3

We reserve the right to make technical changes 83050406cUK – Translation of the operating manual NIBETM AP-AW10

Contents

INFORMATION FOR OPERATORS AND

QUALIFIED SPECIALISTS

PLEASE READ FIRST..................................................................2

SYMBOLS .....................................................................................2

INTENDED USE..........................................................................4

EXCLUSION OF LIABILITY......................................................4

EC CONFORMITY .....................................................................4

SAFETY .........................................................................................4

CUSTOMER SERVICE ................................................................5

WARRANTY / GUARANTEE...................................................5

DISPOSAL ....................................................................................5

FUNCTIONING PRINCIPLE

OF HEAT PUMP SYSTEM ....................................................6

AREA OF UTILIZATION...........................................................6

HEAT QUANTITY RECORDING ............................................6

OPE R ATI ON ................................................................................6

CARE OF THE UNIT..................................................................7

MAINTENANCE OF THE UNIT...............................................7

Cleaning and rinsing of unit components..........................7

MALFUNCTIONS.......................................................................7

INSTRUCTIONS FOR

QUALIFIED TECHNICIANS

SCOPE OF DELIVERY ................................................................8

INSTALLATION ..........................................................................8

Installation location..............................................................8

Transport to installation location......................................9

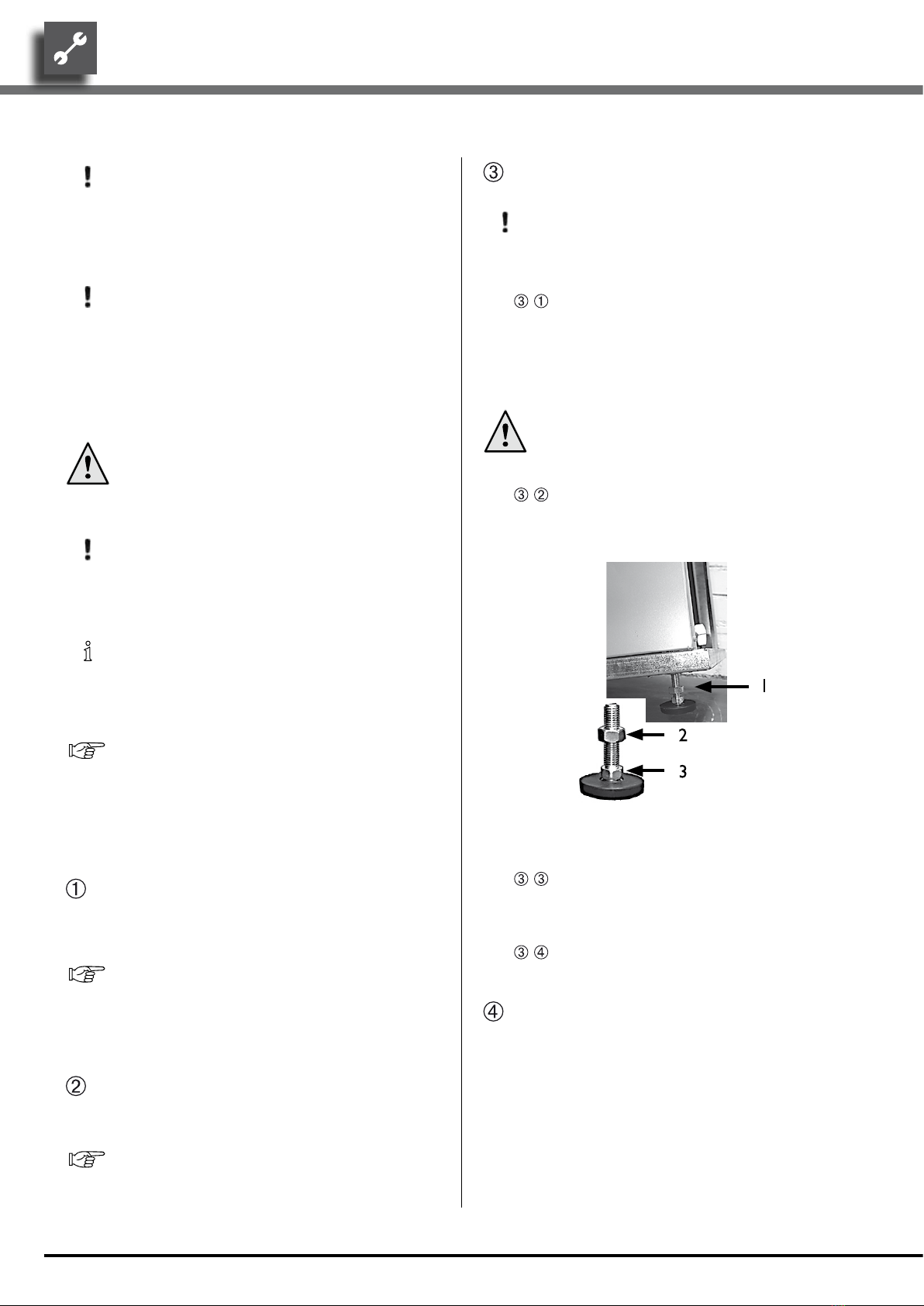

Installation............................................................................10

INSTALLATION OF THE

VENTILATION DUCT....................................................... 11

Converting from air blower on the right to air blower

on the left ......................................................................11

The air duct system 700 (accessory)...............................12

Product advantages.............................................................13

Wall duct(s) assembly.........................................................13

Air ducts assembly..............................................................14

Securing the air duct into the wall duct..........................15

Securing the air duct on the heat pump..........................15

Screen frame assembly.......................................................16

Wire mesh grille and weather/rain guards assembly ....16

INSTALLATION / CONNECTION TO HEATING CIRCUIT

17

Manometer...........................................................................18

Discharge hot water safety valve and condensate

discharge ........................................................................18

HOT-WAT ER TAN K .................................................................19

ELECTRICAL CONNECTIONS .............................................19

RINSING, FILLING AND BLEEDING THE SYSTEM ..........21

Water quality of the fill and additional water in hot

water heating systems .................................................21

INSULATING THE HYDRAULIC CONNECTIONS ..........25

OVERFLOW VALVE..................................................................25

Inspecting and setting up the overflow valve.................25

INSTALLATION OF THE CONTROL ELEMENT ...............26

INSTALLATION AND REMOVAL OF THE SCREEN.........27

COMMISSIONING ...................................................................28

Safety temperature limiter................................................29

DISMANTLING .........................................................................29

TECHNICAL DATA / SCOPE OF DELIVERY ........................30

PERFORMANCE CURVES

Heating capacity/COP / power consumption / Free

compression, heating circuit

AP-AW10-6C.......................................................................32

AP-AW10-8C.......................................................................33

AP-AW10-10C .....................................................................34

AP-AW10-12C .....................................................................35

DIMENSIONAL DRAWINGS .................................................36

INSTALLATION PLANS

Installation plan version 1 .................................................37

Installation plan version 2 .................................................38

Installation plan version 3 .................................................39

Installation plan version 4 ................................................ 40

Installation plan version 5 .................................................41

Installation plan version 6 .................................................42

TERMINAL DIAGRAM.............................................................43

CIRCUIT DIAGRAMS

AP-AW10-6C - AP-AW10-8C ......................................... 44

AP-AW10-10C – AP-AW10-12C ......................................47

APPENDIX

EC DECLARATION OF CONFORMITY..............................50