Nichia 193F Series User manual

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

1/14 SP-QR-C2-220184-1

Jun. 8, 2022

Table of Contents

Application Note

NCSW193F, NC2W193F, NC3W193F, NC4W193F, and NC5W193F refer to Nichia part numbers. These Nichia part numbers within this

document are merely Nichia’s part numbers for those Nichia products and are not related nor bear resemblance to any other company’s

product that might bear a trademark.

・・・・・・・・・2-6

・・・・・・・・・・・・・・・・・・7

・・・・・8

・ ・ 9-12

・・・・・・・・・・・・13

1. LED Outline Dimensions/Tape Dimensions

2. Handling Precautions

3. Design Recommendations for Optimal Amount of Solder

4. Precautions for Setting Up a Pick-and-Place Machine/Nozzle

5. Precautions When Reflow Soldering

Assembly Precautions

for the Nichia 193F Series LEDs

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

2/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

LED Embossed Carrier Tape

Weight: typ. 0.35g

(Unit: mm, Tolerance: ±0.1mm)

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17892

Part No. NCSW193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K A

保護素子

Protection Device

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

1.15±0.05

1.15±0.05

(2.65) 2.5

8

(1.95)

11.8

9.8

(9)

(7.2)

0.5

(2.8)

Cathode Mark

0.2 A

0.2 B

1.8 Max

0.5

0.9

1.27

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.35g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

カソードマーク

ダイヒートシンク

カソード

アノード

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17892

Part No. NCSW193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K A

保護素子

Protection Device

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

1.15±0.05

1.15±0.05

(2.65) 2.5

8

(1.95)

11.8

9.8

(9)

(7.2)

0.5

(2.8)

Cathode Mark

0.2 A

0.2 B

1.8 Max

0.5

0.9

1.27

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.35g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

1

2

Part No. Nxxx193x

No. STS-DA7-17893

(単位 Unit: mm)

テーピング部 Tape

トレーラ部/リーダ部 Trailer and Leader

* 数量は1リールにつき 1800個入りです。

Reel Size: 1800pcs

* 実装作業の中断などでエンボスキャリアテープをリールに巻き取る場合、

エンボスキャリアテープを強く(10N以上)締めないで下さい。

LEDがカバーテープに貼り付く可能性があります。

When the tape is rewound due to work interruptions,

no more than 10N should be applied to

the embossed carrier tape.

The LEDs may stick to the top cover tape.

* 実装作業の開始・中断・再開作業時などでリボンに過度な荷重を加えると、

リボンが変形し、不灯・不具合の原因になる可能性があります。

Ensure that when starting or suspending or resuming the

mounting work, excessive force is not applied to the ribbon.

Otherwise, it may cause damage to the ribbon, which cause

the LED to malfunction(e.g. the LED not to illuminate).

2±0.1 4±0.1

Φ1.5+0.1

1.75±0.1

11.5±0.1

12±0.1

-0

24+0.3

-0.1

トップカバーテープ

引き出し方向

Embossed Carrier Tape

エンボスキャリアテープ

Top Cover Tape

Feed

Direction

Trailer 160mm MIN(Empty Pockets)

リーダ部最小400mm

Leader without Top Cover Tape 400mm MIN

LED装着部

Loaded Pockets

引き出し部最小100mm(空部)

Leader with Top Cover Tape

100mm MIN(Empty Pocket)

トレーラ部最小160mm(空部)

リール部 Reel

Φ100±1

25.5±1

29.5±1

330±2

ラベル

Label

12.05±0.1

0.25±0.05

1.95±0.1

1±0.1

2±0.1

2±0.1

8.25±0.1

2±0.1

2±0.1

Φ2.05±0.05

(0.5 クロスバー凹部)

(0.5 Crossbar Recess)

(0.5 クロスバー凹部)

Feeding

Direction (Unit: mm)

1. LED Outline Dimensions/Tape Dimensions

Table 1. NCSW193F Product Specifications

Direction of the LED in the embossed carrier tape pocket: the

cathode faces the feeding direction of the tape as shown in the

figure above.

Cathode Anode

Die Heatsink

Cathode Mark

(0.5 Crossbar Recess)

1The centerline of the emitting area in the lateral direction is parallel to B; the

deviation in distance between the centerline and B is within ±0.1mm.

2The deviation of the centerline of the emitting area in the longitudinal

direction from the centerline of the die heatsink in the longitudinal direction is

within ±0.1mm.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

3/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

LED Embossed Carrier Tape

Weight: typ. 0.36g

(Unit: mm, Tolerance: ±0.1mm)

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17856A

Part No. NC2W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K A

保護素子

Protection Device

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

1.15±0.05

2.3±0.05

(2.2) 2.5

(3.2)

(2.4)

11.8

8

(7.2)

0.5

9.8

(9)

Cathode Mark

0.2 B 0.2 A

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.36g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17856A

Part No. NC2W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K A

保護素子

Protection Device

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

1.15±0.05

2.3±0.05

(2.2) 2.5

(3.2)

(2.4)

11.8

8

(7.2)

0.5

9.8

(9)

Cathode Mark

0.2 B 0.2 A

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.36g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

カソードマーク

ダイヒートシンク

カソード

アノード

Part No. Nxxx193x

No. STS-DA7-17868A

(単位 Unit: mm)

テーピング部 Tape

トレーラ部/リーダ部 Trailer and Leader

* 数量は1リールにつき 1800個入りです。

Reel Size: 1800pcs

* 実装作業の中断などでエンボスキャリアテープをリールに巻き取る場合、

エンボスキャリアテープを強く(10N以上)締めないで下さい。

LEDがカバーテープに貼り付く可能性があります。

When the tape is rewound due to work interruptions,

no more than 10N should be applied to

the embossed carrier tape.

The LEDs may stick to the top cover tape.

* 実装作業の開始・中断・再開作業時などでリボンに過度な荷重を加えると、

リボンが変形し、不灯・不具合の原因になる可能性があります。

Ensure that when starting or suspending or resuming the

mounting work, excessive force is not applied to the ribbon.

Otherwise, it may cause damage to the ribbon, which cause

the LED to malfunction(e.g. the LED not to illuminate).

2±0.1 4±0.1

Φ1.5+0.1

1.75±0.1

11.5±0.1

12±0.1

-0

24+0.3

-0.1

トップカバーテープ

引き出し方向

Embossed Carrier Tape

エンボスキャリアテープ

Top Cover Tape

Feed

Direction

Trailer 160mm MIN(Empty Pockets)

リーダ部最小400mm

Leader without Top Cover Tape 400mm MIN

LED装着部

Loaded Pockets

引き出し部最小100mm(空部)

Leader with Top Cover Tape

100mm MIN(Empty Pocket)

トレーラ部最小160mm(空部)

リール部 Reel

Φ100±1

25.5±1

29.5±1

330±2

ラベル

Label

12.05±0.1

0.25±0.05

1.95±0.1

1±0.1

2±0.1

2±0.1

8.25±0.1

2±0.1

2±0.1

Φ2.05±0.05

(0.5 クロスバー凹部)

(0.5 Crossbar Recess)

(0.5 クロスバー凹部)

1

2

Feeding

Direction (Unit: mm)

1. LED Outline Dimensions/Tape Dimensions

Table 2. NC2W193F Product Specifications

Direction of the LED in the embossed carrier tape pocket: the

cathode faces the feeding direction of the tape as shown in the

figure above.

Cathode Anode

Die Heatsink

Cathode Mark

(0.5 Crossbar Recess)

1The centerline of the emitting area in the lateral direction is parallel to B; the

deviation in distance between the centerline and B is within ±0.1mm.

2The deviation of the centerline of the emitting area in the longitudinal

direction from the centerline of the die heatsink in the longitudinal direction is

within ±0.1mm.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

4/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

LED Embossed Carrier Tape

Weight: typ. 0.37g

(Unit: mm, Tolerance: ±0.1mm)

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17846A

Part No. NC3W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K A

保護素子

Protection Device

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

3.45±0.05

1.15±0.05

(2.2) 2.5

(2.4)

(4)

11.8

8

(7.2)

0.5

9.8

(9)

Cathode Mark

0.2 B 0.2 A

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.37g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17846A

Part No. NC3W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K A

保護素子

Protection Device

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

3.45±0.05

1.15±0.05

(2.2) 2.5

(2.4)

(4)

11.8

8

(7.2)

0.5

9.8

(9)

Cathode Mark

0.2 B 0.2 A

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.37g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17846A

Part No. NC3W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K A

保護素子

Protection Device

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

3.45±0.05

1.15±0.05

(2.2) 2.5

(2.4)

(4)

11.8

8

(7.2)

0.5

9.8

(9)

Cathode Mark

0.2 B 0.2 A

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.37g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

カソードマーク

ダイヒートシンク

カソード

アノード

Part No. Nxxx193x

No. STS-DA7-17847A

(単位 Unit: mm)

テーピング部 Tape

トレーラ部/リーダ部 Trailer and Leader

* 数量は1リールにつき 1800個入りです。

Reel Size: 1800pcs

* 実装作業の中断などでエンボスキャリアテープをリールに巻き取る場合、

エンボスキャリアテープを強く(10N以上)締めないで下さい。

LEDがカバーテープに貼り付く可能性があります。

When the tape is rewound due to work interruptions,

no more than 10N should be applied to

the embossed carrier tape.

The LEDs may stick to the top cover tape.

* 実装作業の開始・中断・再開作業時などでリボンに過度な荷重を加えると、

リボンが変形し、不灯・不具合の原因になる可能性があります。

Ensure that when starting or suspending or resuming the

mounting work, excessive force is not applied to the ribbon.

Otherwise, it may cause damage to the ribbon, which cause

the LED to malfunction(e.g. the LED not to illuminate).

2±0.1 4±0.1

Φ1.5+0.1

1.75±0.1

11.5±0.1

12±0.1

-0

24+0.3

-0.1

トップカバーテープ

引き出し方向

Embossed Carrier Tape

エンボスキャリアテープ

Top Cover Tape

Feed

Direction

Trailer 160mm MIN(Empty Pockets)

リーダ部最小400mm

Leader without Top Cover Tape 400mm MIN

LED装着部

Loaded Pockets

引き出し部最小100mm(空部)

Leader with Top Cover Tape

100mm MIN(Empty Pocket)

トレーラ部最小160mm(空部)

リール部 Reel

Φ100±1

25.5±1

29.5±1

330±2

ラベル

Label

12.05±0.1

0.25±0.05

1.95±0.1

1±0.1

2±0.1

2±0.1

8.25±0.1

2±0.1

2±0.1

Φ2.05±0.05

(0.5 クロスバー凹部)

(0.5 Crossbar Recess)

(0.5 クロスバー凹部)

1

2

Feeding

Direction (Unit: mm)

1. LED Outline Dimensions/Tape Dimensions

Table 3. NC3W193F Product Specifications

Direction of the LED in the embossed carrier tape pocket: the

cathode faces the feeding direction of the tape as shown in the

figure above.

Cathode Anode

Die Heatsink

Cathode Mark

(0.5 Crossbar Recess)

1The centerline of the emitting area in the lateral direction is parallel to B; the

deviation in distance between the centerline and B is within ±0.1mm.

2The deviation of the centerline of the emitting area in the longitudinal

direction from the centerline of the die heatsink in the longitudinal direction is

within ±0.1mm.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

5/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

LED Embossed Carrier Tape

Weight: typ. 0.38g

(Unit: mm, Tolerance: ±0.1mm)

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17901

Part No. NC4W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K

保護素子

Protection Device

A

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

(9)

9.8

0.5

(7.2)

8

11.8

(2.4)

(5.1)

2.5

(2.2)

1.15±0.05

4.6±0.05

Cathode Mark

0.2 A

0.2 B

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.38g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17901

Part No. NC4W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K

保護素子

Protection Device

A

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

(9)

9.8

0.5

(7.2)

8

11.8

(2.4)

(5.1)

2.5

(2.2)

1.15±0.05

4.6±0.05

Cathode Mark

0.2 A

0.2 B

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.38g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

カソードマーク

ダイヒートシンク

カソード

アノード

Part No. Nxxx193x

No. STS-DA7-17902

(単位 Unit: mm)

テーピング部 Tape

トレーラ部/リーダ部 Trailer and Leader

* 数量は1リールにつき 1800個入りです。

Reel Size: 1800pcs

* 実装作業の中断などでエンボスキャリアテープをリールに巻き取る場合、

エンボスキャリアテープを強く(10N以上)締めないで下さい。

LEDがカバーテープに貼り付く可能性があります。

When the tape is rewound due to work interruptions,

no more than 10N should be applied to

the embossed carrier tape.

The LEDs may stick to the top cover tape.

* 実装作業の開始・中断・再開作業時などでリボンに過度な荷重を加えると、

リボンが変形し、不灯・不具合の原因になる可能性があります。

Ensure that when starting or suspending or resuming the

mounting work, excessive force is not applied to the ribbon.

Otherwise, it may cause damage to the ribbon, which cause

the LED to malfunction(e.g. the LED not to illuminate).

2±0.1 4±0.1

Φ1.5+0.1

1.75±0.1

11.5±0.1

12±0.1

-0

トップカバーテープ

引き出し方向

Embossed Carrier Tape

エンボスキャリアテープ

Top Cover Tape

Feed

Direction

Trailer 160mm MIN(Empty Pockets)

リーダ部最小400mm

Leader without Top Cover Tape 400mm MIN

LED装着部

Loaded Pockets

引き出し部最小100mm(空部)

Leader with Top Cover Tape

100mm MIN(Empty Pocket)

トレーラ部最小160mm(空部)

リール部 Reel

Φ100±1

25.5±1

29.5±1

330±2

ラベル

Label

12.05±0.1

0.25±0.05

1.95±0.1

1±0.1

2±0.1

2±0.1

8.25±0.1

2±0.1

2±0.1

24+0.3

-0.1

Φ2.05±0.05

(0.5 クロスバー凹部)

(0.5 Crossbar Recess)

(0.5 クロスバー凹部)

1

2

Feeding

Direction (Unit: mm)

1. LED Outline Dimensions/Tape Dimensions

Table 4. NC4W193F Product Specifications

Direction of the LED in the embossed carrier tape pocket: the

cathode faces the feeding direction of the tape as shown in the

figure above.

Cathode Anode

Die Heatsink

Cathode Mark

(0.5 Crossbar Recess)

1The centerline of the emitting area in the lateral direction is parallel to B; the

deviation in distance between the centerline and B is within ±0.1mm.

2The deviation of the centerline of the emitting area in the longitudinal

direction from the centerline of the die heatsink in the longitudinal direction is

within ±0.1mm.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

6/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

LED Embossed Carrier Tape

Weight: typ. 0.38g

(Unit: mm, Tolerance: ±0.1mm)

Part No. Nxxx193x

No. STS-DA7-17873

(単位 Unit: mm)

テーピング部 Tape

トレーラ部/リーダ部 Trailer and Leader

* 数量は1リールにつき 1800個入りです。

Reel Size: 1800pcs

* 実装作業の中断などでエンボスキャリアテープをリールに巻き取る場合、

エンボスキャリアテープを強く(10N以上)締めないで下さい。

LEDがカバーテープに貼り付く可能性があります。

When the tape is rewound due to work interruptions,

no more than 10N should be applied to

the embossed carrier tape.

The LEDs may stick to the top cover tape.

* 実装作業の開始・中断・再開作業時などでリボンに過度な荷重を加えると、

リボンが変形し、不灯・不具合の原因になる可能性があります。

Ensure that when starting or suspending or resuming the

mounting work, excessive force is not applied to the ribbon.

Otherwise, it may cause damage to the ribbon, which cause

the LED to malfunction(e.g. the LED not to illuminate).

2±0.1 4±0.1

Φ1.5+0.1

1.75±0.1

11.5±0.1

12±0.1

-0

24+0.3

-0.1

トップカバーテープ

引き出し方向

Embossed Carrier Tape

エンボスキャリアテープ

Top Cover Tape

Feed

Direction

Trailer 160mm MIN(Empty Pockets)

リーダ部最小400mm

Leader without Top Cover Tape 400mm MIN

LED装着部

Loaded Pockets

引き出し部最小100mm(空部)

Leader with Top Cover Tape

100mm MIN(Empty Pocket)

トレーラ部最小160mm(空部)

リール部 Reel

Φ100±1

25.5±1

29.5±1

330±2

ラベル

Label

12.05±0.1

0.25±0.05

1.95±0.1

1±0.1

2±0.1

2±0.1

8.25±0.1

2±0.1

2±0.1

Φ2.05±0.05

(0.5 クロスバー凹部)

(0.5 Crossbar Recess)

(0.5 クロスバー凹部)

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17872

Part No. NC5W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K

保護素子

Protection Device

A

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

5.75±0.05

1.15±0.05

(2.2) 2.5

(6.1)

(2.4)

11.8

8

(7.2)

0.5

9.8

(9)

Cathode Mark

0.2 B0.2 A

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.38g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

(単位 Unit: mm)

This product complies with RoHS Directive.

本製品はRoHS指令に適合しております。

(単位 Unit: mm, 公差 Tolerance: ±0.1)

No. STS-DA7-17872

Part No. NC5W193F

The dimension(s) in parentheses are for reference purposes.

括弧で囲まれた寸法は参考値です。

*

*

K

保護素子

Protection Device

A

ダイヒートシンク

Die Heat Sink

A5.8

B6.8

0.9

1.4

2.2

5.7

7.1

0.9

Cathode Anode

ダイヒートシンク

Die Heat Sink

5.75±0.05

1.15±0.05

(2.2) 2.5

(6.1)

(2.4)

11.8

8

(7.2)

0.5

9.8

(9)

Cathode Mark

0.2 B0.2 A

1.27

0.5

0.9

1.8 Max

項目 Item

パッケージ材質

Package Materials

内容 Description

黒色耐熱性ポリマー

Black Heat-resistant Polymer

電極材質

Electrodes Materials

ダイヒートシンク材質

Die Heat Sink

Materials

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体板材質

Phosphor sheet

Materials

封止樹脂材質

Encapsulating Resin

Materials

シリコーン樹脂

Silicone Resin

銅合金+金メッキ

Au-plated Copper Alloy

蛍光体セラミックス

Phosphor Ceramics

質量

Weight 0.38g(TYP)

Dimensions do not include mold flash or metal burr.

バリは寸法に含まないものとします。

*

It may contain the products having the following ribbon shapes.

製品には以下のようなリボン形状が含まれます。

*

形状1

Shape1

形状2

Shape2

形状3

Shape3

カソードマーク

ダイヒートシンク

カソード

アノード

1

2

Feeding

Direction (Unit: mm)

1. LED Outline Dimensions/Tape Dimensions

Table 5. NC5W193F Product Specifications

Direction of the LED in the embossed carrier tape pocket: the

cathode faces the feeding direction of the tape as shown in the

figure above.

Cathode Anode

Die Heatsink

Cathode Mark

(0.5 Crossbar Recess)

1The centerline of the emitting area in the lateral direction is parallel to B; the

deviation in distance between the centerline and B is within ±0.1mm.

2The deviation of the centerline of the emitting area in the longitudinal

direction from the centerline of the die heatsink in the longitudinal direction is

within ±0.1mm.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

7/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

Caution: Do not touch the

prohibited area.

Suggestion: Grab/hold the LEDs with

tweezers by the package.

2.1 Prohibited area

Do not touch the prohibited area shown in Figure 1. This may cause the LED malfunction (e.g. the LED not to

illuminate).

2.2 Handling with bare hands

Do not handle the LEDs with bare hands:

- this may contaminate the LED surface and have an effect on the optical characteristics,

- this may cause the LED to deform or to be damaged causing a catastrophic failure (i.e. the LED not to

illuminate),

- the electrodes and/or the die heatsink may cause injuries when the LED is handled with bare hands.

2.3 Handling with tweezers

Ensure that when handling the LEDs with tweezers, grab/hold the LEDs by the package (i.e. the black part) and

ensure that excessive force is not applied to the LED. Otherwise, it may cause damage to the LED (e.g. cut,

scratch, chip, crack, etc.) and have an effect on the optical characteristics and/or the reliability. See Figure 2.

2.4 ESD Precautions

The LEDs are sensitive to transient excessive voltages (e.g. ESD, lightning surge). If this excessive voltage

occurs in the circuit, it may cause the LED to be damaged causing issues (e.g. the LED to become dimmer or

not to illuminate [i.e. catastrophic failure]). When handling the LEDs, ensure that necessary measures have

been taken to protect them from transient excess voltages.

2.5 Stacking assembled PCBs together

Do not stack assembled PCBs together. Otherwise, it may cause damage to the LED (e.g. cut, scratch, chip,

crack, etc.) and have an effect on the optical characteristics and/or the reliability.

2.6 Storage

The storage/packaging requirements for the Nichia 193F Series LEDs are comparable to JEDEC Moisture

Sensitivity Level (MSL) 2 or equivalent. Nichia used IPC/JEDEC STD-020 as a reference to rate the MSL of the

LEDs. Table 6 shows the required storage conditions for the LEDs.

Conditions Temperature Humidity Time

Storage

Before Opening Aluminum Bag ≤30℃≤90%RH Within 1 Year from Delivery Date

After Opening Aluminum Bag ≤30℃≤70%RH Within 1 Year Figure 2. Correct/Incorrect Examples

of Handling with Tweezers

Figure 1. Prohibited area

Prohibited

area

2. Handling Precautions

Table 6. Storage Conditions

Correct

Incorrect

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

8/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

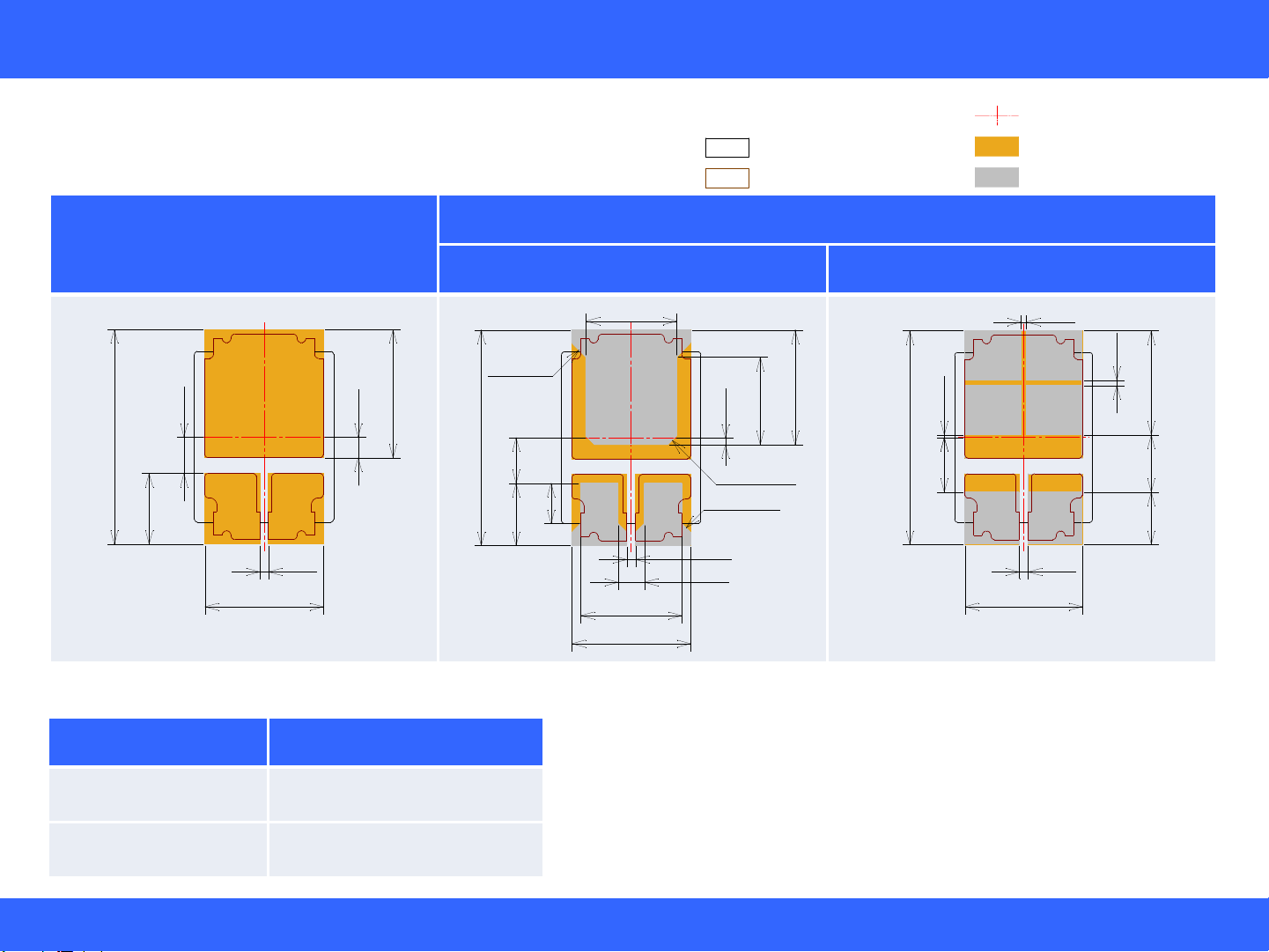

Recommended Soldering Pad Pattern

Recommended Metal Solder Stencil Aperture

Pattern Recommended in the Specification Modified Pattern4

(Unit: mm) (Unit: mm) (Unit: mm)

Item Recommended Conditions

Metal Solder Stencil

(Thickness) 120μm

Solder Paste

(Composition) Sn-3.0Ag-0.5Cu

Center of the Soldering Pad

Pattern

Metal Solder Stencil Aperture

Soldering Pad Pattern

3. Design Recommendations for Optimal Amount of Solder

Soldering Pad Pattern/Metal Solder Stencil Aperture

Table 7. Recommended Soldering Pad Pattern/Metal Solder Stencil Aperture3

Table 8. Recommended Solder/Metal Solder Stencil Conditions3

6 .8

0 .5

2 .1

7 .35

1 .2

12 .3

4 .05

6 .8

0 .5

0 .3

0 .3

6

3 .3

3

3 .15 0 .15

12 .3

5 .2

2 .6

3 .55

12 .3

2 .3

5

6 .55

0 .5

1 .5

5 .8

6 .8

0 .4

2-C0 .8

4-C0 .5

2-C0 .5

Electrodes and Die Heatsink

Package Outline

3The recommended soldering pad pattern, metal solder stencil aperture, and thickness

of the metal solder stencil provided in Tables 7 and 8 have been determined under

Nichia’s conditions: ensure that there are no issues with the chosen assembly conditions

prior to use.

4If the aperture is large, the solder paste may not be applied evenly (i.e. thinner for the

middle area of the aperture) in the solder printing process causing the amount of the

solder paste applied to the soldering pad pattern to vary for each operation. This

modified pattern has four small apertures for the die heatsink instead of one large

aperture while the total area of the aperture is almost the same as that for the pattern

recommended in the specification.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

9/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

Item Recommended Conditions/Specifications Cautions/Suggestions

Pick-and-place machine Modular mounter YS100 High-Speed General-Purpose Modular

(manufactured by Yamaha Motor Co., Ltd.)

Pick-and-place nozzle Nozzle specifically designed for the LEDs (see Figure 3) See “4.1 Pick-and-Place Nozzle” on Page 10 for details.

Tape-and-reel feeder Electrical (motorized) feeder Tape width: 24mm

Feeder pitch: 12mm

Top cover tape removal

position Immediately before pick-up See “4.2 Tape-and-Reel Feeder” on Page 11 for details.

Nozzle height for pick-up

operations

The contact surface of the nozzle head for pick

operations should be adjusted to 1.05mm below the

edge of the embossed carrier tape pocket.

See “4.3 Recommended Nozzle Height for Pick-up

Operations” on Page 11 for details.

Nozzle height for placement

operations (i.e. placement

depth)

0.2mm for the placement depth See “4.4 Recommended Nozzle Height for Placement

Operations (Placement Depth)” on Page 12 for details.

Imaging-based automatic

inspection

To locate the center of the LED, using the electrodes

and die heatsink as a reference is recommended.

See “4.5 Imaging-based Automatic Inspection" on Page

12 for details.

4. Precautions for Setting up a Pick-and-Place Machine/Nozzle

Table 9. Cautions/Suggestions for Setting up the Equipment

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

10/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

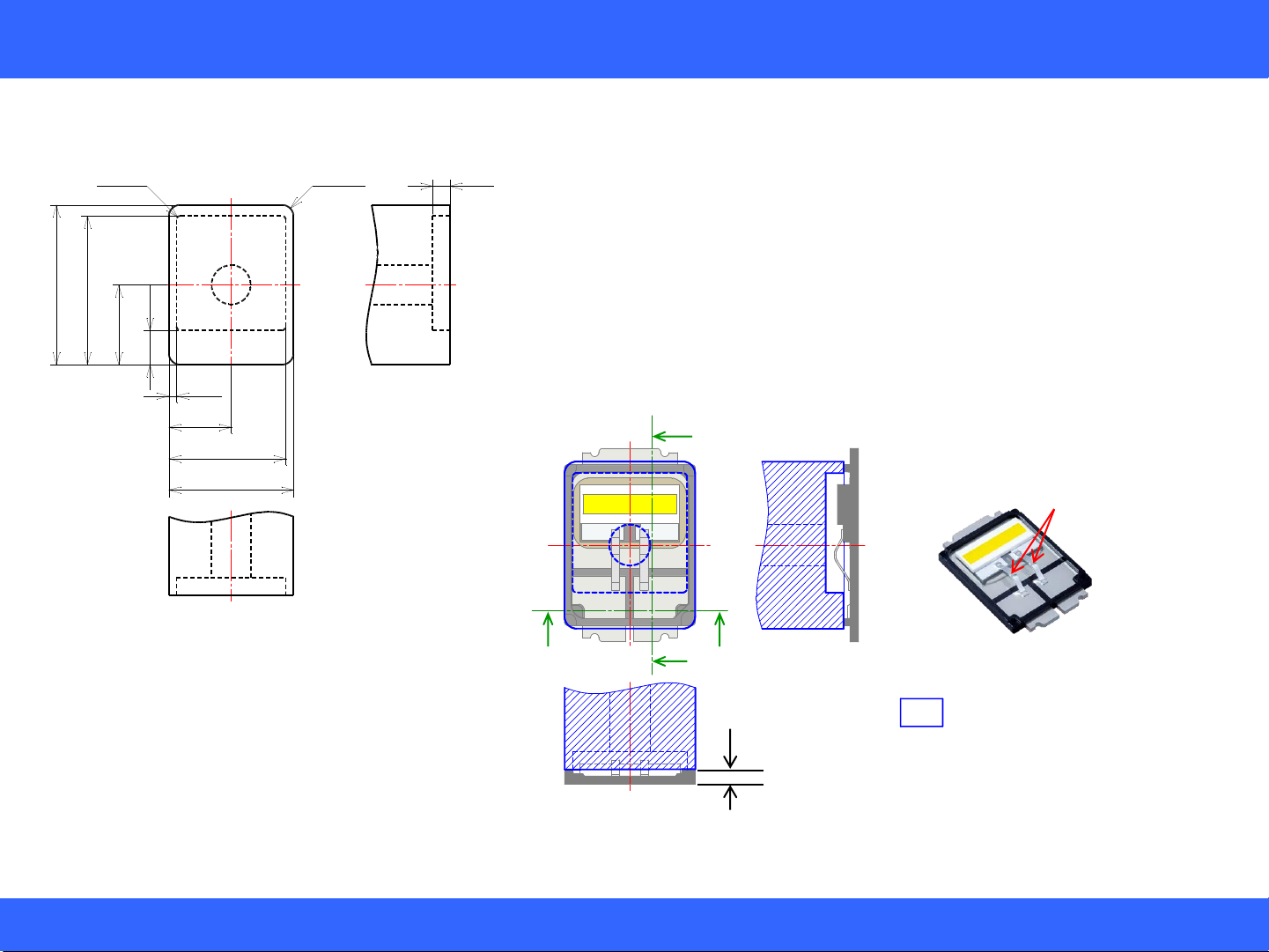

5 The height of the LED is the same for all the LEDs in

the 193F series.

1. Use a pick-and-place nozzle that does not come in contact with the bonding ribbons of

the LED. Figure 3 shows the recommended dimensions for the pick-and-place nozzle.

Ensure that the size and shape of the nozzle tip are appropriate for the LEDs. Otherwise,

this may damage the LED (i.e. scratch, chip, crack, deformation, etc.), affecting the optical

characteristics and/or the reliability, or causing the LED not to illuminate. This may also

lead to an incorrect pick up (i.e. the LED is picked up in a tilted position).

2. When setting the LED pick-up position, ensure that the center of the nozzle and the

center of the LED are aligned and that the nozzle is oriented correctly (see Figure 4).

If the nozzle does not pick up the LED at the center of the LED, and/or if the orientation

of the nozzle is incorrect, this may damage the LED (i.e. scratch, chip, crack, deformation,

etc.), affecting the optical characteristics and/or the reliability, or causing the LED not to

illuminate. This may also lead to an incorrect pick up (i.e. the LED is picked up in a tilted

position).

5 .1

9 .5

10 .2

7 .5

8

4

0 .5

2 .2

1 .1R0 .75

R0 .25

Figure 4. LED Pick-up Position (the NC5W193F LED is shown as an example.)

(Unit: mm)

Bonding Ribbons

A

A’

Pick-and-Place Nozzle

0.9mm 5

BB’

4.1 Pick-and-Place Nozzle

Figure 3. Recommended Nozzle Dimensions Cross-sectional

View along A-Aʼ

Cross-sectional View along B-Bʼ

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

11/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

1. For the tape-and-reel feeder, the tape width is set to

24mm and the feeder pitch is set to 12mm.

2. Use a tape-and-reel feeder that ensures it does not

create excessive vibrations causing assembly issues.

Example: Electric (motorized) feeder

3. It is recommended to remove the top cover tape at

the recommended position shown in Figure 5 (i.e.

immediately before LED pick-up).

4. When handling the reel of the LEDs, ensure that

excessive force is not applied to the bonding ribbons

of the LEDs. Otherwise, this may cause the ribbons to

deform causing the LED to be damaged or not to

illuminate.

Feeding Direction of the Embossed Carrier Tape

LED Pick up

position

Recommended

Top Cover Tape

Removal Position

Top Cover Tape

Feeder Cover

Pick-and-Place Nozzle

1.05mm below the edge

of the tape pocket (i.e.

Pick-up depth)

Pick-and-Place

Nozzle

Embossed Carrier Tape (Pocket)

LED

4.2 Tape-and-Reel Feeder

Figure 5. Recommended Top Cover Tape Removal Position

4.3 Recommended Nozzle Height for Pick-up Operations

Figure 6. Recommended Nozzle Height for Pick-up Operations

1. Ensure that the nozzle goes down onto the LED in the tape pocket until the tip

touches the package (i.e. the black part).

Pick-up depth: 1.05mm

Note: If the reference level for the nozzle setting is at the edge of the tape pocket.

2. The recommended nozzle height for pick-up operations has been determined by

Nichia under specific verification conditions (see Table 9) and may not function as

expected with some other pick-and-place machines. If the pick-up operations are

unstable even with using the recommended nozzle height, adjust the nozzle height

appropriately for the pick-and-place machine being used.

If the pick point of the nozzle is too high,

- it may cause insufficient suction power leading to picking errors (e.g. the

nozzle’s failure to pick/lift the LED into the air, incorrect picking causing the

LED to tilt when in the air).

If the pick point of the nozzle is too low,

- it may cause issues (e.g. causing the embossed carrier tape to shake, causing

the tape pocket to deform) leading to picking failure.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

12/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

Figure 8. Example of Reference Point to Detect, Recognize, or Locate

the Electrodes/Die Heatsink

1. The nozzle should further press the LED 0.2mm onto the PCB from the

height where the LED first touches solder paste.

If the release point of the nozzle is too high,

- it may cause placement issues (e.g. the LED to stick to the nozzle

after placement, the LED to be mounted in an incorrect

place/rotated position, the LED to become soldered to the PCB in

a tilted position, etc.).

If the release point of the nozzle is too low,

- excessive forces may be applied to the LED during placement and

it may cause the LED to become damaged.

1. Nichia recommends using the electrodes and die heatsink as a reference

to locate the center of the LED.

2. If the imaging device has trouble detecting/recognizing the

electrodes/die heatsink, adjust the settings (i.e. the brightness of the

light, etc.) of the pick-and-place machine.

3. If an automatic polarity detector is used for the LEDs, set up the imaging

device to detect the empty space between the die heatsink and

electrodes (i.e. Polarity Detection/Recognition Point in Figure 8 to the

left). In the example in Figure 8, the equipment measures the brightness

of the empty space against the threshold to locate the electrodes

and/or determine the polarity.

Placement

Depth

0.2mm

Pick-and-Place Nozzle

PCB

LED

0.9mm

4.4 Recommended Nozzle Height for Placement Operations (Placement Depth)

Figure 7. Recommended Nozzle Height for Placement (Placement Depth)

4.5 Imaging-based Automatic Inspection

Electrode/Die Heatsink Location

Detection/Recognition Points

Polarity Detection/Recognition

Point

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

13/14 SP-QR-C2-220184-1

Jun. 8, 2022

Assembly Precautions for the Nichia 193F Series LEDs

120sec Max

Pre-heat

180~200℃

260℃Max

10sec Max

220℃Max

60sec Max

1~5℃/sec

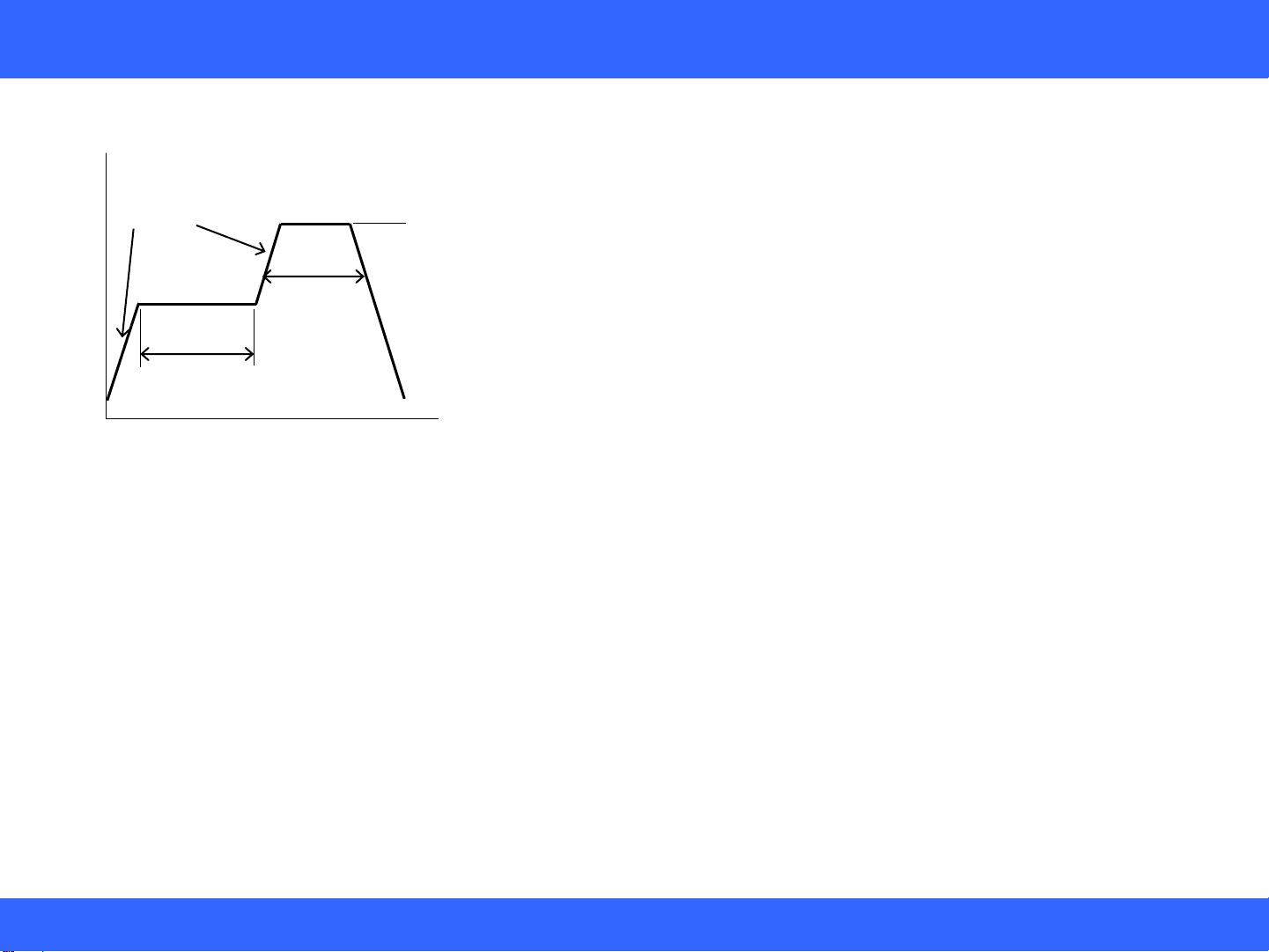

5. Precautions When Reflow Soldering

Figure 9. Recommended Reflow Soldering Condition

(Lead-free Solder)

1. Reflow soldering must not be performed more than twice.

2. Nichia recommends using the reflow soldering conditions detailed in Figure 9

to the left; use the recommended reflow conditions specified by the

manufacturer of the solder paste being used if it works better for the chosen

application.

Note: To ensure that these reflow conditions have no negative effect on the

LEDs, perform sufficient verification prior to use.

3. When cooling the LEDs from the peak temperature a gradual cooling slope is

recommended; do not cool the LEDs rapidly.

4. During reflow soldering, the heat and atmosphere in the reflow oven may cause

the optical characteristics to degrade. In particular, reflow soldering performed

with an air atmosphere may have a greater negative effect on the optical

characteristics than if a nitrogen atmosphere is used; Nichia recommends using

a nitrogen reflow atmosphere.

Light Emitting Diode

This document contains tentative information, Nichia may change the contents without notice.

14/14 SP-QR-C2-220184-1

Jun. 8, 2022

Disclaimer

Assembly Precautions for the Nichia 193F Series LEDs

This application note is a controlled document of Nichia Corporation (Nichia) published to provide technical information/data for

reference purposes only. By using this application note, the user agrees to the following:

•This application note has been prepared solely for reference on the subject matters incorporated within it and Nichia makes no

guarantee that customers will see the same results for their chosen application.

•The information/data contained herein are only typical examples of performances and/or applications for the product. Nichia

does not provide any guarantees or grant any license under or immunity from any intellectual property rights or other rights

held by Nichia or third parties.

•Nichia makes no representation or warranty, express or implied, as to the accuracy, completeness or usefulness of any

information contained herein. In addition, Nichia shall not be liable for any damages or losses arising out of exploiting, using,

or downloading or otherwise this document, or any other acts associated with this document.

•The content of this application note may be changed without any prior or subsequent notice.

•Copyrights and all other rights regarding the content of this document are reserved by Nichia or the right holders who have

permitted Nichia to use the content. Without prior written consent of Nichia, republication, reproduction, and/or redistribution

of the content of this document in any form or by any means, whether in whole or in part, including modifications or derivative

works hereof, is strictly prohibited.

NICHIA CORPORATION

491 Oka, Kaminaka-Cho, Anan-Shi,

TOKUSHIMA 774-8601, JAPAN

Phone: +81-884-22-2311 Fax: +81-884-21-0148

http://www.nichia.co.jp

This manual suits for next models

5

Table of contents

Popular Lighting Equipment manuals by other brands

Robert Juliat

Robert Juliat ZEP 360 manual

Ibiza

Ibiza HYPNO40-LED user manual

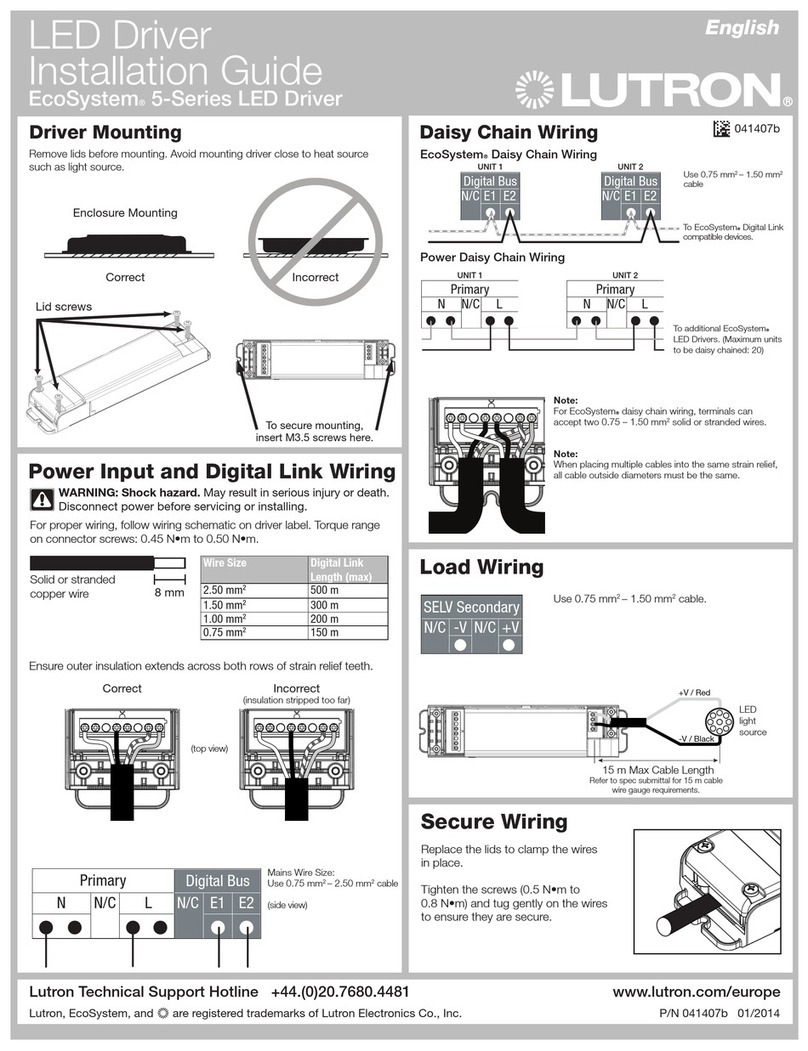

Lutron Electronics

Lutron Electronics EcoSystem 5-Series installation guide

GTD

GTD GTD-L1516P user manual

Home Accents Holiday

Home Accents Holiday TY315-1314 Use and care guide

Starling Technologies

Starling Technologies Pocket Spin Drift instruction manual

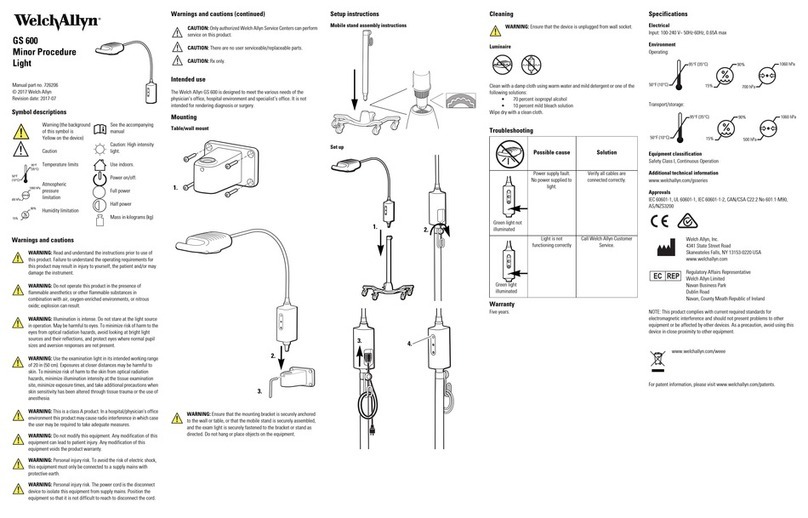

Welch Allyn

Welch Allyn GS 600 quick start guide

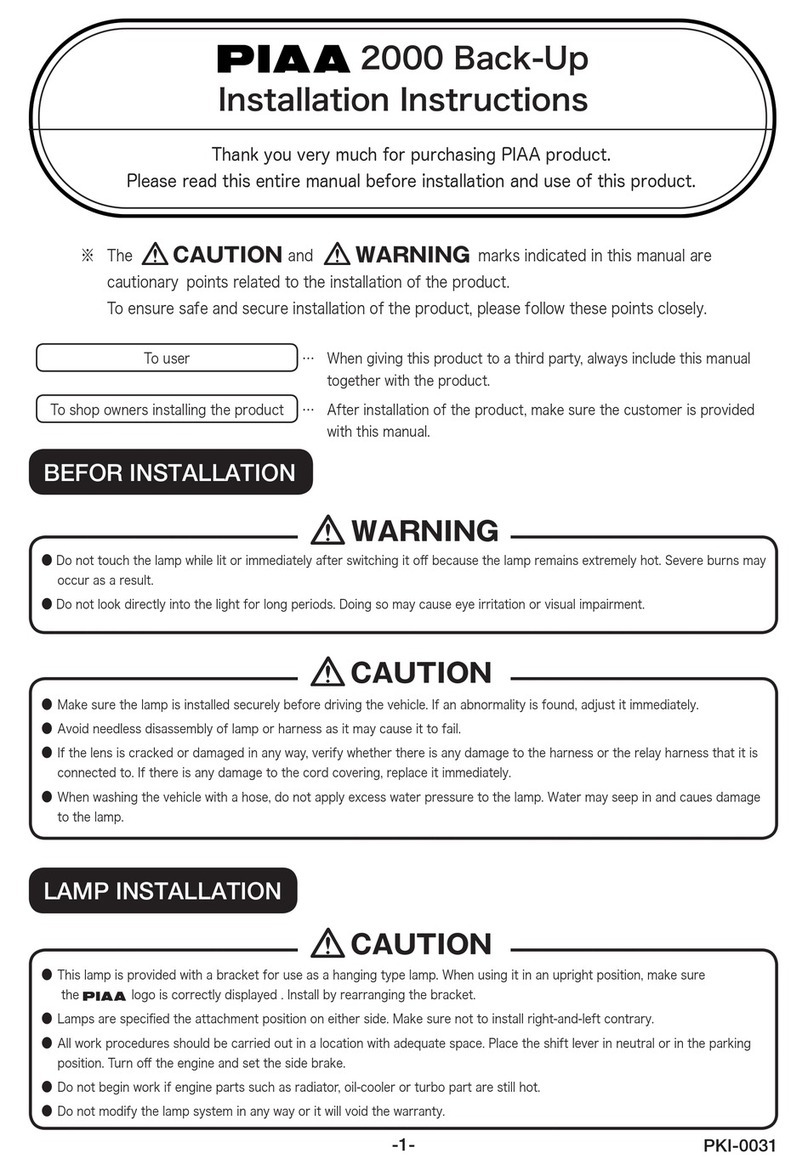

Piaa

Piaa 2000 Back-Up installation instructions

Larson Electronics

Larson Electronics GL-29000GB instruction manual

Poltronova

Poltronova Gherpe instructions

WDT

WDT Tele Indication Touch-V1 Operating and installation instructions

SUNSET

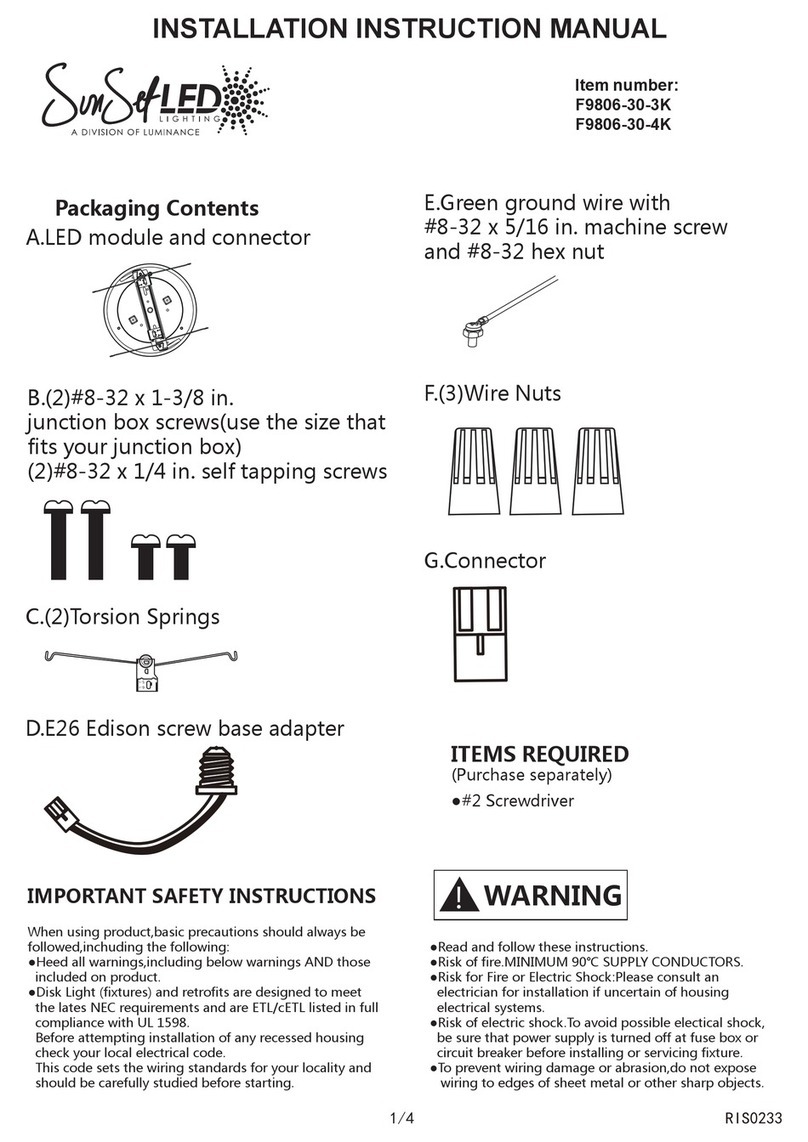

SUNSET F9806-30-3K Installation instructions manual