2Model 240 Quick Start Guide

Safety Precautions

Observe these general safety precautions during all phases of

instrument operation, service, and repair. Failure to comply with

these precautions or with specic warnings in the user’s manual

violates safety standards of design, manufacture, and intended

instrument use. Lake Shore Cryotronics, Inc. assumes no liability

for customer failure to comply with these requirements.

The 240 Series input module protects the operator and

surrounding area from electric shock or burn, mechanical

hazards, excessive temperature, and spread of re from the

instrument. Environmental conditions outside of the conditions

below may pose a hazard to the operator and surrounding area.

Indoor use

Altitude to 2000 m

Temperature for safe operation: -20 °C to 50 °C

Maximum relative humidity: 95% non-condensing

Power supply voltage uctuations not to exceed

±10% of the nominal voltage

Overvoltage category II

Pollution degree 2

IP20: not protected against harmful ingress of water

Ground the instrument

To minimize shock hazard, the instrument is equipped with a

grounded connection to the DIN rail. Connect the DIN rail to an

electrical ground.

Do not operate in an explosive atmosphere

Do not operate the instrument in the presence of ammable gases or

fumes. Operation of any electrical instrument in such an environment

constitutes a denite safety hazard.

Do not substitute parts or modify instrument

Do not install substitute parts or perform any unauthorized

modication to the instrument. Return the instrument to an

authorized Lake Shore Cryotronics, Inc. representative for service and

repair to ensure that safety features are maintained.

Cleaning

Do not submerge instrument. Clean only with a damp cloth,

exterioronly.

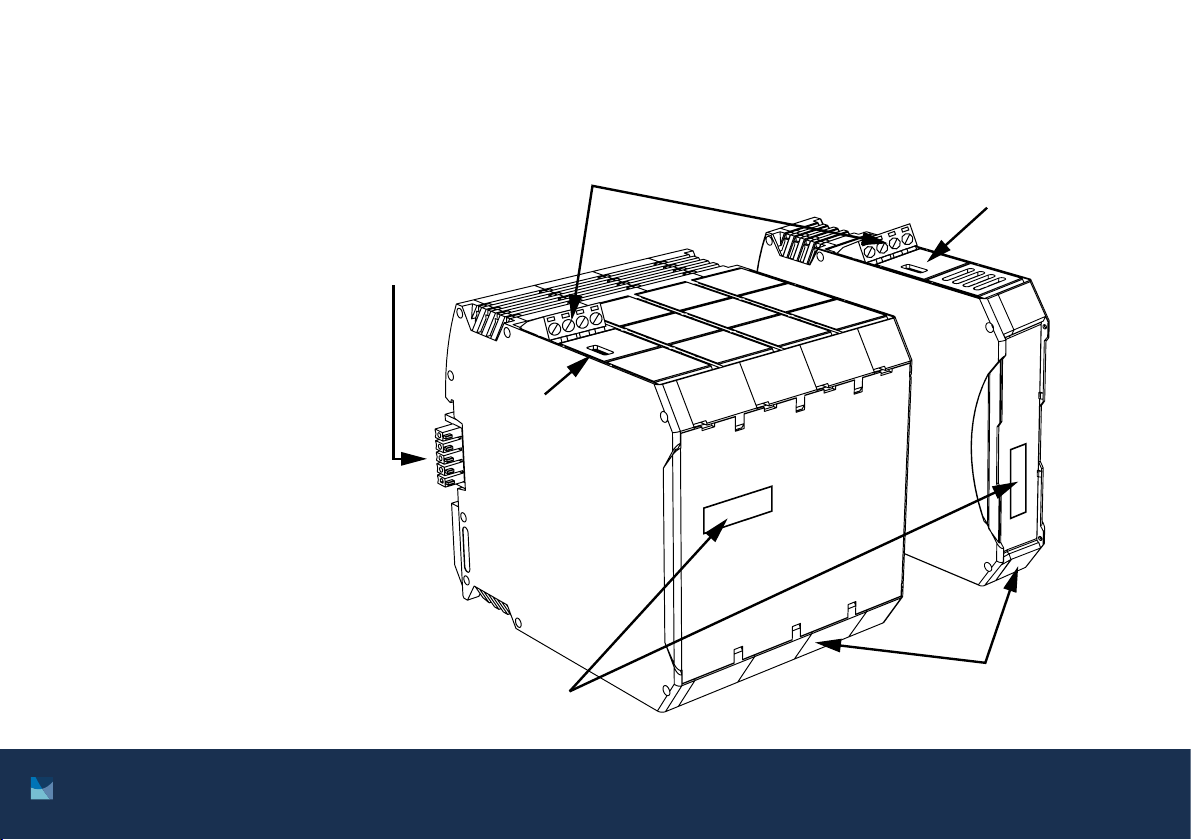

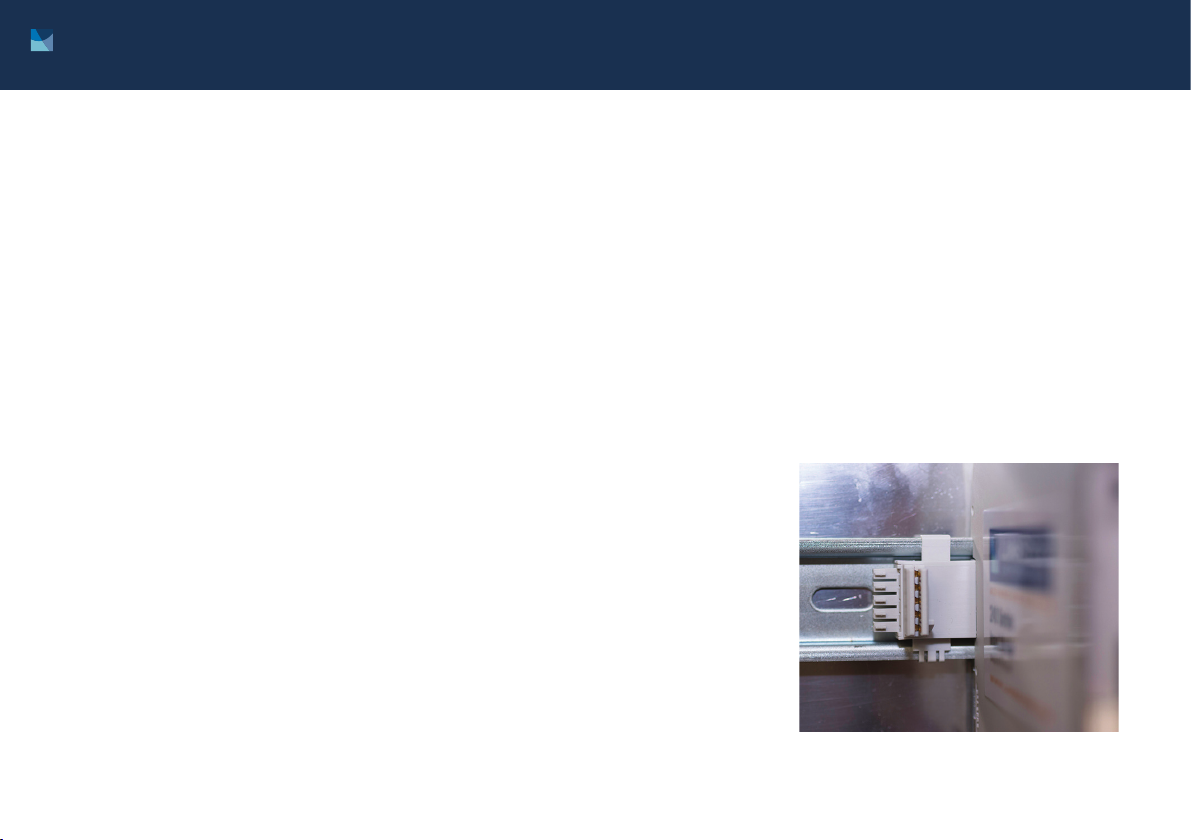

Installation

When installing the instrument, ensure it is mounted securely on the

DIN rail.

Improper Use

If the instrument is used in a manner that is not specied by Lake

Shore, the safety protections provided by the instrument are no

longer guaranteed, and may be impaired.

Refer to the Model 240 user’s manual for more safety information.