WARNING

PERSONAL INJURY MAY

RESULT IF THE FOLLOWING

SAFETY PRECAUTIONS

ARE

NOT OBSERVED.

1.BESURE

THEAREASURROUNDING

MACHINE

IS FREE OF ALL

HAZARDS

SUCH

ASFIRE,

WATER, OIL, RUBBISHOR ANYTHING

THAT

CANCAUSE INJURY.

2.DO NOT OPERATE MACHINE IN AN

EXPLOSIVE AREA OR UNDER WET

CONDITIONS.

THE MACHINE

IS NOTAN

EXPLOS]ON

- PROOF TYPE NORWATER-

PROOF.

3.DO NOT OPERATE MACHINE BEFORE

READINGINSTRUCTIONMANUAL.

4.DONOT OPERATEMACHINEON VOLTAGES

OTHERTHAN

SPECIFIEDFORTHEMACHINE.

5.BE SURE MACHINEIS CONNECTEDTO

BUILDINGELECTRICAL

SAFFTY

GROUND

(EARTH).

6.BE SURE POWER

(AND

ArR SUPPLY)tS

OFF BEFORE PERFORMING MACHINE

MAINTENANCE,

PARTS REPLACEMENT,

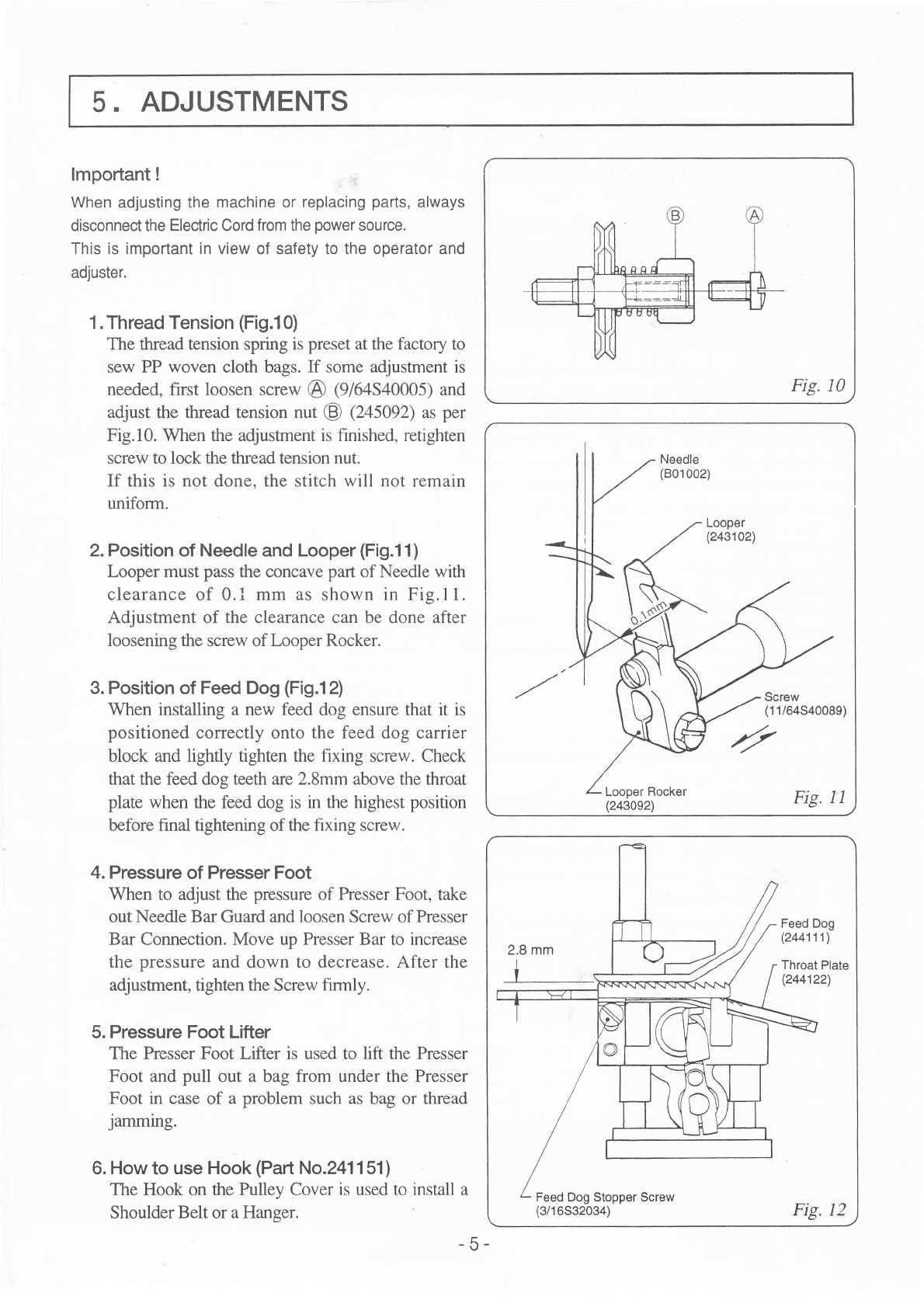

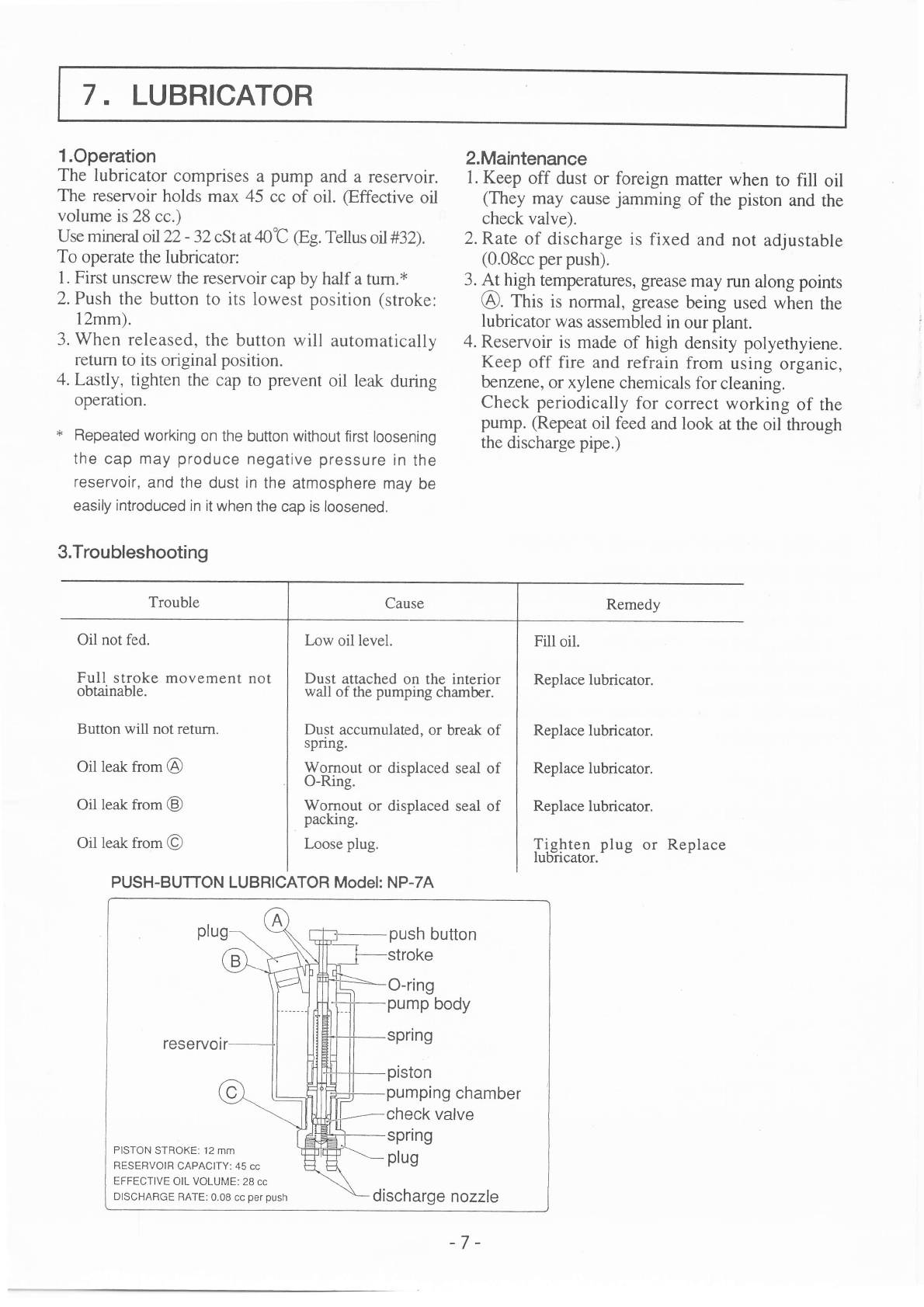

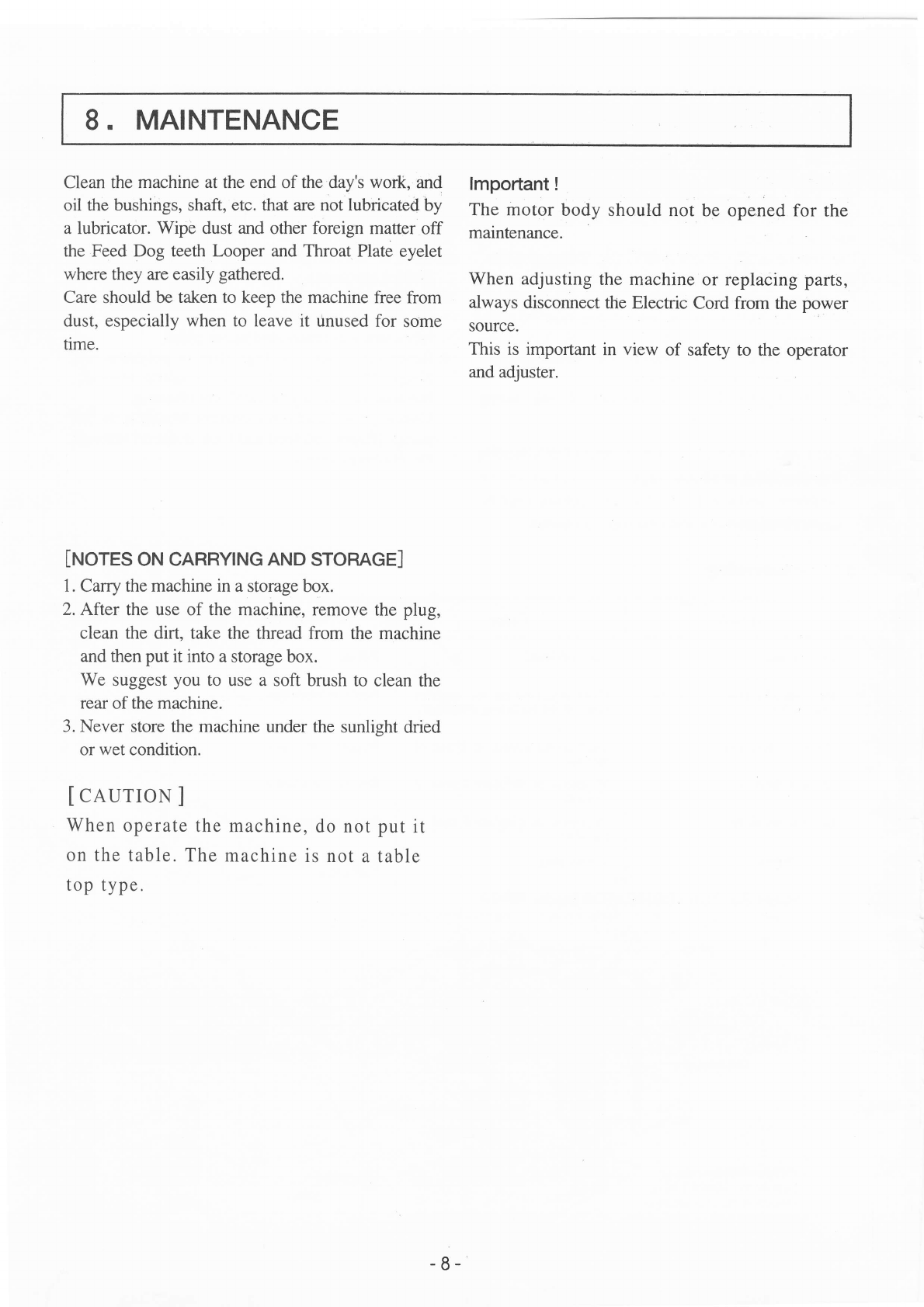

ADJUSTMENTS

OR CLEANING.

7.DO NOT OPERATEMACHINEWITH

GUARDS

AND COVERSREMOVED.

8.DO NOT TOUCH KNIFE,NEEDLE,PULLEY,

BELTANDMOVINGPARTSWHENMACHINE

IS INOPERATION.

g.BE

SUREMACHINEIS PLACEDON ASMOOTH

(LEVEL)

SURFACEWHEN PERFORMTNG

MAINTENANCE,PARTS REPLACEMENT,

ADJUSTMENTS,

CLEANINGOR STORAGE.

1O.BE

SURE THE MATERIALTO BE SEWN

OR CLOSEDCOMPLIESWITHTHEMACHINE

SPECIFICATIONS.

11.DONOT USE SPAREPARTSOTHERTHAN

"NEWLONG"

GENUINEPARTS.

PFIEtrAUGION

NOSEGUIRLASINSTRUCCIONES

OUE SE DETALLANPUEDE

RESULTARPERJUDICIALPARA

SUSALUD.

1.ASEGURARASEOUE ALREDEDOR

DE LA

MAQUINA.NOHAYANINGUNELEMENTOCOMO

FUEGO,AGUA,ACEITEUOTROS

QUE

PUEDAN

OCASIONAR

ALGUNACCIDENTE.

2.NO

USAR

LAMAQUINAENNINGUNAREA

QUE

TENGA RIESGO DE EXPLOSIONOBAJO

CONDICIONESDEHUMEDAD.

LAMAQUINANO

ES

SOLO

EL TIPOA PRUEBADEEXPLOSION,

SINOELTIPOA PRUEBADEAGUA.

3.USARLAMAQUINA,DESPUESDEHABER

LEIDO

CON DETENIMIENTO EL MANUAL DE

INSTRUCCIONES.

4.NOUSAR LA MAQUINARIACON VOLTAJES

DIFERENTESALOSESPECIFICADOSPARALA

MISMA.

5.ASEGURARSEDE QUE LA MAQUINAESTA

CONECTADA A UNA ZONA ELECTRICADE

SEGURIDADCON TOMADE TIERRA.

6.ASEGURARSEDEDESCONECTARLAMAQUINA

ANTESDEPROCEDER

ASUMANTENIMIENTO,

SUSTITUCIONDEPIEZAS.AJUSTEY LIMPIEZA

DELAMAQUINA.

7.NO USAR LA MAOUINACON OBJETOS

EXTRANOS,NICUANDOTENGAUNATAPADERA

ABIERTA.

8.NOTOCARLASCUCHILLAS,AGUJAS,POLEAS,

CORREAS

Y PARTESMOVILESCUANDOLA

MAQUINAESTA

EN FUNCIONAMIENTO.

9.ASEGURARSEDE QUE

LAMAQUINAESTAEN

UN LUGAR

APROPIADOPARAPROCEDERAL

MANTENIMIENTO,RECAMBIO

DE PIEZAS,

AJUSTES,LIMPIEZAOALMACENAJE.

10.

ASEGURARSE

DE

QUE

ELMATERIALACOSER

ENTRADENTRODE LASESPECIFICACIONES

DE LAMAQUINA.

11.NOUSARNINGUNAPIEZADERECAMBIOQUE

NOSEANEWLONG.