NexWatch ENGINERED SYSTEM PRO-2200 User manual

PRO-2200

Single Reader Enclosure

Installation Guide

Part Number: PRO22ENC4

WARNINGS AND CAUTIONS

WARNING

Before installation, turn off the external circuit breaker which supplies power to the system.

Before connecting the device to the power supply, verify that the output voltage is within specifications of the power supply.

Do not apply power to the system until after the installation has been completed. Personal injury or death could occur, and the equipment

could be damaged beyond repair if these WARNINGS are not observed!

Fire Safety and Liability Notice

Never connect card readers to any critical entry, exit door, barrier, elevator or gate without providing an alternative exit in accordance with

all fire and life safety codes pertinent to the installation.These fire and safety codes vary from city to city and you must get approval from

local fire officials whenever using an electronic product to control a door or other barrier. Use of egress buttons, for example, may be illegal

in some cities. In most applications, single action exit without prior knowledge of what to do is a life safety requirement. Always make cer-

tain that any required approvals are obtained in writing. DO NOT ACCEPT VERBAL APPROVALS, THEY ARE NOT VALID.

Engineered Systems never recommends using the PRO-2200 Series or related products for use as a primary warning or monitoring system.

Primary warning or monitoring systems should always meet local fire and safety code requirements.The installer must also test the system

on a regular basis and instruct the end user in appropriate daily testing procedures. Failure to test a system regularly could make installer

liable to the end user for damages if a problem occurs.

WARNING

EARTH ground all enclosures, for proper installation.

WARNING

Use suppressors on all door strikes. Use S-4 suppressors for installation. Engineered Systems recommends only DC strikes.

CAUTION

IF ANY DAMAGE TO THE SHIPMENT IS NOTICED, A CLAIM MUST BE FILED WITH THE COMMERCIAL CARRIER RESPONSIBLE.

CAUTION

Electro-static discharge can damage CMOS integrated circuits and modules.

To prevent damage always follow these procedures:

Use static shield packaging and containers to transport all electronic components, including completed reader assemblies.

Handle all ESD sensitive components at an approved static controlled workstation. These workstations consist of a desk mat, floor mat and

an ESD wrist strap.Workstations are available from various vendors.

NOTICE

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules when

wired using metal conduit for the cabling external to the enclosure.These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment.This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference that will require correcting at the users expense.

NOTICE

This document and the data in it shall not be duplicated, used or disclosed to others for procurement or manufacture, except as authorized

by and with the written permission of, Engineered Systems.The information contained in this document or in the product itself is considered

the exclusive property and trade secrets of Engineered Systems. Copyright laws of the United States protect all information in this docu-

ment or in the software product itself.

The information is this document is subject to change without notice.

TD1148rev0601

A division of Northern Computers, Inc.

CABLE SPECIFICATIONS

Application NCI Part No. AWG Description Max. Dist. Imp. Cap.

N-485 connections NC2442-TN N/A Belden 9842 4000' (1200 m) 120W 12.8pf/ft

N/A or equivalent

Readers/Keypads with NC1861-BL 18 6 conductor shielded 500' (152 m)

Wiegand style INTERFACE

Alarm input points NC 2221-BR 22 2000' (610 m)

Relay outputs NC 1821-OR 18 twisted pair, shielded 2000' (610 m)

Note: For plenum rated cable just add a “P” to Engineered Systems' NC part number prefix; for example NC1861-BL becomes NCP1861-BL.

NCI CABLE PART NUMBERS

Part Number Description Application Length

NC1841-GY 18 AWG/4 conductor reader cable 1,000' (304.8m)

NC1861-BL-500 18 AWG/6 conductor reader cable 500' (152m)

NC1861-BL 18 AWG/6 conductor reader cable 1,000' (304.8m)

NC18121-YL-500 18 AWG/12 conductor keypad cable 500' (152m)

NC18121-YL 18 AWG/12 conductor keypad cable 1,000' (304.8m)

NCNET-1 50 Ωnetwork cable 1,000' (304.8m)

NC2221-BR 22 AWG/2 conductor alarm cable 1,000' (304.8m)

NC1821-OR 18 AWG/2 conductor power/door cable 1,000' (304.8m)

NCC59206-BK RG-59 video cable 1,000' (304.8m)

NCP1841-GY 18 AWG/4 conductor Plenum reader cable 1,000' (304.8m)

NCP1861-BL-500 18 AWG/6 conductor Plenum reader cable 500' (152m)

NCP1861-BL 18AWG/6 conductor Plenum reader cable 1,000' (304.8m)

NCP18121-YL 18 AWG/12 conductor Plenum keypad cable 1,000' (304.8m)

NCP18121-YL-500 18 AWG/12 conductor Plenum keypad cable 500' (152m)

NCPNET-1 50ΩPlenum network cable 1,000' (304.8m)

NCP2221-BR 22 AWG/2 conductor Plenum alarm point cable 1,000' (304.8m)

NCP1821-OR 8 AWG/2 conductor Plenum power/door cable 1,000' (304.8m)

NC2442-TN 24 AWG/120 Ω12.8pf RS485 wire communication cable 1,000' (304.8m)

NCP2442-TN 24 AWG/120 Ω12.8pf Plenum communication cable 1,000' (304.8m)

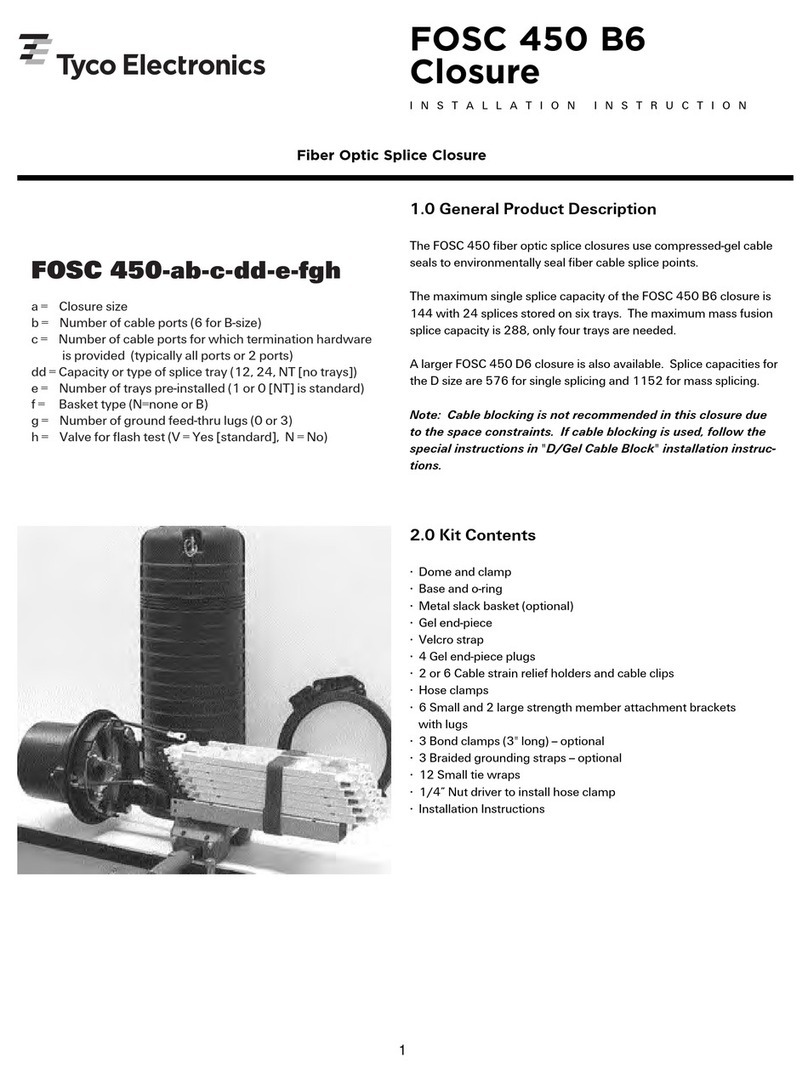

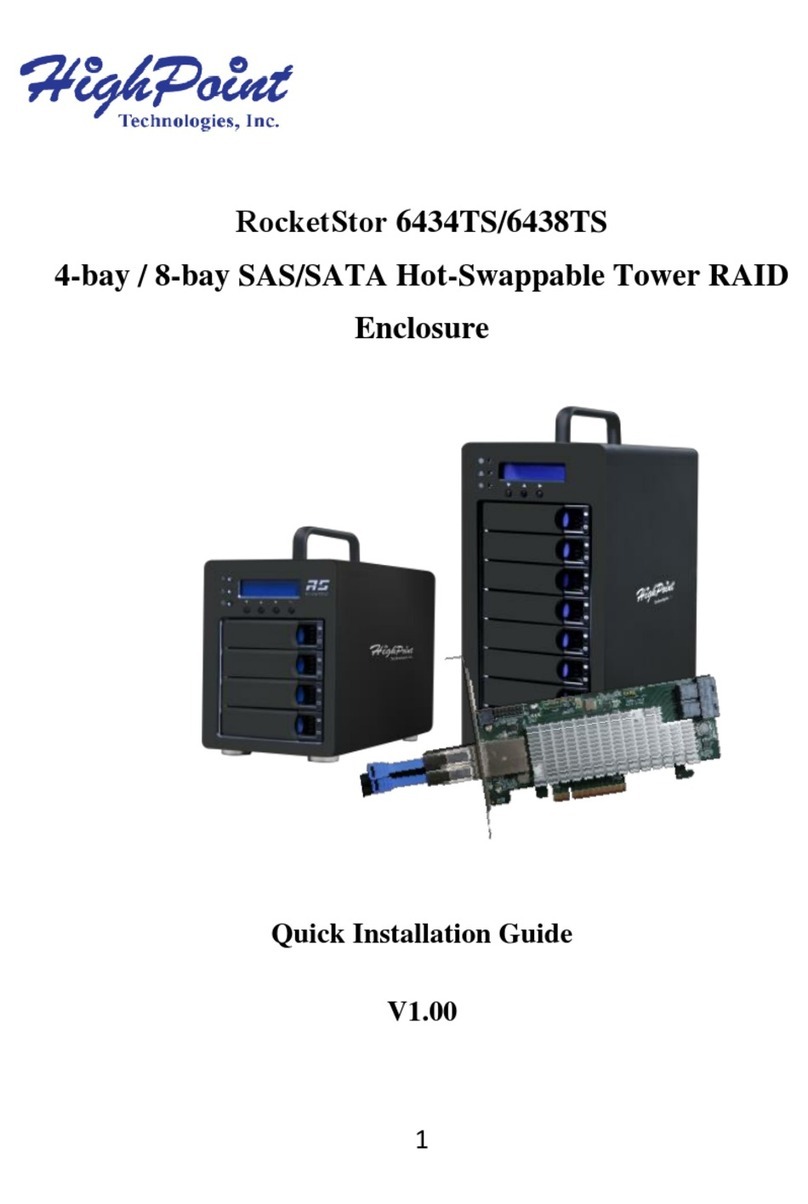

Small PRO-2200 Enclosure - PRO22ENC4

Installation Guide

4

SHAPING SECURITY THROUGH CREATIVE SOLUTIONS

5007 South Howell Ave • Milwaukee, WI 53207 USA • Tel: (414)769-5980 or (800)323-4576

A division of Northern Computers, Inc.

NOTICE

Any use of this product is subject to the terms and acceptance of the Engineered Systems Software Agreement. Please request a copy from

Engineered Systems, and review the agreement carefully.

DISCLAIMER

PRODUCT LIABILITY; MUTUAL INDEMNIFICATION

In the event that a Customer receives a claim that a Product or any component thereof has caused personal injury or damage to property of

others, Customer shall immediately notify Engineered Systems in writing of all such claims. Engineered Systems shall defend or settle such

claims and shall indemnify and hold Customer harmless for any costs or damages including reasonable attorneys’ fees which Customer may be

required to pay as a result of the defective Product or the negligence of Engineered Systems, its agents, or its employees.

Customer shall hold harmless and indemnify Engineered Systems from and against all claims, demands, losses and liability arising out of dam-

age to property or injury to persons occasioned by or in connection with the acts or omissions of Customer and its agents and employees, and

from and against all claims, demands, losses and liability for costs of fees, including reasonable attorneys’ fees, in connection therewith.

UNPACKING PROCEDURE

CAUTION

If any damage to the shipment is noticed before unpacking, a claim must be filed with the commercial carrier.

All containers should be opened and unpacked carefully in order to prevent damage to the contents.

The following steps are used to unpack equipment in preparation for installation:

1. Open the container and remove the unit(s) and all packing material. Retain the container and all packing materials.They may be used again

for reshipment of the equipment, if needed.

2. Inspect the contents for shortage. If items are missing, contact the order entry department at 800-323-4576.

3. Visually check contents. If damage is discovered, perform the following:

• If shipping caused damage to the unit, a claim must be filed with the commercial carrier.

• If any other defect is apparent, call 800-323-4576 for a return authorization.

SHIPPING INSTRUCTIONS

To ship equipment back to Engineered Systems:

1. Contact the customer service department at 800-323-4576 before returning equipment. When calling, please have available:

• A description of the problem or reason for returning the equipment.

• Original purchase order number, invoice number and whether or not the unit is still under warranty.

• A new purchase order number if the unit is not under warranty.

2. Obtain the Return Authorization Number (RMA) from the customer service department at 800-323-4576.

3. Show the RMA number on all packages shipped. Packages not marked with an RMA number will be refused at the factory and returned

COD.

4. Carefully pack the equipment for shipment. Use the original packing material whenever possible.

LIMITED WARRANTY

All Products sold or licensed by Engineered Systems include a warranty registration card which must be completed and returned to Engineered

Systems by or on behalf of the end user in order for Engineered Systems to provide warranty service, repair, credit or exchange. All warranty

work shall be handled through the Customer which shall notify Engineered Systems and apply for a Return Merchandise Authorization (RMA)

number prior to returning any Product for service, repair, credit or exchange. Engineered Systems warrants that its Products shall be free from

defects in materials and workmanship for a period of two years from date of shipment of the Product to Customer.The warranty on Terminals,

Printers, Communications Products and Upgrade kits is 90 days from date of shipment. Satisfaction of this warranty shall be limited to repair or

replacement of Products which are defective or defective under normal use. Engineered Systems’ warranty shall not extend to any product

which, upon examination, is determined to be defective as a result of misuse, improper storage, incorrect installation, operation or maintenance,

alteration, modification, accident or unusual deterioration of the Product due to physical environments in excess of the limits set forth in Product

manuals.THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THIS PROVISION. THIS WARRANTY IS IN LIEU OF ALL OTHER WAR-

RANTIES WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE. NO REPRESENTATION OR WARRANTY OF THE DISTRIBUTOR SHALL EXTEND THE LIABILITY OR

RESPONSIBILITY OF THE MANUFACTURER BEYOND THE TERMS OF THIS PROVISION. IN NO EVENT SHALL ENGINEERED SYSTEMS

BE LIABLE FOR ANY RE-PROCUREMENT COSTS, LOSS OF PROFITS, LOSS OF USE, INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES TO ANY PERSON RESULTING FROM THE USE OF ENGINEERED SYSTEMS’ PRODUCTS.

CONFIDENTIALITY

All software, drawings, diagrams, specifications, catalogs, literature, manuals and other materials furnished by Engineered Systems relating to the

design, use and service of the Products shall remain confidential and shall constitute proprietary rights of Engineered Systems and Customer

agrees to treat such information as confidential. Customer shall acquire no rights in the design of the Products or the related materials except to

use such information solely for the purpose of and only during the time it sells the Products. Customer shall not copy the design of any of the

Products or use or cause to be used any Product design or related materials for its own benefit or for the benefit of any other party.The covenants

contained in this section shall remain effective throughout the term of this Agreement and thereafter unless specifically waived by Engineered

Systems in writing.

DIMENSIONS

Height: 8.375" (21.275cm) Width: 7.625" (19.4cm) Color: Grey

Depth: 7.625" (19.4cm) Metal thickness: .05" (.127cm)

Installation holes: Single ended hanging slots for mounting the cabinet in the

upright position.The 3 hangers are in a triangular pattern. The top two are

located .75" (1.9cm) from the top and spaced 6.125" (15.5cm) apart.The lower

hanger is located .930" (2.36cm) from the bottom and 7.85" (19.9cm) from

each edge. See Enclosure Drawing.

Dual Conduit Knockouts: ½" & 1" (1.27cm x 2.54cm)

Top Side: 1

Bottom Side: 0

Right Side: 1

Left Side: 2

Rear Side: 1

POWER SUPPLY

DO NOT USE POWER SUPPLY TO POWER LOCKS.

PRO22E4PS:12 VDC 1.2 amp continuos power limited output with backup

battery charging. 16.5 VAC 20va wall transformer provided.

Requires 115 VAC/60hz, Maximum battery charge current .5amp

AC on LED

Short circuit and thermal overload protection

All power connection should be made with 18ga or larger wiring

LED DIAGNOSTICS

AC LED DC LED

ON ON Normal operating conditions

OFF ON Loss of AC, standby battery supplying power

ON OFF No DC output

OFF OFF Loss of AC, Discharged or no Stand-by battery.

No DC output.

BACKUP POWER SUPPLY

Automatic Switch over to stand-by battery when AC fails (zero voltage drop)

4.0 AH sealed rechargeable battery

Backup time: 2.5 to 4 hour depending on configuration

CABLES SUPPLIED

Power On Light assembly

Tamper Switch assembly

MAINTENANCE

Replace the 12V 4AH battery every 2 to 2.5 years

Oil the hinges on the door every 12 months

OPERATING PARAMETERS

Temperature: 35 to 110 C (2 to 43 C)

Operating Humidity: Up to 85% non-condensing

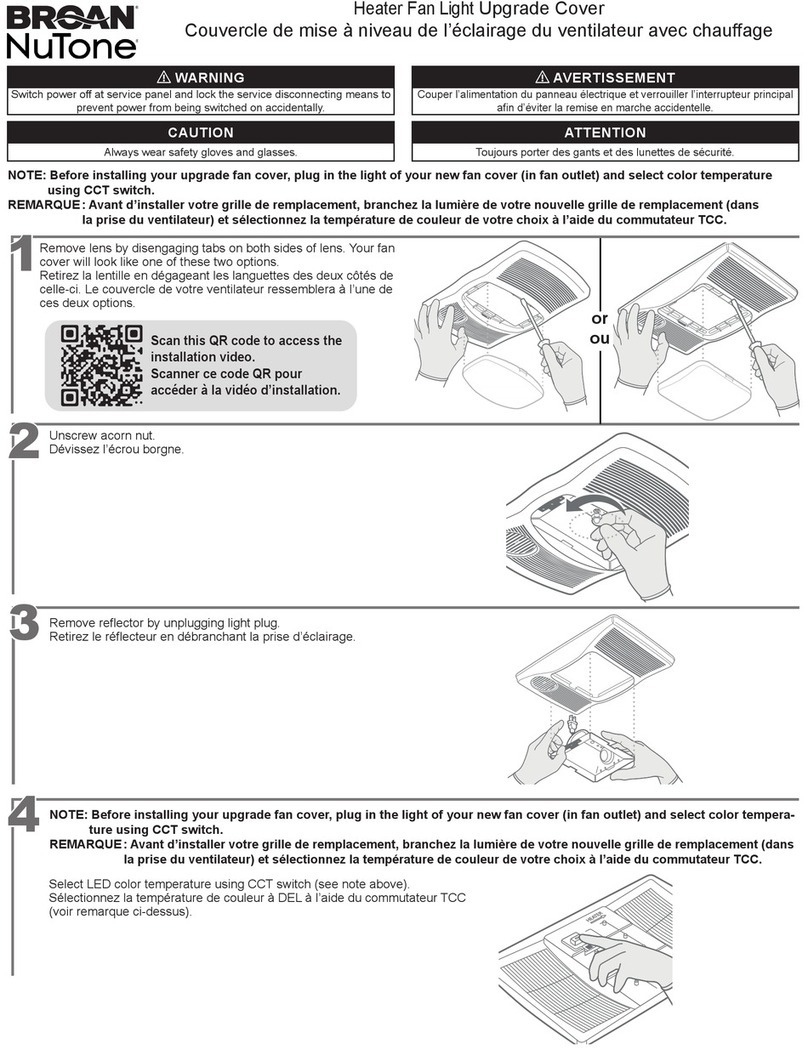

INSTALLATION INSTRUCTIONS

1. Remove the 16.5V 20VA wall transformer, battery and parts bag from the

enclosure.

2. Add all eight plastic standoffs into the mounting holes forming an upper and

lower square.

3. Measure and install the top two mounting screws with heads smaller than .4"

using proper mounting techniques for the material being used to hold the

PRO22ENC4. Space the screws 6 1/8" apart. Leave the screws exposed

approximately 1/2".

4. Open the door of the enclosure and place the hanging slots over the mounting

screws. Push the enclosure over the mounting screws and allow the screws to

slide into the slots. Finish tightening the mounting screws to securely hold the

enclosure. Screw in the lower hanger to secure the enclosure against the wall.

5. Install the tamper switch cable to the bottom two screws on the tamper switch.

Slide the tamper switch holder onto the upper right corner of the enclosure.

Push the tamper switch cable and the tamper switch through the center hole of

the tamper switch holder.

6. Mount the Power on Light assembly to the enclosure by passing the wire ends

from the outside to the inside of the enclosure through the ¼" hole located on

the upper right side of the enclosure. Secure the Power on Light by sliding the

retaining ring over the wires and onto the light holding it snug to the wall of the

enclosure.

7. Run all appropriate wiring to the case. Mark each wire as to the panel, location

and input type. All cable shields should tie to the grounding stud found on the

upper left side of the enclosure.

8. Install the single reader panel onto the 4 standoffs in the bottom left of the

enclosure, placing the power and communications to the top.

9. Wire the readers, input and output connections by removing the terminals for

ease of wiring. Wire according to installation guide supplied with the single

reader panel.

10. CHECK ALL CONNECTIONS PRIOR TO POWERING UP THE ENCLOSURE

AND PANELS.

11. Mount the PRO22E4PS power supply to the 4 standoffs at the upper right of the

enclosure.Place the terminal strip to the right. Connect the two supplied battery

cables: RED to Batt+, BLACK to Batt-. Wire the PRO22E4PS power supply

through the wall transformer provided. Connect to the AC terminals. Wire the

Power on Light to the AC in connections on the power supply. Plug in the Wall

transformer. The Power on Light should light. Check the voltage at ±DC. The

voltage should be approximately 13.8 VDC.

12. Disconnect the power.

13. Connect the DC power to the panel. Insure that the connection has the correct

polarity. Follow the wiring diagram supplied with the panels.

14. Connect the Tamper Switch cable to the two pin connector "9" located on the

mid right of the panel. See individual panel wiring diagrams supplied with the

panel.

15. Connect Communications wiring per the wiring diagram supplied with the panel.

16. Place the 12V 4AH battery in the cabinet on the bottom right hand side. Attach

the red battery charging connection to the positive terminal of the battery and

the black battery charging connection to the negative connection of the battery.

17. CHECK ALL CONNECTIONS PRIOR TO POWERING UP THE ENCLOSURE

AND PANELS.

Small PRO-2200 Enclosure - PRO22ENC4

Installation Guide

2Small PRO-2200 Enclosure - PRO22ENC4

Installation Guide

3

This manual suits for next models

1

Other NexWatch Enclosure manuals