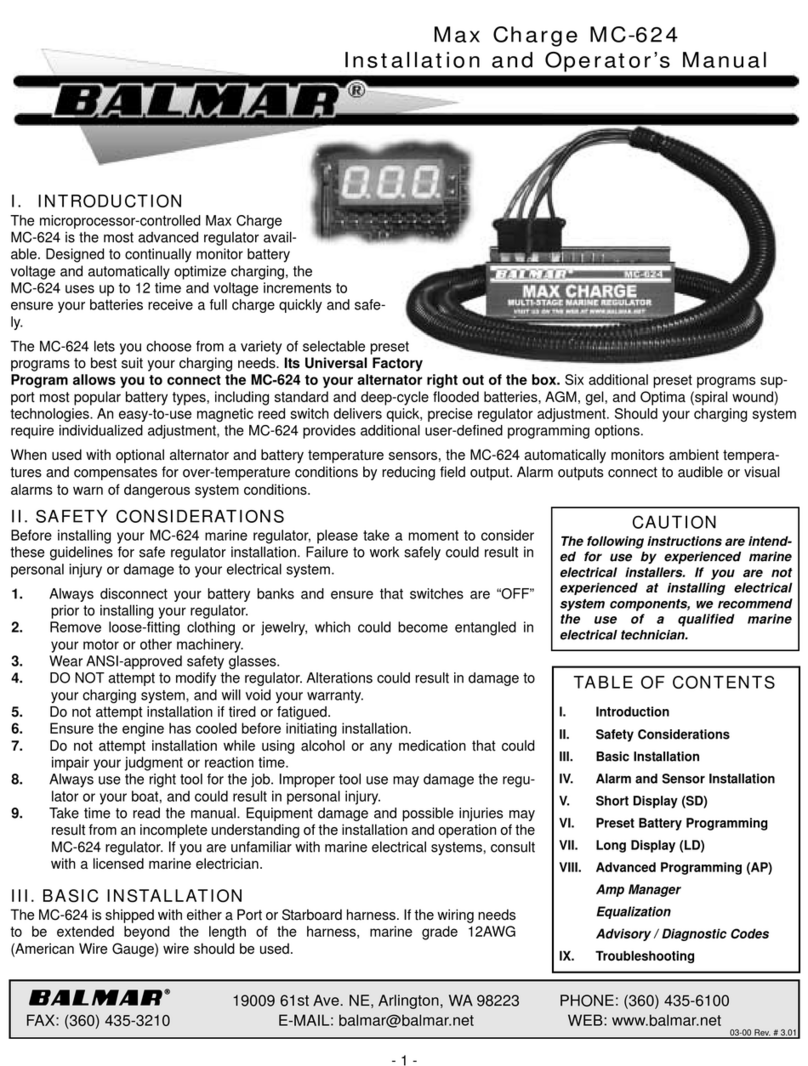

FST-2XT and FST-2XTs jumper J131-J136: definition of the shaft positioning

The position of the shaft positioning system (car or shaft) is dened with J131, J133, J135, J136.

Shaft positioning system on the car; FSM-2 X25:

› all jumpers are jumped to 1-2.

Shaft positioning system in the shaft or machine room; FST X12:

› all jumpers are jumped to 2-3

› depending on the type of shaft positioning, two (incremental positioning with zone magnets) or four (absolute

value positioning) freely travelling cable cores are available at terminal FSM-2 X15 / FST X13.

A+ / CLK+

A- / CLK-

B- / DATA-

B+ / DATA+

J136 J136

J135 J135

J131 J131

J133 J133

X12.2 X12.2

X25.2 X25.2

FST-2 X30.16 FST-2 X30.16

FSM-2 X30.16 FSM-2 X30.16

.4 .4

.4 .4

.3 .3

.3 .3

.15 .15

.15 .15

X13.1 X13.1

Jumper setting 1-2

Connection of the position encoder in the machine room; FST-2 X12

Connection of the position encoder on the car; FSM-2 X25

Jumper setting 2-3

X15.1 X15.1

TC TC

up to four free travelling cable

cores; FSM-2 X15 / FST-2 X13

if TC →

necessary BC →

BC BC

.2 .2

1 2 3 1 2 3

.2 .2

.3 .3

.3 .3

.4 .4

.4 .4

.5 .5

.6 .6

.7 .7

.7 .7

.4 .8

.4 .4

.8 .4

.8 .8

Positioning

A+ / CLK+

A- / CLK-

B- / DATA-

B+ / DATA+

Positioning

Fig. 3.1: Connection point of the position encoder and jumper setting J131, J133, J135, J136

FST jumpers

Generalsafetyregulations

12 ManualforreplacingFST-2swithFST-2XTs

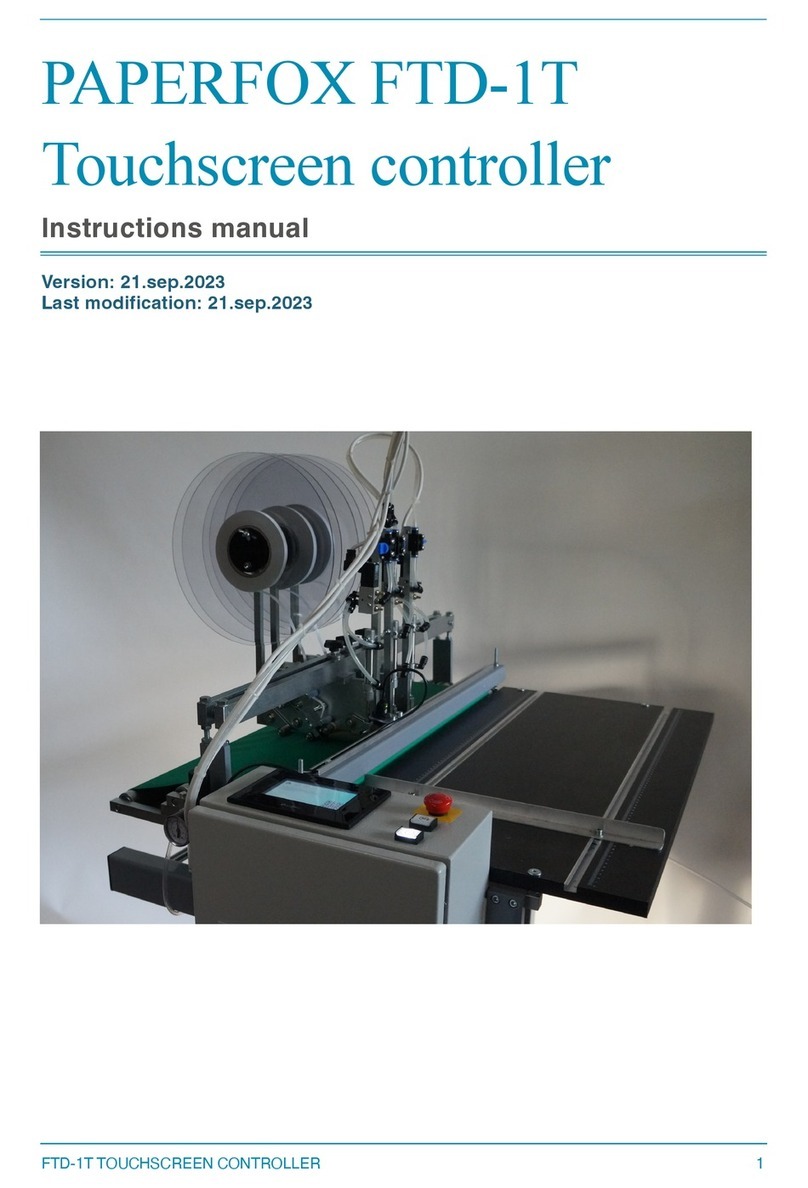

Abb. 3.2: Main board FST-2XTs

Terminal strips

Overviewofterminalstripsrelevanttoreplacement

ManualforreplacingFST-2swithFST-2XTs 13

4 Terminal strips

4.1 Overview of terminal strips relevant to replacement

For terminals that are designated in this table with a capital letter after the ordinal number, the assignment has

changed.

► When replacing the terminals, make certain that the assignment is correct. See also 4.2 Adaptation table.

FST-2s

terminal strip

FST-2s

terminal

Function

FST-2XTs

terminal strip

FST-2XTs

terminal

Function

X1 1 +24V/2A (FST supply voltage) X1 1 +24V/2A (FST supply voltage)

2GND 2GND

3+24V/2A (FST supply voltage) 3+24V/2A (FST supply voltage)

4Programmable I/O port 0 4Programmable I/O port 0

5Programmable I/O port 1 5Programmable I/O port 1

6Programmable I/O port 2 6Programmable I/O port 2

7Programmable I/O port 3 7Programmable I/O port 3

8Programmable I/O port 4 8Programmable I/O port 4

9Programmable I/O port 5 9Programmable I/O port 5

10 Programmable I/O port 6 10 Programmable I/O port 6

11 Programmable I/O port 7 11 Programmable I/O port 7

12 GND 12 GND

13 Car lighting OFF 13 Car lighting OFF

14 Landing calls OFF 14 Landing calls OFF

15 GND 15 GND

16 Temperature monitoring motor room 16 Temperature monitoring motor room

17 Overload 17 Overload

18 Full load 18 Full load

19 Monitoring of brake A 19 Monitoring of brake A

20 Monitoring of brake B 20 Monitoring of brake B

21AOutput 24VDC brake test for contactor

monitoring

21 Drive monitoring

22 Motor monitoring 22 Motor monitoring

23 Standstill monitoring 23 Standstill monitoring

24 +24V/2A (FST supply voltage) 24 +24V/2A (FST supply voltage)

X4 1 +24 V X4 1 +24 V

2GND 2GND

X13 14 Bridge zone release for external

V<0.2m/s contact to terminal 7 if

applicable.

X13 14 Bridge zone release for external

V<0.2m/s contact to terminal 7 if

applicable.

1FSM-2 X15.3 (only if J131 2-3) 1FSM-2 X15.3 (only if J131 2-3)

2Top correction switch "TC" (only for

incremental positioning)

2Top correction switch "TC" (only for

incremental positioning)

3FSM-2 X15.4 (only if J133 2-3) 3FSM-2 X15.4 (only if J133 2-3)

5FSM-2 X15.2 (only if J135 2-3) 5FSM-2 X15.2 (only if J135 2-3)

6FSM-2 X15.1 (only if J136 2-3) 6FSM-2 X15.1 (only if J136 2-3)

7SCBC zone release (with external

SCBC)

7SCBC zone release (with external

SCBC)

8SCBC zone bypass (with external SCBC) 8SCBC zone bypass (with external

SCBC)

9SCBC zone signal (with external SCBC) 9SCBC zone signal (with external

SCBC)

Terminal strips

Overviewofterminalstripsrelevanttoreplacement

14 ManualforreplacingFST-2swithFST-2XTs

FST-2s

terminal strip

FST-2s

terminal

Function

FST-2XTs

terminal strip

FST-2XTs

terminal

Function

10 SCBC encoder zone switch A (always

bridged with X13.11)

10 SCBC encoder zone switch A (always

bridged with X13.11)

11 SCBC encoder zone switch A 11 SCBC encoder zone switch A

12 SCBC encoder zone switch B 12 SCBC encoder zone switch B

13 Simulation zone switch B (bridge with

13.12 if applicable)

13 Simulation zone switch B (bridge with

13.12 if applicable)

X14 1 Safety circuit closed X14 1 Safety circuit closed

3Door lock or bolt contact door side A

closed

3Door lock or bolt contact door side A

closed

4Car door contact of door side A closed 4Car door contact of door side A closed

6Car door contact of door side C closed 6Car door contact of door side C closed

7Emergency stop shaft closed 7Emergency stop shaft closed

8Car emergency stop closed 8Car emergency stop closed

X15 1 Bypass UP X15 1 Bypass UP

2Bypass DOWN 2Bypass DOWN

3L safety circuit 3L safety circuit

5Auxiliary mode bridging function 5Auxiliary mode bridging function

6N safety circuit 6N safety circuit

7Output bypass doors 7Output bypass doors

X16 1 Intercom A or A X16 1 Intercom A or A

2Intercom A or B 2Intercom A or B

3Intercom A or C 3Intercom A or C

4Intercom A or D 4Intercom A or D

X17 0 +24 V or HSG +12 V (beginning of the

emergency call loop)

X17 0 +24 V or HSG +12 V (beginning of the

emergency call loop)

1Emergency call 1Emergency call

2Emergency power supply 2Emergency power supply

3GND 3GND

4Level switch + 4Level switch +

5Level switch - 5Level switch -

6Emergency call line A 6Emergency call line A

7Emergency call line B 7Emergency call line B

X18 1 +24 V X18 1 +24 V

2Auxiliary mode control ON 2Auxiliary mode control ON

3Auxiliary control travel direction UP 3Auxiliary control travel direction UP

4Auxiliary control travel direction DOWN 4Auxiliary control travel direction DOWN

X19 1 Auxiliary mode control ON X19 1 Auxiliary mode control ON

2Auxiliary control bridging function 2Auxiliary control bridging function

3L auxiliary control 3L auxiliary control

4Auxiliary control UP or DOWN 4Auxiliary control UP or DOWN

X20 1 Safety circuit "CLOSED" X20 1 Safety circuit "CLOSED"

2N safety circuit 2N safety circuit

3Pre-selection contact K0,K1 COM 3Pre-selection contact K0,K1 COM

4Pre-selection contact K0 NO 4Pre-selection contact K0 NO

5Pre-selection contact K1 NO 5Pre-selection contact K1 NO

6Pre-selection contact K2, K3 COM 6Pre-selection contact K2, K3 COM

7Pre-selection contact K2 NO 7Pre-selection contact K2 NO

8Pre-selection contact K3 NO 8Pre-selection contact K3 NO

9Pre-selection contact K4,K6 COM 9Pre-selection contact K4,K6 COM

10 Pre-selection contact K4 NO 10 Pre-selection contact K4 NO

Terminal strips

Overviewofterminalstripsrelevanttoreplacement

ManualforreplacingFST-2swithFST-2XTs 15

FST-2s

terminal strip

FST-2s

terminal

Function

FST-2XTs

terminal strip

FST-2XTs

terminal

Function

11 Pre-selection contact K5 NO 11 Pre-selection contact K5 NO

12 Pre-selection contact K6 NO 12 Pre-selection contact K6 NO

X21 1 Pre-selection contact K7 - K8 COM X21 1 Pre-selection contact K7 - K8 COM

2Pre-selection contact K7 NO 2Pre-selection contact K7 NO

3Pre-selection contact K7 NC 3Pre-selection contact K7 NC

4Pre-selection contact K8 NO 4Pre-selection contact K8 NO

5Pre-selection contact K8 NC 5Pre-selection contact K8 NC

6Pre-selection contact K9, K11, K12 COM 6Pre-selection contact K9, K11, K12

COM

7Pre-selection contact K9 NO 7Pre-selection contact K9 NO

8Pre-selection contact K10 COM 8Pre-selection contact K10 COM

9Pre-selection contact K10 NO 9Pre-selection contact K10 NO

10 Pre-selection contact K10 NC 10 Pre-selection contact K10 NC

11 Pre-selection contact K11 NO 11 Pre-selection contact K11 NO

12 Pre-selection contact K12 NO 12 Pre-selection contact K12 NO

13 Emergency call relay contact K13 COM1 13 Emergency call relay contact K13

COM1

14 Emergency call relay contact K13 NO1 14 Emergency call relay contact K13 NO1

15 Emergency call relay contact K13 NC1 15 Emergency call relay contact K13 NC1

16 Emergency call relay contact K13 COM2 16 Emergency call relay contact K13

COM2

17 Emergency call relay contact K13 NC2 17 Emergency call relay contact K13 NC2

X23 1BNC X23 B1Triggering of relay K37 NC contact

2BCOM K37.A FK SET B2Triggering of relay K37 COM FK SET

contact

3BNO B3Triggering of relay K37 NO contact

4BNC B4Resetting of relay K38 NC contact

5BCOM K38.A FK RESET B5Resetting of relay K38 COM FK

RESET contact

6BNO B6Resetting of relay K38 NO contact

7NC Terminals no longer present

8COM K39.A GG SET Terminals no longer present

9NO Terminals no longer present

10 NC Terminals no longer present

11 COM K40.A GG RESET Terminals no longer present

12 NO Terminals no longer present

X24 1 Anti creep device NO 2 X24 1 Anti creep device relay K36 NC

contact 230VAC

2Anti creep device NC 2 2Anti creep device relay K36 NC

contact 230VAC

3Anti creep device COM 2 Terminals no longer present

X25 1CAnti creep device NO 1 X25 C1Anti creep device relay K36 NO

contact 230VAC

2CAnti creep device COM 1 C2Anti creep device relay K36 NO

contact 230VAC

3Anti creep device NC 1 D3Evacuation relay K31 NO contact

230VAC

4EShaft door reset NO D4Evacuation relay K31 NO contact

230VAC

5EShaft door reset COM Terminals no longer present

6DEVAC ON NO Terminals no longer present

Terminal strips

Overviewofterminalstripsrelevanttoreplacement

16 ManualforreplacingFST-2swithFST-2XTs

FST-2s

terminal strip

FST-2s

terminal

Function

FST-2XTs

terminal strip

FST-2XTs

terminal

Function

7DEVAC ON NO Terminals no longer present

X26 1 Brake test relay K34 NO contact 230VAC X26 1 Brake test relay K34 NO contact

230VAC

2Brake test relay K34 NO contact 230VAC 2Brake test relay K34 NO contact

230VAC

3Monitoring contacts of relay

K28(NO),33(NC),32(NC)

3Monitoring contacts of relay

K28(NO),33(NC),32(NC)

4Brake B - relay K33 NO contact 230VAC 4Brake B - relay K33 NO contact

230VAC

5Monitoring contacts of relay

K28(NO),33(NC),32(NC)

5Monitoring contacts of relay

K28(NO),33(NC),32(NC)

6Brake A - relay K32 NO contact 230VAC 6Brake A - relay K32 NO contact

230VAC

7Evacuation relay K31 NO contact

230VAC

7Evacuation relay K31 NO contact

230VAC

8Evacuation relay K31 NO contact

230VAC

8Evacuation relay K31 NO contact

230VAC

9Supply for evacuation/brake test 230VAC 9Supply for evacuation/brake test

230VAC

X27 E1Shaft pit reset K29 NO contact

230VAC

E2Shaft pit reset K29 NO contact

230VAC

3Shaft head reset K35 NO contact

230VAC

4Shaft head reset K35 NO contact

230VAC

X28 1

2

+24VDC

Input of the monitoring contacts of the

external manual brake control

A3Output for contactor monitoring

X32 1 Car door side A X32 1 Car door side A

2Car door side B 2Car door side B

3Car door side C 3Car door side C

4Emergency stop car 4Emergency stop car

5Bypass UP 5Bypass UP

6Bypass DOWN 6Bypass DOWN

7Bypass ON 7Bypass ON

8Bypass 8Bypass

9N safety circuit 9N safety circuit

Terminal strips

Adaptationtable

ManualforreplacingFST-2swithFST-2XTs 17

4.2 Adaptation table

If wires are connected to the following terminals of the FST-2s:

► Reconnect wires to the terminals of the FST-2XTs according to the table.

FST-2s

terminal

► Disconnect wire from the FST-2s and con-

nect to the terminal of the FST-2XTs!

FST-2XTs

terminal

› Connect bridge X28:1

› Connect bridge X28:2

X1:21 ► X28:3

X23:1 ► X23:1

X23:2 ► X23:2

X23:3 ► X23:3

X23:4 ► X23:4

X23:5 ► X23:5

X23:6 ► X23:6

X24:1 ► X24:1

X24:2 ► X24:2

X25:1 ► X25:1

X25:2 ► X25:2

X25:4 ► X27:1

X25:5 ► X27:2

X25:6 ► X25:3

X25:7 ► X25:4

Replacing FST-2s with FST-2XTs

Datatransfer

18 ManualforreplacingFST-2swithFST-2XTs

5 Replacing FST-2s with FST-2XTs

5.1 Data transfer

If a replacement is necessary, the new FST-2XTs is created at the factory with the same order data record as at

the time of the original order.

Possible loss of data!

► The following tasks must absolutely be performed in the specied order!

5.1.1 Data transfer via LON bus

► Switch on the MAIN SWITCH of the FST-2s.

► Switch on the AUXILIARY CONTROL (AUX).

► Make certain that all lift doors are closed.

► Unplug plugs X5 and X6, which belong to the shaft bus.

► Reset the Lift ID number parameter on the display:

»Press button to change to the main menu.

»Use buttons / to navigate to the

Config/ID’s/Lift ID-Number/FST-A submenu and conrm each with .

► Open the original packaging of the new FST-2XTs.

Destruction of electronic components through electrostatic discharge!

When opening the original packaging of circuit boards/electronic components, an electrostatic

discharge may occur.

Before opening the original packaging, touch a grounded piece of metal.

► Set down the FST-2XTs circuit board in an insulated manner so that no contact with electrically conductive

parts can occur, e.g., on the original packaging.

Replacing FST-2s with FST-2XTs

Datatransfer

ManualforreplacingFST-2swithFST-2XTs 19

► Connect the two circuit boards with a bus cable at the respective X3 bus connectors (options bus).

► Wait until the FST-2XTs software has completely started.

► Activate the hidden menus:

»Press button to change to the main menu.

»Use buttons / to navigate to the

System/Factory Menu/Hidden Menus submenu and conrm with .

»Press button , select YES and conrm with .

»Select the Clone FST-2 LON command and conrm with .

FTX appears briey on the display and data transfer starts.

After data transfer has been completed, Config. transfer ok appears.

The FST-2XT performs an automatic restart with the accepted parameters.

► Wait until the FST-2XTs software has completely started.

LON connection

Replacing FST-2s with FST-2XTs

Datatransfer

20 ManualforreplacingFST-2swithFST-2XTs

5.1.2 Data transfer via serial interface (alternative)

► Switch on the MAIN SWITCH of the FST-2s.

► Switch on the auxiliary control (AUX).

► Make certain that all lift doors are closed.

► Unplug plugs X5 and X6, which belong to the shaft bus.

► Reset the Lift ID number parameter on the display:

»Press button to change to the main menu.

»Use buttons / to navigate to the

Config/ID’s/Lift ID-Number/FST-A submenu and conrm with .

► Open the original packaging of the new FST-2XTs.

Destruction of electronic components through electrostatic discharge!

When opening the original packaging of circuit boards/electronic components, an electrostatic

discharge may occur.

Before opening the original packaging, touch a grounded piece of metal.

► Set down the FST-2XTs circuit board in an insulated manner so that no contact with electrically conductive

parts can occur, e.g., on the original packaging.

This manual suits for next models

1

Table of contents

Other New lift Controllers manuals

Popular Controllers manuals by other brands

TELEDYNE OLDHAM SIMTRONICS

TELEDYNE OLDHAM SIMTRONICS MX 43 user guide

Gira

Gira One 5061 00 operating instructions

Hanna Instruments

Hanna Instruments HI 8931 instruction manual

Autonics

Autonics TR1D Series Communications manual

Lamtec

Lamtec ETAMATIC manual

Rockwell Automation

Rockwell Automation Allen-Bradley AADvance T9110 System Build Manual