New lift FST Guide

Installation & Commissioning

Field Bus Control

FST_MIA.DE10/98

Publisher NEW LIFT Steuerun

g

sbau GmbH

Adi-Maislin

g

er-Straße 12

D-81373 München

Tel.: +49

(

0

)

89 / 74 35 44 - 0

Fax: +49

(

0

)

89 / 769 34 85

Doc. No. FST_MIA.DE10/98

Date of issue 10/98

Copyright © 1998, NEW LIFT Steuerun

g

sbau GmbH

All ri

g

hts, includin

g

those of cop

y

in

g

or of reproducin

g

parts of this

description and of the translation are reserved b

y

the publisher.

No part of this description ma

y

be reproduced in an

y

form or copied with an

electronic replication s

y

stem, without the written permission of the

publisher.

Table of contents

FST_MIA.DE10/98 3

1 About this manual .............................................................................................. 5

1.1 General information.................................................................................................. 5

1.2 Signs and symbols employed.............................................................................. 6

2 General safety provisions ............................................................................. 9

2.1 Qualifications of the installing engineer.......................................................... 9

2.2 Residual dangers..................................................................................................... 10

2.3 Safety provisions..................................................................................................... 10

3 Assembly work ...................................................................................................13

3.1 Installation sequence............................................................................................. 13

3.2 Bus Plan...................................................................................................................... 15

3.3 Scope of delivery..................................................................................................... 16

3.4 Control cabinet......................................................................................................... 18

Installin

g

the control cabinet............................................................................................ 18

Connectin

g

the control cabinet........................................................................................ 19

Startin

g

up the control cabinet......................................................................................... 20

Technical details.............................................................................................................. 21

3.5 Car components....................................................................................................... 25

Installation locations of the car components.................................................................... 25

Installin

g

car components................................................................................................ 26

Connectin

g

car components............................................................................................ 27

Commissionin

g

the car components ............................................................................... 28

Technical details - FPM car operatin

g

panel module ..................................................... 29

Technical details - FSM car control module .................................................................... 31

3.6 Installing and connecting the trailing ribbon cable.................................. 33

3.7 The installation run................................................................................................. 35

Connectin

g

the LON bus................................................................................................. 37

Installin

g

zone switches and ma

g

nets............................................................................. 38

Installin

g

and settin

g

the linear cop

y

in

g

control............................................................... 40

Table of contents

4FST_MIA.DE10/98

4 Commissioning the FST Control ...........................................................43

4.1 Commissioning sequence ................................................................................... 43

4.2 User interface of the FST Control..................................................................... 44

The display ...................................................................................................................... 45

The keyboard................................................................................................................... 47

The LEDs......................................................................................................................... 48

4.3 Commissioning the linear copying control .................................................. 49

Checking the direction of rotation of the absolute value encoder.................................... 49

Checking flush position with A6 Safety Monitoring Device.............................................. 50

Checking flush position with A6 Safety Monitoring Device.............................................. 51

4.4 Carrying out a calibration drive......................................................................... 53

4.5 Commissioning the A6 Safety Monitoring Device..................................... 57

4.6 Setting control options.......................................................................................... 58

Crawl drive....................................................................................................................... 58

Password......................................................................................................................... 58

Door times ....................................................................................................................... 59

Group operation............................................................................................................... 60

5 Event and fault messages ...........................................................................61

5.1 LED messages on the user interface .............................................................. 61

5.2 Error list....................................................................................................................... 62

5.3 Event messages....................................................................................................... 64

5.4 Error messages........................................................................................................ 65

6 Terminal and pin assignment ...................................................................69

Trailing ribbon cable ........................................................................................................ 69

LON bus........................................................................................................................... 72

VSM preselection module................................................................................................ 72

FSM car control module.................................................................................................. 72

7 Index ...........................................................................................................................73

1 About this manual

FST_MIA.DE10/98 5

1 About this manual

Before installin

g

and startin

g

upthe FST Control,

y

oushould carefull

y

read

this manual first. The instructions in Chapter 2 “General safet

y

provisions”

alwa

y

s take precedence. How to operate the FST Control is outlined in

Chapter 4.2 “User interface of the FST Control”.

1.1 General information

This manual is intended to facilitate the assembl

y

and commissionin

g

of

the FST Control and its components.

Thisassembl

y

and operatin

g

manualcontains importantinstructionsforthe

safe and proper assembl

y

and commissionin

g

of the FST Control.

Observing them helps to:

- avoid dan

g

ers

- minimise repair costs and downtime

- increase the reliabilit

y

and service life of the FST Control and the lift

s

y

stem.

In addition to this assembl

y

and operation manual, the valid accident

prevention and environmental protection re

g

ulations in the respective

countr

y

and localit

y

must be observed.

Onl

y

those sub-assemblies supplied b

y

NEW LIFT are described in this

manual.

Information about components of the control s

y

stem not produced and

supplied b

y

NEW LIFT can be obtained from the user documentation

provided b

y

the respective manufacturer or supplier.

1 About this manual

6FST_MIA.DE10/98

1.2 Signs and symbols employed

The following signs and symbols have been used for operational

instructions:

Symbols ➤Activity symbol:

The activities described after this sign should be carried out in the

prescribed sequence.

✔Outcome symbol:

The outcome of an activity is described.

+Key combination:

Press the linked keys simultaneously.

Warning signs General danger point

This sign appears before activities where personal injuries may

arise due to various causes.

Risk of crushing injuries

This sign appears in front of activities where there is a danger

of receiving crushing injuries.

Danger of falling

This sign appears in front of activities where there is a danger

of falling.

Suspended load

This sign appears in front of activities where there is a danger

of direct impact from a falling load.

1 About this manual

FST_MIA.DE10/98 7

High voltage

This si

g

n appears in front of activities where there is a dan

g

er

of an electric shock, with possibl

y

fatal conse

q

uences.

Material damage

The instructions provided here are intended to prevent an

y

material dama

g

e to sub-assemblies and devices.

1 About this manual

8FST_MIA.DE10/98

2 General safety provisions

FST_MIA.DE10/98 9

2 General safety provisions

All the most important safet

y

provisions and re

g

ulations are compiled in the

Chapter 2 “General safet

y

provisions”.

Anybody who is assigned to work on the installation and

commissioning of the FST Control, must have read this chapter and

put its provisions into practice.

Over and above an

y

safet

y

provisions specified in this manual, the laws,

re

g

ulations,

g

uidelines and standards in force in the respective countr

y

should be observed.

2.1 Qualifications of the installing engineer

The installin

g

en

g

ineer must:

- be 18

y

ears of a

g

e or older

(

exception: trainees of 16

y

ears or older,

under the constant supervision of a master craftsman

)

.

- be able to carr

y

out first aid.

- know and be able to implement the fire and explosion protection

re

g

ulations applicable for his work area.

-beabletoreco

g

nise, avoid and protect himself a

g

ainst all the dan

g

ers

arisin

g

in con

j

unction with his work in the lift shaft and in the operatin

g

areas.

- be able to identif

y

and rectif

y

all irre

g

ularities and faults arisin

g

durin

g

installation and operation of an lift s

y

stem.

- understand and be able to appl

y

the technical basis of the mode of

operation of electrical controls and drive s

y

stems and their operatin

g

re

q

uirements.

All installation and commissionin

g

work on the electrical and electronic

components of the FST Control are to be carried out under the direction

and supervision of a

q

ualified electrician.

In German

y

, someone is defined as a

q

ualified electrician, who due to his

technical trainin

g

, knowled

g

e and experience and ac

q

uaintance with the

relevant provisions, is able to evaluate the work assi

g

ned to him and to

identif

y

the possible dan

g

ers

(

UVV, VGB 4, §2

(

3

))

.

2 General safety provisions

10 FST_MIA.DE10/98

2.2 Residual dangers

Danger for personnel Risk of electrocution on touching parts under voltage during work on the

electrical installations.

Risk of fatal injuries due to falling down the lift shaft.

Risk of injuries when lifting and transporting the switch cabinet if this falls

or tips over.

Risk of dangers to persons, who are in the lift shaft when the car is in

motion.

Risk of injuries due to unforeseen car movements.

Risk of material damage Destruction of the FST Control and its electronics modules by short

circuiting or excess loading.

2.3 Safety provisions

General information The instructions of the manufacturer and the information in this manual

must be observed when the lift is being installed and commissioned.

The lift shaft must be secured against unauthorised access during

installation and commissioning.

Sub-assemblies, devices and cables should be installed securely and

permanently.

Loads should be transported with suitable aids (e.g. lift trucks, lifting gear

etc.).

Sharp or pointed tools or other potentially dangerous objects may not be

carried in clothing, unless protected by sufficient protective measures.

The consumption of alcohol and drugs before and during installation and

commissioning is forbidden.

2 General safety provisions

FST_MIA.DE10/98 11

Documentation A cop

y

of the installation and commissionin

g

manual must be available to

the installation en

g

ineer when the FST Control and its components are

bein

g

installed and commissioned.

A cop

y

of the installation and commissionin

g

manual to

g

ether with the

circuit dia

g

rams should alwa

y

s be kept in the switch cabinet on completion

of commissionin

g

.

The supplied circuit dia

g

rams for the FST Control are bindin

g

. Alterations

ma

y

onl

y

be made in consultation with NEW LIFT and should be

documented in writin

g

on the s

y

stem.

The on-site test lo

g

s for the FST Control are retained b

y

NEW LIFT.

Electro-technical work The re

g

ulations for settin

g

up and operatin

g

electricals

y

stems

(

VDE 0100

)

as well as the special

g

uidelines of the local power utilities should be

observed.

The prescribed spacin

g

s between the individual electrical assemblies

should be observed.

Assembl

y

work ma

y

onl

y

be carried out when the e

q

uipment is shut down

and volta

g

e-free.

Cables and lines should be provided with sufficient strain relief.

The neutral and

g

round lines should be separatel

y

routed.

A clockwise rotar

y

field must be applied at the switch cabinet.

Working in the lift shaft If the car is bein

g

used as assembl

y

platform, the re

g

ulationsfrom VGB35:

“Bauaufzü

g

e”

(

buildin

g

elevators

)

appl

y

for the whole lift s

y

stem:

Durin

g

work in the lift shaft, there must be unimpaired and continuous

communication between the supervisor at the FST Control in the machine

room and the workers.

““The components in the lift shaft must be arran

g

ed or secured so that

persons who are in the lift shaft for inspection, maintenance or repair work

purposes are not endan

g

ered.”

(

AufzV, Appendix 2.1.5

)

The permitted load for the lift s

y

stem ma

y

not be exceeded.

2 General safety provisions

12 FST_MIA.DE10/98

The prescribed overruns for the emergency limit switches in relation to the

lift speed must be observed.

The emergency installations may not be activated during normal operation.

All emergency installations and braking systems must be checked before

each shift for perfect functioning.

The car must be moved to the lowest resting position during breaks, the

control switched off and the power supply permanently interrupted.

Assembly and operation are prohibited when other persons could be

endangered.

Personnel must be protected against falling.

Personal safety equipment for

the installing engineers - Eye protection

- Safety boots

- Hard hat

- Safety harness

- Clothing appropriate to the environmental conditions at the installation

site

- Jewellery, wrist watches and suchlike may not be worn.

Handling

electronics modules Keep the electronics modules in the supplied packing until installation.

Touch a grounded piece of metal before opening the packaging in order to

electrically discharge your body.

All non-assigned bus inputs or outputs should be provided with a terminal

resistance (terminator).

Disposal The packaging material is to be disposed of in an environmentally friendly

way.

Hand in paper, plastic, metal and electronics components for recycling.

Adhesive residues should be disposed of in an environmentally

responsible way in accordance with the appropriate laws and regulations.

3 Assembly work

FST_MIA.DE10/98 13

3 Assembly work

All the important information on the installation se

q

uence, installation

conditions and settin

g

s of the NEW LIFT components are described.

Specialfeatureson-sitecouldmeanthatdeviationsfromtherecommended

installation se

q

uence recommended below are necessar

y

.

3.1 Installation sequence

NEW LIFT recommends the assembl

y

work accordin

g

to Fi

g

. 3.1 on

Pa

g

e 14. First all those NEW LIFT components are installed, connected

and set, which are re

q

uired for commissionin

g

the car. Once the car is

read

y

, “installation runs” are made to install the NEW LIFT components in

the shaft, such as linear cop

y

in

g

control, LON bus and zone ma

g

nets. The

FST Control is then commissioned

(

See Pa

g

e43

)

.

3 Assembly work

14 FST_MIA.DE10/98

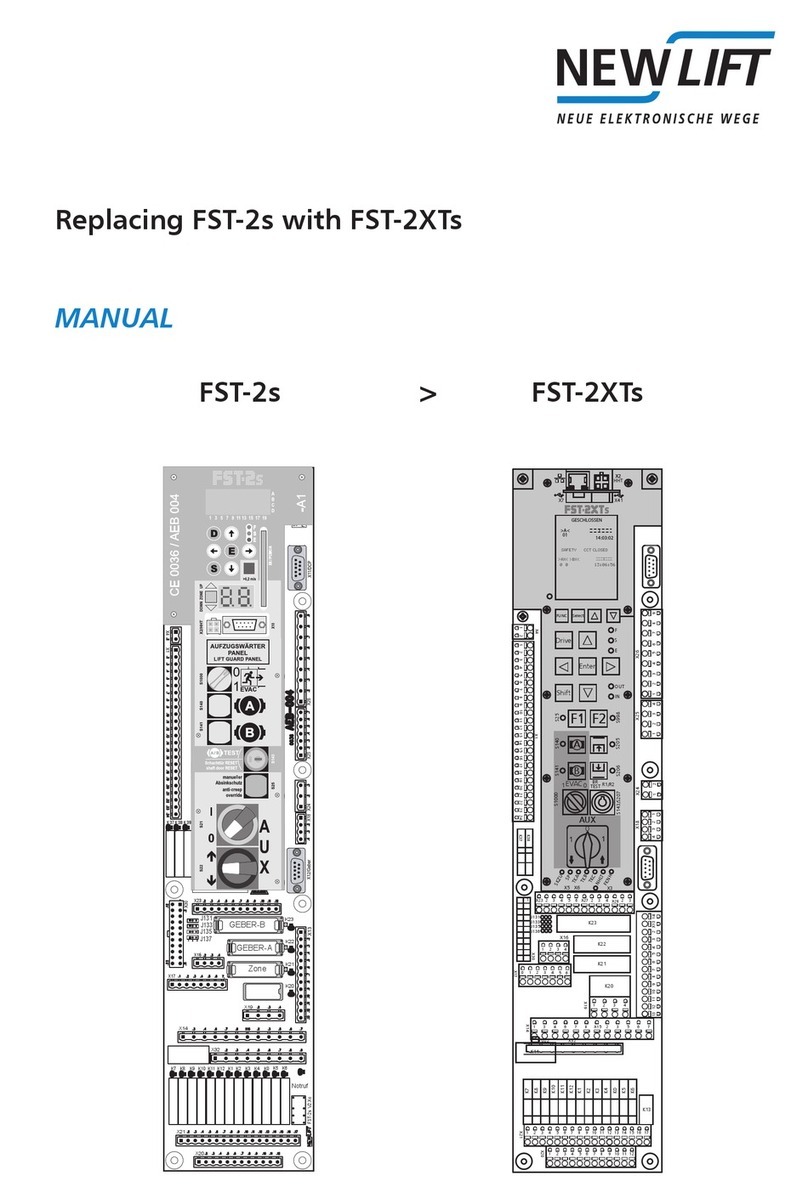

Fig. 3.1 Recommended installation sequence for NEW LIFT components

MIA010.abc

Check the scope

of delivery

Commissioning

the elevator car

Control cabinet

installation /

connection

Drive

installation /

connection

Safety monitoring

device

installation /connection

Elevator car

components

installation /

connection

Linear copying

control

installation /

connection

Trailing ribbon cable

installation /

connection

Magnetic switch panel

and zone magnets

installation /

connection

(

if available

)

LON-Bus

installation /

connection

Commissioning of

FST

Shaft doors

installation /

connection

Installation

run

3 Assembly work

FST_MIA.DE10/98 15

3.2 Bus Plan

Each lift s

y

stem consists of specific electronics modules and cables. NEW

LIFT creates a bus plan for the confi

g

uration of each individual lift control,

enclosed with the circuit documentation. All electronics modules and their

connectionsarepresentedin thebusdia

g

ram with the associated LONbus

cables. Foreachelectronicsmodule, itsinstallationsite,theassociated bus

and with LON bus cables, the respective len

g

th are all specified. Each

electronics module is labelled. With this labellin

g

, it is possible to

unambi

g

uousl

y

assi

g

n components with the bus plan.

Fig. 3.2 FST Control bus plan

3 Assembly work

16 FST_MIA.DE10/98

3.3 Scope of delivery

NEW LIFT components and documentation:

- Switch cabinet with integrated FST Control

- Electronics modules according to bus plan

- Ready-made LON bus cables according to the bus plan

- Ready-made trailing ribbon cable according to the bus plan

- Terminal resistances (terminators)

- FST manual (glued into switch cabinet)

- FST installation & commissioning manual

- Circuit diagrams

- Bus Plan

Check the scope of delivery Checkthe deliveryofNEW LIFT components forcompleteness againstthe

packinglist.Simultaneously makeavisual inspection of the delivereditems

for damage.

When unpacking the delivery, check against the bus plan:

- whether mechanical damage to the NEW LIFT components can be

identified.

- whether the labelling of the NEW LIFT electronic assemblies agrees

with the labelling on the bus plan.

- whether the LON bus cables and the trailing ribbon cable are of the

lengths specified in the bus plan.

NOTE!

Electrostatic discharges, mechanical loading, dampness and dirt

can damage or even destroy electronics modules.

➤Keep the electronics module in the supplied packing until installation.

➤Touch a grounded piece of metal before opening the packaging in

order to electrically discharge your body.

3 Assembly work

FST_MIA.DE10/98 17

Claims for damage

during transport If dama

g

e arises durin

g

transport, a claim must immediatel

y

submitted to

the haulier.

Ordering NEW LIFT

components separately If NEW LIFT electronics modules or cables are missin

g

,

y

ou should report

this immediatel

y

to the NEW LIFT hotline. We will re

q

uire the followin

g

information to ensure rapid processin

g

:

-8di

g

it NEW LIFT serial number, e.

g

.: FC980591

(

obtained from the bus plan

)

- Name of the missin

g

NEW LIFT components

(

obtained from the bus plan

)

-Missin

g

cable t

y

pe and len

g

th

(

obtained from the bus plan

)

- Your telephone/ FAX number or e-mail address for an

y

q

ueries

3 Assembly work

18 FST_MIA.DE10/98

3.4 Control cabinet

Installing the control cabinet

Transport the control cabinet to and install it at the planned installation site

(see ”Technical details” on Page 21). The fixings depend on the nature of

the installation site and the weight of the control cabinet and are to be

selected by the installation engineer.

The planned installation site can only be changed in exceptional cases

since it is unlikely that the ready-prepared cable lengths are sufficient.

Please inform the NEW LIFT hotline so that a solution can be worked out.

DANGER!

The control cabinet may fall over during transport or installation.

Danger of limbs being crushed.

➤Only transport and lift the control cabinet with suitable aids (e.g. lift

truck, lifting gear etc.).

The personnel must have been instructed in the use of these aids and

observe the special accident prevention rules applicable for them.

DANGER!

Electric shock or escaping gas due to holes drilled in supply lines.

Severe, possibly even fatal injuries.

➤Ensure before starting work that no supply lines are routed through

the installation site.

3 Assembly work

FST_MIA.DE10/98 19

Connecting the control cabinet

The cable diameters of the suppl

y

, drive and

g

round lines are determined

b

y

the load connected to the control cabinet and can be obtained form the

enclosed circuit documents.

Equipotential bonding is to be carried out according to the valid

electrical engineering regulations and specifications (VDE, DIN, EN

and ISO), depending on the output load.

The neutral and

g

round lines should be routed separatel

y

!

All lines should be secured a

g

ainst be pulled out b

y

ade

q

uate strain relief.

When attachin

g

the trailin

g

ribbon cable, the correct installation direction of

the cable should be observed

(

see ”Assi

g

nment of terminals and plu

g

s of

the trailin

g

ribbon cable to the modules” on Pa

g

e34

)

.

DANGER!

Electric shock from electricall

y

live lines and parts.

Severe, possibly even fatal injuries.

➤Check and ensure volta

g

e-free condition.

➤Onl

y

carr

y

out installation work on electrical components when the

y

are switched off and volta

g

e-free.

3 Assembly work

20 FST_MIA.DE10/98

Starting up the control cabinet

Check the following before switching on the FST Control:

- clockwise rotary field

- proper functioning of fuses

- proper functioning of control cabinet components

The display and operation of the FST Control is explained in Chapter 4.2

on Page 44.

Switching on the FST ➤Turn on control cabinet at main switch.

➤Turn on FST power supply circuit at the fuse.

✔The FST Control is rebooted.

On completion of the booting procedure, 15 “✔” are briefly displayed on

the bottom line and then switches to the standard display.

If 6$)(7<&&7&/26(' is not displayed on line A, there is a break in the

safety monitoring device wiring or it is faulty and has to be checked,

extended or repaired.

If ,167$//$7,2102'( is not indicated in line B, then installation mode

should be set.

➤Select 0$,10(18,QVWDOODWLRQ,QVWDOODWLRQPRGH.

➤Select <(6.

➤Confirm selection with (.

✔,QVWDOODWLRQPRGH is set.

Switching off the FST ➤Turn off the FST power supply circuit at the fuse.

6$)(7<&&7&/26('

,QVWDOODWLRQPRGH

!$;

Other manuals for FST

1

Table of contents

Other New lift Controllers manuals

Popular Controllers manuals by other brands

Gopel Electronic

Gopel Electronic G CAR 6282 manual

Dynamite

Dynamite DYNM3865 instruction manual

Federal Signal Corporation

Federal Signal Corporation UltraVoice Installation, operation and service manual

FASTRON.

FASTRON. Meridian MEC-110 operating instructions

Parker

Parker 6K8 installation guide

Scion-Tech

Scion-Tech SC08.CTL200 user manual