NGI N39200 Series User manual

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

N39200 Series High-accuracy

Dual-channel Programmable DC Power

Supply

User Manual

©Copyright Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

Version: V20200731

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

Contents

CONTENTS...................................................................................................................... 0

1 PREFACE.......................................................................................................................1

2 SAFETY INSTRUCTIONS............................................................................................... 2

2.1 Safety Notes......................................................................................................2

2.2 Safety Symbols..................................................................................................2

3 PRODUCT.....................................................................................................................3

3.1 Brief Introduction............................................................................................. 3

3.1.1 Features................................................................................................. 3

3.2 N39200 Series Lineup.......................................................................................4

3.3 Appearance & Dimension.................................................................................4

3.4 Package Contents and Accessories...................................................................5

3.5 Default Communication Parameter..................................................................5

4 PANEL INTRODUCTION............................................................................................... 6

4.1 Front Panel Introduction.................................................................................. 6

4.1.1 Screen.................................................................................................... 6

4.1.2 Button....................................................................................................7

4.1.3 Virtual Keyboard....................................................................................8

4.2 Rear Panel Introduction....................................................................................8

4.2.1 Channel Interface.................................................................................. 9

4.2.2 Four-wire Interface................................................................................9

4.2.3 LAN Port.................................................................................................9

4.2.4 RS232 Interface................................................................................... 10

4.2.5 AC Power Socket..................................................................................10

4.2.6 Grounding Screw Hole.........................................................................10

5 POWER-ON TEST....................................................................................................... 11

5.1 Preparation..................................................................................................... 11

5.1.1 Connection and Setting....................................................................... 11

5.1.2 Switch-on............................................................................................. 11

5.2 Output Check..................................................................................................12

5.2.1 Voltage Output Check..........................................................................12

5.2.2 Current Output Check......................................................................... 12

6 LOAD CONNECTION.................................................................................................. 12

6.1 Load Wire....................................................................................................... 13

6.2 Maximum Allowable Current......................................................................... 13

6.3 Connectors..................................................................................................... 13

6.4 Effect of Noise and Impedance...................................................................... 13

6.5 Inductive Load................................................................................................ 14

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

6.6 Local Sense and Remote Sense...................................................................... 14

6.6.1 Local Sense.......................................................................................... 15

6.6.2 Remote Sense...................................................................................... 15

6.7 Load Connection..........................................................................................16

7 OPERATION............................................................................................................... 18

7.1 Menu.............................................................................................................. 18

7.2 V/I................................................................................................................... 19

7.2.1 Channel Selection................................................................................20

7.2.2 Parameter Setting................................................................................21

7.3 SEQ..................................................................................................................21

7.3.1 Channel Selection................................................................................23

7.3.2 Parameter Setting................................................................................24

7.4 SEQ Edit.......................................................................................................... 25

7.4.1 Parameter Setting................................................................................27

7.5 Channel...........................................................................................................28

7.5.1 Channel Selection................................................................................29

7.5.2 Parameter Setting................................................................................30

7.5.3 CC/CV Priority Setting..........................................................................31

7.5.4 CV Priority Mode................................................................................. 34

7.6 System............................................................................................................ 35

7.6.1 IP Address Setting................................................................................36

7.6.2 Baud Rate, Beep and Language Setting...............................................37

8 REMOTE OPERATION................................................................................................ 39

8.1 RS232 Interface.............................................................................................. 39

8.2 LAN Port..........................................................................................................40

8.3 Connection to Computer................................................................................ 41

9 MAINTENANCE AND SELF-INSPECTION....................................................................43

9.1 Regular Maintenance..................................................................................... 43

9.2 Fault Self-inspection....................................................................................... 43

10 MAIN TECHNICAL DATA.......................................................................................... 44

11 APPENDIX................................................................................................................ 46

11.1 Protection and Error Alarm Description.......................................................46

11.2 Communication Interface.............................................................................46

11.3 Recommended Wire Gauge Selection Table................................................ 47

11.4 Trouble Shooting.......................................................................................... 47

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

1

1 Preface

Dear Customers,

First of all, we greatly appreciate your choice of N39200 series DC power supply

(N39200 for short). We are also honored to introduce our company, Hunan Next

Generation Instrumental T&C Tech. Co., Ltd. ( NGI for short).

About Company

NGI is a professional manufacturer of intelligent equipment and test & control

instruments, mainly engaged in design, production, sales, installations and

maintenance of instruments and meters, electronic products, mechanical equipment,

automatic test systems, computer software, automatic control equipment, automatic

monitoring and alarm systems.

NGI maintains close cooperation with many universities and scientific research

institutions, and maintains close ties with many industry leaders. We strive to

develop high-quality, technology-leading products, provide high-end technologies,

and continue to explore new industry measurement and control solutions.

About User Manual

This manual is applied to N39200 series DC power supply, including installation,

operation, specifications and other detailed information. The copyright of the

manual is owned by NGI. Due to the upgrade of instrument, this manual may be

revised without notice in future versions.

This manual has been reviewed carefully by NGI for the technical accuracy. The

manufacturer declines all responsibility for possible errors in this operation manual,

if due to misprints or errors in copying. The manufacturer is not liable for

malfunctioning if the product has not correctly been operated.

To ensure the safety and correct use of N39200, please read this manual carefully,

especially the safety instructions.

Please keep this manual for future use.

Thanks for your trust and support.

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

2

2 Safety Instructions

In the operation and maintenance of the instrument, please strictly comply with the

following safety instructions. Any performance regardless of attentions or specific

warnings in other chapters of the manual may impair the protective functions

provided by the instrument.

NGI shall not be liable for the results caused by the neglect of those instructions.

2.1 Safety Notes

Confirm the AC input voltage before supplying power.

Reliable grounding: Before operation, the instrument must be reliably grounded

to avoid the electric shock.

Confirm the fuse: Ensure to have installed the fuse correctly.

Do not open the chassis: The operator cannot open the instrument chassis.

Non-professional operators are not allowed to maintain or adjust it.

Do not operate under hazardous conditions: Do not operate the instrument

under flammable or explosive conditions.

Confirm the working range: Make sure the DUT is within N39200’s rated range.

2.2 Safety Symbols

Please refer to the following table for definitions of international symbols used on

the instrument or in the user manual.

Table 1

Symbol

Definition

Symbol

Definition

DC (direct current)

N

Null line or neutral line

AC (alternating current)

L

Live line

AC and DC

I

Power-on

Three-phase current

Power-off

Ground

Back-up power

Protective ground

Power-on state

Chassis ground

Power-off state

Signal ground

Risk of electric shock

WARNING

Hazardous sign

High temperature

warning

Caution

Be careful

Warning

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

3

3 Product

3.1 Brief Introduction

N39200 series is a high-accuracy & dual-channel programmable DC power supply,

available for benchtop use. N39200 standalone supports 2 channels output, with

each channel isolated. Both local operation on front panel and remote control on a

computer are supported. N39200 can be widely used in lab test, system integration

test, production aging line, etc.

3.1.1 Features

Automatic switch between CV and CC mode

High definition touch screen

Remote sense for accurate measurement

Single device with 2 channels, each channel isolated

Low ripple and low noise

Intelligent fan control

User-friendly interface

Lock function to avoid misoperation

LAN port and RS232 interface

Compact size, light weight

CC&CV priority function

Dual LAN ports design

Multiple protections: OVP, OCP, OTP and short circuit

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

4

3.2 N39200 Series Lineup

Table 2

Model

Channels

Voltage

Current

Power

N39220-60-10

2

60V

10A

200W

N39240-60-20

2

60V

20A

400W

N39260-60-20

2

60V

20A

600W

N39220-150-04

2

150V

4A

200W

N39240-150-08

2

150V

8A

400W

N39260-150-08

2

150V

8A

600W

3.3 Appearance & Dimension

VI Set

E S C

M e n u C H

O n / O f f

L o c k

S E Q P R O T

- C L R

SEQ Edit CH Config

Figure 1 Front Panel Dimension(mm)

~220VAC /50Hz

RS232

L A N 1

L A N 2

+

-

S-+

CH1

-S +

+

-

S-+

C H 2

-S +

Figure 2 Rear Panel Dimension(mm)

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

5

Figure 3 Side Dimension(mm)

3.4 Package Contents and Accessories

After receiving N39200, please check the instrument according to the following

steps:

1. Check whether the instrument is damaged during transportation. If any severe

damage to the package, please contact our authorized distributor or NGI.

2. Check accessories.

3. Make sure the the following accessories are attached.

Table 3

N39200 Accessories

Instructions

Power cord and fuse

For AC power connection

2 pins green connector

For output connection

4 pins green connector

For local and remote sense

RS232 cable

For RS232 communication

Ethernet cable

For Ethernet connection

USB flash drive

User manual, software & technical information

If any loss or damage, please contact our authorized distributor or NGI.

4. Check the whole instrument. If N39200 chassis is damaged or has abnormal

operation, please contact our authorized distributor or NGI.

3.5 Default Communication Parameter

Table 4

Parameter

N39200 Series Default Value

Default IP Address

192.168.0.123

Baud Rate

115200

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

6

4 Panel Introduction

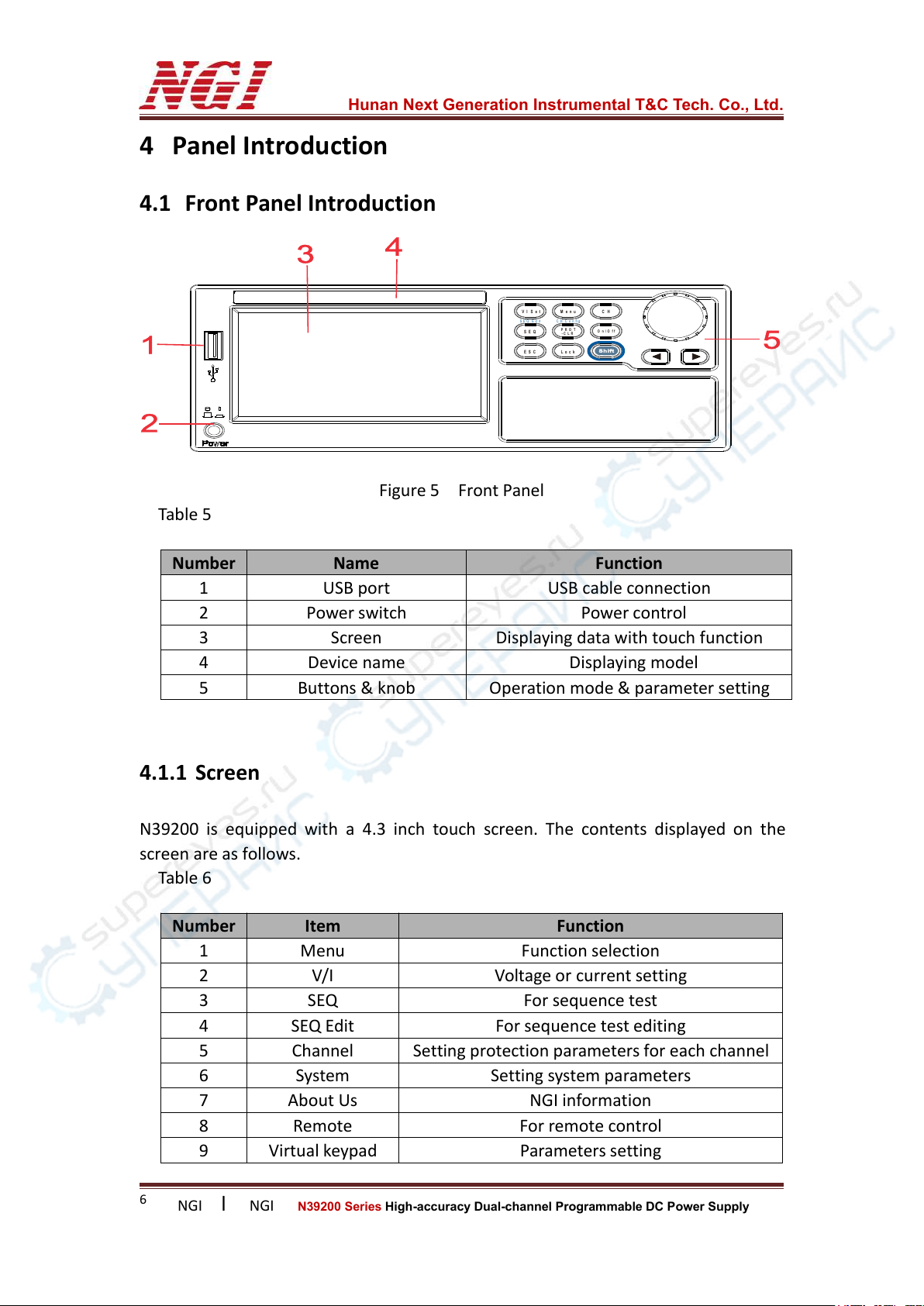

4.1 Front Panel Introduction

VI Set

ESC

M e n u C H

On/Off

L o c k

SEQ P R O T

- C L R

SEQ Edit C H C o n fig

Figure 5 Front Panel

Table 5

4.1.1 Screen

N39200 is equipped with a 4.3 inch touch screen. The contents displayed on the

screen are as follows.

Table 6

Number

Name

Function

1

USB port

USB cable connection

2

Power switch

Power control

3

Screen

Displaying data with touch function

4

Device name

Displaying model

5

Buttons & knob

Operation mode & parameter setting

Number

Item

Function

1

Menu

Function selection

2

V/I

Voltage or current setting

3

SEQ

For sequence test

4

SEQ Edit

For sequence test editing

5

Channel

Setting protection parameters for each channel

6

System

Setting system parameters

7

About Us

NGI information

8

Remote

For remote control

9

Virtual keypad

Parameters setting

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

7

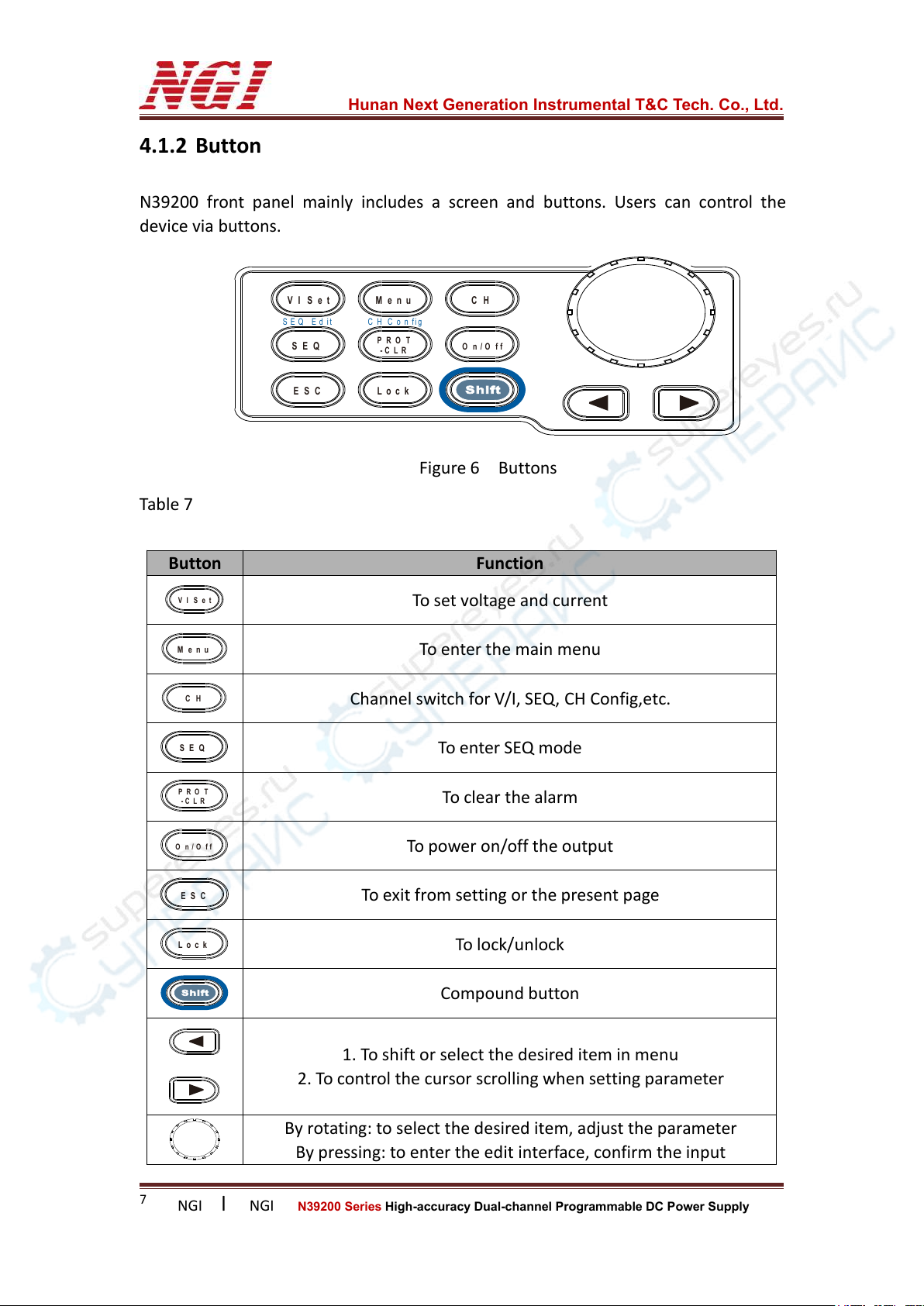

4.1.2 Button

N39200 front panel mainly includes a screen and buttons. Users can control the

device via buttons.

VI Set

ESC

M e n u C H

On/Off

L o c k

S E Q P R O T

- C L R

SEQ Ed it C H C on fig

Figure 6 Buttons

Table 7

Button

Function

V I S e t

To set voltage and current

M e n u

To enter the main menu

C H

Channel switch for V/I, SEQ, CH Config,etc.

SEQ

To enter SEQ mode

P R O T

- C L R

To clear the alarm

O n / O f f

To power on/off the output

ESC

To exit from setting or the present page

Lock

To lock/unlock

Compound button

1. To shift or select the desired item in menu

2. To control the cursor scrolling when setting parameter

By rotating: to select the desired item, adjust the parameter

By pressing: to enter the edit interface, confirm the input

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

8

4.1.3 Virtual Keyboard

N93200 is equipped with a virtual keypad on the screen for numeric input.

Figure 7 Virtual Keypad

4.2 Rear Panel Introduction

~220VAC /50H z

R S232

L A N 1

L A N 2

+

-

S-+

CH1

-S +

+

-

S-+

CH2

-S +

Figure 8 Rear Panel

Table 8

Number

Name

1

Channel interface

2

Four-wire interface

3

LAN port

4

RS232 interface

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

9

4.2.1 Channel Interface

Channel interface is used to connect the DUT. Please select the appropriate output

wire according to the specific N39200 model. Do not use thin wires to avoid

overheating, which may cause danger.

4.2.2 Four-wire Interface

Figure 9 Four-wire Interface

Table 9 Pin Definition

+

Output + (For local sense, internally connected to positive output terminal )

-

Output - (For local sense, internally connected to negative output terminal )

S+

Sense + (For remote sense)

S-

Sense - (For remote sense)

4.2.3 LAN Port

LAN

Figure 10 LAN Port

LAN port is used for remote control, by connecting N39200 with PC via an Ethernet

cable.

5

AC power socket

6

Air outlet

7

Grounding screw hole

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

10

4.2.4 RS232 Interface

RS232 interface is used for remote control. RS232 cable is supplied as standard

accessory.

1 234 5

67 89

Figure 11 RS232 Interface

Table 10

4.2.5 AC Power Socket

Please make sure the AC input voltage before supplying power.

Please ensure that the AC input voltage supplied to N39200 should not be too low

under high load conditions.

4.2.6 Grounding Screw Hole

The chassis of N39200 is insulated from the inner live conductor. However, after

long-term use or by accident, the insulating part may be damaged, which causes the

chassis to become charged. Grounding can effectively prevent electric shock.

Pin

Definition

1

NC

2

RXD, receive data

3

TXD, transmit data

4

NC

5

GND, ground

6

NC

7

NC

8

NC

9

NC

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

11

Warning: Please confirm the AC input power and connect to correct AC power. Wrong

AC power may cause serious damage to the instrument.

5 Power-on Test

Proper inspection should be done before operating on N39200 to ensure N39200 can

be used normally.

5.1 Preparation

5.1.1 Connection and Setting

Please follow the below steps in below table.

Table 11

5.1.2 Switch-on

Please press the power switch on the front panel.

If N39200 can not be switched on properly, please check if the power cord is well

connected and AC power supply is available.

Step

Item

Description

1

Inspection

To inspect if there is physical damage

2

Grounding

To connect the ground to prevent an electric shock

3

AC Power Input

To connect to proper AC power

4

Load Connection

To connect to a load with proper wire

5

Default Setting

To do factory reset

Warning: Even if the power switch is under off state, some components inside N39200

may still carry a high voltage. To avoid electric shock, it is forbidden to open the chassis.

Warning: If N39200 chassis and upper cover are not safely grounded, there is a danger

of electric shock.

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

12

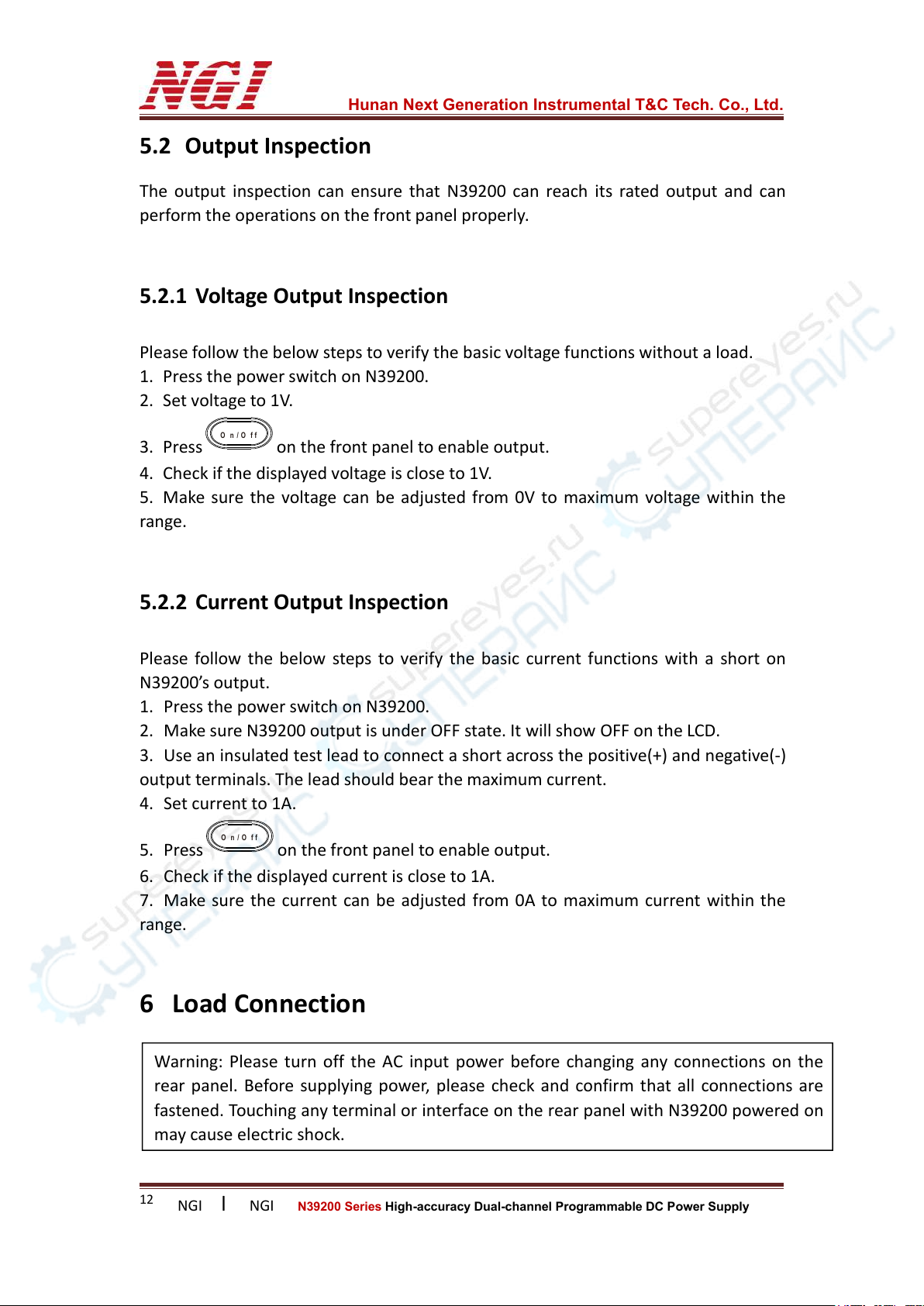

5.2 Output Inspection

The output inspection can ensure that N39200 can reach its rated output and can

perform the operations on the front panel properly.

5.2.1 Voltage Output Inspection

Please follow the below steps to verify the basic voltage functions without a load.

1. Press the power switch on N39200.

2. Set voltage to 1V.

3. Press

O n / O f f

on the front panel to enable output.

4. Check if the displayed voltage is close to 1V.

5. Make sure the voltage can be adjusted from 0V to maximum voltage within the

range.

5.2.2 Current Output Inspection

Please follow the below steps to verify the basic current functions with a short on

N39200’s output.

1. Press the power switch on N39200.

2. Make sure N39200 output is under OFF state. It will show OFF on the LCD.

3. Use an insulated test lead to connect a short across the positive(+) and negative(-)

output terminals. The lead should bear the maximum current.

4. Set current to 1A.

5. Press

O n / O f f

on the front panel to enable output.

6. Check if the displayed current is close to 1A.

7. Make sure the current can be adjusted from 0A to maximum current within the

range.

6 Load Connection

Warning: Please turn off the AC input power before changing any connections on the

rear panel. Before supplying power, please check and confirm that all connections are

fastened. Touching any terminal or interface on the rear panel with N39200 powered on

may cause electric shock.

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

13

Note: Please refer to the recommended wire gauge selection table in the appendix.

6.1 Load Wire

Load wire is not included among N39200 series standard accessories. Users need to

prepare load wire. Please refer to the follow requirements while selecting load wire.

1. The maximum allowable current of wire.

2. The insulation level of wire should not be lower than the maximum output

voltage of the power supply.

3. The maximum wire length and voltage drop.

4. Noise and impedance effects on the load wire.

6.2 Maximum Allowable Current

The following two factors should be considered when selecting the wire gauge.

1. The wire should be thick enough to avoid overheating when carrying rated load

current or load short-circuit current. The greater shall prevail.

2. The wire gauge should be selected properly to minimize the voltage drop on each

wire and to prevent excessive output power consumption of the power supply, which

affects the load regulation. Although N39200 series adopts remote sense to

compensate the voltage, it is still recommended to minimize the voltage drop.

6.3 Connectors

N39200 is supplied with two 2-pin connector and two 4-pin connector for connection

between wire and N39200 output.

Please do not connect wire directly to N39200 output, which is easy to loose. The

2-pin connector or 4-pin connector should be used for connection.

6.4 Effect of Noise and Impedance

In order to reduce noise or radiation, the load wire and the remote sense wire should

be twisted pair. The wire length should be as short as possible. Shielded wires must

be used in high noise environments. The shielding part is connected to chassis

through the grounding screw hole on rear panel.

Note: Please refer to the recommended wire gauge selection table in the appendix.

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

14

Even if the noise is not loud, the load wire and remote sense wire should also be

twisted pair to reduce coupling and increase the stability of power supply. The

remote sense wire must be separated from AC input power cord.

Twisted-pair load wire can reduce the parasitic inductance of the wire and prevent

high-frequency voltage peak on the load and the output of power supply, caused by

fluctuation of the load current.

The impedance between the output of power supply and the load makes the ripple &

noise on the load higher than at the rear panel terminal of power supply. If necessary,

an additional filter circuit with a bypass capacitor can be connected to the load to

limit the high-frequency load current.

6.5 Inductive Load

When using N39200 to supply power to inductive loads such as motors, users can

connect a diode across the output of N39200 since the inductive load will produce a

voltage spike which is harmful to N39200. The rated voltage and current of the diode

should be higher than the rated output voltage and current of power supply. The

negative polarity of diode is connected to the positive output of N39200. The

positive polarity is connected to the negative output of N39200.

When using N39200 to supply power to inductive loads such as motors, load

transients, such as counter electromotive force from motors, may occur. Please

connect a surge current suppressor across the output of N39200 to protect N39200.

The rated breakdown voltage of surge current suppressor must be approximately

10% higher than the rated output voltage of N39200.

6.6 Local Sense and Remote Sense

The four-wire interface at rear panel is used for local sense and remote sense. Please

refer to four-wire interface introduction. N39200 is supplied with 4-pin green

connector for remote sense.

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

15

Figure 12 4-pin Green Connector

6.6.1 Local Sense

In local sense, output voltage is adjusted at the output terminal of N39200. This way

does not compensate for the voltage drop on the load wire. It is recommended to

use local sense when the load current is low or the load regulation is not very critical.

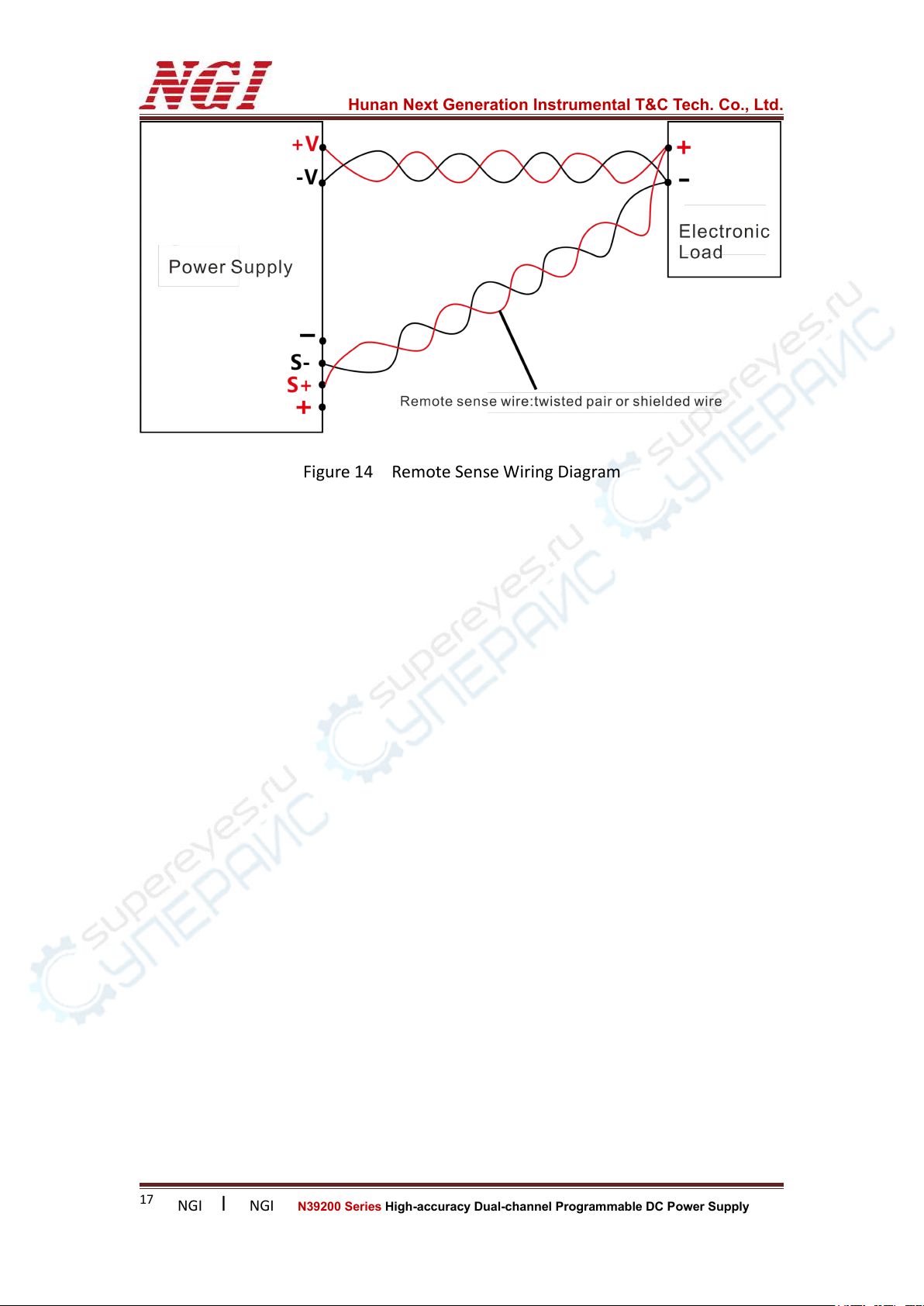

6.6.2 Remote Sense

Due to the parasitic resistance on the wire, a voltage drop will be generated on the

wire after the current flows. Assuming that output of the power supply is set to

55V/10A and the resistance of the load wire is 0.5 ohms, a 5V voltage drop will be

generated on the wire. The actual voltage reaching the load is only 50V, which affects

the output accuracy of the power supply. In this case, it is necessary to compensate

for the voltage drop on the wire.

The remote sense wire is directly connected to the load from four-wire interface on

the rear panel of power supply. Since the remote sense wire is directly connected to

the high impedance measurement circuit inside the supply, and the current on

remote sense wire is very low, the voltage drop generated is negligible. The voltage

across the load is fed back to the power supply control loop via remote sense wire.

The supply will adjust its output to compensate for the voltage drop on the load wire

so that the voltage across the load is equal to the set voltage.

Note: On the 4-pin connector, jumpers have been used to connect S+ to +and S- to -.

When using local sense, please put the 4-pin connector at rear panel. Unplugging the

connector will leave the remote sense terminal disconnected, which will affect the

voltage regulation and may cause the power supply to be unstable and dangerous.

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

16

Note: When rated output voltage of N39200 series is higher than the safe voltage, a

dangerous voltage may exist at the connection between the supply output and the load.

In order to protect operators from accidental contact with dangerous voltages, please

ensure that there are no accessible live parts on the load and its connections. Please

also make sure that the insulation level of the load wire is higher than or equal to the

maximum output voltage of N39200.

It is recommended to use remote sense when load regulation is very critical. The

procedure is as below.

1. Press the power switch to shut off the power supply.

2. Disconnect the jumpers on the 4-pin green connector.

3. Connect S+ to positive polarity on load and S- to negative polarity on load with

proper wire.

4. Plug the connector into the four-wire interface on rear panel of supply.

5. Connect the output of power supply to the load.

6. Press the power switch to power on the power supply.

6.7 Load Connection

Figure 13 Local Sense Wiring Diagram

Hunan Next Generation Instrumental T&C Tech. Co., Ltd.

NGI lNGI N39200 Series High-accuracy Dual-channel Programmable DC Power Supply

17

Figure 14 Remote Sense Wiring Diagram

Table of contents

Other NGI Power Supply manuals

Popular Power Supply manuals by other brands

National Instruments

National Instruments RMX-410 Series user manual

PowerBox Systems

PowerBox Systems EVOLUTION instruction manual

Kompernass

Kompernass TRONIC KH 3002 operating instructions

Dycon

Dycon d1800 Series installation manual

WEG

WEG CFW-09HD Series manual

TDK-Lambda

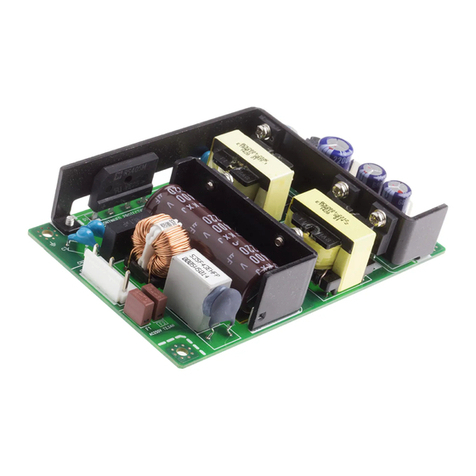

TDK-Lambda CUT75 instruction manual