2.10.14 4

Introduction & Newco Product Warranty

INTRODUCTION

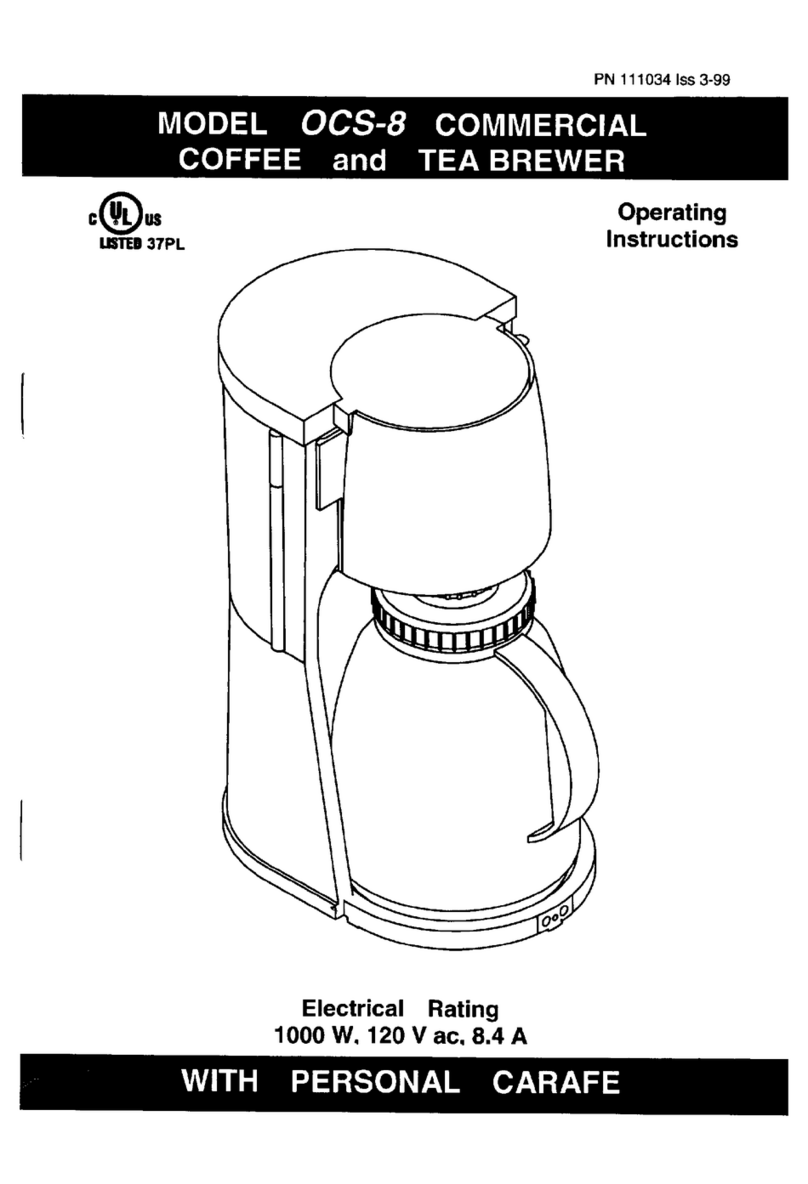

This machine is intended to brew 6-16 ounce single serving of coffee and / or powdered hot

drinks into a cup. This machine will also dispense hot water for allied beverage use. It is

intended for indoor use only on a sturdy counter or shelf.

WARRANTY

Newco warrants equipment manufactured by it for 1 year parts & labor.

These warranty periods run from the date of sale Newco warrants that the equipment

manufactured by it will be commercially free of defects in material and workmanship existing at

the time of manufacture and appearing within the applicable warranty period. This warranty

does not apply to any equipment, component or part that was not manufactured by Newco or

that, in Newco’s judgment, has been affected by misuse, neglect, alteration, improper installation

or operation, improper maintenance or repair, damage or casualty. This warranty is conditioned

on the Buyer 1) giving Newco prompt notice of any claim to be made under this warranty by

telephone at (800) 556-3926 or by writing to 3650 New Town Blvd, Saint Charles, MO 63301; 2) if

requested by Newco, shipping the defective equipment prepaid to an authorized Newco service

location; and 3) receiving prior authorization from Newco that the defective equipment is under

warranty.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER

WARRANTY, WRITTEN OR ORAL, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, ANY IMPLIED WARRANTY OF EITHER MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. The agents, dealers or employees of Newco are not

authorized to make modifications to this warranty or to make additional warranties that are

binding on Newco. Accordingly, statements by such individuals, whether oral or written, do not

constitute warranties and should not be relied upon.

If Newco determines in its sole discretion that the equipment does not conform to the warranty,

Newco, at its exclusive option while the equipment is under warranty, shall either 1) provide at no

charge replacement parts and/or labor (during the applicable parts and labor warranty periods

specified above) to repair the defective components, provided that this repair is done by a Newco

Authorized Service Representative; or 2) shall replace the equipment or refund the purchase

price for the equipment.

THE BUYER’S REMEDY AGAINST NEWCO FOR THE BREACH OF ANY OBLIGATION

ARISING OUT OF THE SALE OF THIS EQUIPMENT, WHETHER DERIVED FROM

WARRANTY OR OTHERWISE, SHALL BE LIMITED, AT NEWCO’S SOLE OPTION AS

SPECIFIED HEREIN, TO REPAIR, REPLACEMENT OR REFUND.

In no event shall Newco be liable for any other damage or loss, including, but not limited to, lost

profits, lost sales, loss of use of equipment, claims of Buyer’s customers, cost of capital, cost of

down time, cost of substitute equipment, facilities or services, or any other special, incidental or

consequential damages.