3FORM NO. L-20222-G-0501

AIR CONNECTIONS

Although 5H50P Tooth Clutches are air actuated with a

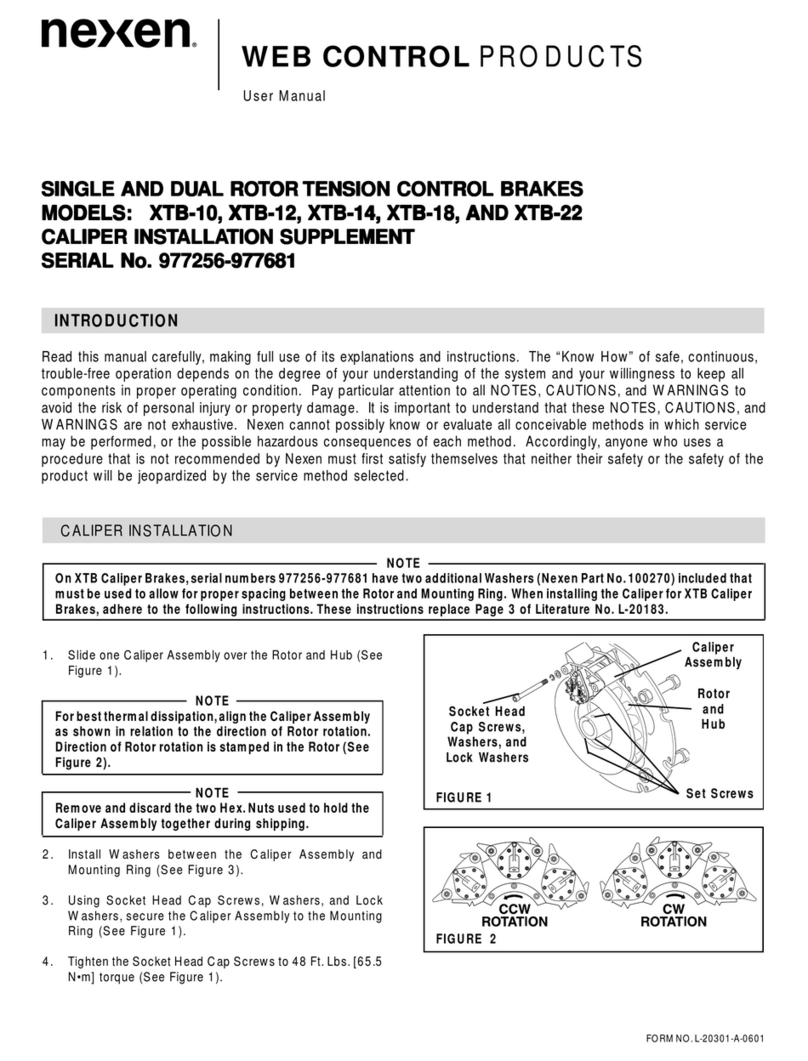

maximum operating air pressure of 80 psi, use only

enough air pressure to deliver ample torque for the

application. Operating air pressures in excess of 80 psi

will eventually cause bearing and seal damage.

Although an air hose is supplied, for quick response,

locate the control valve as close to the 5H50P as

possible. Air controls having 1/8" ports are

recommended, along with a quick exhaust valve to ensure

rapid disengagement where long air lines are required.

1. Apply air pressure to 5H50P.

2. Rotate 5H50P until fully engaged.

3. Slide Engagement Indicator Switch on Bracket until

Engagement Indicator Switch is fully depressed

against Engagement Indicator Dowel Pin.

4. Slide Engagement Indicator Switch away from

Engagement Indicator Dowel Pin until the

engagement indicator light comes on (See Figure 3).

5. Tighten Cap Screws securing Engagement Indicator

Switch to the Engagement Indicator Mounting

Bracket.

6. Check Engagement Indicator Switch adjustment to

verify lighting of the engagement indicator light when

the 5H50P is engaged.

FIGURE 3

Align air inlet port to the six o’clock down position to

allow condensation in the air chamber to drain out of the

exhaust port. Due to bearing seal drag, the cylinder/

piston assembly will rotate, resulting in hose breakage

when 5H50P is engaged. Attach an Anti-Rotation strap

to the 5H50P, mounting it to the tapped holes provided in

the 5H50P Cylinder to prevent the air hose from

breaking.

Rigid pipe or tubing when connected directly

to the 5H50P will prevent proper actuation of

the 5H50P. Use flexible hose or tubing when

making air line connections to 5H50P.

ENGAGEMENT INDICATOR SWITCH ADJUSTMENT

LUBRICATION

NOTE: Pneumatically actuated devices require clean, pressure regulated, and lubricated air for maximum performance

and long life. The most effective and economical way to lubricate Nexen 5H50P is with an Air Line Lubricator,

which injects oil into the pressurized air, forcing an oil mist into the air chamber.

Locate the lubricator above and within ten feet of the 5H50P, and use a low viscosity oil such as SAE-10.

Synthetic lubricants are not recommended.