NICHIYU FBRF14 75 Series User manual

OPERATOR'S MANUAL

ELECTRIC LIFT TRUCK

FBRF14

FBRF16

FBRF20

75 SERIES

Unsafe use of this lift truck may cause serious injury or

death. Operators and maintenance personnel must read this

manual and be sure that they understand its contents before

operating, inspecting or carrying out maintenance on this lift

truck. This manual should be kept near the lift truck for

reference and periodically reviewed by all operators and

maintenance personnel who come in contact with it.

WARNING

OPERATOR’S

MANUAL

ELECTRIC

LIFT TRUCKS

OPERATOR’S

MANUAL

INTRODUCTION

●This operator's manual provides for the proper operation, easy maintenance and periodical

inspection.

●Prior to operation, read this manual carefully for safe and efficient operation.

●Specifications and equipment in this manual are subject to change without any notice by the

manufacturer for further improvement and modifications.

●Make sure these important instructions in this manual are available for the operator on each

delivery or transfer of lift truck. Keep this manual after reading.

●If you have any questions, please feel free to contact NICHIYU local dealer.

and are very important for you and others for safety. Follow these

instructions.

DANGER

Indicates an exteremely hazardous situation which, if not

avoided, will result in death or serious injury.

You must follow this instruction.

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

You must follow this instruction.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

You must follow this instruction.

NOTE Indicates suggestions, tips and hints related to the safety of a

operator and maintenance of a truck.

CAUTION

The operator must read and understand the instruction of safe

operation contained in this manual.

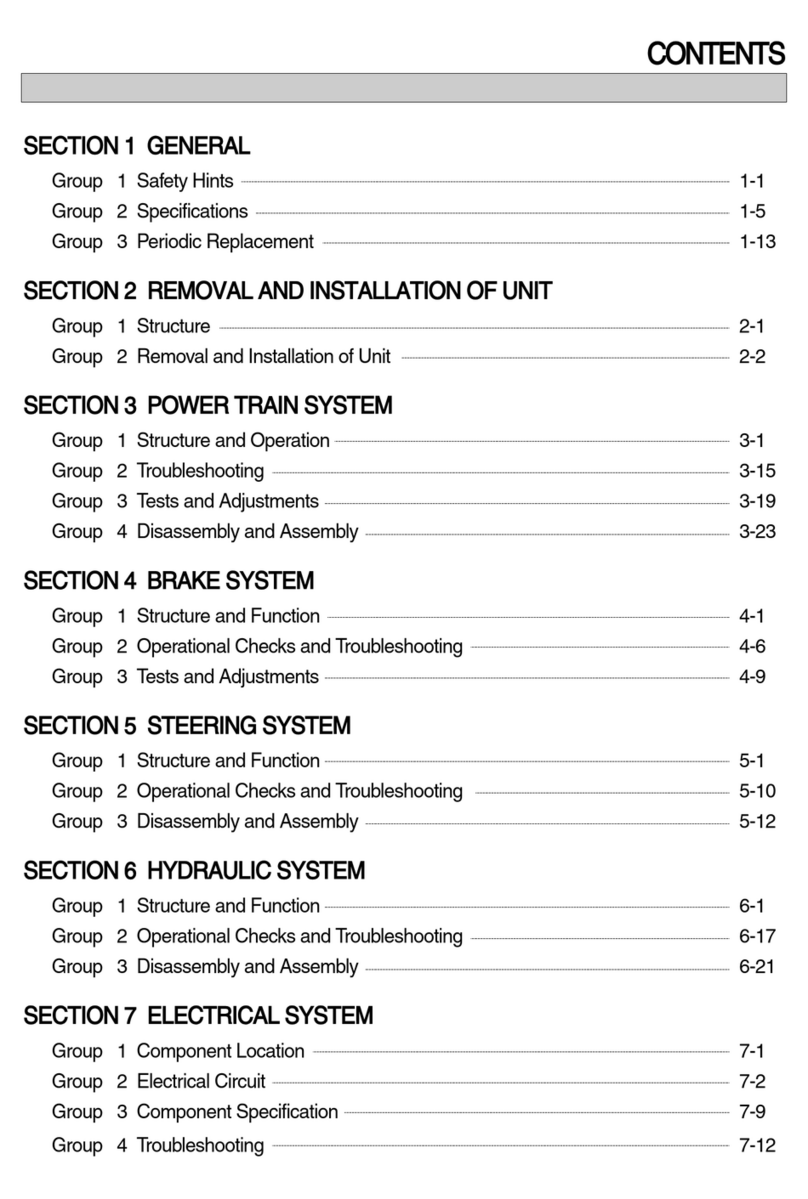

[1]SAFE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Decals and name plates. . . . . . . . . . . . . . . . . . . . . . . . . . 1

Information for safe operation . . . . . . . . . . . . . . . . . . . . . 4

[2]PART NAME AND FUNCTION . . . . . . . . . . . . . . . 18

Name of part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Driving equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Indicator panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Indication of display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Function of display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Various kinds of mode selection. . . . . . . . . . . . . . . . . . . 25

Operating equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

[3]DRIVING AND OPERATION . . . . . . . . . . . . . . . . . . 34

Preparation of start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Traveling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Stacking operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Picking operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

[4]BATTERY AND CHARGER . . . . . . . . . . . . . . . . . . 39

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Precautions for charging the battery . . . . . . . . . . . . . . . 43

Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

How to charge the battery (By stationary charger). . . . . 48

Exchanging battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Level of electrolyte and specific gravity . . . . . . . . . . . . . 54

[5]INSPECTION PRIOR TO OPERATION . . . . . . . . 56

Check point and contents. . . . . . . . . . . . . . . . . . . . . . . . 56

Inspection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

[6]INSPECTION AFTER OPERATION . . . . . . . . . . . 60

Inspection after working . . . . . . . . . . . . . . . . . . . . . . . . . 60

[7]PERIODIC SERVICING . . . . . . . . . . . . . . . . . . . . . . 61

Precautions of maintenance. . . . . . . . . . . . . . . . . . . . . . 61

Weekly (50-hour) servicing. . . . . . . . . . . . . . . . . . . . . . . 64

Monthly (200-hour) servicing . . . . . . . . . . . . . . . . . . . . . 66

Lubrication points and recommended oil . . . . . . . . . . . . 67

Every three-month (600-hour) servicing. . . . . . . . . . . . . 68

Semiannually (1200-hour) servicing. . . . . . . . . . . . . . . . 68

Replacing parts and trouble shooting. . . . . . . . . . . . . . . 69

[8]QUICK FAULT FINDING . . . . . . . . . . . . . . . . . . . . . 70

[9]PERIODICAL REPLACING PARTS . . . . . . . . . . . 72

[10]STABILITY OF FORKLIFT TRUCK . . . . . . . . . . . 73

Load center and load chart . . . . . . . . . . . . . . . . . . . . . . 73

Stability of the forklift truck . . . . . . . . . . . . . . . . . . . . . . . 74

[11]SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

[12]

COLD STORAGE TYPE FORKLIFT TRUCK

. . . . 77

Protection from rust and corrosion . . . . . . . . . . . . . . . . . 78

Protection from low temperature . . . . . . . . . . . . . . . . . . 78

[13]SIDE SHIFT ATTACHMENT . . . . . . . . . . . . . . . . . . 79

Side shift attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Part name and function . . . . . . . . . . . . . . . . . . . . . . . . . 81

Materials handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Periodical inspection and service . . . . . . . . . . . . . . . . . 85

Periodical replacing parts . . . . . . . . . . . . . . . . . . . . . . . 87

[14]AOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

CONTENTS

To know about safe operation

[1]SAFE OPERATION [P1-]

[10]STABILITY OF FORKLIFT TRUCK [P73-]

To know about specification of forklift

[11]SPECIFICATIONS [P75-]

[12]

COLD STORAGE TYPE FORKLIFT TRUCK

[P77-]

[14]AOS [P88-]

OPTIONS

To know about procedure of operation

[2]PART NAME AND FUNCTION [P18-]

[3]DRIVING AND OPERATION [P34-]

[13]SIDE SHIFT ATTACHMENT [P79-]

To know about battery and charger

[4]BATTERY AND CHARGER [P39-]

To know about periodical inspection and maintenance

[7]PERIODIC SERVICING [P61-]

[5]INSPECTION PRIOR TO OPERATION [P56-]

[6]INSPECTION AFTER OPERATION [P60-]

[9]PERIODICAL REPLACING PARTS [P72-]

To know about procedure of

countermeasure for break down

[8]QUICK FAULT FINDING [P70-]

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

SAFE OPERATION

1

1

Decals and name plates

►Indication of direction (Right side / Left side)

The following illustration shows the direction of this

forklift truck from the operator's compartment.

►Decals and Name Plates

CAUTION

Decals and name plates are installed on the

forklift truck to give information about possible

hazards.

CAUTION

If you find that the decals and name plates

are removed and/or unreadable, contact your

NICHIYU local dealer for replacement.

Rear Front

Right

Left

3

2

1

4

5

6

6

7

SAFE OPERATION

2

1

1

3[for Std.]

[for CHINA]

24700-04610

6

4

2

CAUTION

Always depress floor switch while traveling.

Plugging brake dose not work

when release your foot from floor switch.

24700-04670

5

LUBRICATION

MAST

HOSE PULLEY

: GREASE

G

: GEAR OIL

: HYDRAULIC OIL

HO

GO

: REFINED WATER

W

: MACHINE OIL

MO

200HOUR

600HOUR

1200HOUR

: LUBRICATION

: REPLACE

25HOUR

:

CHECK AND ADJUSTMENT

50002-18330

FORK SUPPORT SHAFT LIFT CHAIN

HYDRAULIC OIL TANK

OIL FILTER

BATTERY

STEERING GEAR

DRIVE GEAR

G

HO HO

G

GW

GOGO

MO

MO

7

1

MODEL

MAXIMUM

LOAD/LC

LIFT HEIGHT

SERIAL NO.

MFG. YEAR

VOLTAGE

SERVICE WEIGHT

W/O BATTERY

BATTERY WEIGHT

50006-91500

kg /

kg /

kg

kg

MIN.

mm

mm

V

kg

MAX.

mm

LOAD CHART

LIFT HEIGHT

LOAD CENTER mm

CAPACITY kg

50007-92420㧔㧕

MADE IN JAPAN

SAFE OPERATION

3

1

8 9

Fire hazards !

1. Always charge the battery in well ventilated area.

2. DO NOT use equipment that is liable to produce

sparkes, in this area.

11

PRECAUTIONS FOR BATTERY EXTEND/RETRACT

BATTERY EXTEND

1. Be sure to retract the mast completery.

2. Depress the battery lock pedal to the end of its stroke.

3. Push the reach lever slowly to extend the mast and

battery.

4. Release the reach lever and lock pedal after extended

the battery to the appropriate position for maintenance.

BATTERY RETRACT

1. Be sure to set hoses on the guide properly.

2. Depress the battery lock pedal to the end of its stroke.

3. Pull the reach lever slowly to retract the mast and

battery.

4. Be sure to keep the hoses and battery cables on their

appropriate position.

5. Release the reach lever and lock pedal after retracted

the battery completery.

6. Be sure to check the lock lever to return its proper

position.

All check and maintenance of the battery should be done

on the flat floor, after extended the battery and disconnect

the battery plug.

13

PRECAUTIONS FOR SAFETY OPERATION

1. Do not overload.

Observe allowable load.

2. Prior to operation, check performance of brake.

3. Do not make a sudden start and brake or

turn quickly.

4. Do not make a sudden valve lever operation at

a high lift.

5. Do not run sideways or handle on an incline.

6. When the red lamp of battery capacity indicator

turns on, charge battery.

7. Check electrolyte every week and replenish

water.

8. Be sure to use the prescribed fuses.

12

This is to certify that this is a new fork lift truck

which has been manufactured for exportation by

as stated in the certificate issued by them.

14

10

9

8

10

11

13

14

12

SAFE OPERATION

4

1

1

Information for safe operation

CAUTION

Only a trained and authorized operator shall

operate the forklift truck.

CAUTION

The operator is recommended to wear a helmet,

safety shoes and working clothes.

CAUTION

Do not use a forklift truck in the following cir-

cumstances.

1. Where the temperature is less than –10°C

(except cold-storage use forklift truck) or

more than 40°C.

2. Where the explosive gas (thinner, gasoline

etc.) may exist.

When using a forklift truck in the following area,

consult NICHIYU local dealer before operation.

1. Where the explosive materials such as gun-

powder are exist.

2. The dusty place.

CAUTION

NICHIYU forklift trucks are equipped with an

overhead guard and load backrest extension.

●These designed features are incorporated to protect

the operator from falling loads.

●Make sure they are in place and in good condition.

●Precautions still should be exercised by the operator

for possible falling objects or impacts.

WARNING

Do not operate forklift truck while taking

drugs and/or alcohol; otherwise, an acci-

dent may occur which can cause serious

injury or death.

●Observe the safety regulations and workplace rules.

CAUTION

●Keep the operator's compartment clean at all

times.

●Do not place tools or components in and

around the operator's compartment.

●Doing so may prevent proper operation of the steer-

ing wheel, levers and pedals.

CAUTION

Do not operate the forklift truck with greasy or

wet hands.

●Doing so may result in hazardous operation of the

forklift truck caused by slippery hands or feet.

SAFE OPERATION

5

1

WARNING

Do not overload. Failure to observe the

rated capacity can cause the forklift truck

to tip over.

●Refer to the load chart and make sure that the

weight and the load center are within the capacity of

your forklift truck before handling. If the attachment

is installed on the forklift truck, the maximum capac-

ity should be reduced. Read the instruction manual

of the attachment before operation.

CAUTION

Before handling a load, check the weight and

the center of gravity of the load.

CAUTION

●Be sure to carry out the daily inspection and

the periodic inspection.

●

Do not use a forklift truck that is not inspected.

●Before starting operation, prepare a work

plan and have an important meeting regard-

ing safety.

CAUTION

●Do not modify the forklift truck.

●Do not operate a forklift truck that is equipped

with an overhead guard or a load backrest

extension.

●Always pay attention to possible falling

objects or impacts during cargo handling

operation.

●Modifications and additions shall not be performed

without the written approval of NICHIYU. Contact

NICHIYU local dealer for details.

●Do not install any parts blocking visibility from oper-

ating position.

CAUTION

●Stop operation and report immediately for any

damage or faults on the forklift truck.

●Do not operate the forklift truck until it is

repaired completely.

●Repair and adjustment must be performed by a qual-

ified person.

●If the modification cannot be repaired, contact

NICHIYU local dealer.

CAUTION

Use a pallet of the proper size that has suffi-

cient strength for the load.

SAFE OPERATION

6

1

1

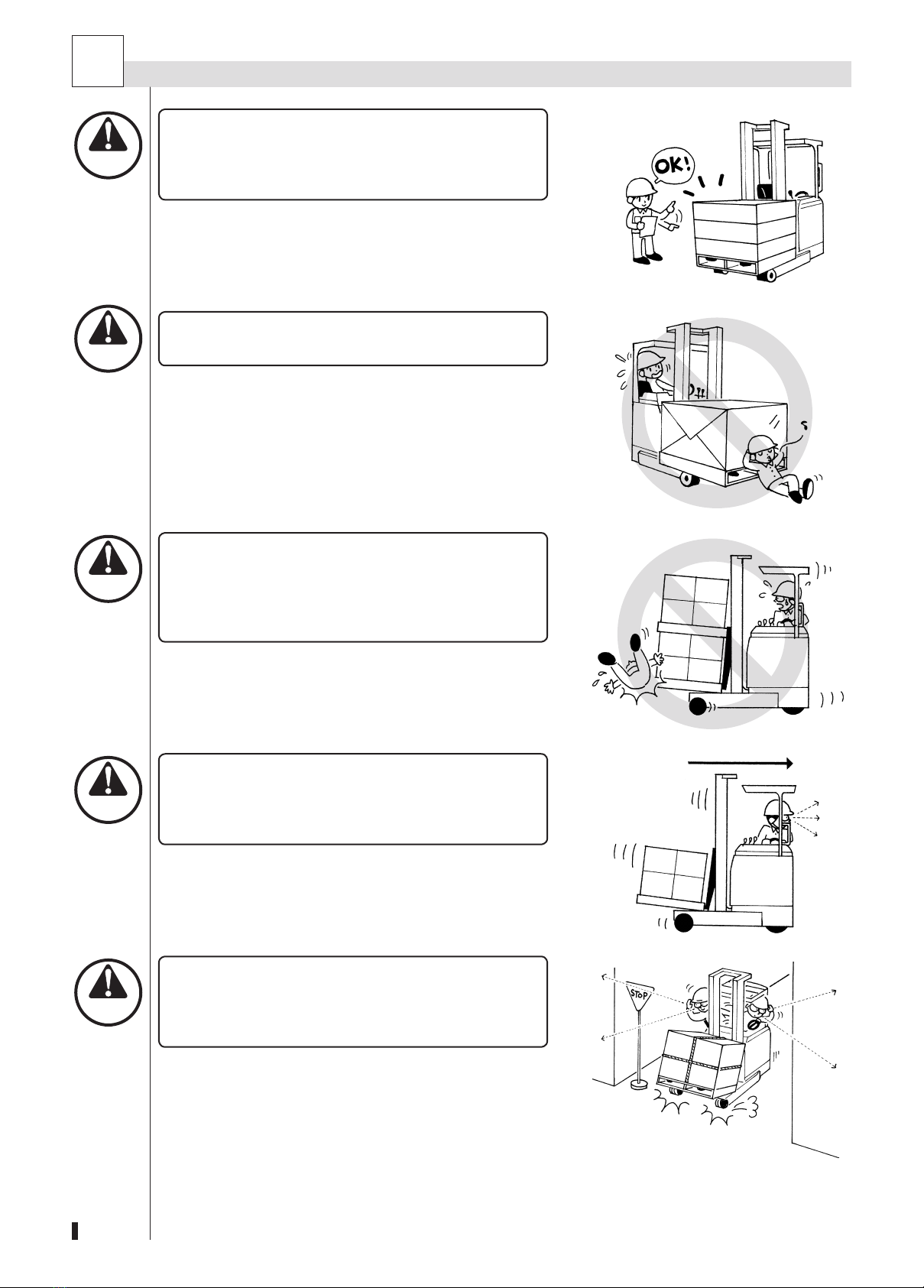

CAUTION

Before operation, make sure that the load is

palletized securely in a proper shape. If a load

is unstable, it can easily shift and fall on some-

one.

CAUTION

Before starting, make sure that no persons or

objects are around the forklift trucks.

CAUTION

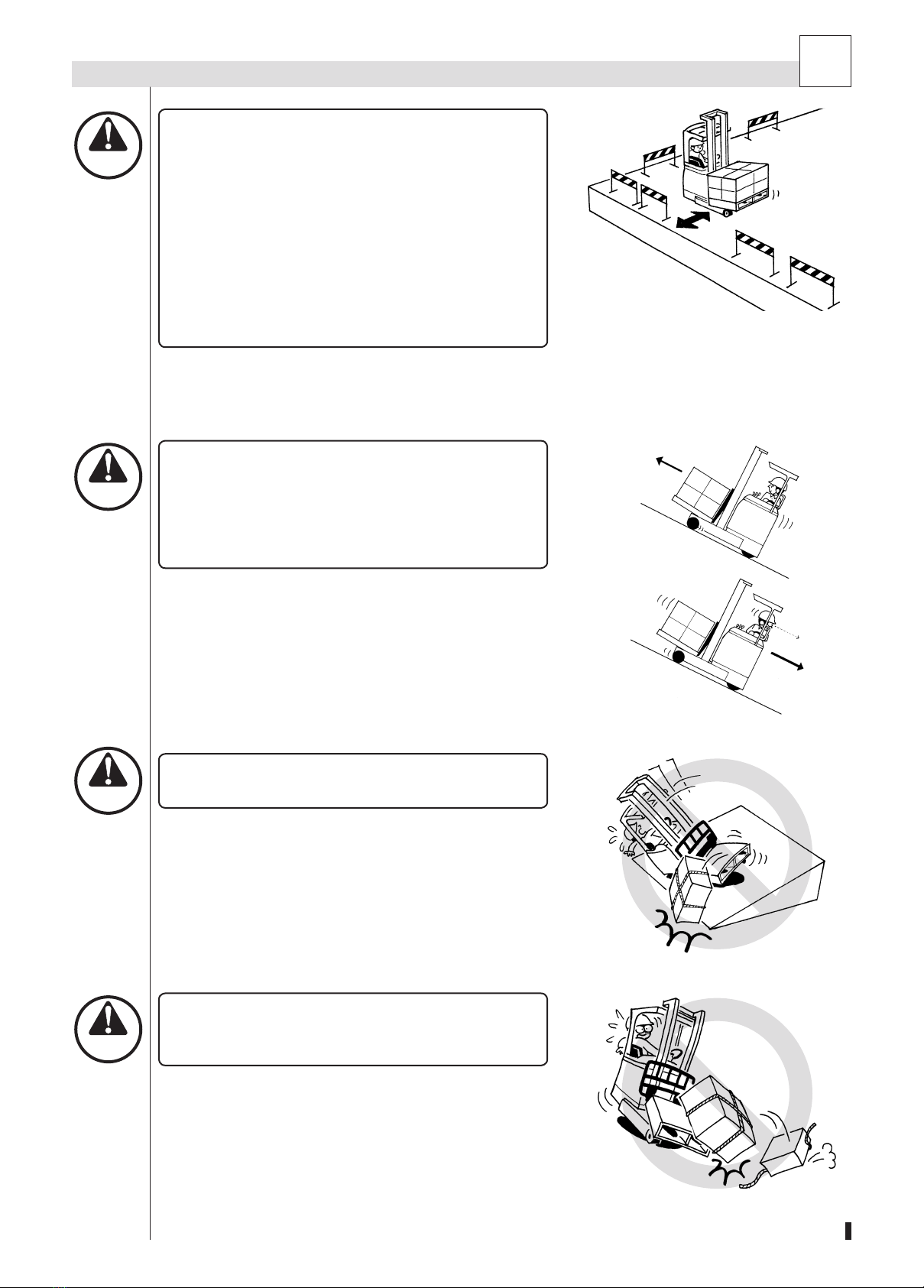

Stop temporarily at intersections, entrances

or areas where visibility is restricted, and then

make sure no one is coming from the right or

left blind corners.

●If you cannot see where you are going, don't move!

Travel slowly around corners.

●Sound the horn at cross aisles and other areas

where you cannot see clearly or where visibility is

restricted.

CAUTION

●Travel in forward if backward visibility is

blocked.

●When transporting a large load, travel in for-

ward or have an assistant perform guidance

in the direction of travel.

CAUTION

Make sure no person is around the forklift truck

when traveling in forward. Look around behind

the forklift truck and sound the horn before

moving.

●If the load blocks your view, or when you travel down

a grade with a load, drive forward. Always look in the

direction of travel. A look-out helper may be required

if your visibility is obstructed.

SAFE OPERATION

7

1

CAUTION

Always look in the direction of travel!

●Always be aware of people near your forklift truck.

Do not proceed near them until they are aware of

you.

CAUTION

Be aware of tail swing.

●Rear wheel steering of the forklift truck causes large

tail swing.

●Always make sure that the tail swing area is clear

before turning.

●When turning in aisles, especially narrow aisles,

keep as far away as possible from stock and racks.

Be extra cautious near people.

●Failure to observe the tail swing area when making a

turn can injure or kill someone.

CAUTION

In a narrow space, have an assistant perform

guidance in the direction of travel, and operate

the forklift truck following the guidance of the

assistant.

CAUTION

Do not make a sudden start, stop or turn.

●Doing so can cause the load to fall.

●Doing so can cause the forklift truck to tip over.

SAFE OPERATION

8

1

1

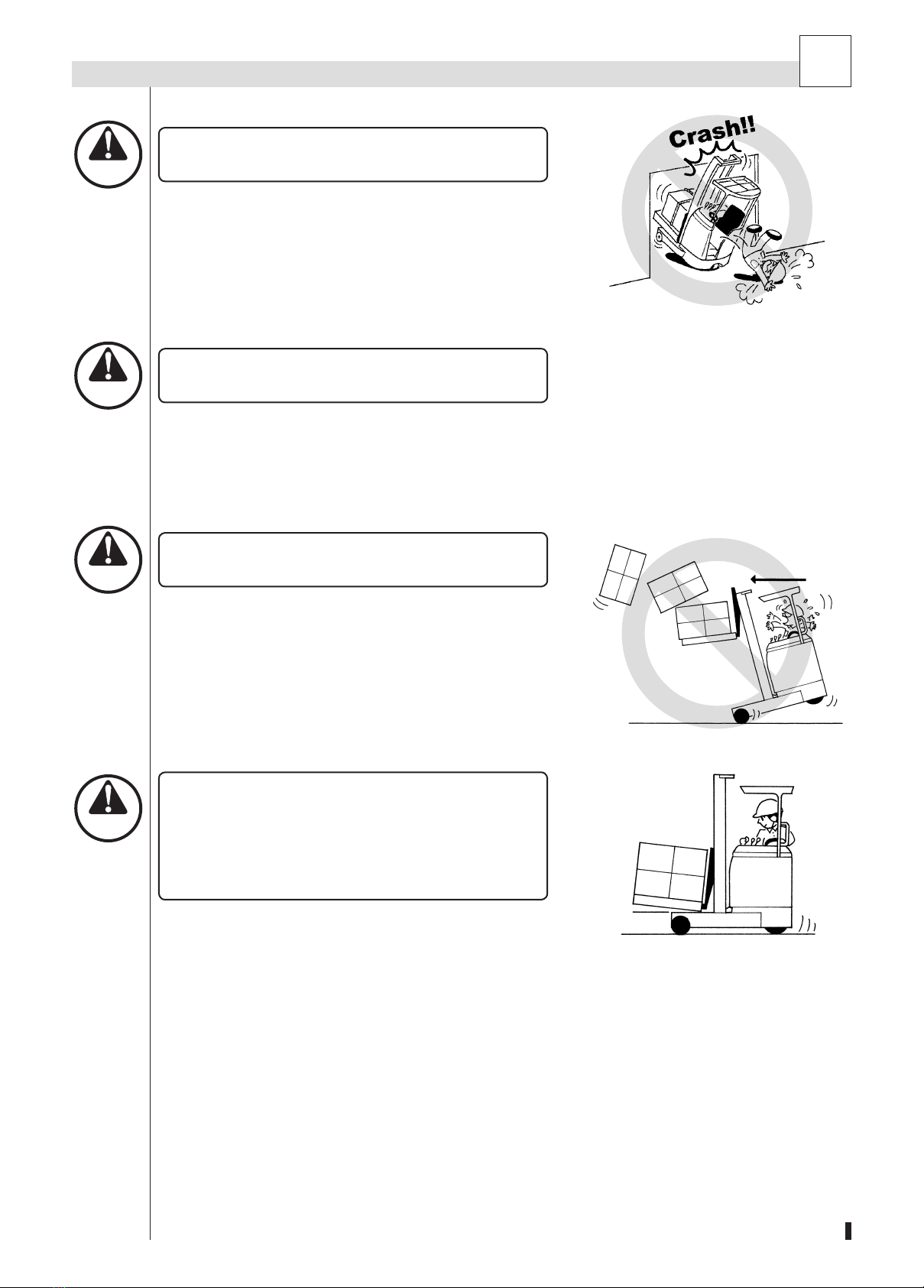

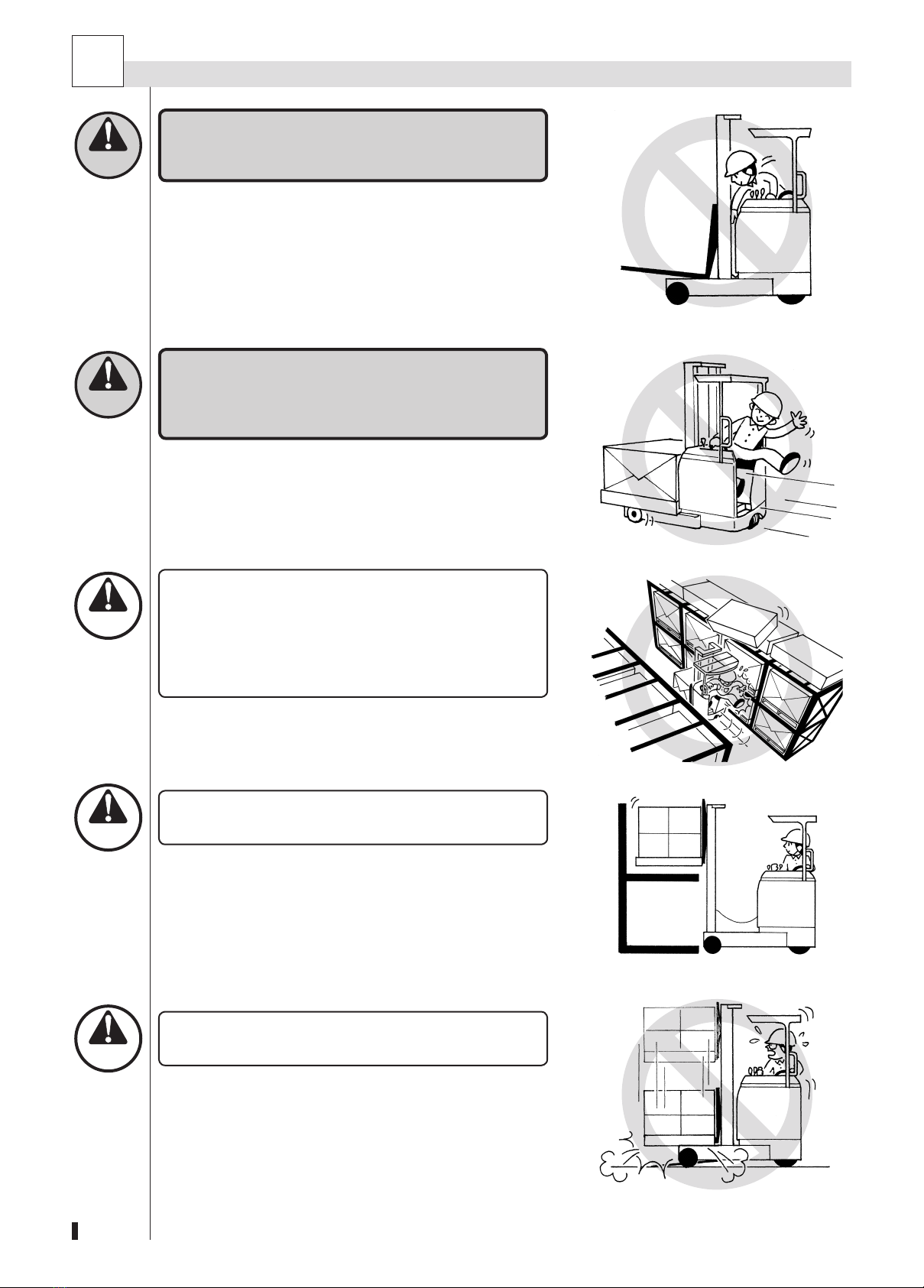

CAUTION

Do not go over obstacles, curbs, ditches, ridges

and railroad trucks.

●Avoid bumps, holes, spill spots and loose materials

that may cause the forklift truck to swerve or tip. If

unavoidable, slow down, and proceed with caution.

CAUTION

●Do not operate on soft surfaces or dirt.

●Always check road surface, and stay away

from soft or uneven ground to avoid a tip

over.

CAUTION

Avoid slippery surface.

●Water, sand, gravel, ice or mud can cause a tipover.

If unavoidable, slow down.

●Do not go into a flooded or water covered area.

CAUTION

Keep enough clearance.

●Serious accidents can be caused by hitting pipes

and beams near the ceiling with mast or overhead

guard. Make sure there is enough clearance for ceil-

ing and height limit of the entrance.

CAUTION

When another truck is approaching from the

opposite side direction, slow down and main-

tain a sufficient distance from the front, rear,

right and left sides of the truck. Do not pass a

forklift that is traveling in the same direction.

SAFE OPERATION

9

1

CAUTION

Do not exceed the limitation of the floor

strength.

●A forklift truck is very heavy. Check the condition of

the driving surface. Make sure the floor, bridge and/

or elevator will support the weight of the forklift truck

and the load.

CAUTION

Check that there is sufficient height and width

for the truck to pass.

CAUTION

Do not travel while the forks are in the raised

position.

●Traveling while lifting the forks can cause the unsta-

ble condition to tip the forklift truck over.

CAUTION

●Before traveling, raise the load 50 to 100 mm

above the top of the straddle legs, retract the

carriage, tilt the carriage backward and main-

tain a clear view of the path of travel.

●Raise the top of the forks 300 mm above the

ground under no load conditions.

300 mm

SAFE OPERATION

10

1

1

WARNING

Never allow anyone to walk or stand

under raised load or the forks.

CAUTION

●Do not push a load by the tip of the forks.

●Do not drag any loads with rope by the lift

carriage or load back rest.

●Do not lift the load by the tip of the forks.

●Doing so may result in damage the load as well as

the forklift truck.

WARNING

Never allow any person to ride on the

straddle legs, the forks or the pallet.

CAUTION

Never allow any person to ride on the forklift

truck other than the operator.

CAUTION

Do not use a person as a counterweight.

SAFE OPERATION

11

1

CAUTION

●When traveling near a shoulder or platform,

maintain a distance from the edges of the

shoulder or platform.

●Always keep the road surface safe, and pro-

vide clear traffic routes.

●Operate the forklift truck on level and firm

roads and floor surfaces.

●Be sure to indicate the operation area of the

forklift truck with signs so that other trucks

and persons cannot enter the area.

●The operation area of the forklift truck should

have sufficient lighting.

●Otherwise, the forklift truck may fall down. Place bar-

riers around the edges for safe operation.

CAUTION

●Travel carefully on grades when loading.

●When traveling on an incline or a slope with

a load, go up or down with the load facing

uphill.

●Travel down slowly and with the brake

applied.

●When traveling down an incline, the stopping dis-

tance will be longer.

CAUTION

Do not turn on, or angle across an incline.

●Failure to observe this rule can cause the forklift

truck to tip over.

CAUTION

Make sure that loads are securely arranged on

a pallet and the forks are properly inserted in

the pallet to avoid an off-centered load.

●Otherwise, the forklift truck may tip over and the load

can easily shift and fall down.

●If a load protrudes outside the pallet, it may contact

a post or other piled loads.

●Do not transport an unstable load.

SAFE OPERATION

12

1

1

CAUTION

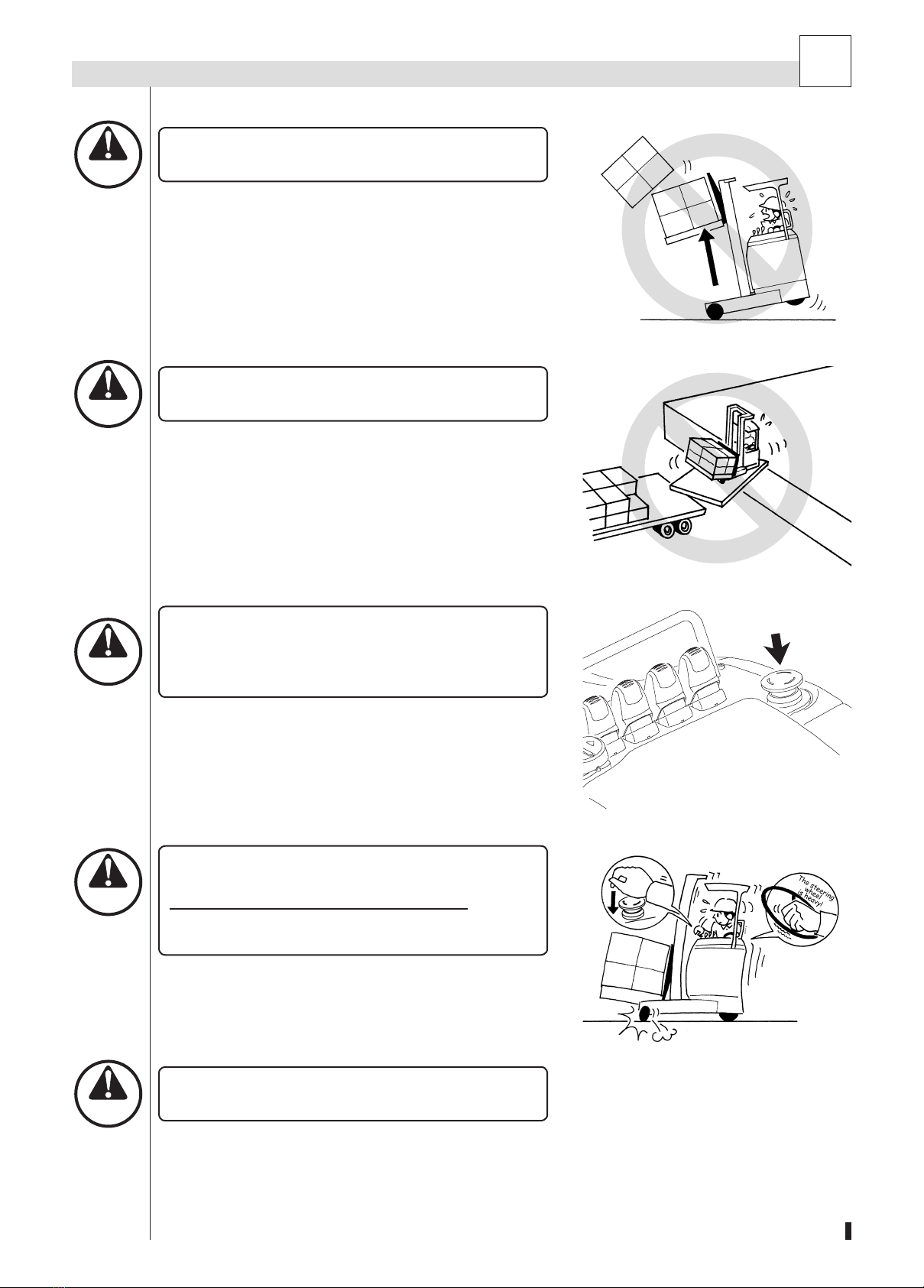

Operate hydraulic control levers slowly when

loading or unloading.

WARNING

Never put any parts of your body between

the mast and the chassis.

●Always operate the key switch, steering wheel and

levers while in the operator's compartment.

●If any part of your body or your work clothes catch-

es a lever, the mast equipment may unexpectedly

move, and then your hands or feet could be pinched.

WARNING

Do not operate the forklift truck with your

body outside of the operator's compart-

ment.

●Keep your body inside the operator’s compartment.

CAUTION

Operating the forklift truck with your head, arms

or feet sticking out of the operator's compart-

ment can cause a part of your body to hit a stor-

age rack, post or other piled lords or be caught

in trucks. Always operate the forklift truck with

your body inside the operator's compartment.

CAUTION

Do not lower or stop the load suddenly.

●Doing so can cause the load to shift and fall down or

the forklift truck to tip over.

SAFE OPERATION

13

1

CAUTION

Drive into a trailer carefully.

●Make sure the trailer brakes are set and the wheels

are blocked while loading or unloading.

CAUTION

Do not travel or lift a load up or down with the

forks tilted forward.

●Tilt the fork up enough to stabilize the load.

CAUTION

Push the emergency switch to shut off the

power supply If a malfunction occurs in the

brake system, the operation equipment, etc.

while operating the forklift truck.

CAUTION

Do not operate the emergency switch when the

truck is traveling or doing hydraulic operations

EXCEPT THE EMERGENCY SITUATION

.

As soon as the power supply is shut off, power

steering function do not work.

CAUTION

Do not jump on or off the forklift truck.

●When getting on or off the forklift truck, make sure

that the truck is stopped.

●When getting on or off the forklift truck, do not grasp

the steering wheel or the hydraulic lever.

This manual suits for next models

2

Table of contents

Other NICHIYU Forklift manuals