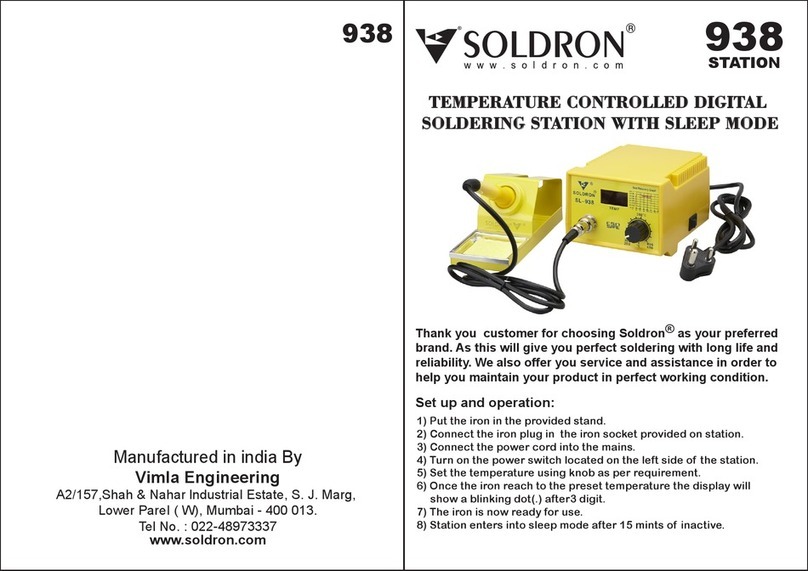

Newacalox 878D User manual

NEWACALOX 878D/8786D

SMD REWORK STATION User Manual

welcome to use newacalox 878D soldering station. This manual will show

the parameters, performance, usage and precautions of this machine.

If you have any problem of usage or any suggestion about this soldering

Warranty :

1: HEAT GUN Accessories and soldering iron accessories if broken within

a month can send a replacement by connecting with after service.

2:If the gadgets in the package are lost, please contact us for reissue,

thank you.

3:We will guide you carefully about the use and maintenance of this

product.

Our products 878D soldering station use the brush-less fan,and long life

and low noise.It is very good for repair phone and PCB.Please read this

operating instruction manual carefully before using the serial products of our

company.Thank you!

If you like our product, can you share your experience or review for it on

Amazon. It can help us a lot,thanks in advance.

Matters Needing Attention :

1. Be careful not to burn yourself when using it because it is hot.

2. make sure that you have connected the heat gun handle to the station before turn

on it. And Only can unplug the heat gun after trun off station. Otherwise, it will burn

out the heat gun handle and damage the main machine of the rework station.

3. When you stop using soldering station, please don’t disconnect the plug

immediately when you turn off the power button of soldering station. And this

soldering station will automatically shut down as soon as it stop blowing wind.

Otherwise you will shorten the life of soldering station. And please remove the

plug if you do not use this station for a long time.

4. when using this station for the first time, please use it in a ventilated environment.

Keep the heat gun away from your eyes. When the oil is exhausted, the heat gun

will no longer have an unpleasant smell.

Features

1. Comfortable portable handhold blower and the Digital LED display.

2. Microcomputer control,warming-up quickly.

3. Adjust button for air flow and temperature control .

4. come with three kinds of nozzles(big 8mm, medium 5mm and small 3mm)

replacement part.

5. Come with replacement Heating Core for long time use

6. Offer Auto Cool Down Function (“stand by” mode)

7. This product is ESD-protected.

8. High-quality resistance good for long service life.

9. Green lines and high-quality silicone body offer good heating for extend life

and save power.

10. Handle with sensor switch. Taking the handle, the station will enter the

working mode. Put back on the bracket, it will enter stand by mode.

Specification

Model

NEW878D

Type

LED indicator light

Power

Consumption

700W

Blower Fan

Brush-less ball fan

Amount Of Wind

120L/min(MAX)

Temperature

Range

100--480℃

Discharge

Feature

LED indicator light

Temperature

Range

±1℃

Size

10.2*6.5*5.8’’

Weight

5.62LB

Noises

<45db

Usage

Essential product for cell phone repair, laptop repair, circuit boards, etc.

Suitable for unsoldering multiple components,such as SOIC CHIP QFP PLCC

and BGA etc (especially for flat cables and cable connectors).International

standard heater for convenient use and exchange, noise-reducing and

space-saving. heat gun part broken can be resend.

Operation Instruction

HEAT GUN PART

1.Assemble the station with the heat gun and soldering accessories.

2.Make sure turn all the on-off button at off station, and then plug in the power

supply.

3. set the temp of blower by press the “↑ or ↓” buttons,press up button to

raise the temperature. Set up the temp and take up the handle, the gun will

warm-up.

4.Set the air flow by rotating the air flow setting knob.

Stand-by mode:

when turn off the power ,the screen will displays”----”,it represents the rework

station enter stand-by mode.it will cool down gradually.

when you put the handle back on the holder, the station will enter stand-by

mode.

4.Temperature memory function:When you turn off the station at 400 degree

centigrade, when you turn on next time, it will auto heat up to the 400 degree

centigrade.

5.When you finish your work, put the blower handle back on the holder,the

station will stop warming automatically. And when the temp is lower than

100℃,the station will show “---”,that meant the tool is going to enter standby

state

6.To switch off the power and unplug if there is no operation for a long period of

time.

IRON PART

1.Assemble the station with the heat gun and soldering accessories. Make

sure turn all the on-off button off, and then plug in the power supply.

2.Turn the iron on by pressing on/off button.

3.Set the temperature by rotating the temperature setting knob. Turn off when

you stop your work and storage it when all the soldering iron is cool down.

4.Temperature memory function:When you turn off the station at 400 degree

centigrade, when you turn on next time, it will heat up to the 400 degree

centigrade.

FAQ:

Q:Low Airflow when “Air” Dial is Turned Up

A:If you are getting low airflow when the “Air” Dial is turned up, make sure

that you have the nozzle securely attached. With the nozzle, you will get more

air flowing through the hot-air rework station’s handle.

S-E Error

“S-E” usually means Sensor Error. It’s a common error. Sometimes it goes

away after messing with the dial and the temperature will display properly

again. Other times it indicates that the heat sensor is failing. The rework station

might be able to be revived by removing and re-attaching the heater. Another

tech support rep thinks it’s oxide building up on the connections. This results in

fooling the controller into thinking the heater has failed.

H-E Error

Units displaying the “H-E” usually means there is a heating error. It might be

that there is something with the heating element failing or not connected

properly. Try checking the connections to see if the heating element needs to

be re-seated. Last resort is getting a replacement heating element. A last

resort is getting a replacement heating element.

Air Turned Too High

If your air flow is turned up too high, it is quite possible that you will start seeing

small projectiles shooting away from your board. Those are your parts. We

recommend starting at a lower air flow and moving up as your needs require.

Destroying a PCB

If you sit too long on a given spot on a PCB while working with hot-air, the glue

that holds the copper layer to the FR4 laminate underneath lets go and comes

out as black goo. The green solder mask on the top side also begins to come

off. Because we don’t have Smell-a-vision yet, we can try to describe the smell

- it’s horrendous. It smells like burning electronics (surprise) but the smell

seems to cling to your skin and clothes. Not cool. So practice and don’t be

surprised if you smell bad things with your first couple re-work attempts.

Pulled Pads

When checking to see if a part is ready to move, we recommend nudging the

part gently. If you push too hard, you can pull the pad.

Nozzles don't fit

The nozzles produced are all tight. In order to avoid being too easy to fall off during use,

there is a danger of burns.

You can take it out with pliers. After a few more uses, there will be no this problem again,

or you can use pliers to adjust the size of the nozzle.

A:What's It Good For?

Q:Hot-air rework stations can be very handy. As mentioned above, they are a

crucial tool when it comes to reworking a board. The term rework just means

you are refinishing or repairing an already reflowed board, and it is a term

commonly used in the electronics world. Just think of it as doing any work to

the board that wasn’t involved in the actual production process. Here are some

common rework scenarios:

Polarized Components - Parts that have been placed incorrectly (backwards,

shifted x degrees off). These include ICs, diodes, some capacitors, connectors,

etc.

Tombstone Parts - This is when a part (usually a resistor or capacitor) reflows

only on one side. The part usually sticks strait up resembling a tombstone.

Cold Joints - This is similar to a tombstone except the parts might not be

sticking strait up, making it harder to see the connection that is not being

made.

Removing Defective Parts - Sometimes, during the IC manufacturing process,

errors can arise and go unnoticed. These ICs are then placed on perfectly

good PCBs. Hot-air is great for replacing these bad parts.

Missing Components - The smaller the component, the easier it is for it to

disappear. This can happen before or during reflow, resulting in a spot where

something should be, but isn’t. Hot-airing a new part in its place is a snap with

this rework station.

Unintentional Solder Jumpers - If too much solder or solder paste is used, the

result can be jumpers on one or more of your surface mount IC’s legs. Hot-air

can sometimes be used in conjunction with a flux pen to remove these pesky

buggers.

Use of accessories

2 x Tweezers(fine tip curved,fine tip straight ): Pick up small items.

1 x IC Extractor: Small hook for easy extracting IC and installation

1 x Desoldering Pump: remove extra solder.

1 x Heating Core for air blower: when the air blower was burns out artificially ,

you can replace the heating core and continue to use it

1 x Power cord * 1 US(length:100mm): connecting the power source

3 x Nozzles( 3.2mm,5mm,8mm): Meet the different diameter of the operation

1 x Heating Core for soldering iron: when the soldering iron was burns out

artificially , you can replace the heating core and continue to use it

5 x Soldering Tip((I K B 3C 1.6D): Meet the different need of the operation

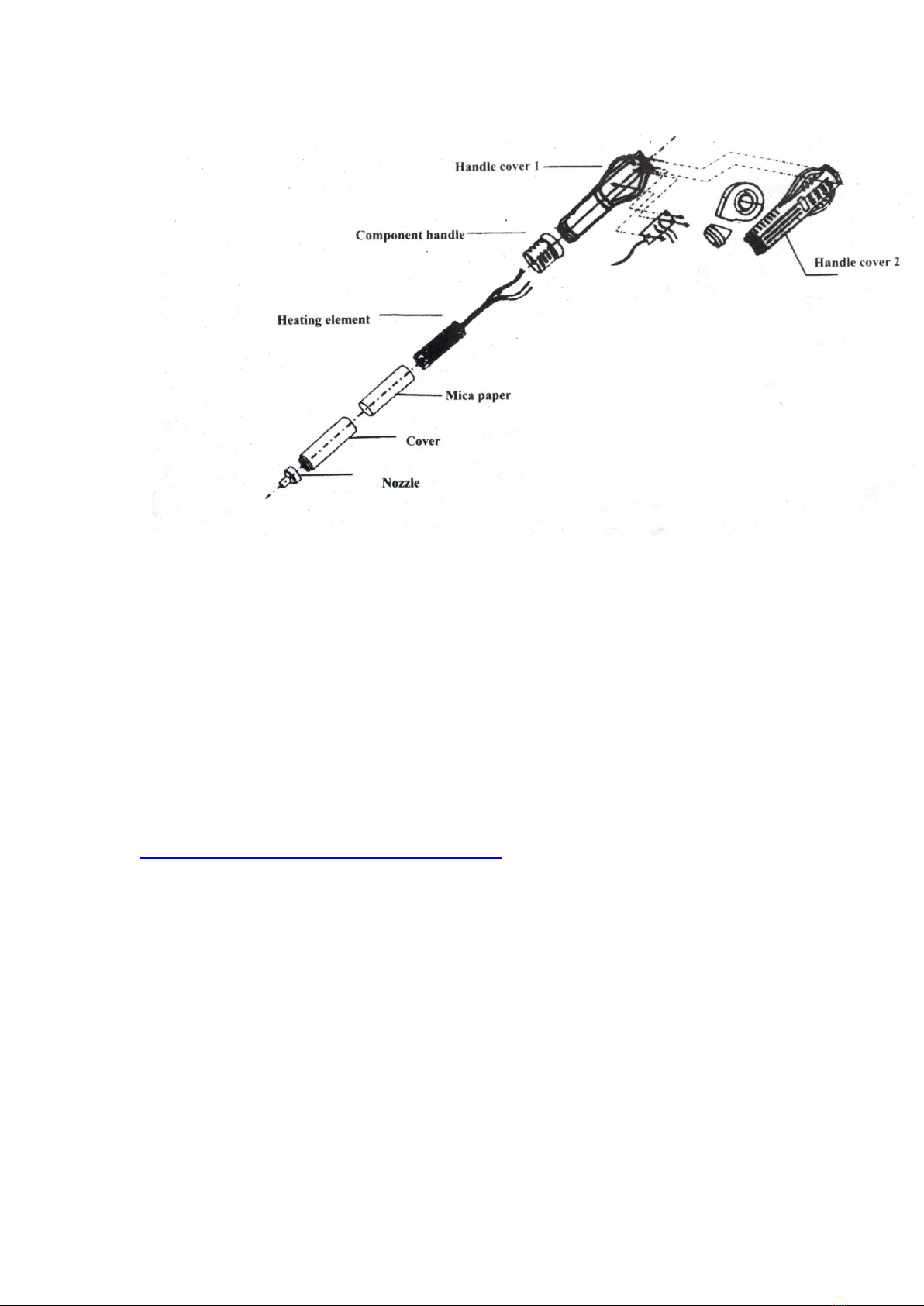

Replacement of Heating Element.

1.Please replace the heating core of soldering iron in rework station cooling

condition. prevent burns.

Most soldering stations utilize a ceramic heating element to generate the heat

required for soldering. As with any resistive heating element, the element will

eventually burn out. The majority of Circuit Specialists-brand soldering stations

include a replacement heating element at no additional charge. The procedure

for testing and replacing this heating element will be described for Circuit

Specialists CSI Station 1A.

The first operation should be to verify that the heating element is indeed

burned out. The resistance of the heating element should measure between 19

and 23 ohms. A reading of several thousand ohms or more would be indicative

of a burned out heating element. On the 1A soldering station the heating

element is connected between pins 1 and 2 on the soldering iron receptacle. If

the resistance measures correctly, the temperature sensor should then be

measured. This measurement is obtained between pins 4 and 5 on the

soldering iron receptacle and should be between 1.2 to 1.5 ohms. If any of

these resistance values are incorrect, the heating element should be replaced.

The hand piece should be disassembled after unplugging it from the main unit.

Remove the copper retaining nut before turning it counterclockwise until it is

free of the threads on the handle. Remove the tip enclosure, soldering tip, and

tip lock by pulling them forward off the hand piece. Next, unscrew the plastic

retaining nut by turning it counterclockwise until it is free of the plastic threads

on the handle. Now push the heating element out from the handle’s body to

expose the connections to the cord and a small PCB. Unsolder the four wire

connections —RED/RED and BLUE/WHITE — of the old heating element and

remove it from the PCB. Be sure to note the location of each of the four wire

connections on the PCB.

Detach the metal protector located at the bottom of the old heating element

and attach it to the bottom of the new heating element. The new heating

element may now be soldered onto the PCB in the same location as the

element that was removed. Solder one of the two RED wires from the heating

element to the RED wire from the cord on the PCB, and then solder the

remaining RED wire from the heating element to the BLUE wire from the cord

on the PCB. (Note: There is no polarity requirement for the two RED heating

element wires, so they may be interchanged with no detrimental effect on the

operation of the soldering station. The sensor wires, however, are polarity

sensitive and must be attached as outlined next.)

Solder the BLUE wire from the heating element to the GREEN wire from the

cord on the PCB, and solder the WHITE wire from the heating element to the

WHITE wire from the cord on the PCB. The heating element PCB assembly

may now be re-inserted into the handle. Make sure that the PCB is secured in

the notch at the mouth of the main handle. The plastic retaining nut may now

be re-installed on the base of the handle and tightened down. To complete the

re-assembly operation, slide the tip holder on (making sure that the smaller

end isintroduced first), insert the soldering tip, and secure the assembly with

the tip enclosure and copper nut. The resistance measurements outlined

above should now be performed again to verify the connections.

This procedure illustrates the steps required to test and replace the heating

element in CSI Station 1A, but the same procedure can be applied to almost

any soldering station with a resistive heating element. Be aware that a

replacement handle is available for all Circuit Specialists soldering stations at a

very reasonable cost if the user does not wish to perform the above listed

service.

Attention:

1.Do not damage the ground connection on the steel tube when replace the

heating element of heat blower.

2.Do not damage the connection on the Unsoldering Equipment during the

replace the heating element of soldering iron

3.The link assembly on the handle cover shall be put inside of fixing hole on

the steel tube during the installing of handle components.

Product link:

https://www.amazon.com/dp/B077WDXD6H

This manual suits for next models

1

Table of contents

Other Newacalox Soldering Gun manuals

Popular Soldering Gun manuals by other brands

Genesis

Genesis GHG1500A Operator's manual

Pace

Pace MBT250E-SDSoftGround Installation, operation & maintenance manual

Sealey

Sealey SD250K quick start guide

Harbor Freight Tools

Harbor Freight Tools Schneider 58005 Owner's manual & safety instructions

TOOLCRAFT

TOOLCRAFT ST50-D operating instructions

Hakko Electronics

Hakko Electronics C5045 quick start guide