1FORM NO. L-20206-A-0601

INTRODUCTION

Read this manual carefully, making full use of its explanations and instructions. The “Know How” of safe, continuous,

trouble-free operation depends on the degree of your understanding of the system and your willingness to keep all

components in proper operating condition. Pay particular attention to all NOTES, CAUTIONS, and WARNINGS to avoid

the risk of personal injury or property damage. It is important to understand that these NOTES, CAUTIONS, and

WARNINGS are not exhaustive. Nexen cannot possibly know or evaluate all conceivable methods in which service may

be performed, or the possible hazardous consequences of each method. Accordingly, anyone who uses a procedure

that is not recommended by Nexen must first satisfy themselves that neither their safety or the safety of the product will

be jeopardized by the service method selected.

INSTALLATION

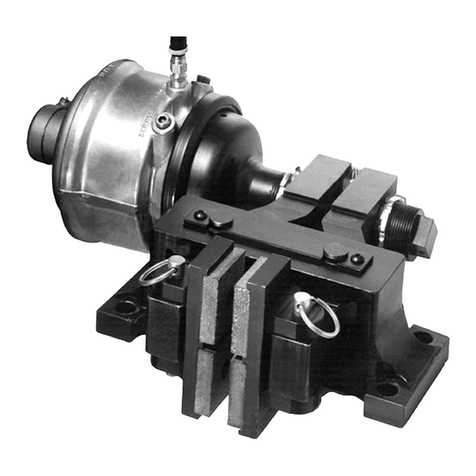

FMBS-875 MOUNTED ON A NEMA C-FACED

MOTOR (See Fig. 1)

1. Insert customer supplied key into motor shaft keyway.

2. Slide FMBS-875 onto motor shaft and secure with

customer supplied socket head cap screws.

3. Tighten customer supplied socket head cap screws

to 12 ft. lbs. [16 N•m] torque.

4. Install Housing Guard.

FMBS-875 MOUNTED BETWEEN GEAR REDUCER

AND NEMA C-FACED MOTOR (See Fig. 1)

1 Insert Nexen supplied Key (Item 26) into FMBS-875

output shaft.

2. Slide FMBS-875 output shaft into gear reducer.

3. Secure FMBS-875 to gear reducer, using customer

supplied socket head capscrews and lockwashers

4. Tighten customer supplied socket head cap screws

and lockwashers to 12 ft. lbs. [16 N•m] torque.

5. Mount NEMA C-Faced motor (See FMBS-875

MOUNTED ON A NEMA C-FACED MOTOR).

6. Install Housing Guard.

FIGURE 1

Input or

Motor End

Output or

Gearbox End

Nexen Supplied

Key

AIR CONNECTIONS

Although Nexen’s FMBS-875 is spring engaged and air

disengaged with a maximum operating air pressure of 80

PSI, use only enough air pressure to insure proper disen-

gagement for the application. Operating air pressures over

80 PSI will eventually cause bearing and seal damage.

For quick response, locate the control valve as close as

possible to the FMBS-875.

Align air inlet port to the six o’clock down position to

allow condensation to drain out of the exhaust port.