impeller end during press operation. Do not hammer

pulley or coupling on shaft; this may damage

bearing or seal.

Three phase capacitor start motor is required to

overcome starting torque of impeller.

3. SPEEDS – 100 RPM to the maximum shown in the

performance curves. For longer pump life, operate

at lowest possible speeds. Lower speeds are

required for viscous liquids. Consult the factory for

proper speeds and horsepower requirements.

4. SELF-PRIMING – Primes at low or high speeds. For

vertical dry suction lift of 10 feet (neoprene) – 4 feet

(EPDM), a minimum of 860 RPM is required. Pump

will produce suction lift up to 22 feet when wet.

BE SURE SUCTION LINES ARE AIRTIGHT OR

PUMP WILL NOT SELF-PRIME.

5. DISCHARGE – When transferring liquids further

than 25 feet, use one size larger discharge line than

discharge port size.

6. RUNNING DRY – Unit depends on liquid pumped for

lubrication. DO NOT RUN DRY for more than 30

seconds. Lack of liquid will damage the impeller.

7. PUMPAGE COMPATIBILITY – Consult the

Chemical Resistance Guide in the JABSCO

Industrial Pump Catalog (available upon request

from the factory) for proper body materials and

impeller compounds. If corrosive fluids are

handled, pump life will be prolonged if pump is

flushed with a neutralizing solution after each use or

after each work day. A Tungsten Carbide Seal

variation is available for pumping liquids that contain

abrasives or are highly corrosive.

8. PRESSURES – Consult Performance Curves for

maximum recommended pressures for pump in

continuous operation. If pressures exceed those

shown, consult the factory.

9. TEMPERATURES – The operating temperature

limits of the pump depend on the impeller

compound. The following ranges apply:

Neoprene - 45° to 150° F (7° to 65° C)

EPDM - 45° to 185° F (7° to 85° C).

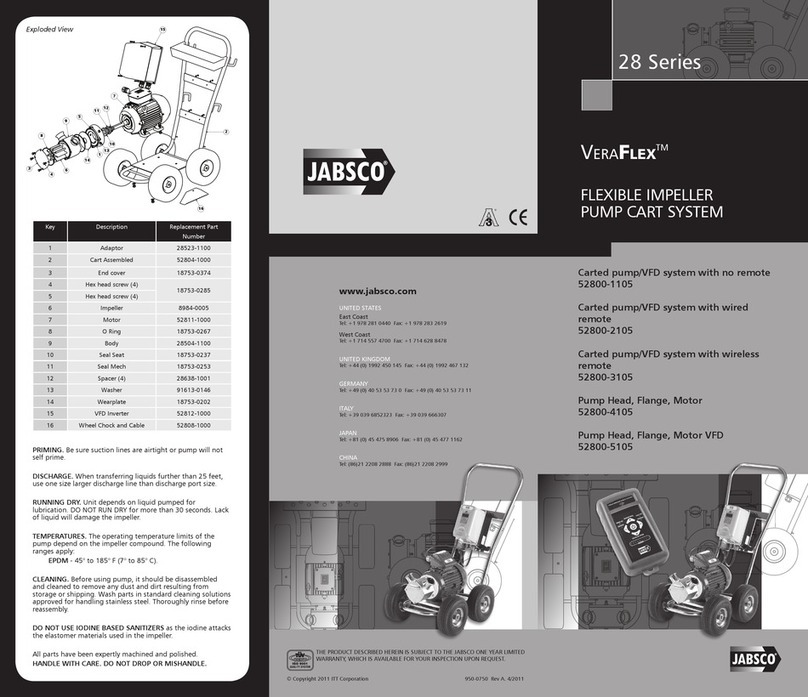

10. CLEANING – Before using pump, it should be

disassembled and cleaned to remove any dust and

dirt resulting from storage or shipping. Wash parts in

standard cleaning solutions approved for handling

stainless steel. Thoroughly rinse before reassembly.

DO NOT USE IODINE BASED SANITIZERS as the

iodine attacks the elastomer materials used in the

impeller.

All parts have been expertly machined and polished.

HANDLE WITH CARE. DO NOT DROP OR

MISHANDLE.

11. IMPELLER TORQUE – The torque required to initiate

rotation of a new impeller in a dry pump body is:

Standard Pressure Impeller (8984-Series):

Forward = 20.8 pounds force – feet

Reverse = 37.4 pounds force – feet

High Pressure Impeller (8600-Series):

Forward = 27.5 pounds force – feet

Reverse = 49.0 pounds force – feet

These values may vary slightly due to impeller

compounding, blade set, and body material of

construction. Consult factory for more information.

12. SPARE PARTS – To avoid costly shutdowns, keep a

spare JABSCO impeller, seal and O-ring set on hand.

SERVICE INSTRUCTIONS

DISASSEMBLY

1. Remove the four end cover screws. Remove end

cover and O-ring.

2. Remove the four screws, holding the body to the

bearing housing flange. Slide body, complete with

impeller and wearplate, from pedestal and shaft

assembly.

3. Remove mechanical seal by inserting two

screwdrivers behind seal collar, and gently lever

collar and seal assembly forward on shaft. Use

extreme care not to mar shaft surface. Remove seal

seat and rubber cup from recess in wearplate.

4. From the drive end of the bearing housing, pry out

bearing seal by inserting a screwdriver blade

between OD of the seal and housing. Remove

retaining ring. Very carefully withdraw shaft and

bearing assembly.

5. Remove inner bearing seal and retaining ring.

6. To remove bearings from shaft, an arbor press is

required. If an arbor press is not available then a

bearing extractor may be used. Supporting inner

race of bearing, apply a steady pressure on shaft

until bearing slides free. Repeat this procedure to

remove second bearing.

ASSEMBLY

1. To replace bearing on shaft. Support ball bearing on

its inner race and locate shaft onto bearing. Apply a

steady pressure to the shaft until bearing locates

against shoulder on shaft. Repeat for second bearing.

2. Fit retaining ring and bearing seal into impeller end

of bearing housing. Spring on bearing seal to face

outwards.

3. Apply bearing grease around and between bearings,

filling cavity between bearings two thirds full. Smear

grease on shaft where bearing seal locates. Push

shaft and bearing assembly into bearing housing.

4. Replace retaining ring and outer bearing seal with

spring facing outwards.

5. Replace mechanical seal by sliding spacer onto

shaft up to locating shoulder, then smear shaft with

light lubricating oil. Push on seal gently until it