Newport 1621 User manual

USER’S GUIDE

Nanosecond Photodetectors

Models 1621 & 1623

These photodetectors are sensitive to electrostatic

discharges and could be permanently damaged if

subjected even to small discharges. Ground your-

self adequately prior to handling these detectors or

making connections. A ground strap provides the

most effective grounding and minimizes the

likelihood of electrostatic damage

phone: (877) 835-9620

e-mail: tech@newport.com • www.newport.com

Warranty

Newport Corporation guarantees its products to be free of defects for one

year from the date of shipment. This is in lieu of all other guarantees,

expressed or implied, and does not cover incidental or consequential loss.

Information in this document is subject to change without notice.

Copyright 2022 Newport Corporation. All rights reserved.

The New Focus logo and symbol are registered trademarks of Newport

Corporation

Document Number 90099917 Rev. A

Nanosecond Photodetectors Contents • 3

Contents

Operation 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Using the Photodetector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Conserving Signal Strength . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Supplying your own load resistor. . . . . . . . . . . . . . . . . . . . . . . . 9

Checking and Replacing the Battery . . . . . . . . . . . . . . . . . . . . 10

General Features and Principles 11

Photoreceiver Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Frequency and Time Response . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Using Filters and Optical Fiber 15

Characteristics 17

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Photodetector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Customer Service 19

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4 • Contents

This page has been intentionally left blank.

Nanosecond Photodetectors Operation • 5

Operation

Introduction

The Model 162X is a general-purpose battery-powered

photodetector for measuring optical signals down to

nanosecond time scales.

There are two versions of the Model 162X detector,

each based on a different photodetector diode:

Model Wavelength Type Diam.

1621 350–1000 nm silicon/PIN 0.8 mm

1623 800–1700 nm InGaAs/PIN 0.1 mm

(with a 1.5-

mm ball

lens)

Complete specifications for the Model 162X

nanosecond photodetectors begin on page 17.

This product is ideal for detecting light pulses or

monitoring optical signals from DC to several hundred

MHz where an electronic amplifier is not required. The

large-diameter detectors and the DC response make

alignment and operation of the Model 162X easy.

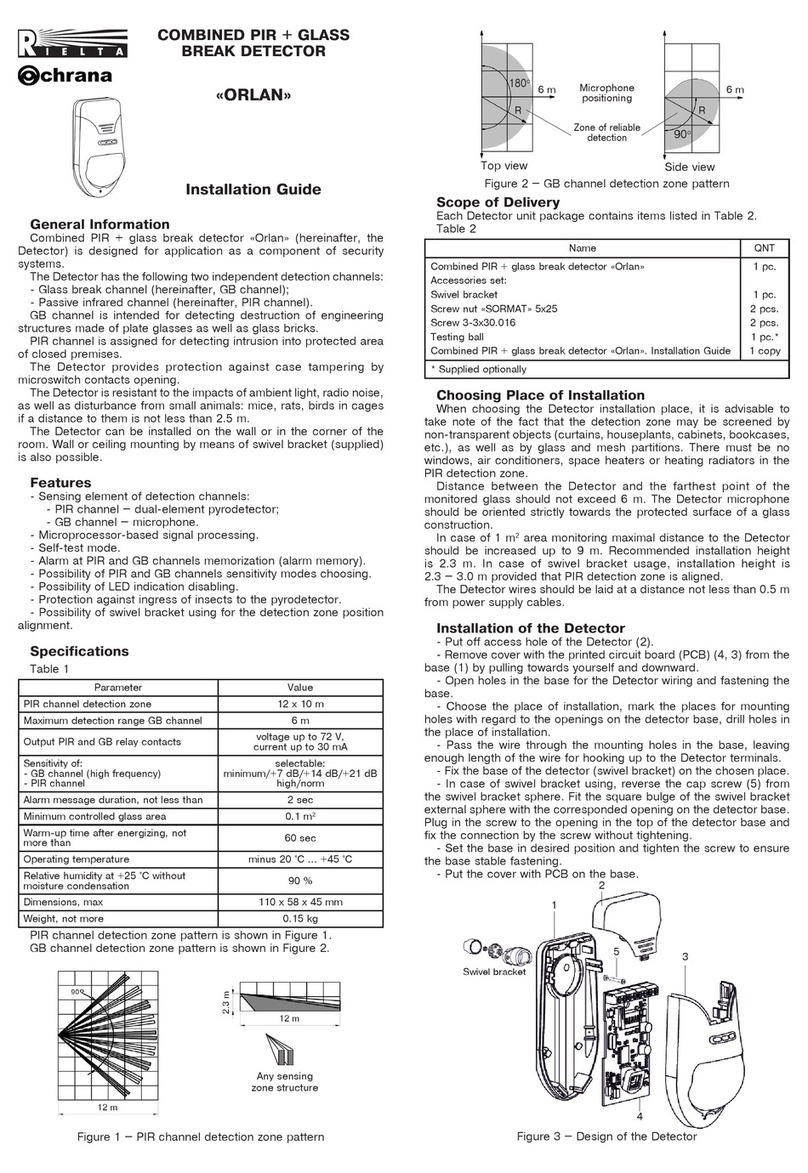

Figure 1 shows the typical responsivity curves for the

photodetectors used in the Models 1621 and 1623.

6 • Operation

Figure 1:

Typical

responsivities

of

Model 1621

and Model

1623

0.0

0.2

0.4

0.6

0.8

1.0

Wavelength, nm

200 400 600 800 1000 1200 1400 1600 1800 2000

Responsivity, A/W

Model 1621

Model 1623

Each Model 162X photodetector runs off a single 9-volt

alkaline battery. The photoreceiver’s slim casing,

shown below, makes it easy to position it in a set-up

between closely spaced optics. The switches and BNC

output connector are located on top of the receiver for

easy access.

Figure 2:

Model 162X

casing

Photodetector

Power switch Battery-check LED

Load-resistor switch

Output (BNC)

8-32 (M4)

Mounting

threads

A full mechanical diagram of the Model 162X casing is

available on page 17.

Nanosecond Photodetectors Operation • 7

Using the Photodetector

1. Check the battery voltage. The Model 162X is

powered by a single 9-volt alkaline battery. To

check the battery condition, push the red power

switch to the BATT CHK position. If the green LED

lights up, the battery is in good condition; if the

LED does not light, the battery needs to be

replaced (see page 10).

2. Mount the photodetector. Use the 8-32 thread (M4

for metric versions) on the bottom of the casing to

mount the photoreceiver to a post or pedestal.

The threading is seated in a non-conductive plastic

pad to reduce the electrical noise associated with

ground loops. Be careful not to over-tighten when

attaching the casing to a post or pedestal, or the

threaded insert can strip out of the plastic pad.

3. Connect the detector output. Connect your

voltmeter, oscilloscope, or other instrument to the

Output BNC connector on top of the detector.

4. Turn the power switch to “on.” The output voltage

should register on your scope or instrument.

5. Align an optical beam onto the detector.

Be careful to keep the optical power under the

maximum optical power of 50 mW to avoid

damaging the photodetector.

6. Select the load. Use the black switch on top of the

detector to set the load to 50 , 10 k, or Open.

(Select Open if you are providing an external load

resistor. See “Supplying your own load resistor” on

page 9.)

7. Turn the detector off. When you are finished with

the detector, return the power switch to the “off”

position.

8 • Operation

Conserving Signal Strength

If you have a low-power signal, 50 of trans-

impedance gain can lead to very small output voltages.

If you need to conserve signal strength, it is important

to focus your optical beam onto the photodiode.

Adjusting the photodiode position for optimal signal is

best performed as a two-step procedure:

1. Set the load resistance to 10 kor Open.

2. Hook the detector output directly into an

oscilloscope or other voltage-measurement device

with a large input impedance.

3. Adjust the photodiode position (in both transverse

and focus directions) for maximum DC voltage.

For optical signal levels above about 1 mW (at 10

k), the voltage will saturate. Remember, the

output voltage can only rise up to the battery

voltage—9 V when the battery is fresh. If you use

the 1-Minput impedance of an oscilloscope,

saturation is even easier to reach.

4. Select the 50-resistor, or supply your own small

load resistance suitable to your gain and

frequency-response requirements. Make fine

adjustments to the photodiode position until the

maximum signal is achieved.

To compute the approximate output voltage for a given

input optical power use the relationship

Vout = Pin · R · G,

where Pin is the input optical power in watts, Ris the

photodetector’s responsivity in A/W (see page 6 for

typical responsivities), and Gis the load resistance (V/

A). For example, with 10 mW of optical power, a

responsivity of 0.5 A/W, and with the load set to 50 ,

the photodetector will produce an output voltage of

approximately (10 mW) · (0.5 A/W) · (50 V/A) = 0.25 V.

Nanosecond Photodetectors Operation • 9

Supplying your own load resistor

At high frequencies, typical resistors begin to exhibit

parasitic inductance and capacitance. For instance, if

you want to operate on the Open setting and supply

your own 100-resistor, you might be tempted to use

a standard carbon-film resistor soldered across the

terminals of a BNC tee. The problem with this

approach is that the parasitic inductance of such a

home-made resistor will cause a significant change in

the impedance at high frequencies. So, for best results

you may need to buy a precision load resistor that is

optimized for high-frequency use.

You must also watch out for impedance mismatch

problems. The internal transmission line from the

photodiode to the BNC output has a characteristic

impedance of 50 . This has been chosen for best

compatibility with 50-impedance equipment. If you

terminate this transmission line with a non-50-load,

you should expect degraded frequency response.

When you use 50-impedance equipment, you

should switch the nanosecond photodetector into the

Open position. If you leave the internal 50-resistor

switched in, the photocurrent will be divided between

the two loads, cutting your signal in half. If you leave

the internal 10-kresistor switched in, it will have little

effect, as the 50-load will draw the majority of the

photocurrent.

DC blocking devices are a potential source of

confusion. Some sensitive high frequency equipment

requires 0 V at DC input. In this case, we recommend

that you put a high-frequency DC blocking load

between the nanosecond detector and your

equipment. If so, you must supply a DC path to ground

for your photocurrent. This is easiest to do by

switching in the photodetector’s 50-internal load

resistor. If you switch in the 10-kload resistor, you

10 • Operation

must be certain that the circuit does not saturate itself

on the DC level.

Checking and Replacing the Battery

The Model 162X is powered by a single, standard 9-volt

battery. The battery lifetime depends on the load

resistor and on the optical input power to the

photodetector. Under normal operating conditions the

battery lifetime will typically be greater than 500

hours.

To check the condition of the battery, push the red

switch to the BATT CHK position. If the green LED

lights up, the battery is in good condition.

When the battery voltage falls below about 6.5 volts,

the green LED will not light up, and the battery should

be replaced.

Replacing the Battery

1. Turn the red power switch to “off” to prevent

damage to the receiver.

2. Remove the screw on the back of the

photodetector casing and remove the back cover.

3. Unplug the old battery.

4. Install a new 9-volt alkaline battery.

5. Reinstall the back cover.

6. Test the new battery’s status by pushing the power

switch to the BATT CHK position.

Nanosecond Photodetectors General Features and Principles • 11

General Features and Principles

Photoreceiver Circuitry

The circuitry inside the Model 162X consists of a

reverse-biased photodetector and a load resistor with

three settings: 50 , 10 k, and Open. The 50-setting

has 50-V/A sensitivity and can be used to achieve the

1-nanosecond response time. The 10-ksetting has a

reduced time response but gives a higher sensitivity

(10,000 V/A) and can be used for alignment purposes

and for detecting low-power pulses. The Open setting

allows you to hook-up your own external load resistor

and choose the best gain-bandwidth combination for

your application.

Figure 3:

Functional

schematic of

the Model 162X

circuitry

Output

Open

10 kΩ50 Ω

ON

+V

LED

Battery Check

Circuit

OFF

Batt

Chk

Frequency and Time Response

The nanosecond photodetector circuitry is quite

straightforward, consisting only of the photodiode,

battery bias and a selectable load resistor. The speed

limitation of the circuit is established by the junction

capacitance of the photodiode and the load resistance

12 • General Features and Principles

value. Figures 4 and 5 give typical frequency responses

and pulse responses for the Model 162X photodetector.

Figure 4:

Typical

frequency

response for

the Model 1623

on the 50-¾

setting

0 100 200 300 400 500 600

Frequency, MHz

Gain (10 dB/div)

When performing high-speed measurements,

impedance-matching effects between your

measurement apparatus and the photo-detector must

be taken into consideration in order to achieve optimal

high-speed response.

Typical laboratory measurement equipment may

prevent you from achieving nanosecond response

times. BNC connectors do not match 50-

transmission lines well for frequencies above 100 MHz.

The frequency response is therefore not flat between

100 MHz and 500 MHz.

Above 500 MHz, the situation can be worse, with

typical BNC connectors and cables proving to be quite

lossy. Therefore, while the time response of the

nanosecond detector is quite fast, it is not expected to

provide flat frequency response in the 100-MHz to

500-MHz regime.

Selecting the internal 50-resistor will usually allow

you to achieve a response speed which is limited by

your detection equipment. Typical laboratory

oscilloscopes, for instance, have only 10-MHz to

100-MHz bandwidth. When you select the 10-k

Nanosecond Photodetectors General Features and Principles • 13

resistor, the speed is RC limited, and the response

speed will typically be 50 ns.

Figure 5:

Typical pulse

response for

the (a) Model

1621 and (b)

Model 1623

photodetectors

0246810

Time (ns)

(a) Model 1621

0246810

Time (ns)

(b) Model 1623

A 0.15-ps pulse at 1.06 µm was used to test the

photodetectors, and the output was measured

using a 12-GHz oscilloscope.

14 • General Features and Principles

This page has been intentionally left blank.

Nanosecond Photodetectors Using Filters and Optical Fiber • 15

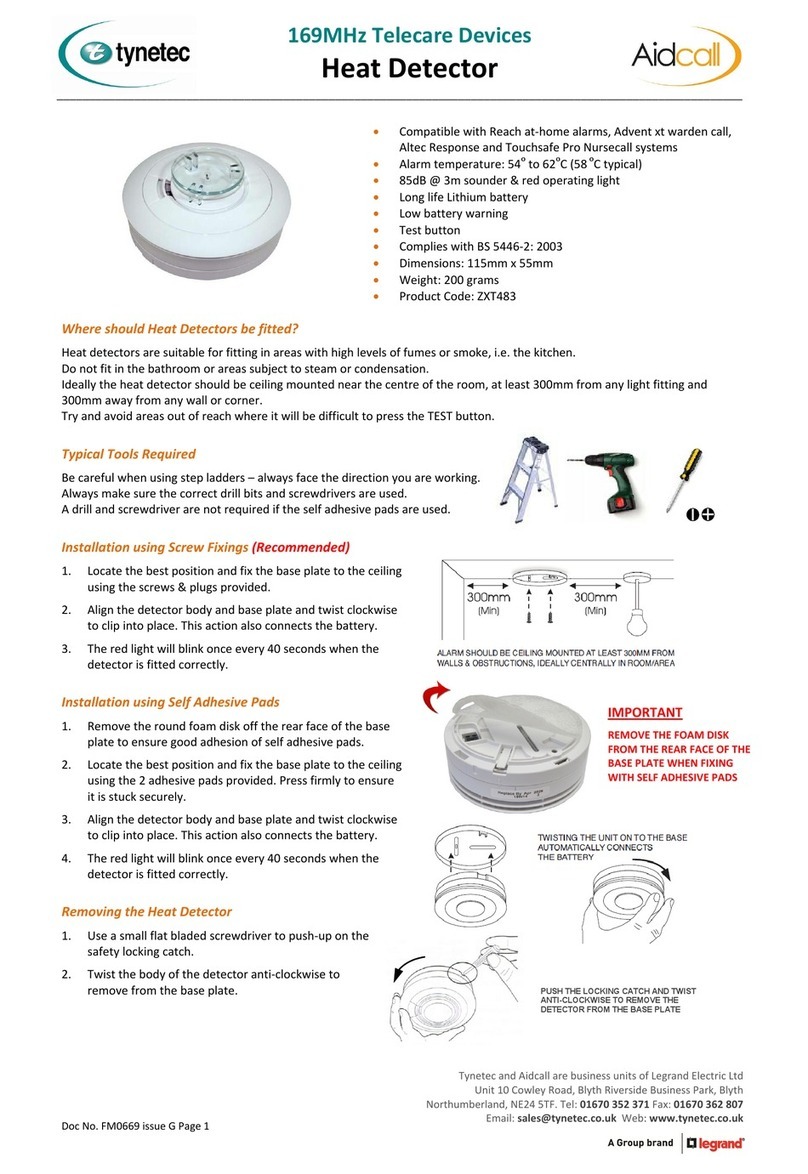

Using Filters and Optical Fiber

Newport offers accessories, sold separately, to attach a

1"- diameter filter or an optical fiber to the detector.

Both accessories attach tothe casing using the 1.04-32

threads located in the casing around the detector.

Note that the accessories are also compatible with the

Model 215X femtowatt photoreceiver.

The Model 1280 1"filter holder allows you to mount a

1"- diameter optic in front of the photodetector. For

instance, you can mount a colored glass filter to

remove unwanted wavelengths or a neutral-density

filter toattenuate the optical power incident on the

photodetector. The Model 1280 has a plastic ring for

mounting a filter that is up toabout 0.25" (6.4-mm)

thick. A thicker optic can be held in place using the

6-32 nylon-tipped set screw. Use a 1/16" or 1.5-mm

Allen key or ball-driver toadjust the set screw.

The Model 1281 FC fiber adapter allows you to

connect an FC connectorized fiber to the front ofthe

photodetector. The coupling efficiency of light from an

optical fiber to the Model 1623 photodetector is

typically 70% or greater. The coupling efficiency is

less than unity because of the small detector size and

small variations in the mechanical position of the

detector and the fiber.

See Figure 6 for drawings ofthese two accessories. A

variety of fiber couplers, fiber collimators and pigtails

are also available from Newport.

16 • Using Filters and Optical Fiber

Figure 6:

Model 1280

1" filter holder

and the

Model 1281 FC

fiber adapter

0.63"

(15.9)

Model 1280

patent pending

dia. 1.30"

(33.0)

holes for

tightening

1.04-32

thread

Retaining ring

for holding 1"

or 25-mm optics.

6-32 nylon-tipped

setscrew for

holding 1" or

25-mm optics.

0.13"

(3.2)

FC connector

holes for

tightening

1.04-32

thread

0.35"

(8.9)

0.19"

(4.8)

Model 1281

Nanosecond Photodetectors Characteristics • 17

Characteristics

Physical Specifications

Figure 7:

Mechanical

drawing of the

Model 162X

casing

4.03

(102.3)

1.00

(25.4)

1.25 (31.8)

1.040-32

Threaded hole

1.16

(29.5)

Battery check LED

2.50 (63.5)

Output (BNC)

Load resistor switch

Power switch

8-32 (M4)

Threaded insert

18 • Characteristics

Photodetector Specifications

Model # 1621 1623

Wavelength Range 350-1000 nm 800-1700 nm

Detector Material/Type Silicon/PIN InGaAs/PIN

Detector Diameter 0.8 mm 0.1 mm (with 1.5-

mm-diameter ball

lens)

Typical Max. Responsivity 0.55 A/W (at 800

nm)

1.0 A/W (at 1600

nm)

Maximum Optical Power 50 mW 50 mW

Load Resistors 50 , 10 k, and

Open (user

provided)

50 , 10 k, and

Open (user

provided)

Typical Rise Time 1 nanosecond (50-

setting)

1 nanosecond (50-

setting)

Typical detector capaci-

tance

3 pF 0.8 pF

Electrical Output Connec-

tor

BNC BNC

Power Requirements One 9-volt alkaline

battery

One 9-volt alkaline

battery

Typical Battery Lifetime >500 hours >500 hours

Nanosecond Photodetectors Customer Service • 19

Customer Service

Technical Support

Service

Information and advice about the operation of any Newport

product is available from our applications engineers. For quickest

response, ask for “Technical Support” and know the model

number and serial number for your product.

Hours: 8:00–5:00 PST, Monday through Friday (excluding

holidays).

Phone: 1-877-835-9620

Support is also available by email and chat

Chat: Connect with us at www.newport.com

Email: [email protected]

We typically respond to emails within one business day.

In the event that your device malfunctions or becomes damaged,

please contact Newport for a return merchant authorization (RMA)

number and instructions on shipping the unit back for evaluation

and repair.

This manual suits for next models

1

Table of contents

Other Newport Security Sensor manuals