Newacalox NEW858D User manual

858D

SMD REWORK STATION User Manual

Welcome to use 858D rework station. This manual will show the parameters, performance, usage

and precautions of this machine.

If you have any problem of usage or any suggestion about this soldering station, please send the

Warranty

1: if hot air gun was broken within a year, we will send a replacement to you after connecting with

After-sales service mailbox.

2:If the gadgets in the package are lost during the shipping, please contact us for re-send.

3:We will guide you carefully about the use and maintenance of this product.

858D rework station is good for repair phone and PCB circuit board. Please read this operating

instruction manual carefully before using the serial soldering station of our company.

If you like our product, can you share your experience or review for it on Amazon. It can help us a

lot,thanks in advance.

Specification

Model

NEW858D

Type

LED indicator light

Power

Consumption

700W

Blower Fan

Brush-less Fan

Amount Of Wind

120L/m(MAX)

Temperature Range

100℃-500℃

Discharge Feature

LED indicator light

Handle Length

(With Cable)

120cm

Size

12.4(h)*18.7(w)*

24.9(l)(cm)

13.8(h)*10(w)*15(l)(cm)

Weight

2.20kg

1.52kg

1.55kg

Noises

<45db

Usage

Hot-air rework stations can be very handy. As mentioned above, they are a crucial tool when it comes to

reworking a board. The term rework just means you are refinishing or repairing an already reflowed board,

and it is a term commonly used in the electronics world. Just think of it as doing any work to the board

that wasn't involved in the actual production process. Here are some common rework scenarios:

Polarized Components - Parts that have been placed incorrectly (backwards, shifted x degrees off). These

include ICs, diodes, some capacitors, connectors, etc.

Tombstone Parts - This is when a part (usually a resistor or capacitor) reflows only on one side. The part

usually sticks strait up resembling a tombstone.

Cold Joints - This is similar to a tombstone except the parts might not be sticking strait up, making it

harder to see the connection that is not being made.

Removing Defective Parts - Sometimes, during the IC manufacturing process, errors can arise and go

unnoticed. These ICs are then placed on perfectly good PCBs. Hot-air is great for replacing these bad parts.

Missing Components - The smaller the component, the easier it is for it to disappear. This can happen

before or during reflow, resulting in a spot where something should be, but isn't. Hot-airing a new part in

its place is a snap with this rework station.

Unintentional Solder Jumpers - If too much solder or solder paste is used, the result can be jumpers on

one or more of your surface mount IC's legs. Hot-air can sometimes be used in conjunction with a flux pen

to remove these pesky buggers.

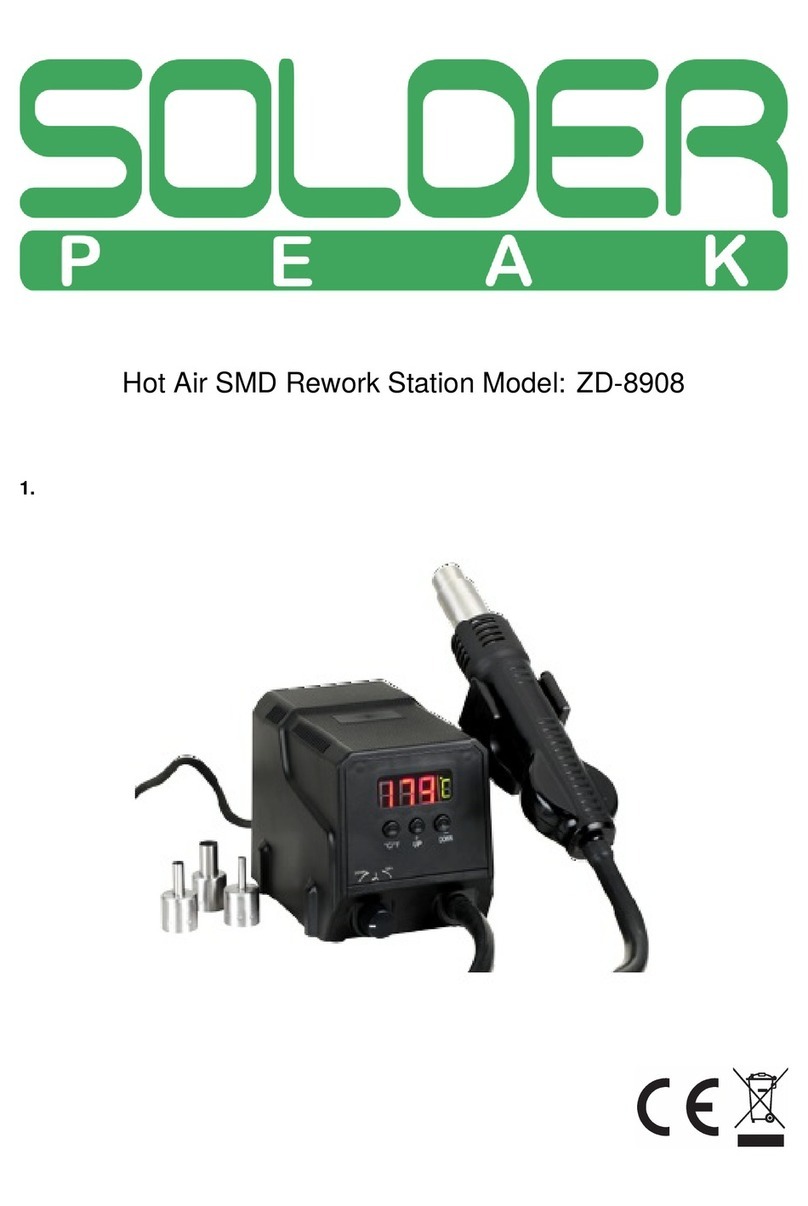

Hardware Overview

Power Switch -- uses a standard North American plug/outlet (~110VAC). Hopefully the power on/off

switch is self-explanatory. Move the switch to "ON" to turn the hot-air rework station on, move the switch

to "OFF" to turn the hot-air rework station off. Easy peasy.

Please Note! The device will not power off immediately after turning the switch to the "OFF" position. It

will continue to blow air until the air temperature is below 100°C.

LED Digital Output -- The LED digital output lists temperature range.The display will change as you press

temperature buttons.

Air Flow Grade -- You can adjust the air flow by turning the air setting knob. The LED output will display

the setting air flow grade for 2 seconds and then return to the current air temperature of the nozzle.

Temperature Range -- Output temperatures range from 100°~ 500°Celsius. You can adjust the

working temperature by press the temperature setting buttons. The LED output will display the setting

temperature.

Nozzles -- comes with 3x changeable hot-air nozzles. The smaller nozzle is good for focusing the hot air on

smaller components. The bigger nozzle is great if you are trying to focus hot air around a big area on the

board.

Operation Instruction

1.Assemble the station with the hot air gun and power line, install required nozzle.

2.set the required temperature

turn on main switch behind the case, then turn on the air gun switch. the air gun will start to heat up. press the air

gun temperature up“▲”or down”▼”buttons to adjust the temperature, and the air flow knob to set the

appropriate air flow. when the air gun operation light flashing regularly at high speed and the temperature is

stable, normal operation can be commenced.

3. Turn off

After operation is completed, turn off the air gun switch. the machine will automatically cut off the power supply

to the air gun heating element, and enter auto cooling mode. when the temperature below 100 ,the air gun

display and air supply are switched off.

Feartures

1.Auto sleep features

To ensure safety and conserve power, when the handpiece is placed in the handpiece holder(or et the

temperature below 100℃), the screen will displays”SLP” means auto sleep function will be activated and it will

start cooling automatically. When you take off handpiece it will stating heating again.

2.Temperature memory function

When you turn off the station at 400 degree centigrade, when you turn on next time, it will auto heat up to the

400 degree centigrade.

4. Overheat Protection Thermostat

NOEVSBIG hot air gun used temperature control switch,when the inside of the heat gun is short-circuited due to

transportation or other reasons, the temperature control switch will automatically power off when it detect that the

temperature reaches a certain value. Avoid the common fire problems of other soldering stations (there will be a

lot of smoke at this time but not catching fire)

Troubleshooting

Low Airflow when “Air”Dial is Turned Up

If you are getting low airflow when the “Air”Dial is turned up, make sure that you have the nozzle

securely attached. With the nozzle, you will get more air flowing through the hot-air rework station’s

handle.

S - E — Sensor error: this message appears in case the sensor, or anything in the sensing circuit, is out of order. At

this moment the power from the defective unit will be switched off. The rework station might be able to be

revived by removing and re-attaching the heater. Another tech support rep thinks it’s oxide building up on the

connections. This results in fooling the controller into thinking the heater has failed.

H - E — Heating elements error: this message appears if there is something wrong with the heating element. At

this moment the power from the defective unit will be switched off. Try checking the connections to see if the

heating element needs to be re-seated. Last resort is getting a replacement heating element. A last resort is

getting a replacement heating element.

Odours — When using rework station for the first time, please use it in a ventilated environment. Keep the heat

gun away from your eyes. When the oil is exhausted, the heat gun will no longer have an unpleasant smell.

Nozzles don't fit —The nozzles produced are all tight. In order to avoid being too easy to fall off during use,

there is a danger of burns. You can take it out with pliers. After a few more uses, there will be no this problem

again, or you can use pliers to adjust the size of the nozzle.

Safety Regulations

To use this product, the following basic measures should be strictly followed to avoid hazards of

electric shock, bodily injury, fire and other phenomenon.

1. In order to ensure safety, please turn off the power switch when not in use. When not in use for

an extended period, please unplug the power cord!!!

2. Serious consequences may result if non-original or non-approved parts are used.

3. Machine failure must be maintained by professional or our designated personal.

4. This product uses three wire grounding plug must be inserted into three grounding socket, do

not change the plug or no use the three floating head adapter bad grounding.

5. After the rework station is switched on, its temperature can exceed 400 degrees centigrade.

Do not use near flammable or explosive objects. To avoid burns, do not touch the metal part of

the soldering iron.

6. Do not leave the work area when the rework station is switched on.

7„ The power cord must be unplugged and the rework station Must be allowed to cool before

installing or replacing parts.

8. After used, remember that cooling the unit before installation.

9. Soldering produces fumes, ensure there is adequate ventilation.

Warning

1. If the power cord is damaged, it must be replaced by a manufacturer or a maintenance

specialist to avoid danger.

2. The tool must be placed on its support when not in use.

3. Be careful when using this device in the vicinity of flammable materials; Never use this device

for extended periods in the same location.

4. Be aware that heat may be transferred to distant flammable materials; Someone must be

present at all times while the device is connected.

This device is not intended to by operated by Individuals with diminished physical, sensory, or mental

capacities or by those who lack experience (such as children), except in the presence of individuals

qualified to provide necessary supervision and guidance

Attached: Technical section-rework process (for reference only)

The air gun with preheating station to facilitate the welding of large flat integrated circuit IC, double

sided board and large components desoldering.

• Remove the components

1. The first successful repair is removing the motherboard fault location component, the solder

heated to the melting point, and then carefully take components from the board.

2. The heating control is a key factor to repair, welding material must be completely melted, so as

avoid to damage the pad and a copper element in the removed. At the same time the

temperature is not too high, to prevent the circuit board heating due to excessive motherboard

distortion.

• Heating of circuit boards and components

1. The advanced rework system uses microcomputer to control the heating process, as close as

possible to the specifications given by the solder paste manufacturer, and shall be combined

with the top and bottom heating.

2. To supplement, at the bottom of the heating circuit board for heat conduction loss, and increase

the temperature of the circuit board; and the top heating is used for heating elements, in

addition to use a large area at the bottom of the heater can eliminate circuit board caused by

local heating excessive distortion.

3. Can use three methods to the motherboard heating, conduction, convection, and heat

conduction effects. When heating the heat source and the motherboard contact (such as the

electric heating board) circuit board components does not apply to the back.

4. The heating element (or top heating) is generally used for gas nozzle, carefully control of the

top heating element, make components uniform heat, is extremely important, especially critical for

small components (Figure 1).

5. In addition to avoid rework of components around again reflow or blow away the small patch

component, nozzle thermal isolation and these components must be, in repair stations

surrounding components on a thin layer of the cover plate or mask. The mask technique is very

effective, but also can be used for model time consuming. BGA desoldering nozzle, it can

reduce the damage of desoldering process on the removal of welding components near the

element and the circuit board.

X. Replacement Instruction

Replacement of Hot Air rework heating element(Figure 7)

1. Ensure that the air gun temp fully cools down before replacing the air gun

heater.

2. As Figure, loosen the two screws on the handle.

3. Screw out the handle assembly and then remove the handle's cover.

4. Gently takes out the fan, loosen the three screws and remove the fixing

wiring board.

5. Turn the wiring board back and take apart the heater connection cable

from the board. Please remember the cable location on the board.

6. Remove the heater and mica paper from the tube and do not break the

connection on the tube.

7. Wrap a new heater well with mica paper and insert the heater to the tube in

right place.

8. Connect the heater according to the original location of the connection

9. Install the handle back in apposite way of disassembling the handle.

Table of contents

Other Newacalox Soldering Gun manuals