Nielsen-Kellerman COX-BOX PLUS SYSTEM Operating instructions

www.nkrowing.com.au

1

The Most Relied-Upon

Pocket Weather Instruments

in the World

Making Work & Play

Easier & Safer

COX-BOXTM PLUS

SYSTEM

INSTALLATION, MAINTENANCE AND

TROUBLESHOOTING GUIDE

Thank you for purchasing this NK CoxBox. PLEASE take a moment to review these instructions

before installiation & use. Your CoxBox system should provide you with years of trouble-free service,

but we are always here to help if a problem arises. To order parts or accessories or obtain technical

support, please call 02 6553 2473 You may also e-mail questions to our support representatives at

[email protected] or visit NK online at www.nk.com.au

www.nkrowing.com.au

2

If any of these functions do not work properly, review each step of the installation, checking all

distances and alignments. Also review the “Troubleshooting” section for help pinpointing the problem.

If you still are having problems, please contact our Repair Department on 02 6553 2473 or write

?

Additional Information

Never attempt to repair the Cox-Box unit yourself. The units are specially sealed to make them

watertight. Breaking this seal often causes very expensive damage and will void the warranty. The

only accessory that we will repair is the microphone. We do encourage and will support experienced

individuals to repair and maintain wiring harnesses and speakers.

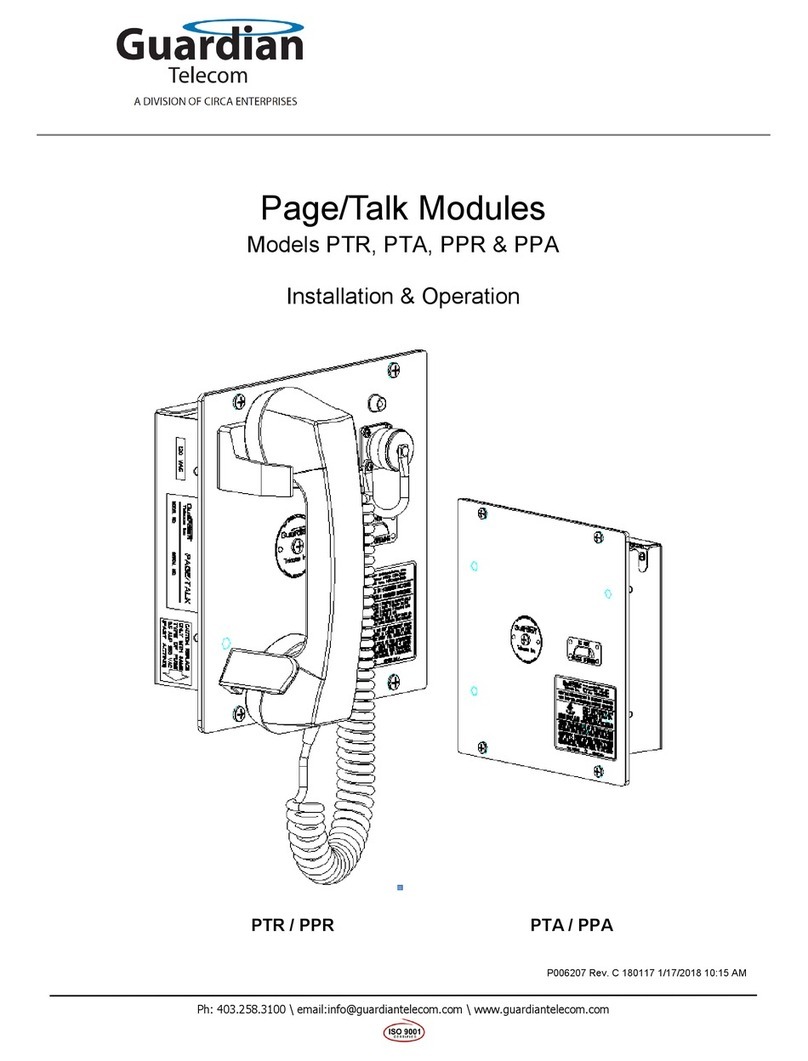

RECALL/EXIT

START/STOP

STORE SPLIT/CLEAR

MICROPHONE

CONNECTOR AUDIO/ CHARGING

CONNECTOR

TIMING/SPLIT

RECALL

STROKE COUNT

STROKE RATE

ON/OFF KNOB

AUTOMATIC

BACKLIGHT

BATTERY LIFE

INDICATOR

PROTECTIVE

RUBBER

BUMPER

www.nkrowing.com.au

3

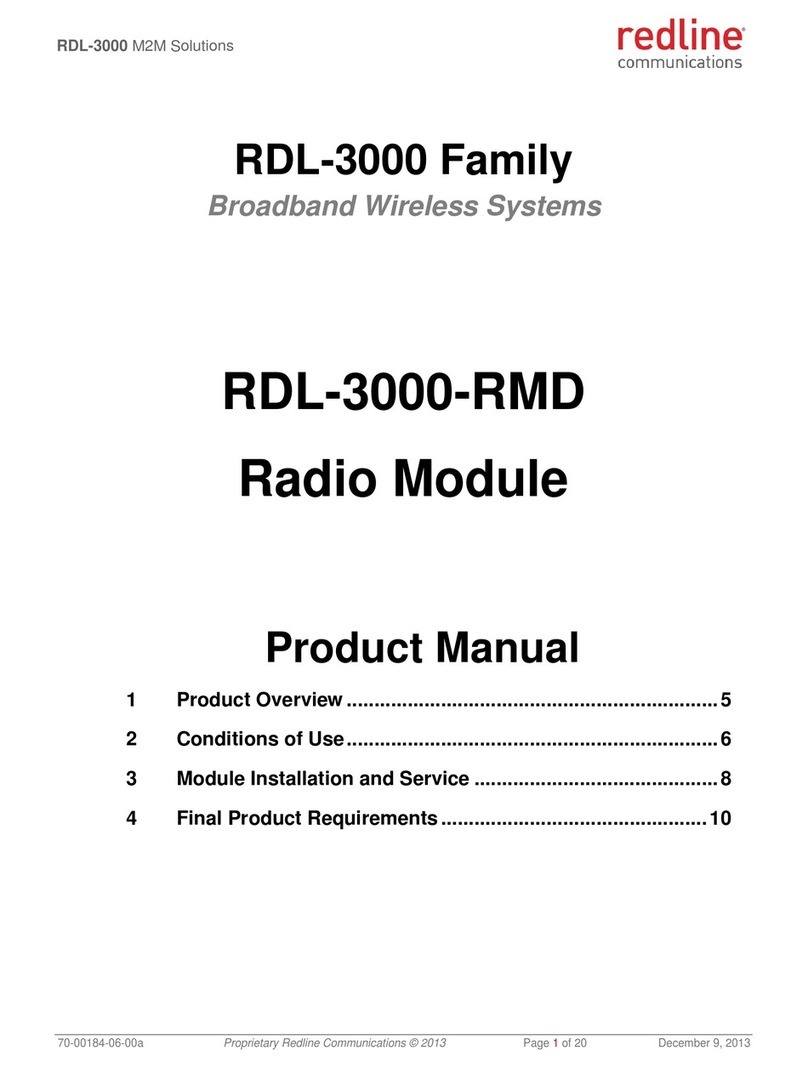

RECHARGEABLE

REMOVABLE

BATTERY

PROTECTIVE

RUBBER

BUMPER

BATTERY

ALIGNMENT

FEATURES

BATTERY

LOCK

BATTERY

ALIGNMENT

FEATURES

Want to take the CoxBox Virtual Tour?

Visit www.nkrowing.com.au

www.nkrowing.com.au

4

OPERATION

TURN ON

TWIST

Turn on amplifier and display. Increase amplifier volume.

Timer and stroke count will turn on in “STOP”. Stroke

Rate will operate.

TURN OFF

TWIST, ‘CLICK’ Turn off amplifier and display.

Decrease amplifier volume.

READY

PRESS Ready timer and stroke count.

START

ROW!

Row to start timer and stroke count.

AUTOMATIC STROKE

MEMORY

Timer, stroke rate and stroke count will keep running

until stopped.

Timer will run to 59:59.99 then roll back to 0.

Count will run to 999 then roll back to 0.

Stroke rate will be stored in memory automatically every

10 seconds for approximately 60 minutes.

STORE/SPLIT

PRESS

Store split and rate manually.

Time will freeze so you can read split.

Timer continues internally and display resumes running

after 5 seconds.

STOP/RESTART TIMER

PRESS

Stop and restart time and stroke count at any time. Stop

time will be recorded as a split.

RECALL MEMORY

PRESS

MANUAL MEMORY REVIEW

PRESS OR

-or-

AUTO MEMORY PLAYBACK

PRESS

Enter memory recall.

(Timer must be stopped.)

Manually step forward or backward through memory.

Time and rate will display for each 10-second interval .

Time, rate and cumulative stroke count will display for

each manually stored split. Stroke rate information is

an instantaneous snapshot, not averaged.

“Playback” memory automatically. Timer will run and

stored rate will display at each 10-second interval. Rate

and cumulative stroke count will display at each

manually stored split. Stroke rate information is an

instantaneous snapshot, not averaged.

EXIT/RECALL

HOLD

Exit recall.

CLEAR/ZERO

HOLD

Hold to clear memory and zero timers.

Timer must be stopped.

Must hold until “CLEAr” disappears and display shows“0’s.”

www.nkrowing.com.au

5

BATTERY USE AND CHARGING

BATTERY LIFE Each bar represents 20% of battery life.

Should run minimum of 4 hours per full charge.

CHARGING

Use any standard Cox Box wall or car charger. A fully

drained battery requires 9.5 hours of charging to reach

full capacity.

FULL CHARGE

Display will show charge percentage and read “Full”

when complete.

Charge management logic protects from overcharging.

However, avoid leaving on charge for more than 7 days to

preserve life of your battery.

REPLACE BATTERY

TWIST

TWIST, ‘CLICK’

Be sure to line up “double bump” end of battery with

double grooves when inserting new battery.

Twist locking ring to “CLICK” to ensure it is locked

in place.

WARNING!

Battery does not float.

If battery pins or contacts become wet, dry thoroughly

before use.

STORAGE

Charged batteries will hold their charge for 12 months.

Keep one on hand to ensure uninterrupted Coxing!

(Avoid storing batteries where temperature will exceed

140º F/60º C such as a car in hot sunlight.

ERROR MESSAGES

Battery voltage temperature or charging time has

exceed normal limits during charge. Continued

charging can be dangerous.

ACTION:

Ensure charging environment is not above 100º F/30º

C. If error persists, replace battery pack. Return failed

pack to NK.

SPECIFICATIONS

WEIGHT Control Unit, Bumper, Battery Pack: 1 lb., 3.9oz. Battery Pack: 3.8oz.

SIZE 4x4 in (fits in all existing cup brackets)

BOUYANCY Control unit with battery installed floats. Control unit alone floats. Battery does not float.

SEALING Waterproof (IP67)

MEMORY Automatic memory: stroke rate every 10 seconds, up to 60 minutes. Manual memory: time, stroke rate, stroke

count. Each manual point stored will decrease the auto memory capacity by 50 seconds.

BATTERY CAPACITY Minimum continuous talk time: 1 hour. Standby: 25 hours. Typical use: 4 hours (typical defined as 1/2 volume and

talking 1/2 of the time). 10w hr. lithium battery.

BATTERY LIFE EXPECTANCY Battery pack can be expected to last 300 full charge/discharge cycles. The expected cycles increases greatly for

partial charge/discharge.

ENVIRONMENTAL

The Cox Box conforms with Council Directive 2004/108/EC (December 15, 2004) on Electromagnetic

Compatibility and is CE-marked accordingly. It is also RoHS (Reduction of Hazardous Substances)

compliant and marked in accordance with the WEEE (Waste Electrical and Electronic Equipment)

Directive. Please do not dispose of the Cox Box or battery pack in your household trash. Return to

NK, an NK dealer, or a designated recycling center for proper recycling and disposal.

www.nkrowing.com.au

6

Care of Your Microphone

Your microphone is shipped attached to a headband and ready for use. The microphone is fully waterproof, and

may be fully immersed, but it will not float on its own. Unless it is attached to a Cox-Box, the microphone will sink.

Microphones should be treated with care.

• Do not attempt to bend the aluminum boom or twist the mouthpiece.

• Do not drop the microphone.

• Do not yank or pull on the microphone cable when disconnecting from the Cox-Box.

• Do not carry the Cox-Box by the microphone.

CARING FOR YOUR COX-BOX SYSTEM

Nielsen-Kellerman equipment is designed, built and tested to withstand the rigors of everyday use, but it is not

invincible and it can be damaged.The following information is intended to help you maintain your equipment and

prevent unnecessary repairs.

Charging

• Place the unit on charge whenever it is not in use,.

• If the low battery sign comes on, be sure to charge the unit for at least 9 hours.

• Under normal conditions, a fully charged battery should last at least 4 hours. If your unit is not providing this much

operational time, it may be time to return it to NK to have new batteries installed. We expect our batteries to need

replacement after three years of normal full-season use.

• Have the batteries exceeded their lifespan? A Cox-Box Battery is expected to provide 3 years of normal use (daily

practices for approximately six to nine months of the year).

NOTE: NK NO LONGER REPAIRS CHARGERS!

If you wish to repair a charger plug, you may obtain pins and instructions from NK. However, for most

people, the most cost- and time-effective approach is simply replacement.

!

www.nkrowing.com.au

7

No Stroke Rate or Intermittent/Incorrect Reading

Is there a problem with the unit?

When there is no reading or there are irregular readings, the problem usually lies

with the sensor, not the unit itself.To test the unit:

• Turn the unit on; clear the memory and place in ready mode.

• Using a bent paperclip (unfolded into a“U” shape) repeatedly poke into the two

exterior holes of the CB plug (“A” & “D” sockets of the P5).

• The stroke rate should update every other poke. If this happens, the Cox-Box

is functioning properly and the problem exists with the rate sensor in the

wiring harness. Order a replacement rate sensor and install it according to the

directions supplied.

• If the rate does not update during this test, check the sockets to confirm that

they are the same height within the plug and have not been pushed into the

plug. If the sockets have become recessed, gently use a pair of needle-nose

pliers to work the socket out to the same level as the other sockets.

• Use the Socket Maintenance Kit (NK Part No.0242) to clean any imbedded dirt or debris from the sockets and

inject a small amount of Nyogel into the sockets to prevent corrosion and ensure good electrical contact.

• If the stroke updates, but the timer does not reset, clear the display..

Is the wiring intact?

Check the wiring for pin alignment and cuts or nicks. Check the sensor and seat magnet placement for proper

positioning and security.

E

CB

E

C

C

C

C

C

C

B

B

B

DA

No Audio/Intermittent Audio/Static

Is the wiring clean of cuts or nicks?

• Cuts or nicks in the wiring are the most frequent causes of audio problems. Be sure that all of the connectors

(pins, sockets, plugs, receptacles) are not damaged and are positioned properly.

Is the microphone working properly?

• The microphone may be the cause of failure.Test the system with a microphone you know is good. Note: A

damaged microphone often causes static.

Are the connectors (pins, sockets, plugs, receptacles) properly positioned?

• See installation.

Are the speakers working properly?

• Be sure all of the speakers are plugged in properly and are in working order (replace one at a time with a

known good speaker to test). If you are getting a loud squealing noise, try pointing the speakers away from the

coxswain to minimize feedback.

www.nkrowing.com.au

8

Tips to Help You Get the Most From Your Cox-Box

· Make sure that the CoxBox is carried by the handle, and NEVER by the microphone. After use, detach the microphone, and do not store the unit with the

mic attached.

· Keep your CoxBox clean by rinsing it off after use, ESPECIALLY if you row in salt water.

· Store your CoxBox in a cool, dry place. Avoid leaving it in severe heat or cold (such as the dashboard of a car or an unheated boathouse in the winter)

which can greatly shorten the life of the rechargeable battery pack.

CHARGING

· Recharging: Recharge a regularly-used CoxBox whenever possible to ensure that it will have enough power for the next practice. A fully drained CoxBox

battery pack requires 10 hours on charge to attain maximum capacity. At the end of the season, charge the unit for 10 hours, disconnect the microphone

and charger, and store in a cool dry place until ready to use next season.

· Memory Effect: It is not necessary to try to discharge the CoxBox batteries fully between charging - there is virtually no memory effect in modern lithium

batteries.

·BATTERY LIFE

The life of your battery depends upon many things: the age of the battery pack, the volume and talkativeness of the coxswain, and the extent of charge.

Here are some performance guidelines that should help you plan your CoxBox use.

· A fully charged battery will power a CoxBox with NO audio (volume turned all the way down) for 25 hours.

· With the volume turned all the way up, the battery can supply power for 60 minutes of continuous talk.

· Therefore, with an average volume setting and a coxswain talking less than half the time, a fully-charged CoxBox will provide at least four hours of power,

and usually more.

· Having the Coxswain turn the volume down as low as possible will help prolong the battery life.

· If your CoxBox unit is more than three years old, the battery performance will decrease. Simply replace the battery. If you're not sure how old your unit is,

give the Service Department at NK a call and they can research your unit's serial number to tell you when it was last serviced.

Visit www.nk.com.au for more maintenance and troubleshooting tips, or contact NK

Cox-Box Maintenance

If you row, cox or coach a coxed boat, you know the CoxBox is an important part of every practice or race. Though designed to perform in conditions that

would destroy most electronics in minutes, there are a few things you can do to help your CoxBox last longer and perform better. For every waterproof

electronic product, the connections are the potential trouble spots. NK sells a complete Cox-Box Maintenance Kit with everything needed to make it easy to

maintain the connections on your equipment. Follow these steps to keep your Cox-Box, Cox-Vox, Microphones & Wiring static-free and reliable for years.

Cox-Box Panel Connectors - MONTHLY WASH the Cox-Box panel with warm water and mild soap. RINSE well. DRY thoroughly

ROTATE DRILL BIT

inside metal sockets of

rubber P5 connector

to dislodge dirt and

corrosion and lift debris

out of sockets.

APPLY

ELECTRICAL

CONTACT GREASE

from syringe inside

metal sockets. Avoid

over filling sockets or

getting into rubber.

USE FOAM SWAB to

apply SILICONE from

small plastic tub to...

OUTSIDE OF P5

until a visible film of

SILICONE covers

surface. (Keep foam

swab in provided bag

for future use.)

ROTATE DRILL BIT

inside metal sockets of

rubber P2 connectors

to dislodge dirt and

corrosion and lift debris

out of sockets.

APPLY ELECTRICAL

CONTACT GREASE

from syringe inside P2

metal sockets. Avoid

over filling sockets or

getting onto rubber.

USE FOAM SWAB

to apply SILICONE to

outside of P2 connectors.

Reconnect all P2/R2

connectors firmly.

Speaker/Harness Connectors - TWICE A YEAR (End of Season)

www.nkrowing.com.au

9

New from Nielsen-Kellerman: the Coxswain’s Kit. Everything

the prepared coxswain needs for practice. Kit Includes: Custom

Pack with pouch and external CoxBox holder, one adjustable

wrench, one 7/16” wrench, one 10mm wrench, athletic tape,

electrical tape, Blister Medic first aid kit, 2 Carabineers, a tube of

waterproof sun block and lip balm. NK PART 4050

With the growing use of licence free, 2-way radios, NK have made

available a special connector that allows a 2-way radio system to be

used through an existing NK Cox-Box or Cox-Vox system. The radio

to microphone ‘T’ piece connector fits on the BNC microphone

input of the amp unit. One end connects to a 2-way radio, the

other is used to connect the existing microphone.The coach (with

another 2-way radio) can then communicate to the crew discreetly.

With multi-channels available, it is possible for the coach to speak

to a number of crews at once or by switching channels, to just one crew individually.

Charge your Cox-Box from any car or truck cigarette lighter. Great when traveling to

regattas! CAR CHARGER – NK PART 0234 –

SILICONE GREASE – NK PART 0241 –Silicone is the proper grease for lubricating

all rubber plugs and receptacles in your Cox-Box system.This grease will ensure that

the plugs will connect and disconnect easily and will not swell or crack. Note: please

do NOT use petroleum jelly or other lubricants that may cause the rubber to wear

prematurely.

SOCKET MAINTENANCE KIT – NK PART 0242 –

NK developed this kit to make it easy for you to care for the

metal connectors inside your Cox-Box P5 connector as well

as the P2 connectors on the NK speakers. The kit includes a

specially sized drill bit for cleaning corrosion and dirt from

inside the sockets, as well as a syringe loaded with Nyogel

for injecting into the sockets. Regular use of these tools will

ensure long life and reliable performance of the connectors. One kit will allow you to maintain numerous Cox-

Boxes for at least a season.

www.nk.com.au

10

LAY OUT THE PARTS OF YOUR SYSTEM

Uncoil the wiring harness and lay it out in the shell. If you are installing your COX BOX in a sectional

shell, the harness should be equipped with a plug/receptacle pair which should be within a foot of

the sectional bulkheads.

NSTALL THE STROKE SENSOR (CoxBox system only)

1. Refer to FIGS 1a, 1b. Note the position of the sensor – it should be close to the center of the

seat travel and it MUST be perpendicular to the length of the shell.

It is not necessary for the sensor and magnets to be centered between the rails as shown

in Figure 1a.They may be positioned off center as shown in Fig 1b. It is essential however

that the magnet passes directly over the sensor.

INSTALLING YOUR SYSTEM

Check that you received everything required. If you purchased a complete CoxBox system you should

have received the following items:

Carrying bag .......................................................................................................(1)

CoxBox (or Cox Vox) control unit ...............................................................(1)

microphone.........................................................................................................(1)

charger..................................................................................................................(1)

speakers............................................................................... (as ordered 2 or 3)

mounting cup ....................................................................................................(1)

harness, with sensor installed.......................................................................(1)

This manual.........................................................................................................(1)

hardware pack with magnet ........................................................................(1)

NOTE: The double-sided “VHB” tape provided for mounting is epoxy based and requires 12 hours of cure

time. Do not get this tape wet while curing for best results.

www.nk.com.au

11

2. The spacing between the stroke sensor and the magnet assembly is critical. If the

magnet passes too far from the sensor the sensor may fail to register every stroke,

resulting in low readings. If the magnet is too close to the sensor, it may strike the

sensor and knock one or both out of place.

Because the distance between the seat plate (to which the magnets will be attached)

and the deck (to which the sensor will be attached) varies considerably from shell to

shell, you should start by measuring this distance. Refer to FIG 2.

• If the distance measured as in FIG 2 is between 7/8” and 1 1/8” you may mount the

sensor and magnet with no further adjustment.

• If the distance measured as in FIG 2 is GREATER than 1 1/8” then you will need to

make a spacer of appropriate thickness.You may choose to shim the sensor or the

magnet, whichever is easier. DO NOT use any magnetic material for your shim.

• If the distance measured in FIG 2 is LESS than 7/8” then you will have to remove

material from either the seat or the deck OR try mounting the magnet on the upper

side of the seat plate.

You can install the sensor and magnets semi-permanently by using the 3M VHB (Very

High Bond) tape supplied. Should you wish to make a temporary installation, use

the screws provided and DO NOT peel away the protective layer from the VHB tape.

FOLLOW STEPS 3-4 FOR DOUBLE SIDED TAPE INSTALLATION OF THE SENSOR. FOR

THE MOST SECURE INSTALLATION USE TAPE AND SCREWS.

3. Check that the sensor cable is routed conveniently. Use a solvent to clean the area of the

deck to which you will attach the sensor. This is essential for a good bond. Peel away the

protective layers of the VHB double-sided tapes, and firmly press the sensor onto the

cleaned area of the deck.

4. Using two cable clips provided, secure the sensor wire.

PLEASE NOTE: The sensor must be installed at the CENTRE of the seat travel. If the sensor is too close to

either end of the seat travel, the COX BOX may indicate ONE-HALF the correct stroke rate.It is essential

that the holes in the magnet assembly pass directly over the holes in the sensor. The dashed horizontal

line in each figure indicates the correct alignment. If the sensor and magnet are installed offset from

the centerline of the seat as in Fig. 1b, the holes of the magnet assembly MUST still pass directly over

the holes of the sensor.

www.nk.com.au

12

INSTALL THE MAGNET

1. Remove and inspect the seat plate to find an appropriate place to mount the magnet.

2. Use a solvent to clean the area to which you will attach the magnet.This is essential if a

good bond is to be obtained.

3. Determine the exact location of the magnet assembly on the seat plate. Peel away the

protective layer of the VHB double-sided tape and install the magnet assembly.

4. If possible, use #8 screws to secure the magnet to the seat plate.

5. Return the stroke seat to its slide and check that the clearance between the magnet and

sensor is no more than 3/8” (refer to FIG 2). Check also that the magnets pass directly over the

sensor (refer to FIGS 1a, 1b).

INSTALL THE LOUDSPEAKERS

The NK loudspeakers are factory assembled and waterproofed using silicone-based protective

coatings. Rain, fresh water, and salt water should not harm the speakers, but we strongly recommend

that you install and angle the speakers so that any water which gets in can run out again.The plug-in

feature of NK speakers makes replacement very easy.

1. Install the speakers using #6 x 1/2” panhead screws and the metal bracket (attached to the

speaker). We have supplied SIX screws; you will not use all of them unless you are installing a

three speaker system. Remember, it is best if the speakers are angled downward to let water

run out.

2. Connect the speakers to the wiring harness. Use the remaining six cable clips to secure the

wiring harness.We suggest you use the #6 x ½” brass screws supplied to fully secure these

clips.

INSTALL THE MOUNTING CUP

Decide where you want to secure the cup and mark off the surface using the cup as a template. Drill

two pilot holes for the #8 x ½”panhead screws and secure the cup. Do NOT over tighten the screws!

This new NK Gear Bag is a great replacement for your old black Cox-

Box Carry Case.

It features multiple compartments with adjustable dividers that can

easily swallow up a Cox-Box, mic, charger, SpeedCoach, Mainte-

nance Kit, tools and more.

Water-resistant construction and sturdy padding throughout will

keep all your gear protected, and a padded shoulder strap lets you

load the bag up and still carry everything hands-free.

Available NOW. Part #0117

If problems persist after checking the unit against this guide, please call our Repairs Department on

02 6553 2473 or e-mail [email protected]

?

www.nkcom.au

13

Airline Travel

With increased airport security, traveling with your Cox-Box is trickier than ever.We recommend you check

the Cox-Box in with your luggage. Include product literature that explains what the Cox-Box is. Brochures

can be obtained from NK, or product literature can be printed from the website.

You certainly do not want to try to carry them onto an airplane. Cox-Boxes have been thrown into bomb

chutes, even before 9/11.

REGULAR MAINTENANCE SCHEDULE AND TIPS

Daily Maintenance

1. If you row on salt water, rinse the Cox-Box off with fresh water and dry it after every use.

2. Charge the unit whenever it is not in use, but do not leave the unit on charge indefinitely.

Once a Month

This maintenance is easy to perform with a Cox-Box Maintenance Kit, available from NK.

1.Wash the Cox-Box display panel with warm water and mild soap. Rinse well and dry.

2. Use the drill bit from the Cox-Box Maintenance kit to clean out the metal sockets inside the rubber plug on the

unit. Rotate the bit inside the sockets to dislodge any dirt or debris.

3. Check the inside of the rubber plug on the wiring harness for any dirt. Inspect the wires leading to the plug for

any nicks or cuts.If these exist, contact NK about repairing them.

4. Apply silicone grease to the outside of the rubber plug on the Cox-Box.This helps to minimize the damage done

by repeatedly removing the unit from the boat.Try not to get silicone into the plug itself.

5. Inject a small amount of electrical contact grease (Nyogel) into the sockets on the rubber Cox-Box plug. Connect

the unit to the harness.This will coat the pins with Nyogel and push some Nyogel deeper into the sockets,

protecting them as well.

End of the Season

1 Wash the Cox-Box with fresh water and dry it carefully.

2. Repeat the cleaning and lubricating steps under“Once a Month”maintenance.

3. Fully charge the Cox-Box then unplug it and store it in a cool, dry place.

www.nkrowing.com.au

14

Wiring built as tough

as your workouts.

Nielsen-Kellerman’s

All New Modular Harness System

You want to spend your time on rowing, not repairs.

The unique engineering of NK’s modular harness

ensures improved durability and flexibility. • Fully molded and sealed

design to stand up to the

harsh demands of rowing

and environmental exposure.

• Build EVERY harness you

need from three simple

pieces. Even add on pieces as

your budget allows.

• Affordable modules

eliminate the need for

repairs - simply plug in a new

section if needed.

• Plug-in rate sensor for

instant repairs and

trouble-shooting.

• NK proprietary gold-plated

pins and sockets

resist corrosion.

• Lighter than the HD harness

system

(24oz/680g for

8-3 harness).

• Fully compatible with all NK

speakers and Cox-Box systems.

• Full 3-year warranty:

Date coded with month

and year.

MODULARHARNESS

COMPONENTS (SEE BACK FOR TYPICAL CONFIGURATIONS)

1. A+ (AUDIO & RATE SENSOR)

2. R (RATE SENSOR)

3. A (AUDIO)

4. M (MULTI-SPEAKER)

www.nkrowing.com.au

www.nk.com.au

15

NK Rowing Electronics Warranty & Service

NK does not believe in "disposable electronics." We know our products don't lead a pampered life, and we

design them for years of performance in tough conditions. We guarantee every NK product to be free of

defects in materials and workmanship for a period of TWO YEARS from your date of purchase. We will repair

or replace any defective product or part when notified within the warranty period, and will return the product

via domestic ground shipping at no charge. The following issues do not result from a manufacturing defect

and are not covered under this warranty: damage due to improper use or neglect, including corrosion; impact

damage; modifications or attempted repairs by someone other than an authorized NK repair agent; normal

wear and tear; failed batteries. NK wants you to be an NK customer for life, so we take care of you even beyond

the terms of the normal product warranty with our Customer Care Program. Trade-in any NK display unit, no

matter the age or condition, and receive a generous discount on the replacement product.

Visit www.nk.com.au at any time for detailed product specifications & troubleshooting guides.

CUSTOMER CARE

NK wants you to be a customer for life, so we take care of you even beyond the terms of your product’s

warranty. We offer you a quick & economical service for the repair of your NK rowing equipment.

All repairs have a ONE YEAR warranty. Should your unit not be economical repair, then we can offer you a

NEW unit, with a TWO YEAR warranty at our customer care price.That is, you send us your old unit & we

sell you a new unit at a discounted price (contact us for exact prices). No ifs, no butts, that is a brand new

unit. We do ask that the unit that you are sending to us has a valid serial number and must not have been

repaired or attempted to be repaired by anyone other than us. This offer excludes products that have been

physically abused. Customer must pay freight to have the unit delivered.

Customer Care Pricing Chart (all prices include GST)

Please check our web site or call us.

* Customer Care policy is valid only for components listed above for as long as we manufacture them and does not cover product upgrades. All other

parts and accessories are covered under warranty up to one year from date of purchase.

MODULAR harness has a 3 year warranty.

Warranty covers defects in materials & workmanship. Excludes damage due to improper use or neglect (including corrosion), modifications or attempted

repairs by someone other than NK, impact damage, failed batteries & normal wear & tear.

Units must have been purchased in Australia from an authorised Nielsen Kellerman agent.

Except as otherwise provided herein, no other warranties, expressed or implied, are made with respect to these products, including, but not limited to, any

implied warranty of merchantability or fitness for a particular purpose. NK assumes no liability for any damages, losses or expenses resulting directly or

indirectly from product use.

All prices & services offered are subject to change.

Details are correct as at 1st April 2009

NOTE: The NK warranty covers defects in materials and workmanship. It DOES NOT cover damage

caused by abuse, misuse, or attempts to repair on your own or by an unautorised person.

!

www.nk.com.au

16

Contact Info:

Delivery Address

(Please send all parcels to this address)

Nielsen Kellerman Australia Pty Ltd

206 Cowans Land

Oxley Island NSW 2430 AUSTRALIA

Email: [email protected]om.au

Web: www.nk.com.au

Phone: 02 6553 2473

Fax: 02 6553 2544

COX-BOX PLUS OWNERS MANUAL 01 MAY 2014 E&OE

Marc Douez

Table of contents

Popular Control Unit manuals by other brands

Ytc

Ytc YT-700 Series product manual

Grundfos

Grundfos IO 112 Installation and operating instructions

RSF Elektronik

RSF Elektronik UFC 430 user manual

WAGO

WAGO WAGO-I/O-SYSTEM 750-506 manual

Ebsray

Ebsray RV18 Installation, operation and maintenance instructions

Metso

Metso Neldisc L1 Series Installation, maintenance and operation instructions