Manual

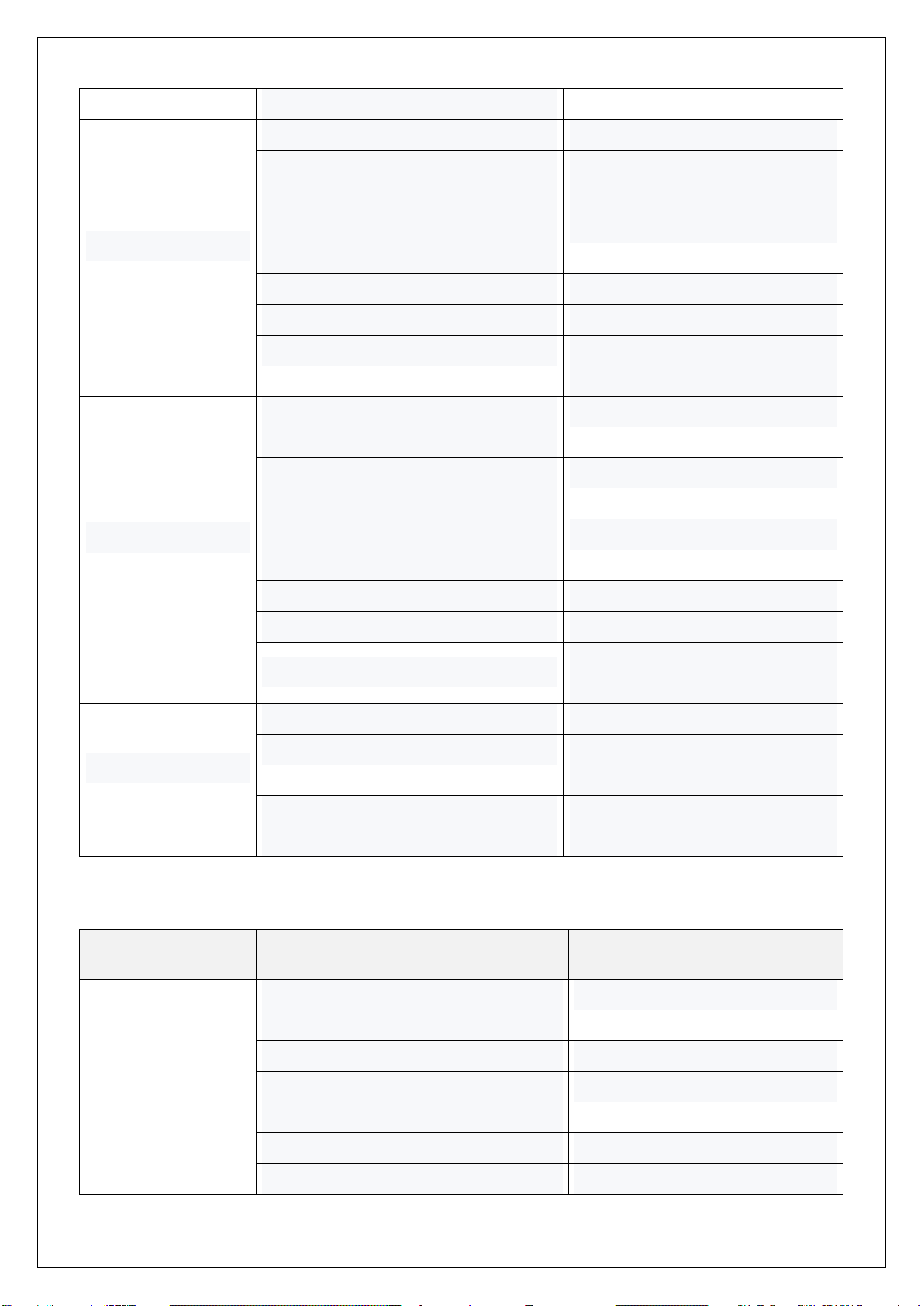

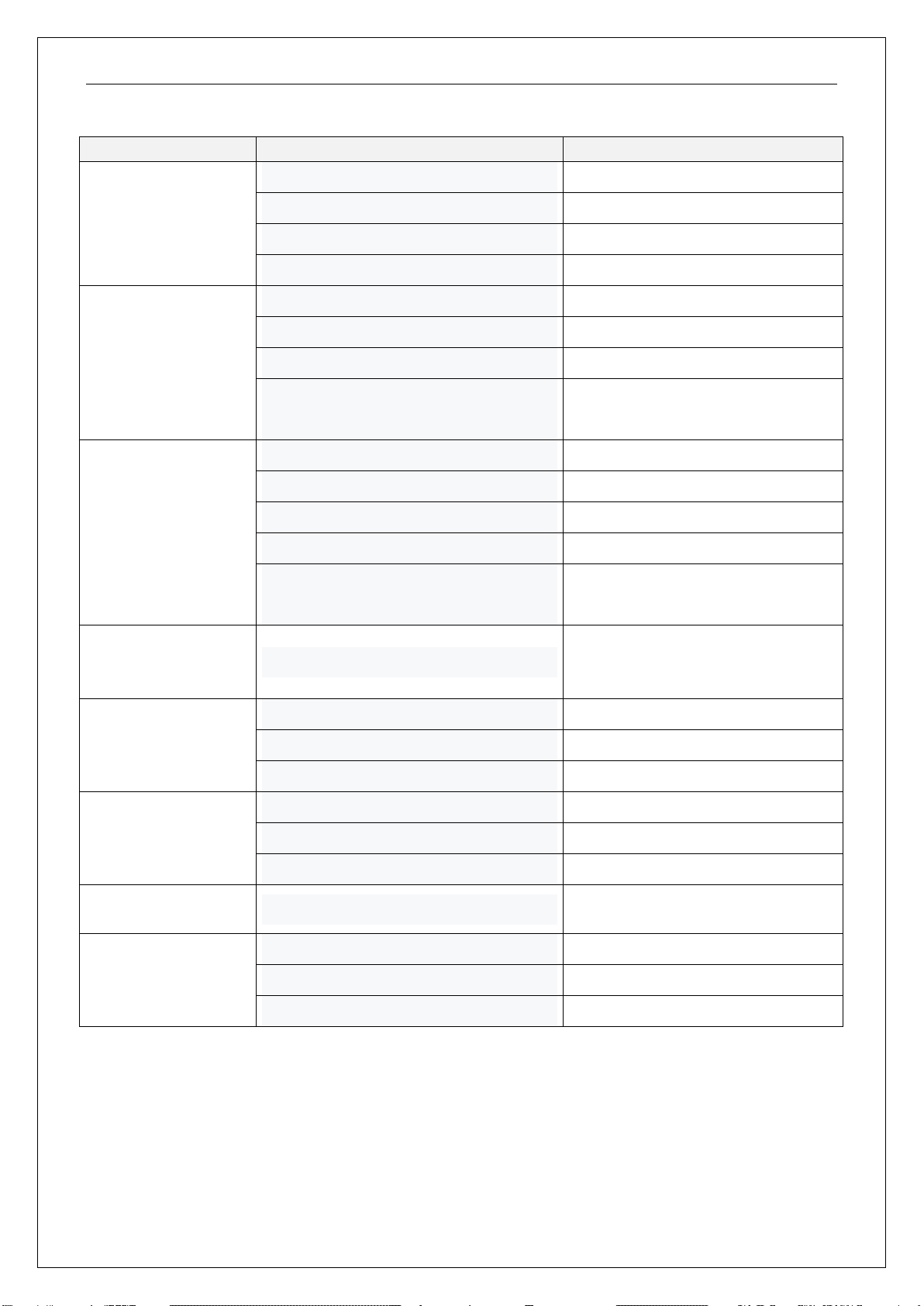

1. Maintenance List ...................................................................................................................................... 1

a. Overview of main components ............................................................................................................. 2

b. Lubrication point .................................................................................................................................... 3

c. Check and refill hydraulic oil.................................................................................................................. 4

d. Check the fuse....................................................................................................................................... 5

2. Fault Analysis ............................................................................................................................................ 6

a. Common Fault analysis ....................................................................................................................... 7

b. The fault code is displayed.................................................................................................................... 8

3. Wiring/circuit Diagram ............................................................................................................................... 9

a、Schematic diagram and wiring diagram..................................................................................................... 10

b、Hydraulic circuit .........................................................................................................................................11

4. Main parts disassembling........................................................................................................................ 12

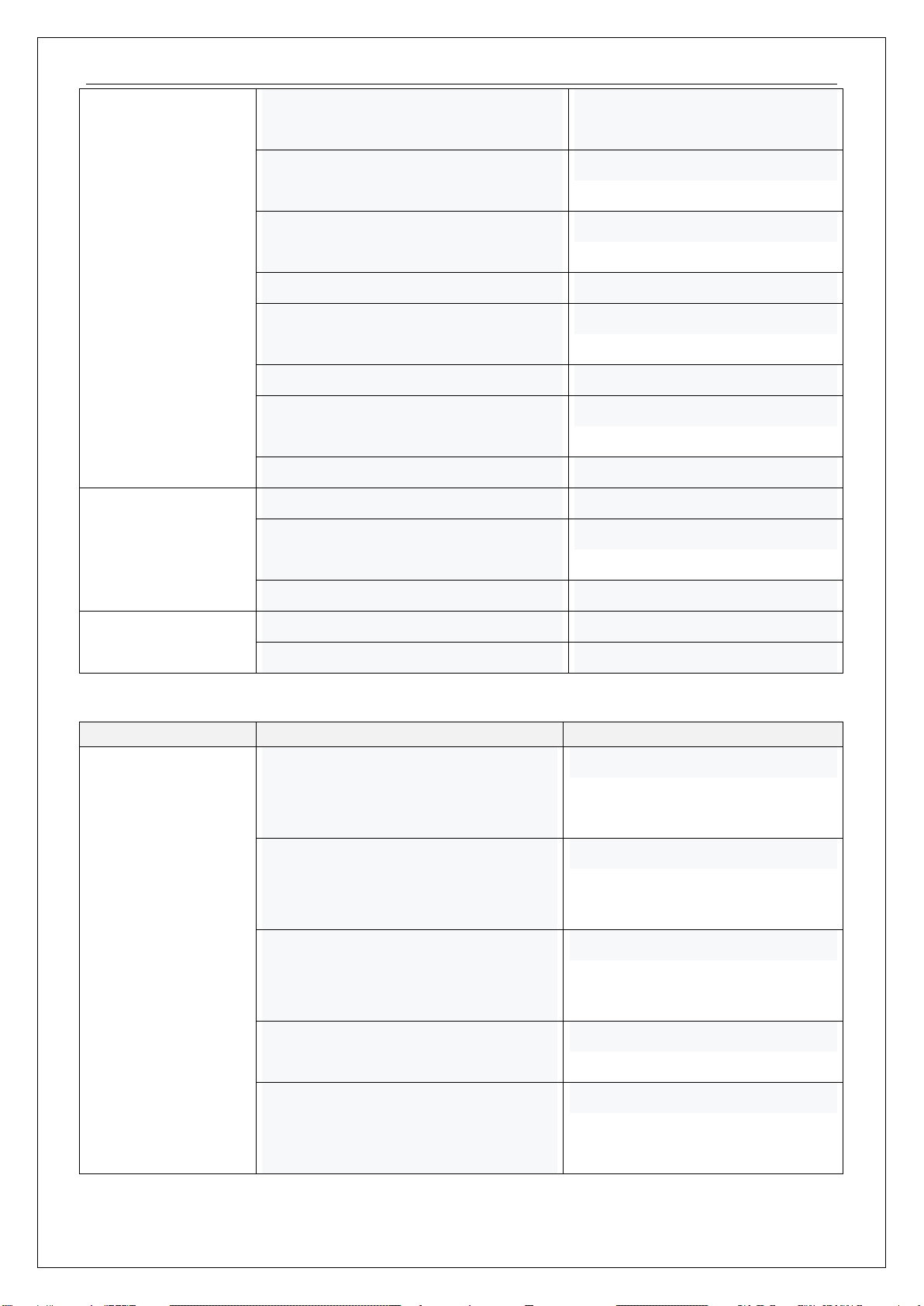

4.1 Driver Removal...............................................................................................................................12

4.2 Steering disassembly ....................................................................................................................14

4.3 Brake disassembly ........................................................................................................................16

4.4 Hydraulic disassembly................................................................................................................... 17

4.5 Removing the top guard ................................................................................................................20

4.6 Frame Disassembly .......................................................................................................................22

4.7 Removing the slide frame ..............................................................................................................25

4.8 Adjustment method of chain tightness ...........................................................................................26

5. Electric System........................................................................................................................................ 27

5.1 electrical schematic diagram .............................................................................................................. 27

5.2 Electronic assembly............................................................................................................................. 28

5.3instrument ............................................................................................................................................... 29

5.4 storage battery..................................................................................................................................... 32

5.5 Fault Diagnosis menu.......................................................................................................................... 33

6. CURTIS handhold unit 4......................................................................................................................3