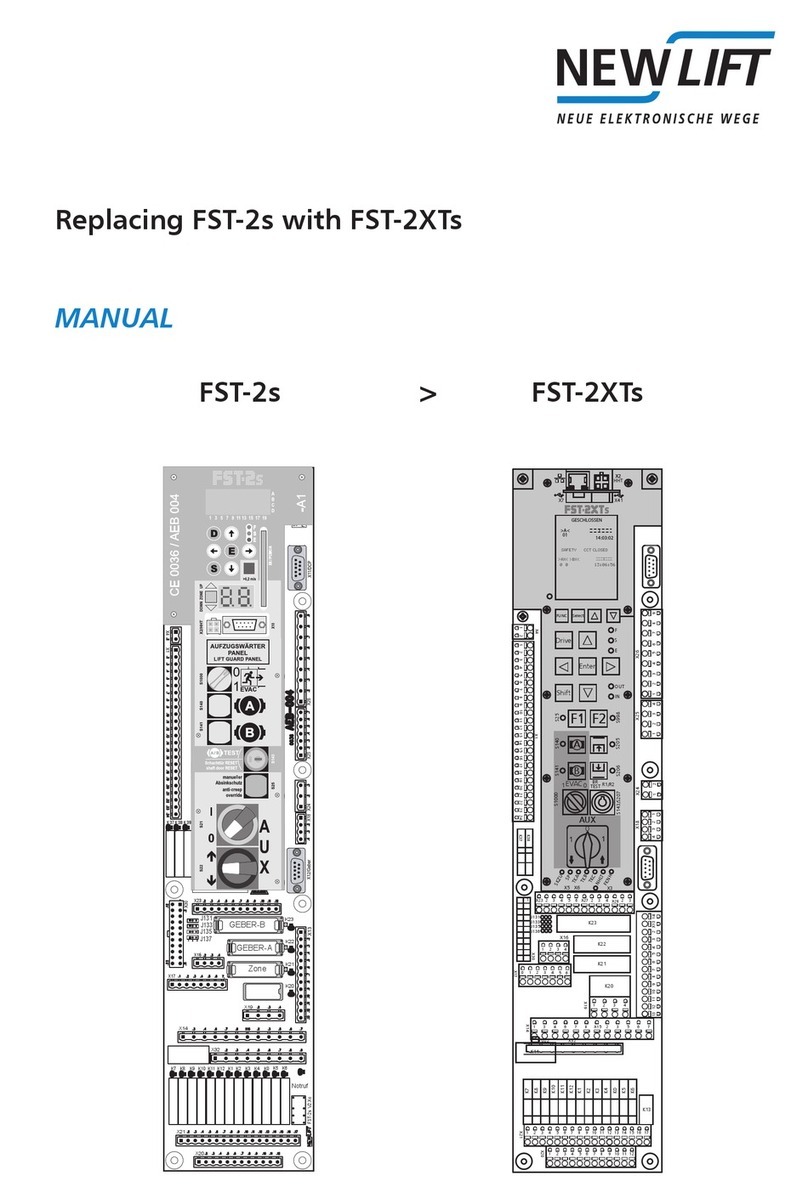

New lift FST-2 User manual

Manual

Field Bus Controller

X7 .2 .

3

.4 .

5

.

6

X

8

.2 .

3

.4 .

5

.

6

X

9

.2 .

3

.4 .

5

.

6

9

.

8

7

.

6

5

.

4

.

3

.

2

6

X

5

.

4

.

3

2

5

X

4

.

3

2

4

X

6

5

.

4

3

2

.

3

X

6

.

5

.

4

3

.

2

.

2

X

9

8

7

6

.

5

.

4

.

3

.

2

.

1

X

5

.

4

3

.

2

.

1

1

X

4

.

3

.

2

.

5

1

X

6

.

5

.

4

3

.

2

.

4

1

X

9

.

8

.

7

.

6

.

5

.

4

3

.

2

.

0

1

X

4

.

3

2

3

1

X

4

.

3

2

7

1

X

4

.

3

2

6

1

X

X19

.

2

.

3

.

4

.

5

.

6

.

7

.

8

X18

.

2

.

3

.

4 .

X2

0

.2 .

3

.4

.

T

1

1

12

13

14

15

16

17

18

19

20

1

2

3

4 5

6

7

8

9

1

0

1

1

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

7

8

8

9

1

0

1

1

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

1

0

T

GESCHLO

S

SEN

>A< ###@###-

01 14:03:02

D

42.32.22.12.02.91.81.71.61.51.41.31.21.11.01.9.8.7.6.5.4.3.2.1X

X20.2 .3 .4 .5 .6 .7 .8 .9 .10 X21.2 .3 .4 .5 .6 .7 X22.2 .3 .4 .5 .6

21.11.01.9.8.7.6.5.4.3.2.31X

SKZU SPB SPA TKA TKB TKC NHLT FKNHLT

2.4X

H

N

K

F

H

N

C

K

T

B

K

T

A

K

T

A

P

S

B

P

S

U

Z

K

S

Rev. D2.2b

A1

0036

AEB-004

B

C

A

Speicherkarte / memory-card

FST

STATUS

ERROR

Modem

(RS-232)

X10

D

151353791111719

Oberster Ruf / top call

[ oneup ]einsauf /

Unterster Ruf / bottom call

[einsab/ ]one down

[]

Umschalttaste /

shift

Antrieb /

drive

Testmenü / test menu

[]Anzeige rechts / display right

Außensteuerung Aus /

landing calls off

[display left ]

Anzeige links /

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

1

X12

Drehgeber /

encoder

X5

X6

X4

X3

X2

HHT

BUS

Schacht-BUS Einspeisung /

shaft or group-bus power input

Option

BUS

Service

(RS-232)

X9

Antrieb /

drive

X11

X8

Menü, Eingabe / menu, enter

[]Infoanzeige / info screen

X1

Sicherheitskreis / safety circuit

Schach t BUS /

shaft bus

FST-2_HB.EN12/05

Publisher NEW LIFT Steuerungsbau GmbH

Lochhamer Schlag 8

D-82166 Gräfelfing

Phone: +49 (0) 89 / 89 866 - 0

Fax: +49 (0) 89 / 89 866 - 300

Doc. No. FST-2_HB.EN12/05

Date of issue 12/05

Software version V1.100-0350

Copyright © 2005, NEW LIFT Steuerungsbau GmbH

All rights including those of copying and reproduction of parts of this

description and of the translation are reserved by the publisher.

No part of this description may be reproduced in any form or copied with an

electronic replication system without the written permission of the

publisher.

Table of contents

FST-2_HB.EN12/05 1

1 About this manual ..............................................................................................5

1.1 General........................................................................................................................... 5

1.2 Signs and Symbols used ....................................................................................... 5

1.3 Further information................................................................................................... 6

2 General Safety Regulations .........................................................................7

2.1 Standards and regulations applied.................................................................... 7

2.2 Electromagnetic compatibility (EMC)................................................................ 8

2.3 Handling electronic components........................................................................ 8

3 FST-2-Controller user interface ................................................................9

3.1 LC-Display and messages................................................................................... 10

Main screen..................................................................................................................... 10

Line A .............................................................................................................................. 10

Line B .............................................................................................................................. 11

Line C.............................................................................................................................. 13

Line D.............................................................................................................................. 27

Information texts.............................................................................................................. 28

Information page.............................................................................................................. 31

3.2 Keypad functions................................................................................................... 32

Frequency converter with DCP interface......................................................................... 32

When switching on .......................................................................................................... 32

Main screen..................................................................................................................... 33

Main menu and test menu............................................................................................... 33

Error list........................................................................................................................... 34

Information page.............................................................................................................. 34

3.3 LEDs.............................................................................................................................. 34

4 Technical data ..................................................................................................... 35

4.1 Component overview – bus plan ...................................................................... 36

4.2 FST-2-Controller....................................................................................................... 37

Table of contents

2FST-2_HB.EN12/05

Safety Monitoring Device................................................................................................. 44

4.3 FSM car control module........................................................................................ 53

4.4 FPM car panel module........................................................................................... 65

4.5 FPE car panel extension module..................................................................... 72

4.6 FPA car control panel adapter........................................................................... 77

4.7 ADM landing call module ..................................................................................... 81

4.8 RIO-ADM remote I/O module............................................................................... 84

4.9 RIO-FPM remote I/O module ............................................................................... 87

4.10 LON bus....................................................................................................................... 91

4.11 Trailing ribbon cable.............................................................................................. 92

5 Menu tree .................................................................................................................95

5.1 General......................................................................................................................... 95

5.2 MAIN MENU – Service.......................................................................................... 104

5.3 MAIN MENU – Drive.............................................................................................. 106

5.4 MAIN MENU – Config........................................................................................... 111

5.5 MAIN MENU – Positioning.................................................................................. 127

5.6 MAIN MENUE – Calls............................................................................................ 134

5.7 MAIN MENUE – System....................................................................................... 136

5.8 MAIN MENUE – Doors.......................................................................................... 139

5.9 MAIN MENU.............................................................................................................. 144

5.10 TEST MENU.............................................................................................................. 145

6 Programmable inputs and outputs ....................................................147

Table of contents

FST-2_HB.EN12/05 3

General.......................................................................................................................... 147

Programming................................................................................................................. 148

Setting the RAW register............................................................................................... 148

Function “landing call” ................................................................................................... 153

Function “fire signal”...................................................................................................... 154

Function “priority landing”.............................................................................................. 155

Function “position indicator” .......................................................................................... 156

Function “flag”................................................................................................................ 157

User error ...................................................................................................................... 161

Function “signal”............................................................................................................ 162

Function “evacuation”.................................................................................................... 164

Function “special drive” ................................................................................................. 166

Function “alarm misuse”................................................................................................ 167

Function “speed threshold”............................................................................................ 168

Function “ramp drive” .................................................................................................... 169

Function “override floor blocking”.................................................................................. 170

Function “block floors”................................................................................................... 171

7 Error List ................................................................................................................173

7.1 LC-Display................................................................................................................ 173

7.2 Keypad functions.................................................................................................. 173

7.3 Event messages..................................................................................................... 174

7.4 Error messages...................................................................................................... 175

8Index.........................................................................................................................181

Table of contents

4FST-2_HB.EN12/05

1 About this manual

1.1 General

FST-2_HB.EN12/05 5

1 About this manual

1.1 General

The FST-2 manual is a comprehensive reference work for experienced lift

service experts.

Goals of this manual

- describe the characteristics of the LON bus technology

- describe technical details and functions of the FST-2 and its

components

- describe the operation of the FST-2

- describe the configuration of the FST-2

- describe the FST-2 menu and its settings

- describe the messages of the FST-2

1.2 Signs and Symbols used

Below you can find a description of the signs and symbols used in this

manual.

Symbols +Key combination:

Press the linked keys simultaneously.

³

Action:

Actions are executed immediately and will not be saved as permanent

settings.

1 About this manual

1.3 Further information

6FST-2_HB.EN12/05

LC-Display and keypad In the left column you will find the LC-Display of the FST-2-Controller with

a grey background. The displays and messages or possible keypad

functions are explained in the table.

1.3 Further information

The following documentation is available for the FST-2-Controller and its

components:

- Description of FST-2-Controller

- FST-2 Installation & Commissioning

- FST-2 Quick Guide

- FST-2 Manual (this document)

- GST Manual

- System description – pawl Device

- Installation & Commissioning – FAX Modem

- Quick Guide EAZ-256

- Quick Guide EAZ-VFD

- Quick Guide EAZ-LCD

- Quick Guide FST-2-IRT

- Manual for Fireman Mode

- System description – Speech Output

- System description – Attika Control

- System description – Bank-Control

- System description – Ramp-Drive

- System description – Panel Test

- System description – Safety curtain

NEW LIFT is happy to provide this documentation on request. Please

contact our marketing department.

Line or

key Description of display or keypad functions

LC-Display

2 General Safety Regulations

2.1 Standards and regulations applied

FST-2_HB.EN12/05 7

2 General Safety Regulations

The FST-2-Controller must be in technically perfect condition and may only

be used in accordance with regulations and in awareness of safety and

risks. The “FST-2 Installation & Commissioning” manual as well as the

relevant guidelines for the prevention of accidents and the guidelines of

local power utilities must be observed.

2.1 Standards and regulations applied

The FST-2-Controller complies with:

- Regulation for lift systems

(German regulation for lift systems, AufzV)

- Safety regulations for the construction and installation of passenger

lifts, building hoists and service lifts (DIN EN 81 Parts 1 and 2)

- Technical regulations for lifts (TRA, Technische Regeln für Aufzüge)

Operation of lift systems (TRA 007)

Testing parts and components (TRA 101)

Passenger lifts, building hoists and service lifts (TRA 200)

- Regulations for the erection of power installations with rated voltages of

up to 1kV (DIN VDE 0100)

- Measures for contact voltage protection in the engine room (DIN EN

60990)

- Data sheet on safety measures during installation, maintenance and

servicing or repair of lift systems (ZH 1/312)

2 General Safety Regulations

2.2 Electromagnetic compatibility (EMC)

8FST-2_HB.EN12/05

2.2 Electromagnetic compatibility (EMC)

An accredited inspection body has verified that the FST-2-Controller and

its components comply with the standards, limits and test intensities

according to EN 12015/1995 and EN 12016/1995.

The FST-2-Controller and its components are:

- resistant against electrostatic discharges

(EN 61000-4-2/1995)

- resistant against electrostatic fields

(EN 61000-4-3/1997)

- resistant against transient disturbances

(EN 61000-4-4/1995)

The field strengths of electromagnetic disturbances radiated by the FST-2-

Controller and its components do not exceed the permitted limits.

(EN 55011/1997)

2.3 Handling electronic components

Leave electronic components in their original packaging until installation.

Touch a grounded piece of metal prior to opening the original packaging to

prevent damage from static charges.

All bus inputs and outputs not in use must be equipped with a terminal

resistance (terminator).

3 FST-2-Controller user interface

FST-2_HB.EN12/05 9

3 FST-2-Controller user interface

The user interface of the FST-2-Controller is located on the FST-2 main

circuit board in the control cabinet of the lift system. The FST-2 user

interface consists of front panel, LC-Display, keypad and LEDs.

Fig. 3.1 FST-2-Controller user interface

SAFETY CCT CLOSED

3 FST-2-Controller user interface

3.1 LC-Display and messages

10 FST-2_HB.EN12/05

3.1 LC-Display and messages

The LC-Display consists of four lines A, B, C and D with 20 digits each.

After switching on and during normal operation, the FST-2-Controller

displays the main screen.

Main screen

Line C has a special status. In normal mode (after switching on), it displays

status messages (see “Status messages in line C” on page 13). When

switching with key combination

S

+

¥

+

¤

it displays diagnostic

messages, see “Diagnostic messages in line C” on page 14.

Also see “Keypad functions” on page 32.

Line A

Safety circuit messages

in Line A

A Maximum active state of the safety circuit

B Active state or error

C Status of the lift system / diagnostic message

D Data for current drive mode

SAFETY CCT CLOSED

>AX< ###@###

00 13:06:56

Display Description

SAFETY CCT CLOSED

The safety circuit is completely closed

(FST X14.1 & FST X14.2).

SFTY-CLOSED MISSING

The input “Safety circuit closed”has no power.

Possible reasons:

-Terminal FST X14.1 has no power (normally

bridged with X14.2)

-Relay K14 on the FST is faulty

DOOR LOCK B OPEN

The shaft door contact of door side B is

interrupted (FST X14.2 and X14.3).

DOOR LOCK A OPEN

The shaft door contact of door side A is

interrupted (FST X14.3 and X14.4).

DOOR A OPEN

The car door contact of door side A is

interrupted (FST X14.4 and X14.5).

DOOR B OPEN

The car door contact of door side B is

interrupted (FST X14.5 and X14.6).

DOOR C OPEN

The car door contact of door side C is

interrupted (FST X14.6 and X14.7).

MANUAL DOOR OPEN

A manual door contact is interrupted

(FST X14.6 and X14.7).

EMERGENCY END

SWITCH

The top emergency end switch of an hydraulic

lift is interrupted (FST X14.6 and X14.7).

3 FST-2-Controller user interface

3.1 LC-Display and messages

FST-2_HB.EN12/05 11

The messages

DOOR C OPEN

,

MANUAL DOOR OPEN

and

EMERGENCY

END SWITCH

are triggered by the same safety circuit input of the FST-2

(TC input: FST-2 X14.6) and exclude each other.

Line B

State messages in line B

EMERGENCY STOP

An emergency switch in the shaft is interrupted

(terminals FST X14.7 and X14.8).

EMERGENCY STOP-CAR

An emergency switch on the car is interrupted

(terminal FST X32.4).

Display Description

Display Description

24V LOW!

The 24V supply of the FST-2 board (FST X1.1

and X1.2) is below the permitted range of 24V -

10%. Check power supply and wiring.

LANDING CALLS OFF

Landing control is blocked by a safety circuit

interruption (interruption before terminal FST

X32.4), line A displays

EMERGENCY STOP

,

see “

EMERGENCY STOP

” on page 11.

LANDING CONTROL OFF

Landing control was switched off manually.

Possible sources:

-

¥

key of the FST-2 keypad

-Programmable input of an external RIO

module

-Input FST X1.14

-Programmable input of the FST-2-Controller

-Key switch on car panel (FPM input X4.34)

-Key switch on landing panel (ADM input

X3.12 / X3.13)

FIREMAN

A fire input is active. Possible reasons:

-Fire input on landing call module (ADM input

X3.12 / X3.13)

-Programmable input of the FST-2-Controller

-GST Group Controller (see GST Manual)

END-SWITCH TEST

The manual end switch test is running, see test

menu.

ES-SPEED MON. TEST

The manual test of the deceleration monitoring

function at the top and bottom limits is running,

see test menu.

EVACUATION

The controller is in evacuation mode. Possible

sources for the evacuation signal:

-Programmable input of the FST-2-Controller

-Programmable input of the GST Group

Controller

-LMS over PAM protocol adapter module

SEND FAX

The controller is in fax mode (see Installation &

Commissioning – Fax modem).

3 FST-2-Controller user interface

3.1 LC-Display and messages

12 FST-2_HB.EN12/05

LIFT OFF

The controller was shut down. Possible

sources:

-Car light failure

-Input “Car Light OFF”, FST X1.13

-Programmable input/output of an external

RIO module

-Programmable input/output of the FST-2-

Controller

-Externallyby theGST Group Controllerorthe

LMS Lift Monitoring System

FIREMAN MODE

Fireman mode is activated. Possible sources:

-Key switch on car panel (FPM X4.4)

-Programmable input/output of the FST-2-

Controller

-The state was saved after a powerfailureand

hasbeenreconstructed.Function

Fireman

Mode Reset

must be used to reset this

state.

-Key switch on landing panel (ADM input

X3.12 / X3.13)

-GST Group Controller (see GST Manual)

FILE TRANSFER

ACTIVE

The controller is in remote data transmission

mode to transfer files to a GST Group

Controller or to a PC.

INSPECTION

The controller is in inspection mode (input FSM

X22.2).

Attention: Line A of the FST-2 display must

show

EMERGENCY STOP-CAR

!

CALIBRATION -

A calibration drive was started. The number of

remaining runs is displayed.

APRON-OPEN!

The hinged car apron is open (due to a shaft

door interruption). Monitoring is done via a

programmable input of the FST-2-Controller.

LEARN DRIVE ACTIVE

The controller performs a learn drive.

LEARN DRIVE-START

The controller performs a learn drive.

LEARN DRIV-OK!

Learn drive completed successfully.

LEARN DRIVE-ABORT

The learn drive was cancelled due to a fault.

The reason is entered in the error list.

SAFETY CURTAIN

The safety curtain replacing the car door was

interrupted. The contact is in the safety circuit

instead of the car door contacts (see System

description – Safety curtain).

DRM ..

A runtime monitoring error has occurred. There

are different types of runtime monitoring

functions that can shut down the lift.

INSTALLATION MODE

The controller is in installation mode.

ORIENTATION

The controller performs an orientation drive to

the top or bottom limit after switching on (only

when using INK – incrementalpositioning). The

orientationdrivecan takeplaceautomaticallyor

when the first call is placed.

Display Description

3 FST-2-Controller user interface

3.1 LC-Display and messages

FST-2_HB.EN12/05 13

Line C

Status messages in line C Line C is divided and displays one of the following status messages in the

left and in the right part. For scrolling the status messages in the left part

use the key combination

S

+

¤

, for the right part use the key combination

S

+

¥

.

The door positions marked with

A

also apply to doors

B

and

C

.

PARK DRIVE ACTIVE

The controller sends the car to a programmed

parking floor.

PRIORITY LANDING

A priority landing drive was triggered. Possible

sources:

-Key switch on landing panel (ADM input

X3.12 / X3.13)

-Programmable input of the FST-2-Controller

-Programmable input of an external RIO

module

PRIORITY CAR

A priority car drive was triggered. Possible

sources:

-Key switch on car panel (FPM input X4.37)

-Automatically after a type Auto 2 priority

landing drive.

AUXILIARY

The controller is in auxiliary mode (input FST

X18.2).

Attention: Line A of the FST-2 display must

show

EMERGENCY STOP

!

HOMING ACTIVE

The hydraulic lift is sent to the lowest landing.

SERVICE ACTIVE

The controller is in service mode, see test

menu.

SERVICE REQUIRED!

Oneof the service counters has exceededa set

limit.

SYSTEM STOP

The controller was stopped via the FST-2

menu.

OVERLOAD

The overload input on the FSM or on a

programmable input is active.

USER ERROR -

A user error has occurred. The number of the

error is displayed.

VIP MODE

The controlleris in VIP mode. Possible sources

VIP mode:

-LMS over PAM protocol adapter module

-Programmable input of the FST-2-Controller

-FPM input X4.34 on car panel

FULL LOAD

The full load input of the FSM is active.

Display Description

3 FST-2-Controller user interface

3.1 LC-Display and messages

14 FST-2_HB.EN12/05

Diagnostic messages in line C Line C canbe switched from status messages to diagnostic messages with

key combination

S

+

¥

+

¤

. Use key combinations

S

+

¥

and

S

+

¤

to

scroll through the diagnostic messages.

Status Display Description

Car doors

<A>

Door A completely open

>A<

Door A closed

<-A->

Door A is opening

->A<-

Door A is closing

<A*>

PhotocellorreversingcontactdoorA

active

<AX>

Door A is locked (test menu)

<AL>

Door is in loading mode (loading

button activated)

-A-

Door A is stopped

?A?

State of door A is unknown (check

door limit switches)

<-<>->

Door open button active

->><<-

Door close button active

Shaft positioning

Z

Zone message active

F

Zone message missing

-

Car is in levelled position

###@###

Car position relative to levelled

position (each pixel = 2.5 mm)

ö

Correction switch bottom KU active

ä

Correction switch top KO active

Car position

P=6200

Current position of the car relative to

levelled position of lowest landing in

[mm]

Levelling

Pd= -2

Current position of the car relative to

closest levelled position in [mm]

Car speed

V=1300

Current speed of the car in [mm/s]

Set / actual speed

@######V2

Comparison between setand actual

speed of the car. The left bar is a

graphic display of the relation

between actual speed and the set

speed on the right.

Motor hours

BS=4351

Operating hours of the drive

Drive counter

FZ=123456

Number of completed drives

Memory occupied

Rec: 45%

Memory occupied on the PC-Card

when recording

3 FST-2-Controller user interface

3.1 LC-Display and messages

FST-2_HB.EN12/05 15

Display Description

LIK-Errs:00000 00000

Diagnosis of absolute value encoder

function (see page 16), this display is

irrelevant when using incremental

positioning.

ENC:10000000[989680]

Real-time display of increments counted by

the encoder on plug X2. The counted

increments together with the covered

distance can help when calculating the

required

Resolution

.

Gray=43210 KO KU ZB

Current state of the solenoid switches with

incremental positioning, see page 16

Door-A: F1=00 F2=00

Current state of the FSM for door A, see

page 16

Door-B: F1=00 F2=00

Current state of the FSM for door B, see

page 16

Door-C: F1=00 F2=00

Current state of the FSM for door C, see

page 16

Motor=00 VST=0000

Internal motor state (see page 19) and

states of the pre-selection contact outputs

(see page 20)

Pos:Virt=0b Real=00

Generated and actual position messages

from the car, see page 20

SHK=SABCN

State of the safety circuit, see page 22

Mgr1:Drv=00 Call=00

Internal NEW LIFT diagnostic message

Mgr2:A=02 B=00 C=00

Internal NEW LIFT diagnostic message

NextPoss=ff VT=V2

Next possible stop (

NextPoss

) that can

be approached and the setspeed (

VT

), see

page 22

Port EXIN1=EGALPUDR

State of input EXIN1, see page 22

Port EXIO2=76543210

State of input EXIN2, see page 23

Port H8IN1=ZBSMVO

State of input H8IN1, see page 23

FSM-X6: L=1 V=0 K=0

State of outputs on FSM X8 and X19, see

page 23

SRC:00 00 00 00 00

Source of the special drive signals fireman,

fireman mode, landing control OFF, lift off

and service mode, see page 24

LWE: 255% E0 F0 O0

State of the weight sensor, see page 25

Proj.Status=........

State of the project specific parts of the

program (internal)

PC:s0 m1 c0 f0 Mb005

State of the PC-Card slot, see page 26

Pkt\s In=005 Out=002

Incoming and outgoing data packets of the

FST-Controller in [packets/sec]

ASV: 0000000 P=[00]

State of the pawl device, see page 26

FSM msgs=00123

Number of message packets from the FSM

car control module to the FST-2-Controller

3 FST-2-Controller user interface

3.1 LC-Display and messages

16 FST-2_HB.EN12/05

Absolute value encoder

function

LIK-Errs:00000 00000

The two numbers on the display show the number of encoder failures since the last

activation of the system. The left number shows the different values resulting from

double scanning, the right number shows the number of failed plausibility checks.

Sporadic errors are compensated by the FST Software and can be tolerated. A

continuous increase of one of these values indicates an encoder or cable failure.

Left number:

Right number:

State of incremental

positioning

Gray=43210 KO KU ZB

Display Description

00000

or constant value Communication between the FST-2-Controller

and the absolute value encoder is working

correctly. Double scanning to suppress electric

interference does not show any differences.

constantly rising value Double scanning to suppress electric

interference does show differences. There is

electric interference on the connection cable

between FST-2-Controller and encoder.Check

connection cable and inform your NEW LIFT

Hotline.

Display Description

00000

The position values of the absolute value

encoder are plausible (are within the regular

shaft). There are no invalid jumps in the

position value.

RANGE

The position values of the absolute value

encoder are not plausible (are outside the

regular shaft). Check direction of rotation of the

encoder and commission the linear positioning

function, see “Installation and Commissioning

Manual”.

DELTA

There are invalid jumps in the position value.

Absolute value encoder faulty.

Code Description

43210

Stateof Gray-coded pre-limitswitches for high-speed lifts (optional)

KO

Correction switch top (KO) active

KU

Correction switch bottom (Ku) active

ZB

Zone switch B active

3 FST-2-Controller user interface

3.1 LC-Display and messages

FST-2_HB.EN12/05 17

States of the FSM car

control module

Door-A: F1=00 F2=00

State bytes F1 and F2 describe the states of eight functions each in real-

time (8 bits, hexadecimal code). Hexadecimal bytes are coded number by

number. Each number has a decimal value according to the following table:

Fig. 3.2 Hexadecimal encoding of an 8-bit register

Hexadecimal

number Decimal

value

0

0

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

a

10

b

11

c

12

d

13

e

14

f

15

digit

digit

3 FST-2-Controller user interface

3.1 LC-Display and messages

18 FST-2_HB.EN12/05

Each number codes four functions (bits) of the F1/F2 table with its decimal

value. The decimal value of the number corresponds to the sum of the

values of the activated functions according to the following tables.

* Signal only relevant for door versions A and B.

Example:

State byte F1 = 6c and state byte F2 = 21

This results in the following hexadecimal numbers:

F1:

Number 1 = “c” (decimal = 12)

Number 2 = “6” (decimal = 6)

F2:

Number 1 = “1” (decimal = 1)

Number 2 = “2” (decimal = 2)

The decimal numbers are calculated from the following values:

F1:

Number 1 = 12 = 8 + 4

Bit Number Value Setting

F1 =

Byte F1

0Number 1

(right number)

1 active FSM car control module configured

1 2 active Door locked

2 4 active Door reversing

38Doorcompletely

open Limit switch “door open”

4Number 2

(left number)

1Doorcompletely

closed Limit switch “door closed”

5 2 active Photocell interrupted

6 4 active Reversing contact

7 8 active Minimum load input*

Bit Number Value Setting

F2 =

Byte F2

0Number 1

(right number)

1 on Car light sensor*

1 2 active Inspection signal “fast”

2 4 active Inspection signal “down”

3 8 active Inspection signal “up”

4Number 2

(left number)

1 active Inspection signal “ON”

5 2 active Door closing motor

6 4 active Door opening motor

7 8 active Door ready for drive

SAFETY CCT CLOSED

Door-A: F1=6c F2=21

00 13:06:

Table of contents

Other New lift Controllers manuals

Popular Controllers manuals by other brands

Loctite

Loctite Single CureJet Operation manual

Emerson

Emerson Fisher 133H installation guide

Dometic

Dometic 9600023541 Installation and operating manual

DEMA

DEMA Olympian O-RDV manual

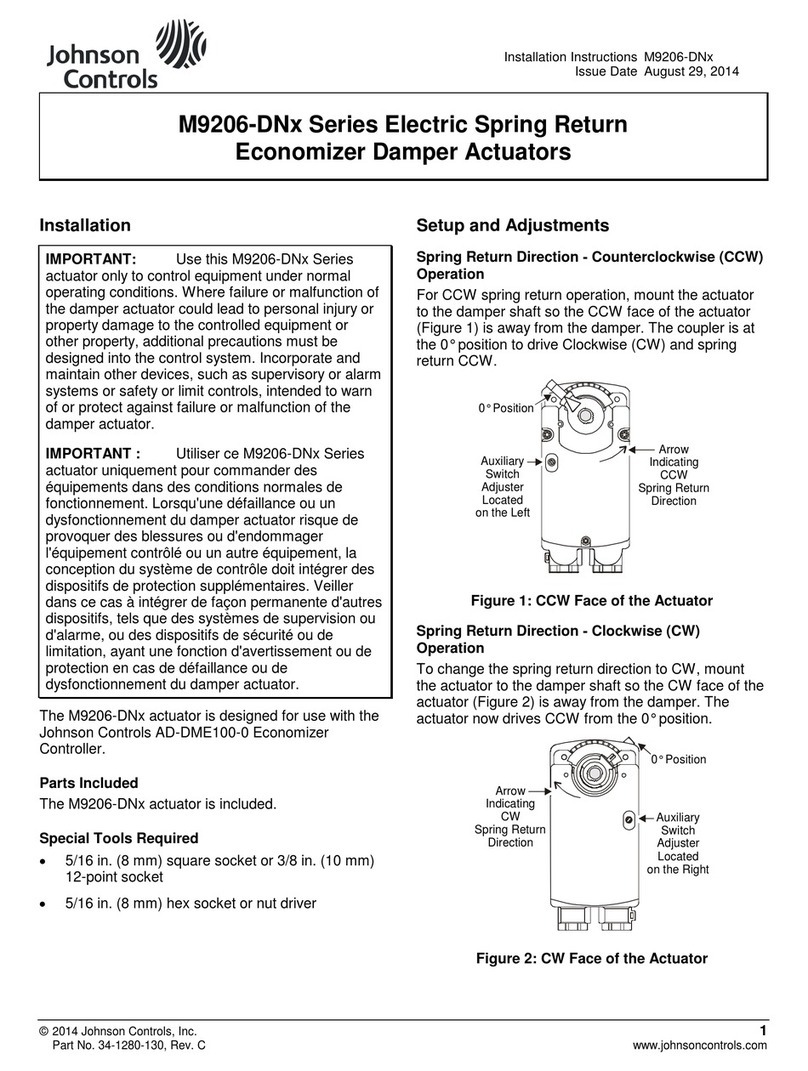

Johnson Controls

Johnson Controls M9206-DN Series installation instructions

Rockwell Automation

Rockwell Automation Allen-Bradley AADvance T9110 Solutions handbook

IBM

IBM Netfinity ServeRAID-4L Ultra160 User reference

Johnson Controls

Johnson Controls ATC1510 installation guide

SAH

SAH WSK Series user manual

QuietCool

QuietCool IT-AF-SMT owner's manual

Easyrain

Easyrain Rain Bird ESP-TM Series Installation, Programming, & Operation

Watlow Electric

Watlow Electric F4S Series user manual