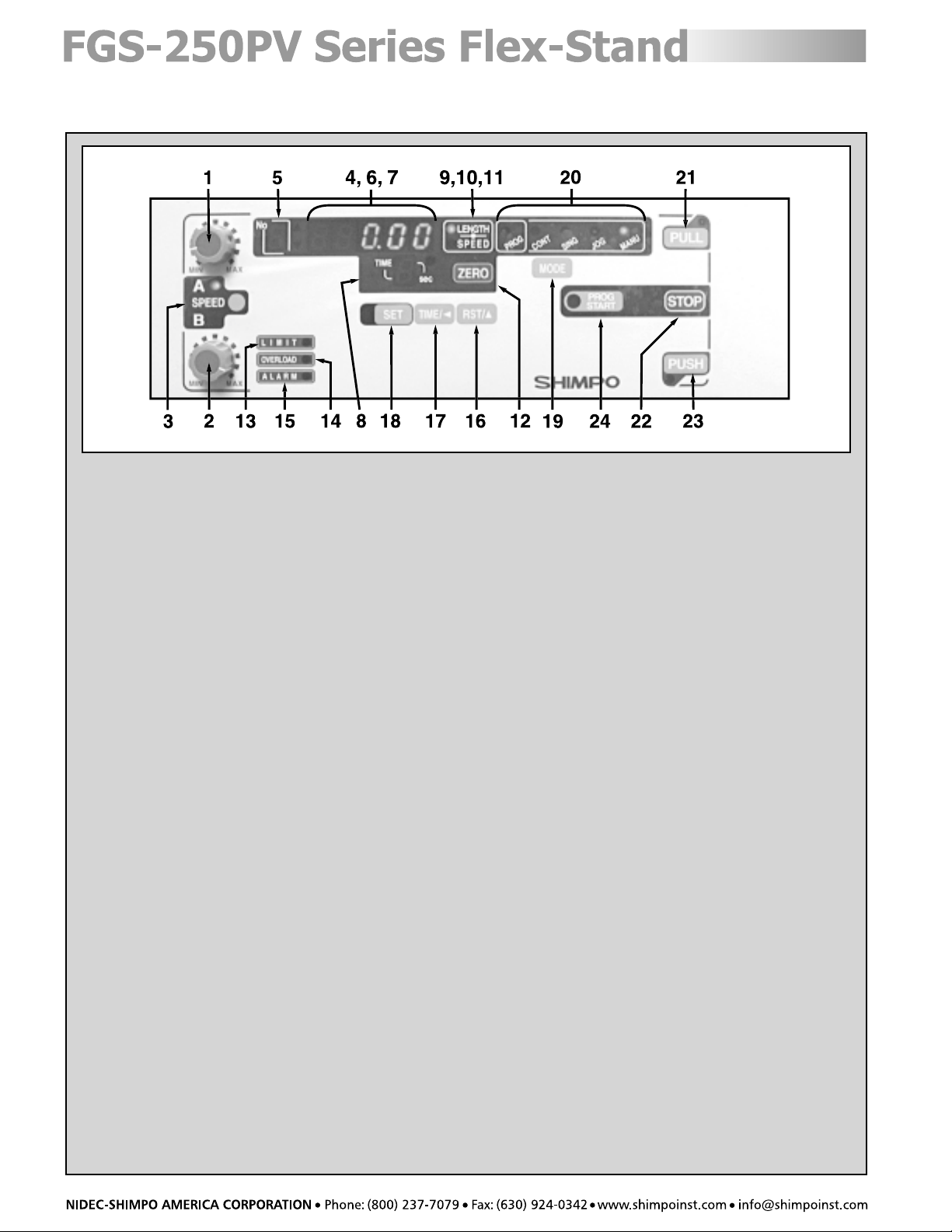

7

CONT (Continuous)

Press “MODE” button until “CONT” LED is illuminated.

This mode of operation is ideal if the user wants the test

stand to repeatedly cycle up and down continuously or

for a user-programmed number of times. The stand will

start in either direction depending on whether “PUSH”

or “PULL” is selected.

To begin programming the test stand, press the “SET”

key; the display will indicate a “C” in the “No” box. The

“C” designates that the digits programmed into the

adjacent LED’s will determine the number of cycles (number

of times) a program will run. Using the “TIME/#” and

the “RST/!” buttons, select the number of cycles you

want the program to complete (0001-9999) or select four

“0’s” if you want the program to run continuously; press

“SET” to store the number of cycles.

The letter “Ft“ appears in the LED’s in the “No” box; this

informs the user that the upper force limit should be

programmed. Use the “TIME/#” and “RST/!” buttons to

select the desired force limit. Use “TIME/#” to change

digit position and “RST/!” to increment each digit until

the desired limit force is displayed. NOTE: Pressing the

“TIME/#” button until no digits are blinking allows the

user to select a negative sign by pressing the “RST/!”

button. With no negative sign displayed, the test stand

platform is programmed to move downward (this denotes

compression). With the negative sign displayed, the test

stand platform will move upward (this (-) denotes tension).

Press “SET” to store the upper force limit in memory. The

down arrow LED (Fu) will light indicating that the test

stand is ready to have its lower force limit programmed.

Program the force limit using the “TIME/#” and “RST/!”

buttons. Use “TIME/#” to change digit position and

“RST/!” to increment each digit until the desired limit

force is displayed. NOTE: The upper limit must be greater

than the lower limit (Fupper>Flower ; -5>-20). Again press

“SET” to store the lower force limit into memory.

You may delay the time between upward and downward

movements by selecting 0, 1, 2, 3, 4 or 5 seconds using

the “TIME/#” button. You may view distance traveled

by pressing “LENGTH/SPEED/CYCLE” until the LED

adjacent “LENGTH” is lit. Speed can be displayed by

pressing “LENGTH/SPEED/CYCLE” until the LED adjacent

“SPEED” is lit. Finally, the number of cycles completed

can be displayed by pressing “LENGTH/SPEED/CYCLE” until

no LED’s are lit.

The test stand will move downward or upward after

automatically zeroing the force value of a Shimpo gauge

when the respective “PUSH” or “PULL” button is selected.

The stand will continue to move until one of the following

events occurs: the “STOP” button is pushed, one of the

manual limit switches is tripped, the emergency reset

button is pushed or the force limit is reached. If the

stand is stopped for any of these reasons the gauge’s

value will be reset to zero once either the “PUSH” or

“PULL” button is pushed again to resume movement.

Length, speed or cycle count can be displayed as

described in the “SING (Single)” section on page 6.

NOTE: An RS232C output is produced when using this mode

of operation, refer to “RS232C Output Format” on page

8 for details.

PROG (Program Operation)

Press the “MODE” key until the LED adjacent to “PROG”

is lit.

NOTE: An RS232C output is produced when using this

mode of operation, see “RS232C Output” section on

page 9 for details.

Before programming the stand, it is best to get the two

speed levels set appropriately. One should be set for the

speed the user wants their test performed at and the

other should be set at the highest acceptable level to have

the stand moving when not performing the actual force

test (this is usually at the maximum the stand will allow).

To begin programming the test stand, press the “SET”

key; the display will indicate a “C” in the “No” box. The

“C” designates that the digits programmed into the

adjacent LED’s will determine the number of cycles

(number of times) a program will run. Using the “TIME/#”

and the “RST/!” buttons, select the number of cycles

you want the program to complete (0001-9999) or select

four “0’s” if you want the program to run continuously.

Press “SET” to go to the next step.

See the “Setting a Force Limit” section on page 6 for

force limit programming details.

The display in “No” box now shows “H”; the “H”

designates the home position. Select the “PUSH” or

“PULL” button to set the HOME position; press “SET”.

The test stand platform will automatically move to the

appropriate (manually set) distance limit position.

The display in “No” box now shows “F”; the “F” designates

the auto zero function. This function is only available

when using the FGV or DRI Shimpo force gauges. Use

the “TIME/#” and “RST/!” buttons to program the “zero”

force.

NOTE: The recommended minimum zero force that the

user should program into the test stand is 0.2% of the

full scale (rating of the force gauge), i.e. if the

programmer is using an FGV-200H force gauge, the

programmed “zero” force should be 0.4 lb (0.002 X 200

= 0.4). If no force is programmed in this step and the

display reads all zeros, the test stand will not zero the

distance and this feature is inoperative. Press the “SET”

button to move on to the next step. This very useful

function allows the operator to reset the distance display

and RS232 output data to zero once the force gauge

senses a force measurement.