1

FORM NO. L-20016-U-0305

CLUTCH

END BRAKE

END

INSTALLATION

PILOT MOUNT CLUTCH-BRAKE

1. Secure a customer supplied sheave or sprocket to the

Clutch-Brake (See Figure 2).

2. Insert the first Key (Item 30) into the shaft (See Figure 2).

3. Slide the Clutch-Brake onto shaft and key; then, insert the

second Key (Item 30) (See Figure 2).

4. TightenSetScrews(Items27and28)totherecommended

torque (See Table 1 and Figure 2).

NOTE

If a bushing for smaller diameter shafts is required, use a

bushing on both ends of the Clutch-Brake.

5. Align air inlet ports to a six o’clock down position to allow

condensation to drain out of exhaust port.

6. FastenoneoftheearsoftheClutch-Braketoafixedmember

of the machine (See Figure 2).

NOTE

The Piston Air Chamber (Item 7) floats axially

approximately 1/16 inch [1.59 mm] during operation.

Makesure securing pin allows1/16inchto 1/8 inch[1.59

mm to 3.18 mm] movement of Piston Air Chamber.

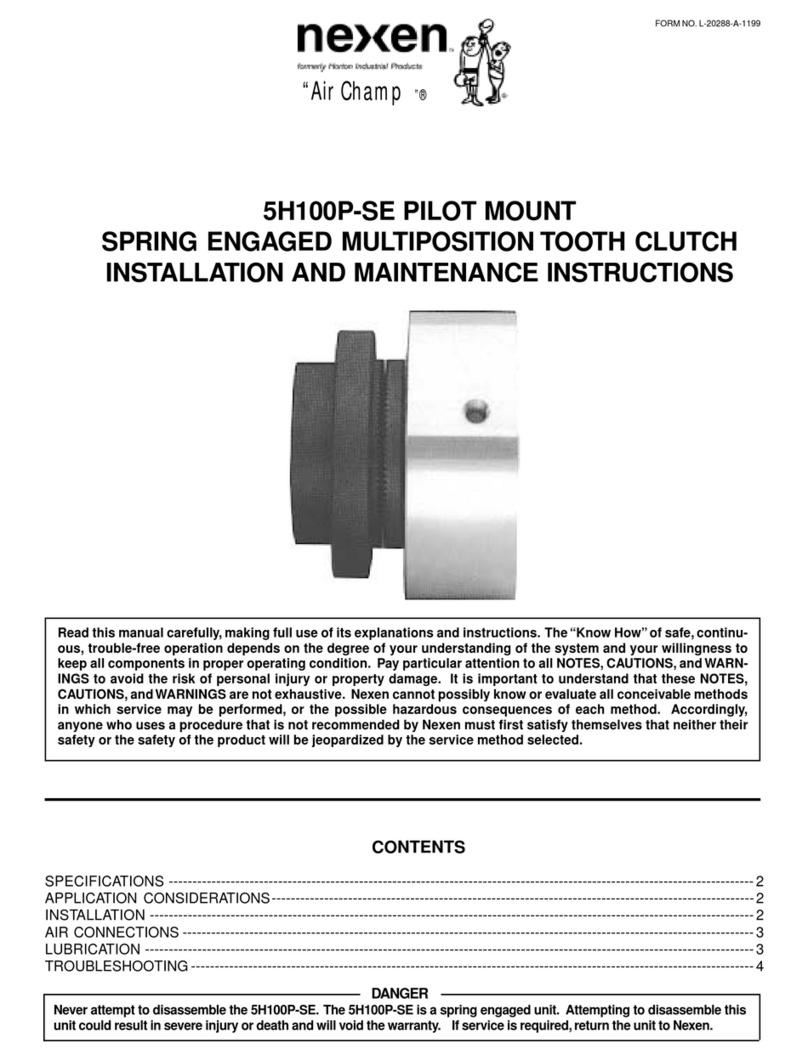

INTRODUCTION

TheNexenAirChampClutch-BrakeisanAirChampClutchandan

Air Champ Brake combined into a single unit.

Becauseheatfromboththeclutchandbrakeareabsorbedwithin

theunitduringengagement,cautionmustbeusedwhenaClutch-

Brake is applied on high speed, high cyclic applications. If heat

generated from the clutching and braking of the Clutch-Brake

becomes great enough that the surface temperature of the unit

is 180oF [82.2° C] or higher, the unit may experience excessive

facingwearandareductioninbearingando-ringlife. TheClutch-

Brake must be mounted on a bearing supported, through shaft.

Twoseparateairinletsprovideindependentclutchingandbraking

action. FIGURE 1

AIR TO

CLUTCH

AIR TO

BRAKE

DESCRIPTION FWCB LWCB MWCB HWCB

35In.Lbs. 80In.Lbs. 80In.Lbs. 23Ft.Lbs.

SetScrew (Item27) [3.9N•m] [8.9N•m] [8.9N•m] [31.2N•m]

20In.Lbs. 20In.Lbs. 80In.Lbs. — —

SetScrew (Item28) [2.2N•m] [2.2N•m] [8.9N•m] — —

.

TABLE 1

RECOMMENDED TIGHTENING TORQUES

FIGURE 2

Shaft

Key

(Item 30)

Set Screw

(Item 28)

Set Screw

(Item 27)

Key

(Item 30)

Clutch-Brake

Sheave

or

Sprocket

Read this manual carefully, making full use of its explanations and instructions. The “Know How” of safe, continuous,

trouble-free operation depends on the degree of your understanding of the system and your willingness to keep all

components in proper operating condition. Pay particular attention to all NOTES, CAUTIONS, and WARNINGS to avoid the

risk of personal injury or property damage. It is important to understand that these NOTES, CAUTIONS, and WARNINGS

are not exhaustive. Nexen cannot possibly know or evaluate all conceivable methods in which service may be performed,

or the possible hazardous consequences of each method. Accordingly, anyone who uses a procedure that is not

recommendedbyNexenmustfirstsatisfythemselvesthatneithertheirsafetyorthesafetyoftheproductwillbejeopardized

by the service method selected.

WARNING

This unit has rotating parts. A guard that will not restrict the flow of cooling air around the unit must be used if the unit is

installed where injury to an operator could occur, as stated in the Occupational Safety and Health Act (OSHA), Standard

(29 CFR 1910) Section 1910.219K.

®

DIST. AUTORIZADO

MEX (55) 53 63 23 31

QRO (442) 1 95 72 60

MTY (81) 83 54 10 18