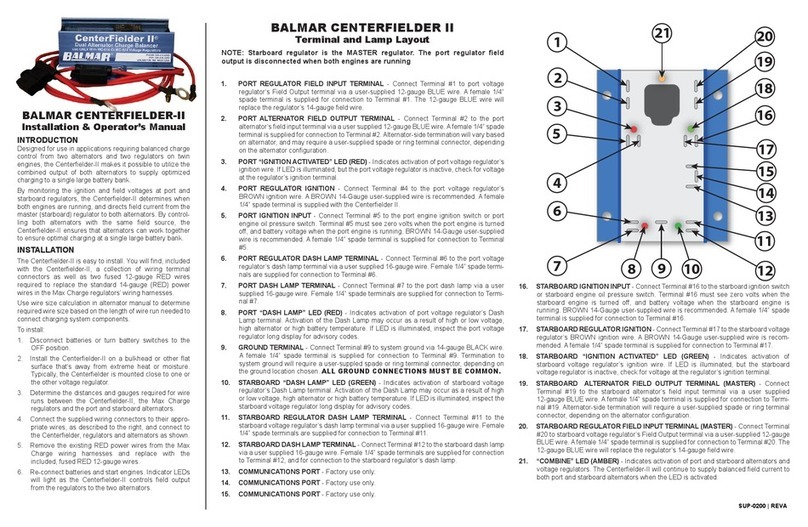

VIII. Advanced

Programming

Advanced programming levels can

be accessed when the MC-624 is in

Long Display mode. To access:

1. With regulator in Long Display

mode, ACTIVATE-HOLD until

the “Pro” display code appears.

RELEASE. The “PrA” display

code will appear. (CAUTION: If

the switch is held too long,

the regulator will return to the

preset program adjustment

mode). Once in advanced pro-

gram mode, the display will

cycle through the the individual

advanced programming selec-

tions (see Figure 14).

2. When the desired advanced

program mode is reached,

ACTIVATE-HOLD. The display

will scroll through the available

time or voltage value selections. - 5 -

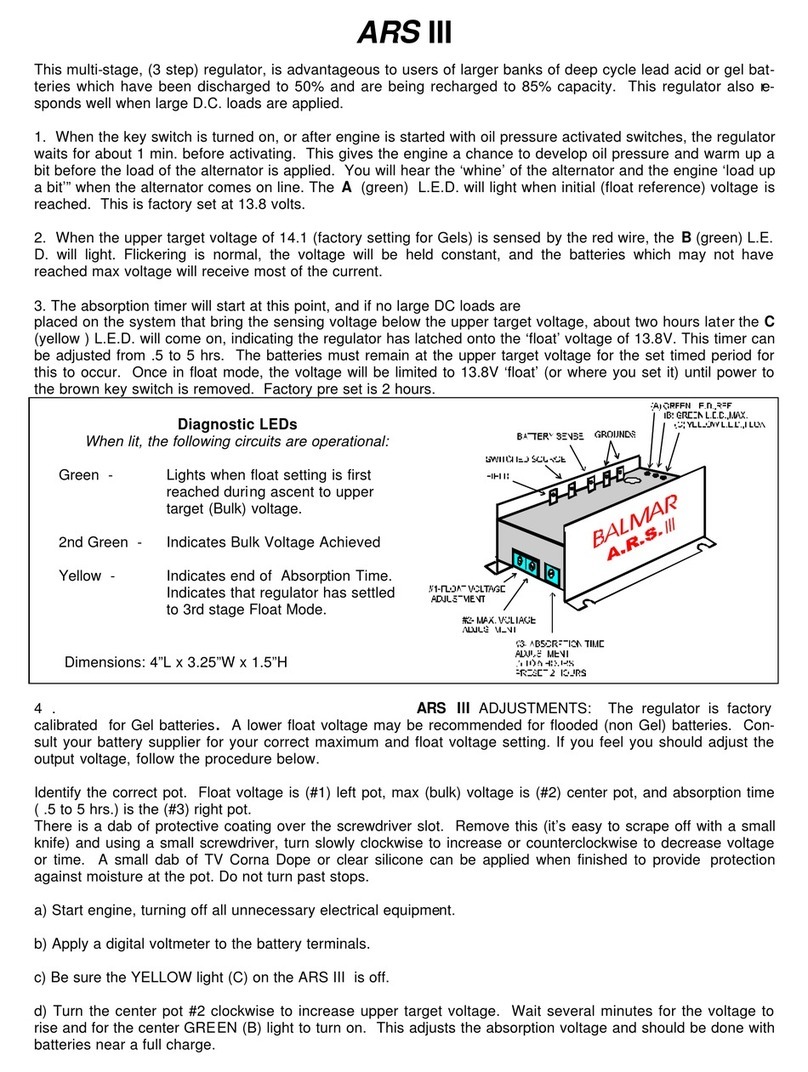

Figure 13 - Long Display (LD) attributes as displayed on digital numeric readout.

Figure 14 - Advanced Programming (PrA) as displayed on digital numeric readout.

VII. Additional Displays

Charging Stages

The MC-624 utilizes up to 12 individ-

ual stages to ensure proper charg-

ing. Each stage may contain a spe-

cific voltage or time value, or a com-

bination of values which may be

implemented by the regulator’s

microprocessor as it monitors your

battery’s state of charge. These

stages are displayed in both Short

and Long Display modes, and are

described in Figure 12.

Long Display

At any time during the Short

Display’s continuous cycle, addition-

al data for various operations and

diagnostic information can be moni-

tored by accessing the numeric read-

out’s Long Display mode.

To access the Long Display, ‘ACTI-

VATE-RELEASE’ the reed switch

while the Short Display is cycling.

The numeric LED will immediately

return to the “BAL” code and start

cycling through the Long Display.

See Figure 13 for code definitions.

Once the Long Display has cycled

through all of its information modes,

the display will automatically revert

to the Short Display.

LD Mode 1 - Readout displays “BAL”

(Short for Balmar.)

LD Mode 2 - Regulator model.

Readout displays “624”.

LD Mode 3 - Program level. (P)

Displays program currently in memory.

LD Mode 4 - Battery type. Readout

displays abbreviated battery type.See

Figure 10 for descriptions.

LD Mode 5 - Charging stage Displays

the specific stage of the charging

cycle. See Figure 13 for descriptions.

LD Mode 6 - Battery voltage.

Shows current system voltage.

LD Mode 7 - Calculated (Target) volt-

age based on program mode.

LD Mode 8 - Revision number.

Displays software version.

LD Mode 9 - Battery #1 temp.

Followed by the sensor reading

in degrees(Celcius).

LD Mode 10 - Battery #2 temp.

Followed by the sensor reading

in degrees(Celcius).

LD Mode 11 - Factory use only.

LD Mode 12 - Factory use only.

LD Mode 13 - Run time. “Hr ”

code is followed by a numeric

readout in 1/10-hr increments.

LD Mode 14 - Explanatory

mode. May be followed by one or

more diagnostic codes. See

Figure 17 for details.

PrA Mode 1 - Advanced program

mode indicator.

PrA Mode 2 - Start delay “DL”. Adjusts

seconds before ramp up.

PrA Mode 3 - Bulk voltage control. “Bv”

code is followed by volt reading. Adjust up

or down.

PrA Mode 4 - Bulk time control. “Bc”

code is followed by time reading. Adjust

up or down.

PrA Mode 5 - Absorption voltage control.

“Av” code is followed by volt reading.

Adjust up or down.

PrA Mode 6 - Absorption time control.

“Ac” code is followed by time reading.

Adjust up or down.

PrA Mode 7 - Float voltage con-

trol “Fv”. Followed by time read-

ing. Adjust up or down.

PrA Mode 8 - Float time control.

“Fc” code is followed by time

reading. Adjust up or down.

PrA Mode 9 - Amp Manager

control. See details for Amp

Manager on following page.

PrA Mode 10 - Equalization

Voltage control. See details for

Equalization on following page.

PrA Mode 11 - Equalization

Time control. See details for

Equalization on following page.

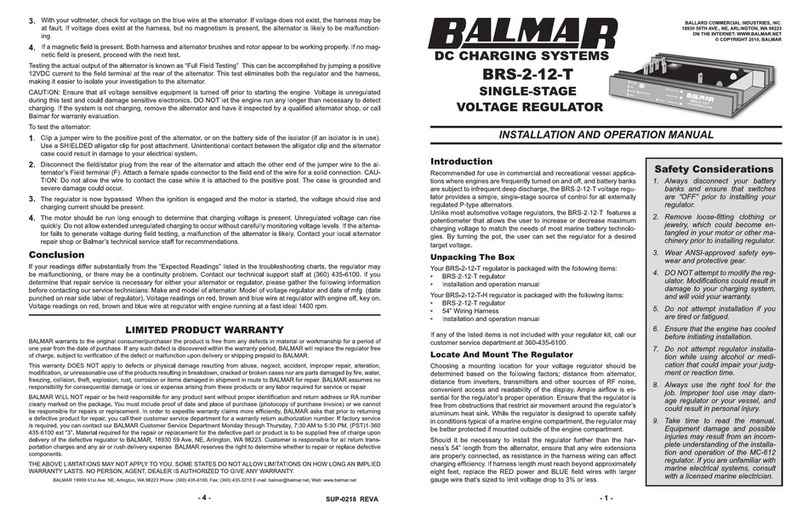

Stage 1 - Start Delay. Provides a 45-

second delay before load is placed on

engine and belts. Adjust time in PrA*.

Stage 2 - Soft Ramp. One minute volt-

age ramp minimizes belt slippage.

Non-adjustable.

Stage 3 - Bulk. 30-minute set period.

Program determines charging voltage.

Time/voltageadjustable in PrA*.

Stage 4 - Calculated Bulk. Time varies

by state of charge at end of Stage 3.

Adjustable in PrA*.

Stage 5 - Ramp Down. Transition

from Bulk to Absorption stage. Non-

adjustable.

Stage 6 - Absorption. 30-min. set time.

Preset program sets charging voltage.

Time/voltage adjusts in PrA*.

Stage 7 - Calculated Absorption.

Time varies by state of charge at

end of Stage 6. Adjust in PrA*.

Stage 8 - Ramp Down.

Transition from Absorption to

Float stage. Non-adjustable.

Stage 9 - Float. 30-minute time

period. Program sets charging

voltage. Time/volts adjust in PrA*.

Stage 10 - Calculated Float. Time

& voltage based on state of charge

at end of Stage 9.Adjust in PrA*.

Stage 11 - Ramp to Equalize.

Batteries should be at full charge

before initiating eqalization.

Stage 12 - Equalization. Time

and Voltage adjustable in PrA*.

See battery mfg. limits for time

and voltage values. User set.

PrA* - Time and/or voltage adjustments can be made in the Advanced Program mode.

Figure 12 - Charge stage codes as seen in Short and Long displays.

Advanced Programming and Diagnostics