NexWatch PW-5000 User manual

PW-5000

Enclosure

Installation Manual

Part Number: PW5K2ENC1

PW5K2ENC2

TD1151rev1101

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 3Installation Guide

TD1151 rev1101

Contents

Warnings and Cautions ................................................................................... 4

Disclaimer........................................................................................................... 6

Product Liability; Mutual Indemnification................................................................ 6

Unpacking Procedure ........................................................................................... 6

CAUTION ........................................................................................................... 6

Shipping Instructions ............................................................................................ 7

Limited Warranty ................................................................................................. 7

Confidentiality ..................................................................................................... 8

PW-5000 Enclosure...................................................................................... 9

Description .......................................................................................................... 9

Dimensions ....................................................................................................... 10

Conduit Knockouts ............................................................................................. 10

Power Supply ..................................................................................................... 10

Maintenance ..................................................................................................... 10

Installation Instructions ....................................................................................... 10

Installation Diagram .......................................................................................... 11

UL1076 Setup ............................................................................................. 12

PC Minimum Requirements ................................................................................. 12

Peripheral Hardware Requirements...................................................................... 12

Operating System Requirements ......................................................................... 12

Software Packages Required ............................................................................... 12

Receiving Unit minimum configuration ................................................................ 12

Priority of incoming signals for UL1076 ............................................................... 12

Other UL1076 Notes .........................................................................................13

Procedures ........................................................................................................ 13

Second PC Installation ....................................................................................... 14

Enterprise Manager Setup .................................................................................. 14

Pre-Redundancy Verification: ............................................................................... 15

DTS Package Verification .................................................................................... 15

Interim Steps Before Full Redundancy Verification ................................................. 15

Redundant Test Examples ................................................................................... 16

Dimensions ....................................................................................................... 16

Conduit Knockouts ............................................................................................. 17

Power Supply Enclosure ...................................................................................... 17

Installation Diagram .......................................................................................... 17

Dimensions ....................................................................................................... 17

Installation Instructions ...................................................................................... 18

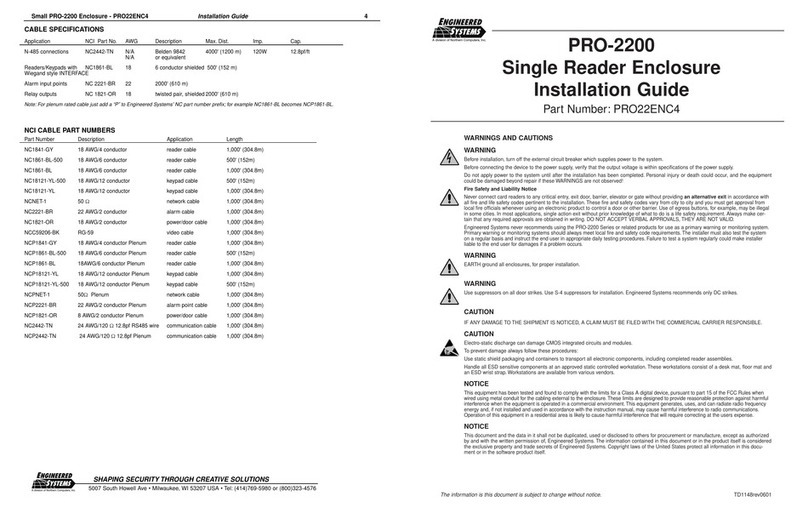

Cable Specifications .................................................................................. 19

NexWatch Cable Part Numbers ................................................................ 20

NOTES ........................................................................................................ 21

4 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

Warnings and Cautions

WARNING

Before installation, TURN OFF the external circuit breaker which supplies power to the

system.

Before connecting the device to the power supply, verify that the output voltage is within

specifications of the power supply.

Do not apply power to the system until after the installation has been completed.

Personalinjuryor deathcould occur,and the equipment could be damaged beyond repair

if this precaution is not observed!

WARNING

Fire Safety and Liability Notice

Never connect card readers to any critical entry, exit door, barrier, elevator or gate without

providing an alternative exit in accordance with all fire and life safety codes pertinent to

the installation.These fire and safety codes vary from city to city and you must get

approval from local fire officials whenever using an electronic product to control a door or

other barrier. Use of egress buttons, for example, may be illegal in some cities. In most

applications, single action exit without prior knowledge of what to do is a life safety

requirement.Always make certain that any required approvals are obtained in writing.DO

NOT ACCEPTVERBAL APPROVALS,THEY ARE NOTVALID.

NexWatch never recommends using the PW-5000 or related products as a primary warning

or monitoring system. Primary warning or monitoring systems should always meet local

fire and safety code requirements.The installer must also test the system on a regular

basis by instructing the end user in appropriate daily testing procedures.Failure to test a

system regularly could make installer liable for damages to the end user if a problem

occurs.

WARNING

EARTH groundall enclosures, for proper installation.

EARTH groundcan beobtained through the power supply or by grounding the cabinet,

BUTNOTBOTH!

WARNING

Use suppressors on all door strikes.Use S-4 suppressors for installation.NexWatch

recommends only DC strikes.

The information in this document is subject to change without notice.

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 5Installation Guide

TD1151 rev1101

CAUTION

If any damage to the shipment is noticed, a claim must be filed with the responsible

commercialcarrier.

CAUTION

Electro-static discharge can damage CMOS integrated circuits and modules.

To prevent damage always follow these procedures:

Use static shield packaging and containers to transport all electronic components,

including completed reader assemblies.

Handle all ESD sensitive components at an approved static controlled workstation.These

workstations consist of a desk mat, floor mat and an ESD wrist strap.Workstations are

available from various vendors.

NOTICE

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules when wired using metal conduit for the

cabling external to the enclosure.These limits are designed to provide reasonable

protectionagainst harmful interference when the equipment is operated in a commercial

environment.This equipment generates,uses,and can radiateradio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause

harmfulinterference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference that will require correction at the users ex-

pense.

NOTICE

This document and the data in it shall not be duplicated, used or disclosed to others for

procurement or manufacture, except as authorized by and with the written permission of

NexWatch, Inc.The information contained in this document or in the product itself is

considered the exclusive property and trade secrets of NexWatch.Copyright laws of the

United States protect all information in this document or in the software product itself.

NOTICE

Any use of this product is subject to the terms and acceptance of the NexWatch Software

Agreement.Please request a copy from NexWatch, and review the agreement carefully.

6 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

Disclaimer

Product Liability; Mutual Indemnification

In the event that a Customer receives a claim that a Product or any component thereof

has caused personal injury or damage to property of others, Customer shall immediately

notify NexWatch in writing of all such claims.NexWatch shall defend or settle such claims

and shall indemnify and hold Customer harmless for any costs or damages including

reasonable attorneys’ fees which Customer may be required to pay as a result of the

defective Product or the negligence of NexWatch, its agents, or its employees.

Customer shall hold harmless and indemnify NexWatch from and against all claims,

demands, losses and liability arising out of damage to property or injury to persons

occasioned by or in connection with the acts or omissions of Customer and its agents and

employees, and from and against all claims, demands, losses and liability for costs of

fees,including reasonableattorneys’ fees,in connectiontherewith.

Unpacking Procedure

CAUTION

If any damage to the shipment is noticed before unpacking, a claim must be filed with the

commercialcarrier.

All containers should be opened and unpacked carefully in order to prevent damage to the

contents.

The following steps are used to unpack equipment in preparation for installation:

1. Open the container and remove the unit(s) and all packing material. Retain the

container and all packing materials. They may be used again for reshipment

of the equipment, if needed.

2.Inspect the contents for shortage. If items are missing, contact the order entry

departmentat800-227-1667Option-2.

3.Visually check contents.If damage is discovered, perform the following:

If shipping caused damage to the unit, a claim must be filed with the

commercialcarrier.

If any other defect is apparent, call 800-227-1667 Option-2 for a return authorization.

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 7Installation Guide

TD1151 rev1101

Shipping Instructions

To ship equipment back to NexWatch:

1.Contactthe customer servicedepartmentbefore returning equipment at 800-227-1667

Option-2. Pleasehave the following available when calling:

• A description of the problem or reason for returning the equipment.

• Original purchase order number, invoice number and if the unit is under warranty.

• A new purchase order number if the unit is not under warranty

2.From the customer service department, obtain the Return Authorization Number (RMA).

3.Show the RMA number on all packages shipped.Packages, which are not marked with

an RMA number will be refused at the factory and returned COD.

4.Carefully pack the equipment for shipment. Use the original packing material whenever

possible.

Limited Warranty

All Products sold or licensed by NexWatch include a warranty registration card which

must be completed and returned to NexWatch by or on behalf of the end user in order for

NexWatch to provide warranty service, repair, credit or exchange. All warranty work shall

be handled through Customer which shall notify NexWatch and apply for a Return Mer-

chandise Authorization (RMA) number prior to returning any Product for service, repair,

credit or exchange. NexWatch warrants that its Products shall be free from defects in

materials and workmanship for a period of two years from date of shipment of the Product

toCustomer.ThewarrantyonTerminals,Printers,CommunicationsProducts and Upgrade

kits is 90 days from date of shipment. Satisfaction of this warranty shall be limited to

repair or replacement of Products which are defective or defective under normal use.

NexWatch’warranty shall not extend to any Product which, upon examination, is deter-

mined to be defective as a result of misuse, improper storage, incorrect installation,

operationor maintenance,alteration, modification,accident orunusual deteriorationof the

Product due to physical environments in excess of the limits set forth in Product manuals.

THEREARE NOWARRANTIESWHICHEXTEND BEYONDTHIS PROVISION.THIS

WARRANTY IS IN LIEU OF ALL OTHERWARRANTIES WHETHER EXPRESS, IMPLIED

ORSTATUTORY,INCLUDINGIMPLIEDWARRANTIESOF MERCHANTABILITYOR

FITNESSFOR ANY PARTICULARPURPOSE.NO REPRESENTATIONORWARRANTY

OFTHE DISTRIBUTOR SHALL EXTENDTHE LIABILITY OR RESPONSIBILITY OFTHE

MANUFACTURER BEYONDTHETERMS OFTHIS PROVISION.IN NO EVENT SHALL

NEXWATCH BE LIABLE FOR ANY RE-PROCUREMENT COSTS, LOSS OF PROFITS,

LOSS OF USE, INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGESTO ANY

PERSONRESULTING FROMTHE USE OF NEXWATCH’PRODUCTS.

8 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

Confidentiality

All software, drawings, diagrams, specifications, catalogs, literature, manuals and other

materials furnished by NexWatch relating to the design, use and service of Products shall

remainconfidential andshall constitute proprietary rightsof NexWatch,andCustomer

agrees to treat such information as confidential. Customer shall acquire no rights in the

design of Products or the related materials except to use such information solely for the

purpose of and only during the time it sells Products. Customer shall not copy the design

of any Products or use or cause to be used any Product design or related materials for its

own benefit or for the benefit of any other party.The covenants contained in this section

shall remain effective throughout the term of this Agreement and thereafter unless specifi-

cally waived by NexWatch in writing.

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 9Installation Guide

TD1151 rev1101

PW-5000 Enclosure

Description

The PW-5000 system is designed for maximum efficient use of wall space through the

use of a secure metal cabinet (PW5K2ENC1/PW5K2ENC2) that can hold up to nine

modules,a 4amp powersupply (PW5K2E1PS)and aself-contained replaceable

backupbattery.

Typically,one of the nine modules can be an intelligent controller(PW55K1IC/PW3K1IC).

The remaining eight slots can be used and configured in a variety of combinations of

readers,

supervised inputs, relay outputs and other specialized modules to customize the system

for the individual site.

ThePW5K2ENC1/PW5K2ENC2 canbe configuredin anycombination ofthe PW5K1IC,

PW3K1IC, PW5K1IN, PW5K1OUT,PW5K1R2 andPW5K1R1.An optional daisy chain

cable(PW5K1DCC) provides anRS-485 communicationand power busbetween the

ninemodules.

PW5K2ENC1 / PW5K2ENC2

10 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

Dimensions ENC1 ENC2

Height: 13.9" [0.353 m] 13.9" [0.353 m]

Width: 17" [0.4318 m] 18.9" [0.48006 m]

Depth: 9" [0.2286 m] 9" [0.2286 m]

Metal thickness: .05" [1.27 mm]

Color:AutumnWhite

Installation holes: Four hangers in a rectangular pattern 12.1” [0.30734 m] H x 16"

[0.40640m]W

Conduit Knockouts

½" [0.0127 m] 2" [0.05080 m]

Back: 9 2

Top: 9 2

Right Side: 2 1

Left Side: 2 1

Power Supply

Use PW5K2E1PS or other approved power supply.(See Installation Manual for details).

Maintenance

Oil lock once per year.If battery backup is used, change battery every 2 to 2 1/2 years.

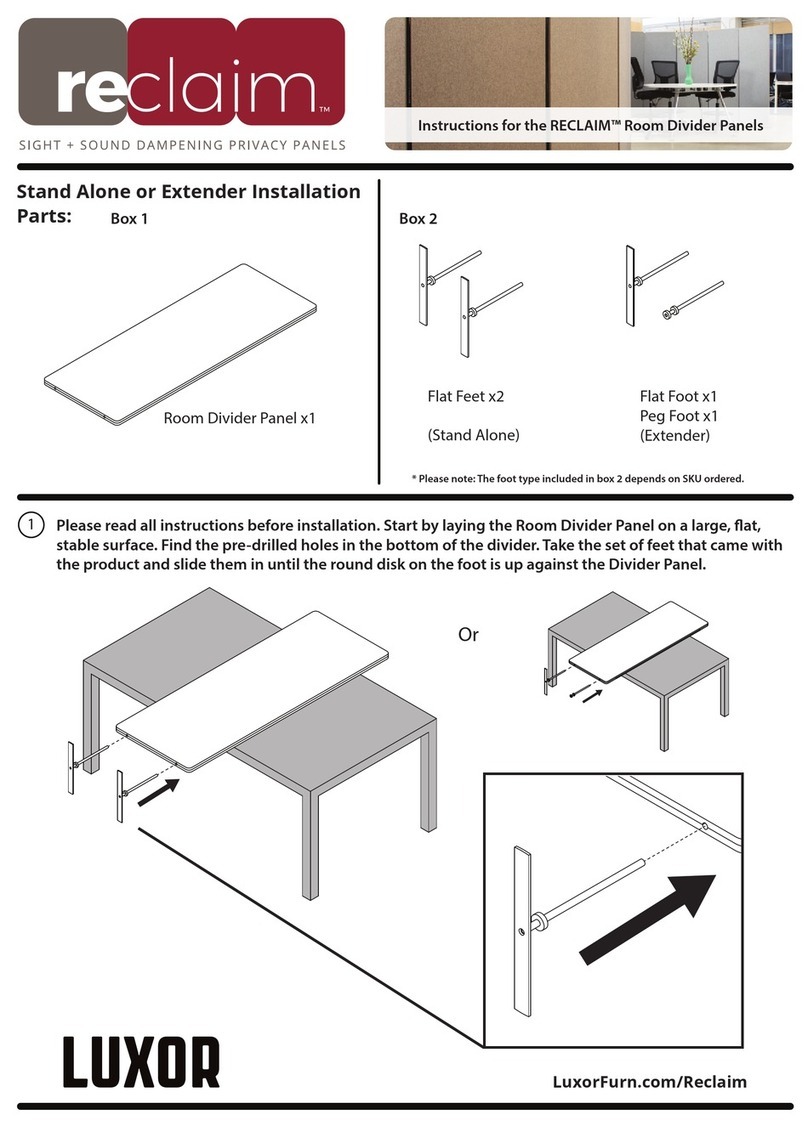

Installation Instructions

1. Measure and install four mounting screws with heads smaller than .4" [0.01016 m]

using proper techniques for the material on which the PW-5000 is being mounted.Use

a rectangular screw pattern 12.1" [0.30734 m] H x 16" [0.40640 m]W.Leave the

screws exposed approximately 1/2" [0.0127 m].

2. Open the door of the enclosure and place the hanging slots over the mounting screws.

Push the enclosure over the mounting screws and allow the screws to slide into the

slots. Finish tightening the mounting screws to securely hold the enclosure.

3. Run all appropriate wiring to the case. Mark each wire as to the panel, location and

input type. All cable shields should tie to one of the grounding lugs found at the top of

theenclosure.

4. Install the required panels into the metal runners.The PW5K2E1PS should be placed

in the right most location and installed according to its own instruction manual.The

PW5K1IC should be installed next to it as the right-most panel.

5. Wire the readers, input and output connections (see wiring guide at end of manual)

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 11Installation Guide

TD1151 rev1101

6. CHECKALL CONNECTIONS PRIORTO POWERING UPTHE ENCLOSURE

AND PANELS.

7. Theremainder of the panels can be manuallywired forpower andRS-485

communications using 18 AWG wire.The wires will be daisy-chained from one panel

to the next so the power and the communications are wired in parallel. PW5K1DCC is

available as an option to be purchased with the equipment.This will reduce wiring time

in the field since the power and RS-485 communications between panels is factory-

wired in a harness that plugs into the bottom two connectors on each panel.The only

field wiring required is the two wiring connections of the red and black 12VDC cables

connectingthe PW5K1DCC and the PW5K2E1PS powersupply.

Installation Diagram

PW5K2ENC1

PW5K2ENC2

12 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

UL1076 Setup

PC Minimum Requirements

Tworequired:

• 500 Mhz • 128Mb RAM

• 9.1Gb hard drive • CD ROM

• 10/100TX network card • 17”SVGA Monitor

Peripheral Hardware Requirements

• UL approved network HUB with at least 4 ports.

• UL approved CAT 5 network cable and connectors.

•PW5K1IC/PW3K1IC Controllerand accompanyingI/O boards.

•Network card (conrollermounted)

Operating System Requirements

•Windows 2000 Server.

•Windows 2000 Service Pack 2 or higher.

Software Packages Required

• Microsoft SQL Server 2000.

• Microsoft SQL Server 2000 Service Pack 1 or higher.

•PROWATCHCorporateEditionRelease4 or higher.

Receiving Unit minimum configuration

•PW5K2ENC1 or PW5K2ENC2 cabinet

• PW5K1E5PS (ALTRONIX AL400 ULX) power supply with 40 AH battery back up

•PW5K1IC/PW3K1IC controller panel

•PW5K1IN input panel

•PW5K1EN LantronixEthernet cardor pw3k1enCobox Ethernetcard

•PW5K1ENSPTripp LiteDNET1 Ethernet surge protector

The following priority of incoming signals must be used for UL1076

1. Fire alarm (N/A) PROWATCH is not certified for fire alarm supervision

2. Hold up / Panic alarm

3. Burglaralarm

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 13Installation Guide

TD1151 rev1101

4. Watchmantour

5. Fire alarm supervision (N/A) PROWATCH is not certified for fire alarm supervision

6. Burglaralarm supervision

7. Industrialsupervision

8. Other supervisory services

NOTE: 2 and3 may have equal priority: 5 and 6 may have equal priority &

7 and 8 may have equal priority

Other UL1075 Notes

• All alarms and troubles must be acknowledged by attending guard.

• Reports of all alarms and troubles must be printed and stored at least once per week.

• When communications are disrupted from the protected area unit to the Central

Supervisory station all panels must be buffered.They must transmit all stored alarms

andtroubles tothe CentralSupervisory Stationwhen communicationsare restored.

• If Cameras are used they must be UL approved. Camera operation was not verified by

UL.

• GuardTour was not verified by UL to NFPA 72 standards

• Exit and Entry Delay can not exceed 60 seconds.Polling of a receiving unit may

not exceed 200 seconds

Procedures

1.Configure the PC’s by installing theWindows 2000 Server.

A. PC names should be unique and described with Alpha characters.

B. IP addresses should be unique and have the same Subnet Mask.

C. Each PC should be of the same workgroup name.

2. InstallWindows 2000 Service Pack 2 or higher.

3. Install SQL Server 2000. Select either NT Authentication or Local System, but be

consistent with both PC installations.

4. Install SQL Server 2000 Service Pack 1.

5.Setup the Lantroix PW5K1EN or PW3K1EN per it’s installation manual.

6. Createa domain admin user account.

7. Install the PROWATCH Software on the MAIN PC.

A. Select Full Installation.

B. Select SQL for Database.

C.Upon reboot of the PC, stop the PROWATCH Service.

14 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

8. Launchthe User Interface.Thedatabase shouldnow be programmed to accommodate

the PW5K1IC panel and accompanying I/O boards. Refer to the PROWATCH Installa-

tion Manual for additional detail.The programming should continue until the system is

fully functional andcommunications havebeen established.Below arethe program-

mingrequirements forsetting upthe PW5K1ICpanel.

A.TCP/IP channelselection requiredwhen adding a newPW5K1IC.

B.UniqueTCP/IP address is required for assignment to the panel and should match

the IP address you programmed through the Ethernet setup software.

C. Program all the downstream devices for the hardware so that you will be able to

monitor the points and system alarms.

D. Once the program is configured, shut down the User Interface and restart the

service.LaunchtheUserInterfaceandverifycommunications.

E.Program aControl Mapand/or Floorplanswiththe hardware.Example:Panels,

SIO boards, Inputs, Outputs, readers, Comm Server.

NOTE: Use the SQL Enterprise Manger to backup the programmed database. Refer to

the SQL Server Manual for instructions.

CAUTION: If the instructions describing the Data Transformation Services are not

followedexactly your database could be overwriten.

Second PC Installation

Follow Instructions 1 through 4 and 7 through 8 listed on pages 12 and 13.

Enterprise Manager Setup

1. Open up Enterprise Manager from the secondary PC, the PC you will use for Redun-

dancy.

2. Right-click and expand the SQL Server Group.

3. Right-clickand expand theComputer Name Group.

4. Right-click on the PROWATCH Database and select AllTasks then Import Data.

5. Click Next.Verify that the Server is selected as MAIN.The database should be

PROWATCH.(Thesourcedatabase)

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 15Installation Guide

TD1151 rev1101

6. Click Next.Change the Server to match the name of theLOCAL PC.The database

should be selected as PWNT from that Server.(The destination database).

7. Click Next.Select Transfer objects and data between SQL Server database.

8. ClickNext. Uncheckthe Create destination objects box.

9. Click Next. Check the Create DTS package for replication box. Also check the Save

DTS Package box.Leave the radial button set for SQL Server.This menu saves the

replication using a DTS package which will be run when the user wants to keep the

database current with the MAIN PC.

10. Click Next. Change the name or accept the default for the local package being

created. Leave the Server name as LOCAL. Select either NT Authentication or SQL

ServerAuthentication, whichevermatches yourrequirements.

11.Click Next.Select finish and DO NOT ABORTTHIS PROCESS.This DTS process

will import all the data from the MAIN PC to the Redundant PC.When the transfer is

successful, click OK.

12. If a PublicationWizard opens select Cancel.Use the SQL Server Manual to utilize

this feature later, however it is not required for this setup.Click Done and minimize

EnterpriseManager.

Pre-Redundancy Verification:

1. Stop all the services on the MAIN PC.

2. Start services on the Redundant PC and launch the User Interface.Log in as ADMIN.

3. Verify that the data is consistent with the MAIN PC.

4. Verify communication with the hardware by using the AlarmView, Control Map or

Floorplans.

5. Next, close the user interface and stop the services on the Redundant PC.

DTS Package Verification

1. MaximizeEnterprise Manager andlocate theDataTransformation ServicesFolder.

Expand the folder and the click on Local Packages.

2. Find the Local Package that was created earlier.Double-click on the package to open

up the DTS menu.Select Package on the menu bar and then Execute.

3. The DTS package will run until it is done transferring the data from the MAIN PC to

theREDUNDANT one.

4. Follow steps 1-5 in the Pre-Redundancy Section on page 14.

Interim Steps Before Full Redundancy Verification

1. Shut down the Redundant PC.

2. Restart all the service on the MAIN PC.Launch the User Interface and verify that

communicationshave resumed.

16 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

Redundant Test Examples

NOTE: Stop watch needed for all three test examples.

Example #1

1. Use the MAIN PC’s OFF button to shut it down.Turn on the REDUNDANT PC and

start the stop watch.

2. Log into NT with Administrator rights.

3. Launch the User Interface.

4. Openthe EventViewer.When theReturnedPanel Communications Normalappears,

stop the stop watch.This time represents the amount of time that has passed since

theMAIN PC wentdown.

Example #2

1. Unplug the power to the MAIN PC.Turn on the REDUNDANT PC and start the stop

watch.

2. Log into NT with Administrator rights.

3. Launch the User Interface.

4. Openthe EventViewer.When theReturnedPanel Communications Normalappears,

stop the stop watch.This time represents the amount of time that has passed since

theMAIN PC wentdown.

Example #3

1. Unplug the network cable from the HUB for the MAIN PC.Turn on the REDUN-

DANT PC and start the stop watch.

2. Log into NT with Administrator rights.

3. Launch the User Interface.

4. Openthe EventViewer.When theReturnedPanel Communications Normalappears,

stop the stop watch.This time represents the amount of time that has passed since

the MAIN PC went off line.

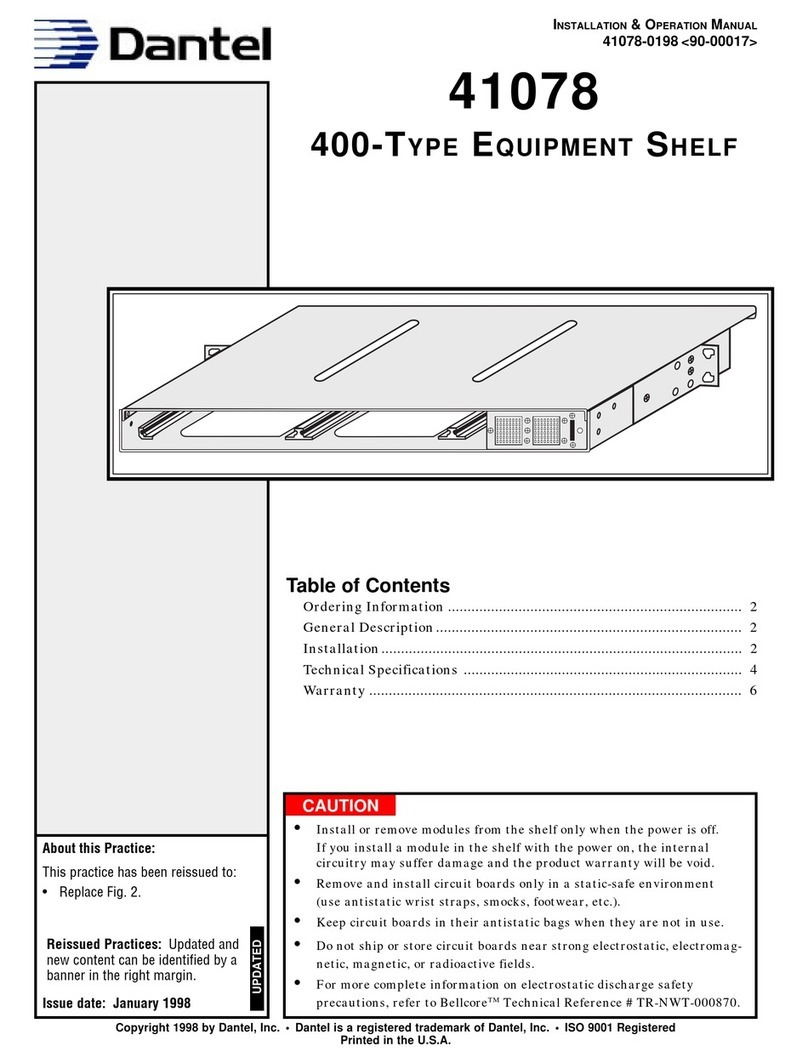

Power Supply Dimensions

Height:15.5"(39.4cm)

Width:12" (30.5cm)

Depth:4.5"(11.43cm)

Color: Grey

Installation holes:Four hangers in a rectangular pattern 13.5" H x 9.825"W (34.3cm

H x 25cmW)

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 17Installation Guide

TD1151 rev1101

Power Supply Enclosure

+ DC -

AL400ULXB

L G N

ALTRONIX CORP.

BKLYN,N.Y.

11220

MADE IN

USA

PTC3

NO C NC NO C NC

+ BAT -

DC

24V -

OPEN

12V -

CLOSED

AC

FAIL

RL

2

BAT

FAIL

RL

1

RL

3

DC Output

to devices

(power limited)

Battery and AC

Supervision Circuit

(non-power limited)

CAUTION: De-energize unit prior to servicing.

For continued protection against fire hazard replace

fuse with the same type and rating 3.5A, 250V

Green Lead

Battery connection

(non power limited)

Switch Position:

24VDC = SW1 OPEN

12VDC = SW1 CLOSED

SW1

Wire Strap

(from Enclosure to Door)

115 power

mains

Fuse

Strain

Relief

To Battery Enclosure

with 40AH Battery

AL400ULX Assembly diagram for use with the PRO22ENC1 and PRO22ENC2 for UL1076

Installation Diagram

Dimensions

.875" 1.3"

2"

1.22"

3.25"

1"

2"

1.22"

1.25"

2.2"

15.5"

(2.22cm)

(3.1cm)

(5.08cm)

(3.3cm)

(2.54cm)

1"

(2.54cm)

(39.4cm)

(5.1cm)

(3.09cm)

(8.25cm)

(5.58cm)

(3.16cm)

(5.71cm) (9.34cm) (11.6cm)

2.25" 3.68" 4.56"

1.22"

12"

4.5"

(30.5cm)

(3.1cm)

(11.4cm)

(5.71cm) (9.34cm) (11.6cm)

2.25" 3.68" 4.56"

1.22"

(3.1cm)

Conduit Knockouts

3/4”

Top: 3

Bottom: 3

Right Side: 3

Left Side: 1

ALTRONIX AL400ULX (PW5K1ESPS)

18 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

Installation

Installation Instructions

1. InstallthePW5K1E5PS(AltronixAL400ULX)powersupplyandbattery enclosure

perthesupplied instructions.

2. Measure and install four mounting screws with heads smaller than .4" (1cm) using

proper techniques forthematerial onwhich the PW5K2ENC1 or PW5K2ENC2 is being

mounted.Use a rectangular screw pattern 12.1" H x 16"W (0.307m H x 0.4064mW).

Leave the screws exposed approximately 1/2" (1.27cm).

3. Open the door of the enclosure and place the hanging slots over the mounting screws.

Push the enclosure over the mounting screws and allow the screws to slide into the

slots. Finish tightening the mounting screws to securely hold the enclosure.

4. Run all appropriate wiring to the case. All cable shields should tie to the grounding lug

found on the top of the enclosure.

5. Install the required panels into the runners.The PW5K1IC should be placed in the

right-most position.The PW5K1EN ethernet card should be mounted on the PRO22IC

prior to mounting in the enclosure. See panel instructions.

6. Wirethe readers, input and output connections.

7. CHECKALL CONNECTIONS PRIORTO POWERINGUPTHE ENCLOSUREAND

PANELS.

8. Wire the 12VDC, AC Fail, Battery Fail and tamper switch from the AL400ULX to the

enclosure. Make sure that the power supply is not powered up at the time.

9. Wire the 12VDC to the Panel on the far right first making sure that the polarity of the

wiresare correct.

10. Wire the tamper switch, AC Fail and Battery Fail to assigned inputs.

11. Wire the PW5K2ENC1 or PW5K2ENC2 tamper switch to the tamper input located on

the first panel on the right.

12. The remainderof thepanels canbemanually wiredfor powerand RS-485communica-

tions using 18 AWG wire.The wires will be daisy-chained from one panel to the next

sothe power and the communications are wired in parallel.

They may also be wired using the Auxiliary Rack Harness purchased with the equip-

ment.This will reduce wiring time in the field since the power and RS-485 communica-

tions between panels is factory-wired in a harness that plugs into the bottom two

connectors on each panel.The only field wiring required is the two wiring connections

of the red and black 12VDC cables connecting the Auxiliary Rack Harness and the

RackPower SupplyHarness.

13. CHECK ALLCONNECTIONSPRIORTO POWERINGUPTHE ENCLOSURE AND

PANELS.

14. Wire theTCP/IP connection to the network HUB.

PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2 19Installation Guide

TD1151 rev1101

Cable Specifications

Application Nexwatch Part No. AWG Description Max. Dist. Imp. Cap.

N-485 connections* NC2442-TN N/A Belden 9842 4000' (1200 m) 120Ω 12.8pf/ft

N/A or equivalent

CR-1, TR-1, CI-1, KR-1 NC1861-BL 18 6 conductor shielded 500' (152 m)

Wiegand card readers

NR-1 magstripe reader NC1861-BL 18 6 conductor shielded 500' (152 m)

PR-1-280 Cotag reader:

280 read head to SZC NC1861-BL 18 6 conductor shielded 300' (91 m)

SZC to N-1000-II NC1861-BL 18 6 conductor shielded 500' (152 m)

PR-2 Hughes reader:

scanner to reader NC1861-BL 18 6 conductor shielded 30' (9 m)

reader to N-1000-II NC1861-BL 18 6 conductor shielded 500' (152 m)

PR-3, PR-5 Indala readers:

A-3/A-5 read head to RE-2 NC18121-YL 18 12 conductor shielded 75' (23 m)

RE-2 to N-1000-II NC1861-BL 18 6 conductor shielded 500' (152 m)

PR-20 , PR-22 Indala readers:

A-20/A-22 read head

to RE-2 NC18121-YL 18 12 conductor shielded 75' (23 m)

RE-2 to N-1000-II NC1861-BL 18 6 conductor shielded 500' (152 m)

PR-10, PR-12 Indala readers: NC1861-BL 18 6 conductor shielded 500' (152 m)

HG-3 hand geometry reader: NC1861-BL 18 6 conductor shielded 500' (152 m)

5 conductor keypad NC1861-BL 18 6 conductor shielded 500' (152 m)

Alarm input points NC 2221-BR 22 2000' (610 m)

Relay outputs NC 1821-OR 18 twisted pair, shielded 2000' (610 m)

NOTE: For Plenum rated cable just add a“P”to NexWatch part number prefix;for example

NC1861-BLbecomesPNC1861-BL

20 PW-5000 Enclosure PW5K2ENC1 & PW5K2ENC2Installation Guide

TD1151 rev1101

NexWatch Cable Part Numbers

Part Number Description Application Length

NC1841-GY 18 AWG/4 conductor reader cable 1,000' [305 m]

NC1861-BL-500 18 AWG/6 conductor reader cable 500' [152 m]

NC1861-BL 18 AWG/6 conductor reader cable 1,000' [305 m]

NC18121-YL-500 18 AWG/12 conductor keypad cable 500' [152 m]

NC18121-YL 18 AWG/12 conductor keypad cable 1,000' [305 m]

NCNET-1 50 ohm network cable 1,000' [305 m]

NC2221-BR 22 AWG/2 conductor alarm cable 1,000' [305 m]

NC1821-OR 18 AWG/2 conductor power/door cable 1,000' [305 m]

NCC59206-BK RG-59 video cable 1,000' [305 m]

NCP1841-GY 18 AWG/4 conductor Plenum reader cable 1,000' [305 m]

NCP1861-BL-500 18 AWG/6 conductor Plenum reader cable 500' [152 m]

NCP1861-BL 18AWG/6 conductor Plenum reader cable 1,000' [305 m]

NCP18121-YL 18 AWG/12 conductor Plenum keypad cable 1,000' [305 m]

NCP18121-YL-500 18 AWG/12 conductor Plenum keypad cable 500' [152 m]

NCPNET-1 50 ohm Plenum network cable 1,000' [305 m]

NCP2221-BR 22 AWG/2 conductor Plenum alarm point cable 1,000' [305 m]

NCP1821-OR 8 AWG/2 conductor Plenum power/door cable 1,000' [305 m]

NC2442-TN 24 AWG/120Ω12.8pf RS485 wire communication cable 1,000' [305 m]

NCP2442-TN 24 AWG/120Ω12.8pf RS485 wire communication cable 1,000' [305 m]

Other manuals for PW-5000

6

This manual suits for next models

2

Table of contents

Other NexWatch Enclosure manuals

Popular Enclosure manuals by other brands

Sans Digital

Sans Digital MobileStor MS4UM user manual

KAIREN

KAIREN Lubic-BASIC NE General Assembly instruction manual

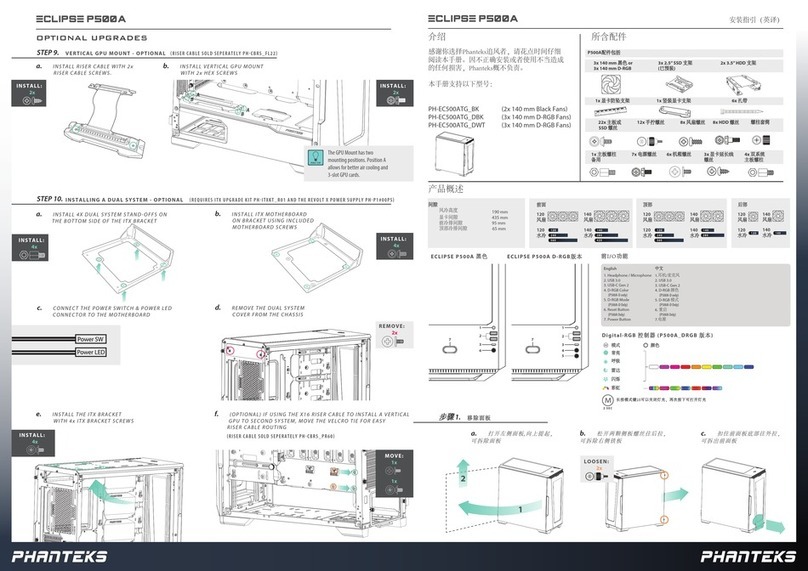

Phanteks

Phanteks ECLIPSE P500A quick start guide

StarTech.com

StarTech.com SAT2510B12U3 instruction manual

StarTech.com

StarTech.com S252BU33R user guide

Vantec

Vantec Desktop PC NST-360FBSU-BK user manual

National Instruments

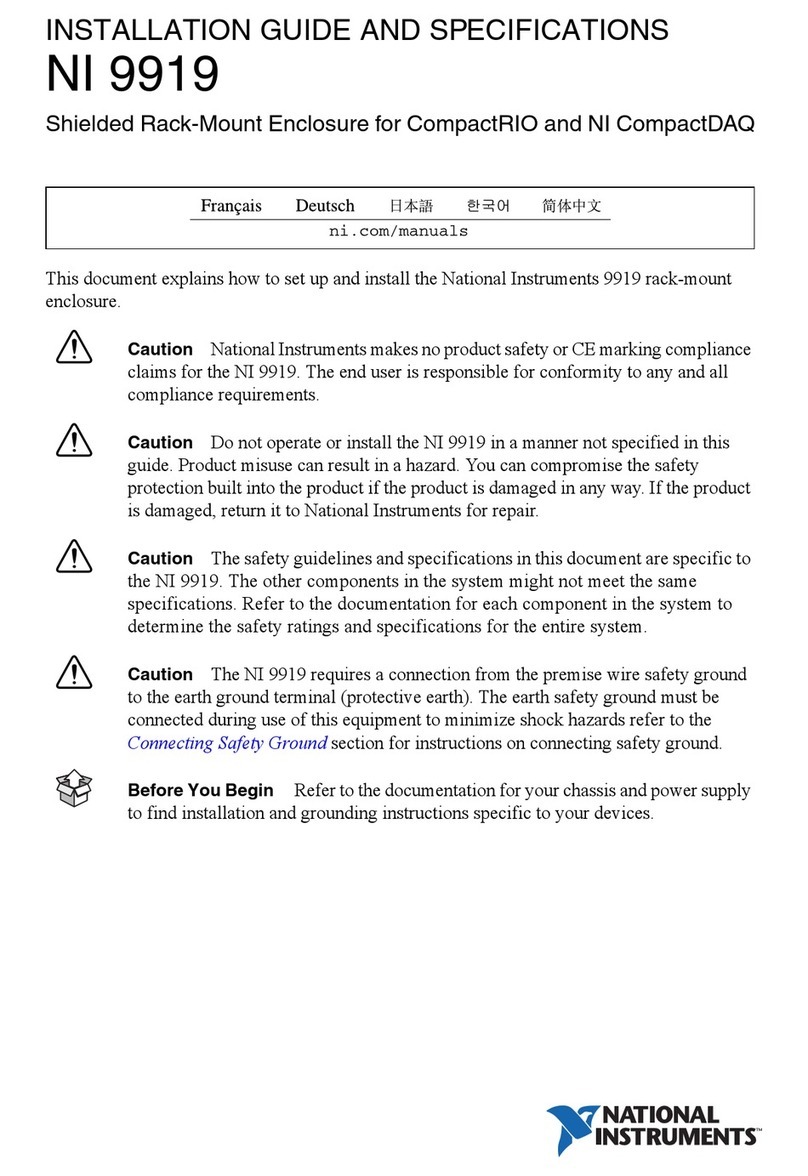

National Instruments NI 9919 installation guide

Conceptronic

Conceptronic DANTE04B Quick installation guide

Thermaltake

Thermaltake V2 Plus VO5000 Series user manual

Icy Box

Icy Box IB-1807MT-C31 manual

Eaton

Eaton Smart Online S3M BP240V09 manual

ADTRAN

ADTRAN Type 400 Installation and Maintenance