8

Issued August 2013

TEA BREWER FEATURE DESCRIPTIONS

The AKPA brewer incorporates the latest features in brewer control technology. Although providing for enhanced functionality

brewer controls remain intuitive and setup of keyoperating parameters couldn’t be easier. Multiple brew volumes, visa-brew

delay, tank temperature set point, brewmode, filter parameters and more are all set from the front control panel using a digital

display for precise control. The Tim Horton brewers incorporate an additional program sequence, “Quality Check”, which

allows display of the programmed brew volume(s) in ounces, actual tank temperature and number of brews. The quality

information is displayed using a quality check button. The following pages will explain the control features and then step

through the process required to program your unit.

Brew Volume – The Digi Brew II series control has two independently programmable brew volumes denoted Tea

1/2 and Tea 1. Brew time is set bydesired brewvolume in ounces. Either of these brew times maybe turned off or set for any

volume from 30 ounces to 255 ounces for the ultimate in flexibility. Selected brew volume is converted to brewtime internally

for calculations and to add to countdown time. PDS valve must be calibrated to deliver 1/4 gallon per minute in order to

ensure programmed brew volume is delivered.

Quality Check Mode

–

The quality check mode is used to display the programmed brew volume(s) in ounces, actual tank

temperature and the total number of brews for each side. To activate the displaydepress the quality check button. When the

button is depressed the display will show the programmed volume in ounces that brew one (TEA 1/2) is set for. Subsequent

presses of the QUALITY button will displaybrew volume for brew 2 (TEA 1), the actual tank temperature and total number of

brews for brew 1 and brew 2. The selected item will display until beginning a brew cycle or pressing cancel.

Visa-Brew Time – Provides for additional time to add to the programmed brew time. This additional time allows display to

continue countdown after the water deliveryportion of brew cycle to allow for the coffee to finish draining from the brewbasket.

The digital countdown, and the delayin the audible coffee readysignal, aid in preventing premature removal of either the brew

basket or the dispenser.

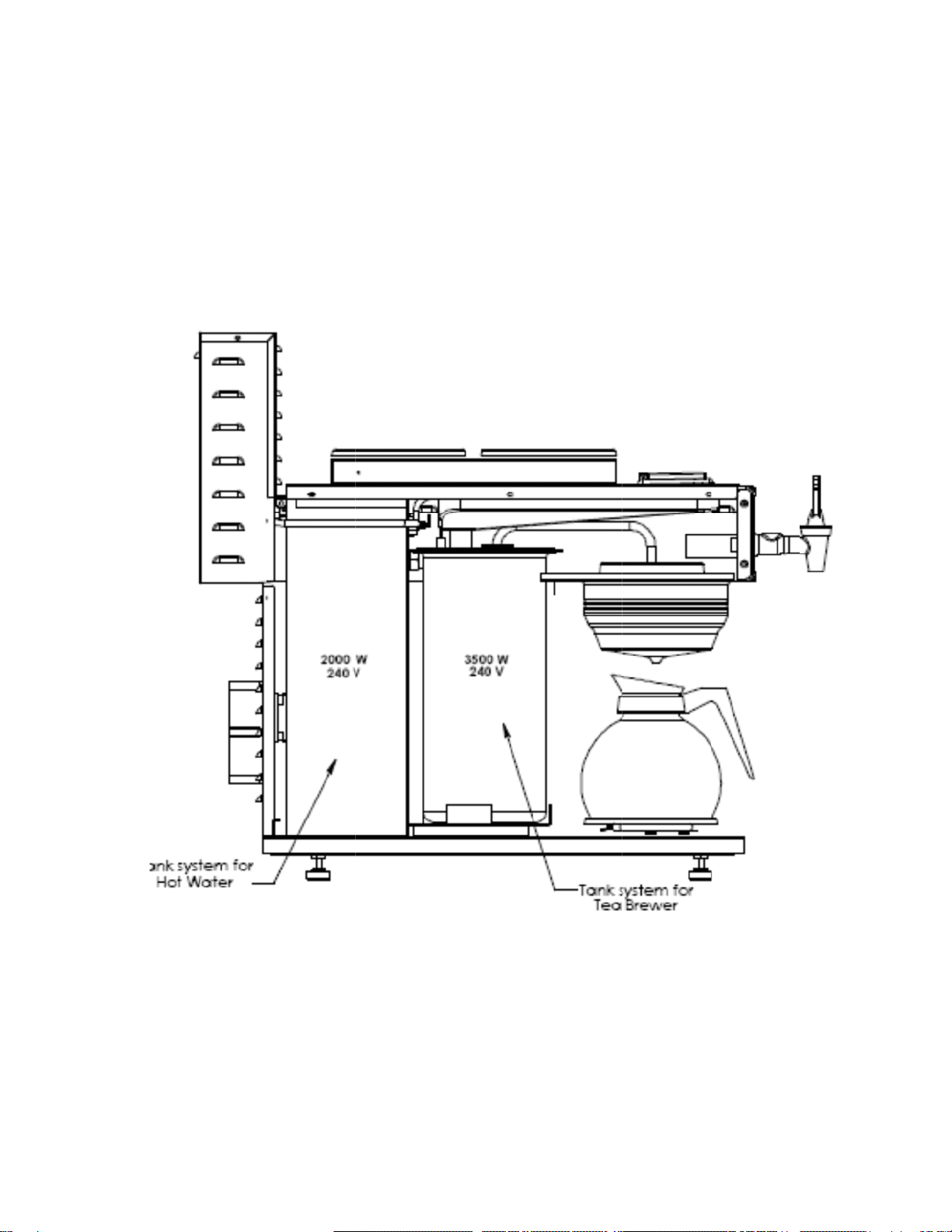

Water Temperature Set Point – Allows for digitally setting the temperature of the water in the brewers tank system to any

value between 170 and 205 Deg F. Caution: Brewer temperature is set at 203 deg and HotWater Dispenser is set at 205 deg.

In higher altitude locations, over 3500 feet above sea level, the temperature will need to be adjusted down to prevent boiling.

Auto Arm – When enabled this feature ensures that the brewer is up to temperature prior to brewing to ensure proper

extraction is obtained. If the water temperature in the tank is below the water temperature set point when the brew cycle is

initiated the water deliveryportion of the brewcycle is delayed. The heating light will begin to flash indicating that the unit is in

the brew mode but is not up to temperature. At the same time the tank heater will begin heating and when the tank reaches

the preset temperature the brew cycle will resume. Auto arm may be overridden bypressing and holding the appropriate brew

button for several seconds until the brew cycle starts.

Pre-infusion mode – This mode delivers a small amount of hot water over the coffee grounds and then pauses to allowwetting

of the brewed product and to allow the product to absorb the water before continuing. After thispause the brewcycle resumes

normally. Pre-infusion can yield better extraction rates than normal brewing modes. The pause time is added to the brewand

visa-brew time. The pre-infusion times are preset at the factory. Pre-infusion for Brew 1 and 2 may be turned on and off

independently.

Pulse Brew Mode – This mode cycles the fill valve on and off during the brewcycle. This slows the entry of cold water into the

tank and minimizes the mixing action caused by introducing a large volume of cold water into the tank at one time resulting in

an increase in brew temperature. The additional turbulence and mixing created in the brew basket along with the increased

temperature can result in higher extraction rates for the coffee or tea. The time set for pulse brewing should exceed the time

required for brewing. The time difference between the pulse brew time and the brew time is the amount of time available as

off time. The difference is divided equallyand distributed throughout the brew cycle to provide a pulse after every30 seconds

of brewing. Pulse brew mode for Brew 1 and 2 may be turned on and off independently.

Audible Alert Mode – Provides an audible signal when tea has finished brewing notifying everybody that fresh tea is available.

May be turned off, set for 1-9 beeps or set to on for continuous beeping until cancel button is depressed. The empty basket

light will also flash to prompt operator to dump grounds from brew basket.

Brew Ready – Monitors the temperature of the water in the tank and lights when the programmed temperature has been

reached. If a brew cycle is started when the icon is not lit brew temperature may not be optimal if the autoarm feature,

described above, has been turned off.