Newgrind RHINO RM350 User manual

For your personal safety, READ and UNDERSTAND before using.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

!

equipment usages

• Concrete leveling, grinding and polishing

• Glue, thinset and mastic removal

• Terrazzo grinding and polishing

• Stone grinding and polishing

• Hardwood sanding and refinishing

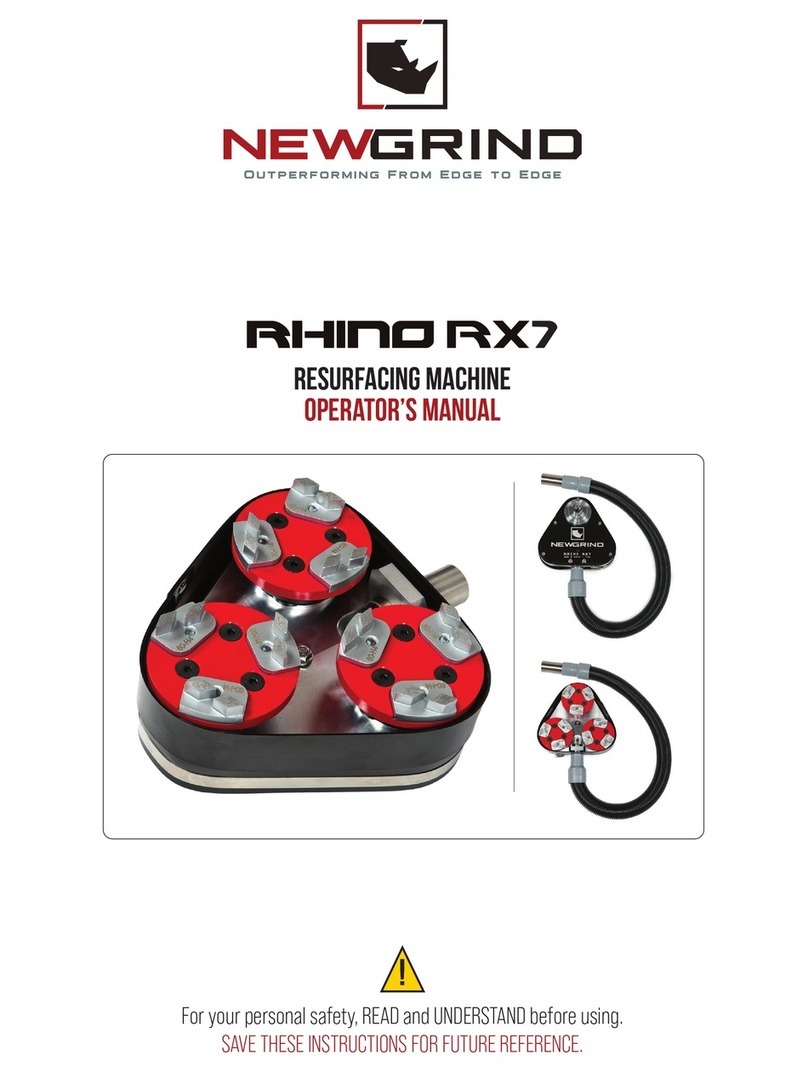

resurfacing machine operator's Manual

LENZE VFD i550 protec IP31 / NEMA 1, NEMA 4X outdoor

Rhino Rm350 user Manual

2

Table of Contents

EQUIPMENT USES................................................................................................

RM350 DIAGRAM .................................................................................................

RM350 BOTTOM DIAGRAM ..................................................................................

MACHINE SPECIFICATIONS .................................................................................

Tooling ...........................................................................................................

Average Production Rates............................................................................

SAFETY INSTRUCTIONS ......................................................................................

Work Area Safety ..........................................................................................

Electrical Safety ...........................................................................................

Personal Safety .............................................................................................

Equipment Use and Care .............................................................................

Service ..........................................................................................................

Specific Safety Rules ..................................................................................

MACHINE OPERATION ........................................................................................

Starting the Equipment ................................................................................

Stopping the equipment ..............................................................................

Handle Adjustment ......................................................................................

Double Grommet System ............................................................................

Using the Biased Weight Kit ........................................................................

VFD Features .................................................................................................

MAINTENANCE ....................................................................................................

General Maintenance ...................................................................................

Daily Maintenance ........................................................................................

Monthly Maintenance ...................................................................................

Yearly Maintenance ......................................................................................

VFD ERROR CODES ..............................................................................................

VFD ERROR SCREENS .........................................................................................

LIMITED EQUIPMENT WARRANTY OF SALE ........................................................

FORCE MAJEURE .................................................................................................

LIABILITY LIMITATIONS ......................................................................................

TERMS & CONDITIONS ........................................................................................

AGREEMENTS .....................................................................................................

1

3

4

5

5

5

6

6

6

6

7

7

7

8

8

9

9

9

10

10

10

10

10

10

10

11

14

14

15

15

16

17

3

Rhino Rm350 diagram

FORWARD SPIN BUTTON STOP BUTTON REVERSE SPIN BUTTON

VARIABLE SPEED

ADJUSTMENT POTENTIOMETER

30A 250V PLUG

TILT ASSIST FOOT LEVER

LOWER RATCHET

LENZE VFD

(MOTOR SPEED CONTROL)

DUAL VACUUM MANIFOLD PORT

HEAVY DUTY WHEELS

LIFT HANDLE

(BOTH SIDES)

QUICK BELT CHANGE BOLTS

(1/2” WRENCH)

2 IN FRONT

1 EACH SIDE NEAR VACUUM PORT

TOP WEIGHT POST

5HP MOTOR

BIASED WEIGHT-KIT POSTS

HAND GRIPS

VACUUM CONNECTOR PORT

VELCRO STRAPS FOR POWER

CABLE AND VACUUM HOSE

VELCRO STRAP

MULTI ARTICULATING HANDLE

UPPER RATCHET

UHMW FIXED

DUST SKIRT

UHMW FLOATING

DUST SKIRT

Rhino Rm350 bottom diagram

QUICK-CHANGE DRIVE BELT

SINGLE OR DOUBLE GROMMET

TOOL PLATE

MOUNTING SYSTEM

COUNTER-CLOCKWISE

SPINNING RHINO TOOL PLATES

(RED)

CLOCKWISE

SPINNING RHINO TOOL PLATES

(BLACK)

RHINO STYLE TOOLING

ATTACHES USING 8MM SCREW

4

HYTREL COUPLER

(SPIDER GEAR)

SECONDARY DRIVE

SPROCKET X 5

MAIN DRIVE SPROCKET

IDLER SPROCKET X 2

(1 ON EACH SIDE)

5

Rhino Rm350 machine specifications

POWER 30 AMP/220-240V Single Phase

MAXIMUM WATTS DRAW 3750

HP 5

MACHINE WEIGHT 318 lbs

BIASED WEIGHT KIT MAX WEIGHT 210 lbs

COMBINED WEIGHT 528 lbs

DISC SPEED 350-1200 rpm

VARIABLE SPEED CONTROL YES

NUMBER OF GRINDING HEADS 6

COUNTER-ROTATING HEADS YES

DISK SIZE 5 inches

GRINDING FOOTPRINT 14 inches

QUICK CHANGE TOOLING PLATES YES

QUICK BELT CHANGING SYSTEM YES

WET OR DRY GRINDING YES

UHMW FLOATING DUST SKIRT YES

MULTI-ARTICULATING HANDLE YES

RUNS FORWARD OR REVERSE YES

CAN BE USED AS AN EDGER YES – grinds to within 1/8 of the edge

DUAL VACUUM MANIFOLDS YES

Tooling

RHINO STYLE TOOLING YES

STANDARD TRAPEZOID NO

Average Production Rates

(on Medium Hard Concrete)

EXTREMELY HEAVY REMOVAL 300400 sq./ft. per hour

HEAVY REMOVAL 400-700 sq./ft. per hour

LIGHT REMOVAL 550-800 sq./ft. per hour

GRINDING AND PROFILING 550-800 sq./ft. per hour

POLISHING 900-1200 sq./ft. per hour

Table of contents

Other Newgrind Industrial Equipment manuals